Haoyang rough-surfaced(textured)geomembrane: the capable assistant of project protection

In Haoyang Environmental Protection Co., Ltd., we take technology as the lead and concentrate on manufacturing the unique rough-surfaced geomembrane. This geomembrane will provide efficient and reliable protection for your project, making it durable and stable.

I. The Rough-surfaced Process

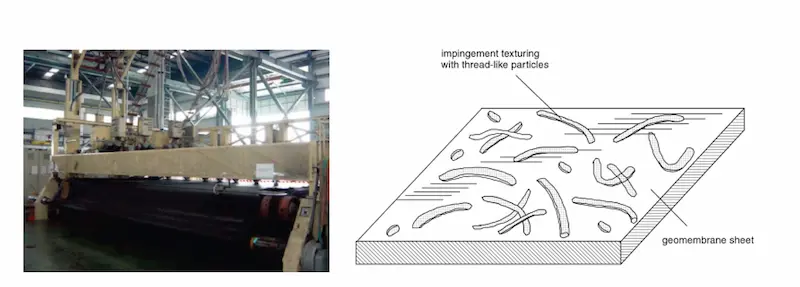

Our geomembrane uses a unique rough-surfaced process that forms clusters on the surface to enhance the friction coefficient, effectively increasing its anti-skid performance. This process not only improves the stability of the geomembrane but also ensures its excellent performance in adverse environments. Your project will become safer and more stable.

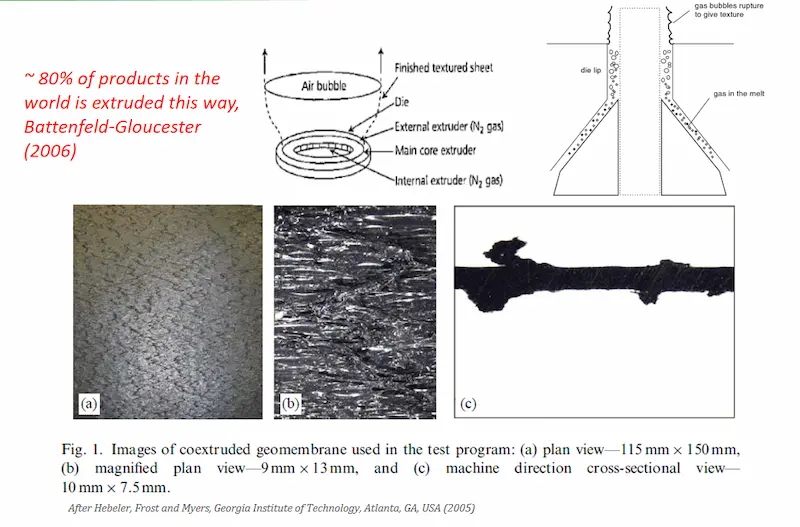

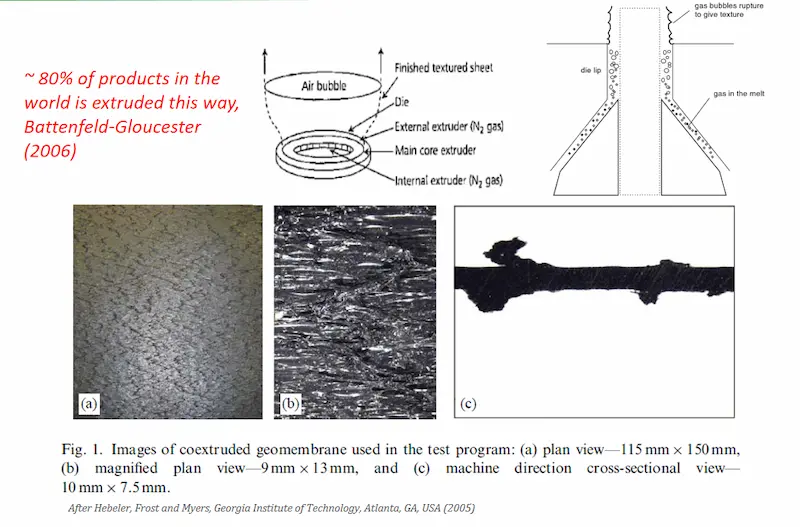

(3 layer co-extrusion process)

II. High-performance Material

We select high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) as raw materials to ensure that the geomembrane has excellent durability and anti-aging performance. After strict selection, cleaning, and drying treatment, each of our geomembranes meets high-quality standards. Choose us and enjoy protection for decades.

