Specification Table for 2 in. x 500 ft x 1000 ft HDPE Water Pipe Rolls

| Specification | Description |

|---|---|

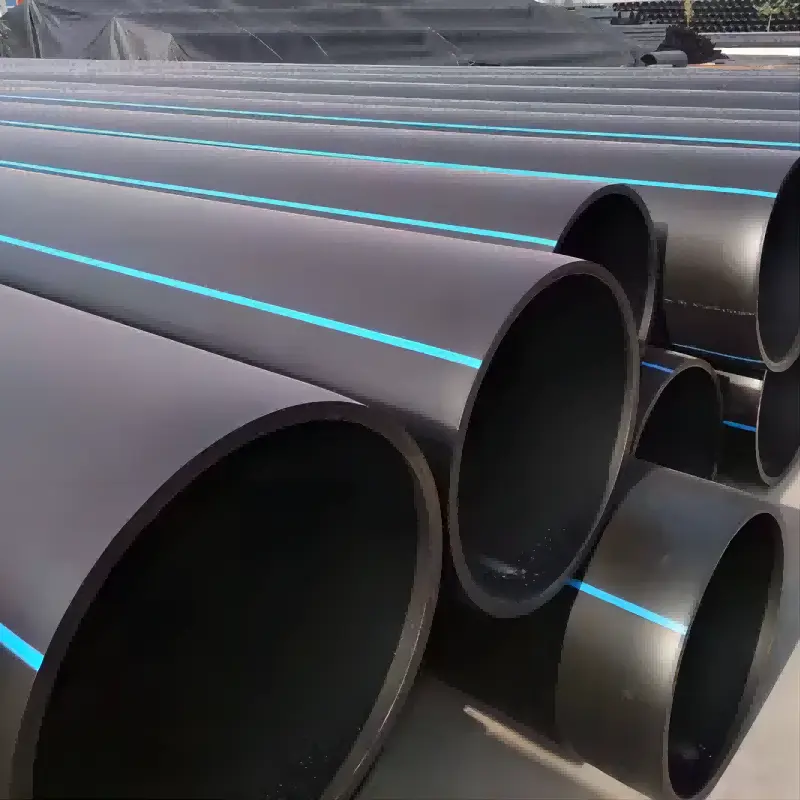

| Pipe Material | High-Density Polyethylene (HDPE) |

| Nominal Diameter | 2 inches (50.8 mm) |

| Wall Thickness | Varies based on SDR (Standard Dimension Ratio) |

| Length per Roll | 500 ft (152.4 m) and 1000 ft (304.8 m) |

| Pressure Rating | Varies based on SDR and design requirements |

| Color | Typically Black with optional colored stripes for identification |

| Standard Dimension Ratio (SDR) | Common options include SDR 11, SDR 13.5, SDR 17, etc. |

| Maximum Working Pressure | Varies based on SDR, ranging from 100 psi to 200 psi |

| Temperature Range | -40°F to 140°F (-40°C to 60°C) |

| Connection Type | Heat fusion, electrofusion, mechanical fittings |

| UV Resistance | High UV resistance, suitable for above-ground installation |

| Compliance Standards | ISO 4427, ASTM D3035, AWWA C901, NSF/ANSI 61 |

| Recyclability | 100% recyclable |

| Application Areas | Municipal water supply, agricultural irrigation, industrial fluid transport, residential water systems |

| Weight | Varies based on length and SDR |

| Flexibility | High flexibility for easy installation and handling |

| Abrasion Resistance | Excellent resistance to wear and tear |

| Chemical Resistance | Resistant to most chemicals and corrosive substances |

| Jointing Method | Butt fusion, socket fusion, electrofusion, mechanical fittings |

This specification table provides a detailed overview of the key features and characteristics of 2 in. x 500 ft x 1000 ft HDPE water pipe rolls. Depending on specific project requirements, additional customization options and specifications may be available from the manufacturer.

466128.webp)

How to Manufacture 2 in. x 500 ft x 1000 ft HDPE Water Pipe

526764.webp)

The manufacturing process for 2 in. x 500 ft x 1000 ft HDPE water pipes involves several stages, from raw material preparation to final quality control checks. Here is an overview of the key steps involved:

1. Raw Material Preparation

Resin Selection: High-Density Polyethylene (HDPE) resin is the primary raw material. It is chosen for its strength, flexibility, and resistance to chemicals and environmental stress.

Additives: Various additives such as stabilizers, UV inhibitors, and colorants (if needed) are mixed with the HDPE resin to enhance its properties.

