1.5mm Single Textured Rough Surface Geomembrane Waterproof Soil Consolidation

At Haoyang Environmental Co., Ltd., we take pride in being a leading high-tech comprehensive service provider in the field of geosynthetic materials. Established in June 2008, our company specializes in research and development, manufacturing, and environmental engineering services. We are pleased to introduce our exceptional product: the 1.5mm single textured rough surface geomembrane, designed to provide reliable waterproof soil consolidation solutions.

Product Advantages

Superior Waterproofing: Our 1.5mm single textured rough surface geomembrane offers exceptional waterproofing capabilities, ensuring reliable and long-lasting soil consolidation. It effectively prevents water infiltration, protecting the integrity of structures and preventing soil erosion.

Enhanced Durability: Crafted with the highest quality geosynthetic materials, our geomembrane is engineered to withstand harsh environmental conditions, including UV exposure, chemical resistance, and puncture resistance. Its superior strength and durability make it suitable for a wide range of applications.

Easy Installation and Maintenance: Our geomembrane is designed for easy installation, saving both time and effort during construction projects. Additionally, its low maintenance requirements translate into reduced long-term costs, making it a cost-effective solution for soil consolidation projects.

Company Advantages

Extensive Expertise: Haoyang Environmental Co., Ltd. boasts a team of dedicated professionals with extensive experience in environmental engineering design, consulting, and geosynthetic material research and development. Our expertise allows us to deliver innovative and customized solutions tailored to meet our clients' specific needs.

Quality Assurance: We hold ourselves to the highest standards of quality, as evidenced by our ISO 9001 quality management system and ISO 14001 environmental management system certifications. These certifications reflect our commitment to delivering products and services of exceptional quality while adhering to stringent environmental principles.

Technological Innovation: With a focus on research and development, Haoyang Environmental Co., Ltd. has obtained numerous patents and scientific and technological achievement certifications. We continuously strive to stay at the forefront of environmental engineering materials and technologies, ensuring that our clients benefit from cutting-edge solutions.

Factory Display

Welcome to the geomembrane production workshop of Haoyang Environment! It is a modern production site that combines advanced technology and innovative ideas. We have the largest radius of geomemofilm production equipment in the production process shows its unique advantages, perfectly meet the needs of customers, efficient extrusion machine with its precise temperature control and stable production speed, to ensure the uniformity and thickness accuracy of geomemofilm. At the same time, the advanced cooling system ensures the rapid solidification of the film, ensuring the quality and stable performance of the product.

This production workshop not only has superior equipment, more experienced team. Our staff are professionally trained and constantly explore innovative production methods to ensure that our geomembranes are always at the leading level in the industry.

Performance

The data in the National standard form is based on the results of professional testing and specification development and represents the key performance, quality standards or technical requirements of the products or services in the industry. This data typically includes a variety of indicators, parameters, and specifications that are used to assess the safety, reliability, and conformity of the product.

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

Technical performance index of rough HDPE geomembrane for environmental protection (GH-2T1, GH-2T2) GBT17643-2011

No. | Item | Unit | Index | |||||||

1 | Thickness | mm | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

2 | Density | g/cm3 | ≧0.940 | |||||||

3 | Roughness height | mm | ≧0.25 | |||||||

4 | Tensile yield strength | N/mm | ≧11 | ≧15 | ≧18 | ≧22 | ≧29 | ≧37 | ≧44 | |

5 | Tensile breaking strength | N/mm | ≧8 | ≧10 | ≧13 | ≧16 | ≧21 | ≧26 | ≧32 | |

6 | Yield elongation | % | ≧12 | |||||||

7 | Break Elongation | % | ≧100 | |||||||

8 | Right-angle Tearing strength | N | ≧93 | ≧125 | ≧160 | ≧190 | ≧250 | ≧315 | ≧375 | |

9 | Puncture strength | N | ≧200 | ≧270 | ≧335 | ≧400 | ≧535 | ≧670 | ≧800 | |

10 | Resistance to tensile cracking under extension load | h | - | ≧300 | ||||||

11 | Carbon black content | % | 2.0~3.0 | |||||||

12 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | |||||||

13 | Oxidation induction time | min | Atmospheric pressure OIT≧100 | |||||||

High tension OIT ≧400 | ||||||||||

14 | 850CThermal aging | % | ≧55 | |||||||

15 | Ultraviolet resistance | % | ≧50 | |||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | |||||||||

HDPE Geomembrane Weld Field Detection Method

At present, there is no good method for on-site inspection of welds, generally more visual inspection, to see whether the two welds are smooth, clear, wrinkle-free, transparent, no slag, bubble leakage point, melting point or weld bubble edge.

(1) Both ends of the weld are welded with a welding gun, and then the cylinder with a pressure gauge is used to clamp the gas needle, and the gas needle is inserted into the hole between the weld, the detection distance of each section is about 1.5m ~ 3.0m, and the pressure is controlled at 0.5 ~ 2mpa according to the requirements of the geosynthetic material test regulations, and the time is about 30s. When pumping, if there is a leak in the weld between the gas and the gas needle, then as long as the gas needle part is stuffed with plasticine, hit the air, press the finger in front of the gas needle, if the observation is more than 30 seconds, the gas will not leak, it is regarded as qualified connection.

(2) When testing with a microscope, put the microscope in a suspicious place, such as leakage points, virtual points, with a welding torch or adhesive treatment.