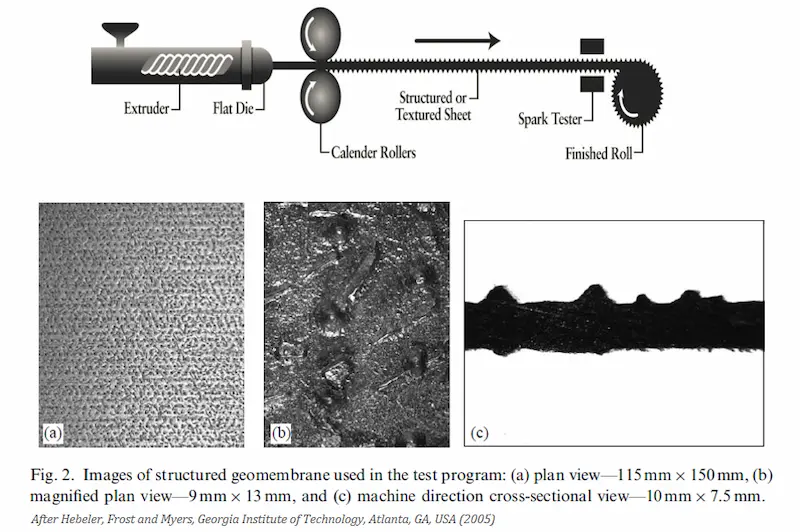

(Embossing process)

III.Comprehensive Quality Testing

During the production process, we conduct comprehensive quality testing on the rough-surfaced (textured) geomembrane, including thickness, density, tensile strength, puncture strength and other key indicators. We strictly control each production link to ensure that each geomembrane meets or exceeds your expectations. The quality is guaranteed, and your business will become more stable.

Specifically, here are the production processes of the rough-surfaced (textured) geomembrane:

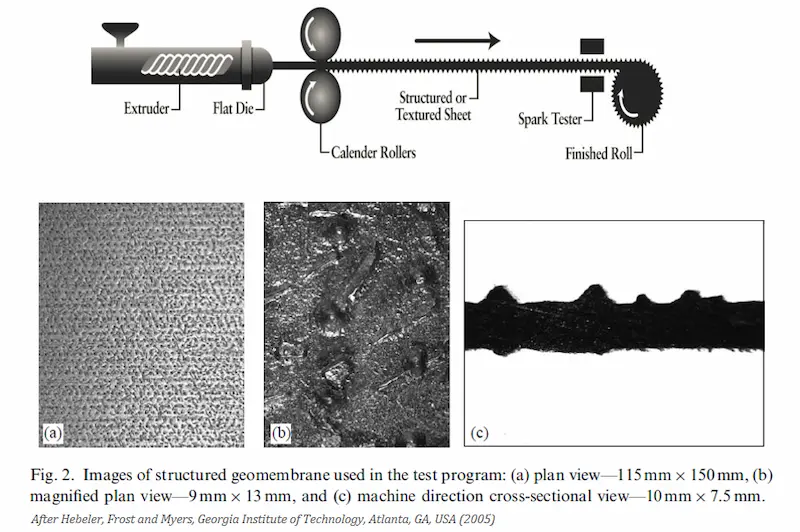

About 80% of the rough surface geomembranes in the world are prepared by co-extrusion molding.

1. Raw material preparation: select HDPE or LLDPE as raw materials, which undergo selection, cleaning, drying, and other treatments before being fed into an extruder.

2. Extrusion molding: The pre-treated raw materials are fed into an extruder, where they are heated to a molten state and then extruded into a film shape at the head of the extruder.

3. Cooling and cutting: The extruded geomembrane needs to be cooled, usually using cooling rolls or water cooling. The cooled geomembrane is then cut to the desired size and shape.

4. Roughening treatment: a flame spraying process is used to roughen the surface of the needle-punched geotextile, forming fiber clusters on the surface until they solidify into fixed points, increasing the friction coefficient. Then it is integrated with the polyethylene film to form a double-sided roughened composite geomembrane.

5. Inspection and packaging: The geomembrane is inspected for thickness, density, tensile strength, puncture strength and other indicators. Geomembranes that meet the standard requirements are packaged, usually in rolls or folded.

Please note that the production process of the textured geomembrane may vary depending on specific production requirements. If needed, we recommend consulting us for more specific information.

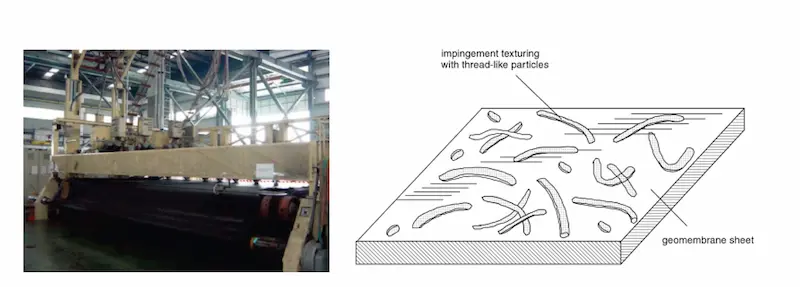

(Sand blasting process)

IV. Professional Service Team

Our professional service team will provide you with full support from product consultation to scheme design to construction installation. We have experienced professionals to provide help. We are committed to providing your project with the best rough-surfaced (textured) geomembrane solution. Choose us and receive support from our expert team.

Haoyang's rough-surfaced (textured) geomembrane is your capable assistant for project protection. It not only has efficient and reliable protective functions but is also easy to install and use conveniently. It will provide stable and long-lasting protection for your project to make it more successful. Contact us immediately to learn more about rough-surfaced geomembranes!

503.webp)

759.webp)

776.webp)