2. Extrusion Process

Extruder Setup: The HDPE resin mixture is fed into an extruder, where it is heated and melted. The extruder consists of a barrel with a rotating screw that pushes the melted HDPE through the system.

Die Head and Sizing: The molten HDPE is forced through a die head, which shapes the material into a pipe. For a 2 in. diameter pipe, the die head is precisely calibrated to ensure uniform thickness and diameter.

Calibration and Cooling: As the extruded pipe exits the die, it passes through a calibration sleeve that shapes and cools the pipe. This process is typically performed using water or air cooling systems to solidify the HDPE quickly and maintain its shape.

3. Length Cutting and Coiling

Length Measurement: The continuous pipe is measured and cut into the desired lengths of 500 ft and 1000 ft. Automated systems ensure precise measurement and cutting.

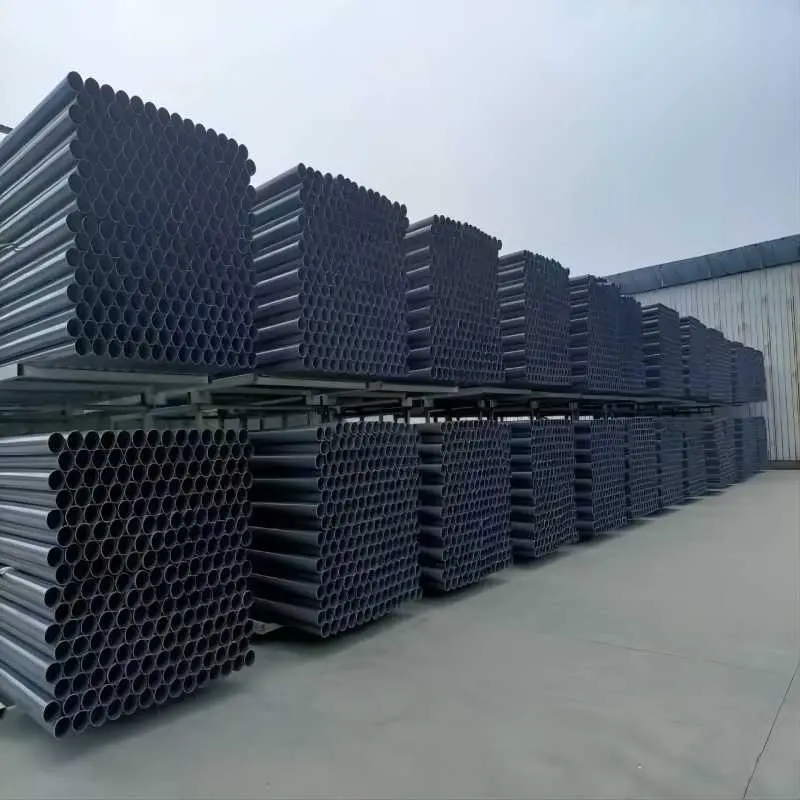

Coiling: The cut pipes are coiled into rolls for ease of transport and installation. Special coiling machines handle the pipes gently to avoid damage or deformation.

4. Quality Control

Dimensional Checks: Pipes are checked for correct dimensions, including diameter and wall thickness. This ensures they meet the required specifications.

Pressure Testing: Pipes undergo hydrostatic pressure testing to verify their ability to withstand the designated working pressures without leaking or bursting.

Visual Inspection: Inspectors check for surface defects such as scratches, bubbles, or discoloration that might affect the pipe's performance.

Tensile and Impact Testing: Samples are taken from each batch and subjected to tensile strength and impact resistance tests to ensure the material's integrity.

5. Marking and Labeling

Marking: Each pipe is marked with essential information such as size, pressure rating, manufacturing date, and batch number. This is typically done using a printing system that applies the markings directly to the pipe's surface.

Labeling: Rolls are labeled with additional information, including the manufacturer’s name, product specifications, and handling instructions.

6. Packaging and Shipping

Packaging: The coiled pipes are securely wrapped and packaged to prevent damage during transportation. Packaging may include plastic wraps, straps, and protective covers.

Shipping: Packaged pipes are loaded onto trucks or containers for delivery to distributors or direct to project sites. Proper handling procedures ensure the pipes reach their destination in perfect condition.

Key Equipment Used in Manufacturing

Extruder Machine: Melts and extrudes the HDPE resin into pipe form.

Die Head: Shapes the molten HDPE into the desired pipe diameter.

Calibration Sleeve: Ensures the pipe maintains its shape and size during cooling.

Cooling System: Rapidly cools and solidifies the extruded pipe.

Cutting Machine: Precisely cuts the continuous pipe into specified lengths.

Coiling Machine: Coils the cut pipes into rolls for easy handling and transport.