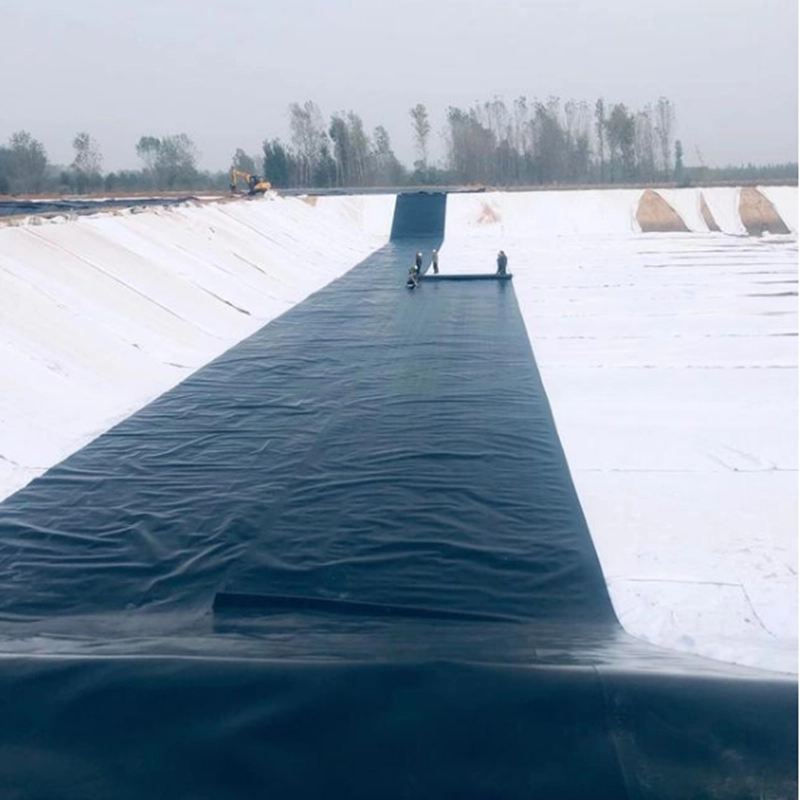

Project Construction Photo

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

Special Application of Rough Geomembrane

Rough geomembrane is a kind of geomembrane with special texture or uneven surface, which is characterized by a certain roughness rather than smooth surface.

The application of rough geomembrane is mainly reflected in the following aspects:

(1)Improved friction and slip resistance: The rough surface structure increases the friction between the geomembrane and soil or other materials, helping to improve its slip resistance and stability. Therefore, in slope protection, dam or retaining wall and other projects, rough geomembrane can better prevent soil sliding and erosion.

(2)Enhance the combination of geomembrane and soil: rough surface design can increase the binding force between geomembrane and soil, which is conducive to the firm combination of geomembrane and soil, and reduce the risk of geomembrane displacement in engineering.

(3)Soil and water conservation and erosion prevention: In soil and water conservation projects such as banks, ditches, earth and rock slopes, rough surface geomembrane can effectively slow down the flow rate, reduce the flow erosion, and protect the soil from erosion.

(4)Improve drainage function: the rough surface structure helps to discharge the geomembrane water, improve the drainage performance of the lower part of the geomembrane, and prevent water retention between the geomembrane and the surface.

(5)Ecological landscape design: In ecological garden and landscape design, rough geomembrane is often used to simulate natural terrain and create an environment closer to natural ecology.

In general, because of its special surface structure, rough geomembrane is more suitable for engineering scenes that need to enhance the binding force between geomembrane and soil, improve the friction force or achieve soil and water conservation.

Mode of Transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

Contact Us

Are you ready to experience the reliability and effectiveness of our 1.5mm single textured rough surface geomembrane for your soil consolidation needs? Reach out to us today to discuss your project requirements and explore how our expertise can transform your environmental engineering endeavors.

Partner with Haoyang Environmental Co., Ltd. and let us help you achieve sustainable and efficient soil consolidation solutions. Together, we can build a greener and more resilient future.

FAQ

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q2: What is the lead time?

A2: Usually 5-10 working days after receiving the deposit.

Q3: Can you produce according to the customer's requirements?

A3: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q4: How do you guarantee the quality testing of your products?

A4: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

Q5: What is the main material of this geomembrane?

A5: Our geomembranes are usually made of plastic materials such as polyethylene (HDPE).

Q6: What should I pay attention to in terms of installation and use?

A6: During installation, ensure that the base surface is smooth, avoid sharp objects scratching the geomembrane, and pay attention to prevent damage during installation.

Q7: What about product price and quality assurance?

A7: We offer competitive prices and guarantee that our products meet quality standards to ensure that our customers receive high quality products.

Q8: Is this geomembrane environmentally friendly?

A8: Geomembranes are often manufactured from recycled materials, meet environmental standards, and remain stable after use

![]() 0.75 Double-sided smooth HDPE geomembrane.pdf

0.75 Double-sided smooth HDPE geomembrane.pdf

![]() 1mm Single-texture HDPE geomembrane.pdf

1mm Single-texture HDPE geomembrane.pdf

![]() 2mm Single-texture HDPE geomembrane.pdf

2mm Single-texture HDPE geomembrane.pdf

![]() 1 Double-sided smooth HDPE geomembrane.pdf

1 Double-sided smooth HDPE geomembrane.pdf

503.webp)

759.webp)

776.webp)