Quality Control Instruments: Used for dimensional checks, pressure testing, and material strength testing.

Manufacturing 2 in. x 500 ft x 1000 ft HDPE water pipes involves a well-coordinated process that ensures high-quality, durable, and reliable pipes for various applications. By following stringent quality control measures and using advanced manufacturing equipment, manufacturers can produce HDPE pipes that meet industry standards and customer requirements.

Primary Uses of 2 in. x 500 ft x 1000 ft HDPE Water Pipes

High-Density Polyethylene (HDPE) water pipes, especially those measuring 2 inches in diameter and available in lengths of 500 feet and 1000 feet, are versatile and widely used across various sectors. Here are some of the primary applications:

1. Municipal Water Supply Systems

HDPE pipes are a popular choice for municipal water distribution due to their high strength, flexibility, and resistance to corrosion and chemicals. The long lengths reduce the number of joints, minimizing potential leak points and maintenance needs.

2. Agricultural Irrigation

In agriculture, HDPE pipes are extensively used for irrigation systems, including drip and sprinkler irrigation. Their flexibility allows for easy installation in fields and adaptability to varying terrains. The pipes can withstand the harsh conditions of agricultural environments, such as exposure to fertilizers and pesticides.

3. Industrial Applications

HDPE water pipes are utilized in various industrial applications for transporting water and other fluids. Their resistance to a wide range of chemicals makes them suitable for industries such as chemical processing, mining, and wastewater treatment.

4. Residential Water Systems

Homeowners and builders use HDPE pipes for residential water supply systems, including connecting homes to municipal water lines and setting up irrigation systems for lawns and gardens. The pipes' ease of installation and durability make them ideal for these applications.

5. Landscaping and Drainage

HDPE pipes are used in landscaping projects for water management and drainage systems. They help direct water away from buildings, reduce erosion, and manage stormwater. Their flexibility allows them to be routed easily around obstacles and through varying terrains.

6. Firefighting Systems

HDPE pipes are employed in certain firefighting systems due to their ability to handle high pressure and their resistance to corrosion. They can be used in underground fire mains and other parts of a fire protection infrastructure.

7. Temporary Water Supply

For events, construction sites, and other temporary setups, HDPE pipes provide a reliable and easily deployable solution for water supply. Their lightweight nature and long roll lengths facilitate quick installation and removal.

Benefits for Specific Applications

Municipal Water Supply Systems

Benefit: Reduced leakage and maintenance costs due to fewer joints.

Example: A city upgrading its aging water infrastructure can use 2 in. HDPE pipes to ensure a reliable and long-lasting water supply network.

Agricultural Irrigation

Benefit: Flexibility and durability to withstand harsh environmental conditions.

Example: A large farm implementing a new drip irrigation system can use HDPE pipes to ensure efficient water distribution to crops.

Industrial Applications

Benefit: Chemical resistance and high-pressure tolerance.

Example: A chemical processing plant using HDPE pipes to transport various fluids safely within the facility.

Residential Water Systems

Benefit: Easy installation and low maintenance.

Example: Homeowners installing an underground water supply line from the municipal connection to their house.

Landscaping and Drainage

Benefit: Effective water management and erosion control.

Example: A landscaping company using HDPE pipes to set up a comprehensive drainage system for a new housing development.

Firefighting Systems

Benefit: High-pressure handling and corrosion resistance.

Example: An industrial park installing HDPE pipes as part of its underground fire protection system.

Temporary Water Supply

Benefit: Quick and easy deployment and removal.

Example: An outdoor event organizer using HDPE pipes to set up a temporary water distribution system for a festival.

The 2 in. x 500 ft x 1000 ft HDPE water pipes are essential for a variety of applications, providing reliable performance in both permanent and temporary setups. Their flexibility, durability, and resistance to a wide range of environmental and chemical factors make them an excellent choice for municipal, agricultural, industrial, residential, landscaping, firefighting, and temporary water supply needs.

Advantages of purchasing from factories

Purchasing 2 in. x 500 ft x 1000 ft HDPE water pipes directly from the factory can provide several significant cost advantages compared to buying from intermediaries or retailers. Here are the key reasons:

1. Elimination of Middlemen

Cost Reduction: By cutting out distributors and wholesalers, you avoid their markup on the products. This results in a lower purchase price as you are buying directly from the source.

Direct Negotiations: You have the opportunity to negotiate prices directly with the manufacturer, potentially securing better deals and discounts.

2. Bulk Purchase Discounts

Economies of Scale: Factories often offer discounts for bulk purchases. Buying large quantities directly can reduce the per-unit cost of the HDPE pipes.

Lower Shipping Costs: Bulk orders typically have lower shipping costs per unit, as shipping large volumes at once is more efficient and cost-effective.

3. Customized Solutions

Tailored Specifications: Manufacturers can customize the HDPE pipes to your specific needs, ensuring you get exactly what you require without paying extra for unnecessary features or modifications.

Production Control: Direct purchasing allows you to have more control over the production schedule, quality standards, and material specifications, ensuring higher quality and reducing the risk of defects.

4. Faster Delivery Times

Direct Supply Chain: Eliminating intermediaries often results in faster delivery times, as the product moves directly from the factory to the end-user. This can be particularly advantageous in time-sensitive projects.

Inventory Management: Factories can provide better insights into production timelines, helping you manage your inventory and project schedules more effectively.

5. Better Quality Assurance

Consistent Quality: Direct interaction with the factory ensures that the quality control measures are in place according to your standards. You can be assured of the consistent quality of each batch.

Long-term Relationship: Establishing a direct relationship with the manufacturer can lead to better service and quality over time, as manufacturers value repeat business and customer loyalty.

6. Cost Transparency

Clear Pricing: Purchasing directly from the factory provides clear insight into the pricing structure, helping you understand where your money is going. This transparency can lead to more informed purchasing decisions.

Avoid Hidden Fees: Retailers and distributors often add hidden fees for handling, storage, and logistics. Direct factory purchases typically have a more straightforward pricing model, reducing unexpected costs.

Example Cost Comparison

Here’s a hypothetical cost comparison to illustrate the potential savings:

| Source | 500 ft Length Cost | 1000 ft Length Cost | Total for 5000 ft | Total for 10000 ft |

|---|---|---|---|---|

| Factory Direct | $750 | $1,500 | $7,500 | $15,000 |

| Distributor | $900 | $1,800 | $9,000 | $18,000 |

| Retailer | $1,100 | $2,200 | $11,000 | $22,000 |

In this example, purchasing directly from the factory results in significant savings, particularly for large quantities.

Wholesale prices

The wholesale prices for 2 in. x 500 ft x 1000 ft HDPE water pipes can vary based on several factors such as the manufacturer, quality, location, and order volume. Below are estimated wholesale price ranges for these HDPE pipe rolls.

Estimated Wholesale Prices

500 ft Length HDPE Water Pipe Rolls

Low-End Price: $600 - $800 per roll

Mid-Range Price: $800 - $1,200 per roll

High-End Price: $1,200 - $1,500 per roll

1000 ft Length HDPE Water Pipe Rolls

Low-End Price: $1,200 - $1,600 per roll

Mid-Range Price: $1,600 - $2,400 per roll

High-End Price: $2,400 - $3,000 per roll

Factors Influencing Prices

Material Quality

Higher quality HDPE will generally cost more due to better durability and performance characteristics.

Pressure Rating and SDR (Standard Dimension Ratio)

Higher pressure ratings and lower SDR values (indicating thicker walls) will increase the cost.

Order Volume

Bulk orders often qualify for significant discounts, lowering the per-roll price.

Manufacturer Location

Local manufacturers might offer lower prices due to reduced shipping costs compared to international suppliers.

Customization

Custom specifications or additional features (like UV protection, specific colors, or fittings) can affect pricing.

Example Price Table

| Length | Low-End Price | Mid-Range Price | High-End Price |

|---|---|---|---|

| 500 ft | $600 - $800 | $800 - $1,200 | $1,200 - $1,500 |

| 1000 ft | $1,200 - $1,600 | $1,600 - $2,400 | $2,400 - $3,000 |

Bulk Purchase Example

For a bulk purchase scenario, assuming a mid-range price:

10 rolls of 500 ft:

Price per roll: $1,000 (average mid-range)

Total cost: 10 * $1,000 = $10,000

10 rolls of 1000 ft:

Price per roll: $2,000 (average mid-range)

Total cost: 10 * $2,000 = $20,000

Wholesale prices for 2 in. x 500 ft x 1000 ft HDPE water pipes typically range from $600 to $3,000 per roll depending on length, quality, and other factors. Purchasing directly from manufacturers in bulk can result in significant cost savings, making it a cost-effective option for large-scale projects.

Buying 2 in. x 500 ft x 1000 ft HDPE water pipes directly from the factory offers numerous cost advantages, including lower prices, bulk discounts, and better quality assurance. These benefits make direct factory purchases a smart choice for large-scale projects and long-term procurement strategies.

Manufacturing Standards for 2 in. x 500 ft x 1000 ft HDPE Water Pipe Roll

The production of 2 in. x 500 ft x 1000 ft HDPE water pipes adheres to various international and national standards to ensure quality, safety, and performance. These standards govern aspects such as material properties, dimensions, pressure ratings, and durability. Here are some of the key standards typically followed:

1. ASTM Standards (American Society for Testing and Materials)

ASTM D3035: Standard Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled Outside Diameter. This standard specifies the requirements for PE pipes based on controlled outside diameter.

ASTM F714: Standard Specification for Polyethylene (PE) Plastic Pipe (SDR-PR) Based on Outside Diameter. It covers requirements and test methods for PE pipes based on outside diameter.

2. ISO Standards (International Organization for Standardization)

ISO 4427: Plastics Piping Systems - Polyethylene (PE) Pipes and Fittings for Water Supply. This international standard specifies the requirements for PE pipes and fittings intended for water supply.

ISO 4437: Plastics Piping Systems for the Supply of Gaseous Fuels - Polyethylene (PE). Although focused on gaseous fuels, it highlights the durability and quality standards applicable to HDPE pipes.

3. AWWA Standards (American Water Works Association)

AWWA C901: Standard for Polyethylene (PE) Pressure Pipe and Tubing, 1/2 inch (13 mm) Through 3 inch (76 mm), for Water Service. This standard applies to smaller pipes but establishes guidelines relevant to HDPE pipe production.

AWWA C906: Standard for Polyethylene (PE) Pressure Pipe and Fittings, 4 inch (100 mm) Through 63 inch (1,600 mm), for Waterworks. This standard covers larger diameter pipes and fittings used in water systems.

4. DIN Standards (Deutsches Institut für Normung - German Institute for Standardization)

DIN 8074: Polyethylene (PE) Pipes; PE 80, PE 100; Dimensions. This standard defines the dimensions and requirements for PE pipes.

DIN 8075: Polyethylene (PE) Pipes; General Quality Requirements, Testing. It covers the quality requirements and testing procedures for PE pipes.

5. Other Relevant Standards

NSF/ANSI 61: Drinking Water System Components - Health Effects. Ensures the pipe materials are safe for use in drinking water systems.

EN 12201: Plastic Piping Systems for Water Supply, and for Drainage and Sewerage Under Pressure - Polyethylene (PE). European standard covering the requirements for PE pipes used in water supply and sewage.

Compliance and Certification

Manufacturers like Haoyang Environmental ensure their HDPE pipes comply with these standards through rigorous quality control and testing. Compliance certificates and third-party inspection reports are often provided to verify adherence to these standards.

Key Parameters Defined by Standards

Material Composition: Specifies the grade of HDPE used, typically PE80 or PE100.

Dimensions: Outside diameter, wall thickness, and length specifications.

Pressure Ratings: Specifies the pressure capacity of the pipes, such as SDR11 or SDR17.

Durability and Longevity: Requirements for resistance to environmental stress cracking and long-term hydrostatic strength.

Quality Assurance: Standards for testing methods, including hydrostatic pressure tests, tensile strength, and elongation tests.

Adhering to these standards ensures that the 2 in. x 500 ft x 1000 ft HDPE water pipes are of high quality, durable, and safe for their intended applications. It also guarantees that the pipes meet the necessary performance criteria for various water supply systems.

About Haoyang Environmental

Haoyang Environmental is a leading manufacturer and factory specializing in the production of high-quality 2 in. x 500 ft x 1000 ft HDPE water pipes. Established with a commitment to excellence and innovation, we have become a trusted name in the industry, known for delivering durable and reliable piping solutions.

Our state-of-the-art manufacturing facility is equipped with advanced machinery and technology, enabling us to produce HDPE pipes that meet the highest standards of quality and performance. Our pipes are designed to offer superior durability, flexibility, and resistance to environmental stress, making them ideal for a wide range of applications, including agricultural irrigation, water supply systems, and industrial fluid transfer.

At Haoyang Environmental, we prioritize customer satisfaction and strive to provide products that meet the specific needs of our clients. Our experienced team of engineers and technicians work diligently to ensure that every pipe leaving our factory is thoroughly tested and inspected for quality assurance.

We understand the importance of cost-efficiency in large-scale projects and offer competitive wholesale pricing to our clients. By choosing Haoyang Environmental, you are not only investing in top-notch HDPE water pipes but also benefiting from our dedicated customer support and tailored solutions.

Whether you are undertaking a large infrastructure project or need reliable piping for agricultural purposes, Haoyang Environmental is your go-to source for premium HDPE water pipes. Contact us today to learn more about our products and how we can assist you in achieving your project goals.

886.webp)

503.webp)

759.webp)

846.webp)

904.webp)