Exploring the Application of 2mm (60 mil) HDPE Geomembrane Liner for Pond Construction: Advantages, Disadvantages, and Principles

Ponds serve various purposes, from irrigation and aquaculture to stormwater management and recreational use. Constructing a pond requires careful consideration of materials to ensure its integrity and longevity. Among the options available, the use of 2mm (60 mil) High-Density Polyethylene (HDPE) geomembrane liner stands out as a popular choice due to its unique characteristics and performance. In this article, we delve into the advantages, disadvantages, and underlying principles of using 2mm HDPE geomembrane liner for pond construction.

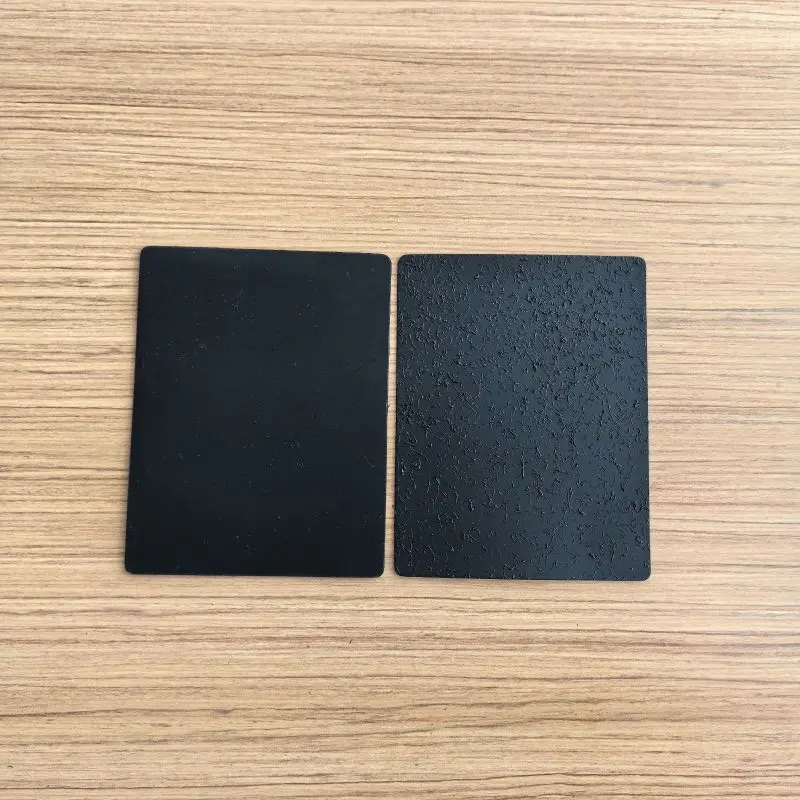

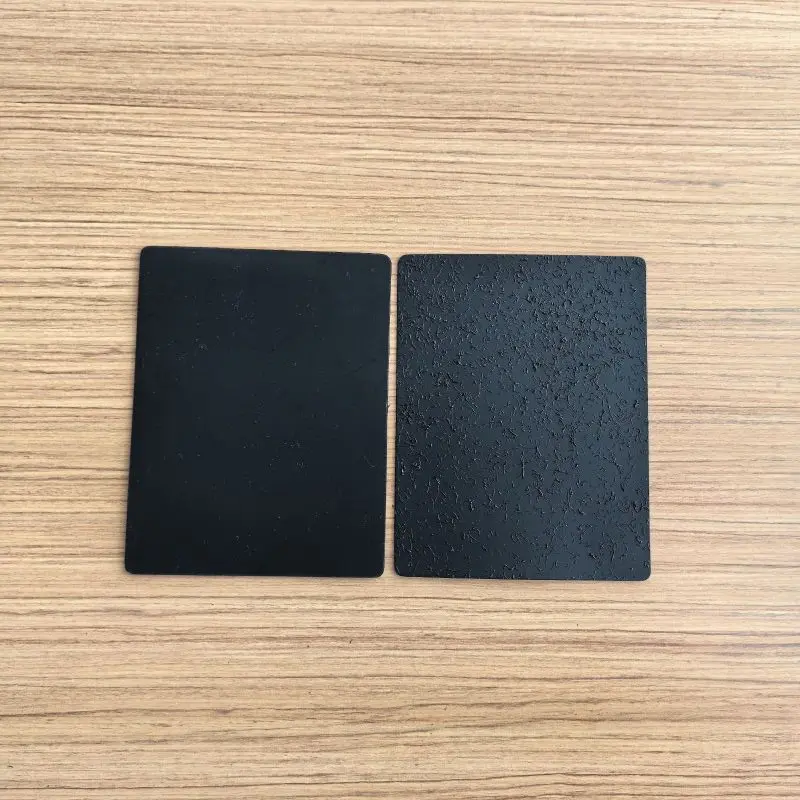

60 mil hdpe geomembrane parameter specifications

Thickness (min. ave.) | nom. |

. lowest individual of 10 values | - 10% |

Formulated Density mg/l (min.) | 0.940 g/cc |

Tensile Properties (1) (min. ave.) . yield strength . break strength . yield elongation . break elongation | 126 lb/in. 228 lb/in. 12% 700% |

Tear Resistance (min. ave.) | 42 lb |

Puncture Resistance (min. ave.) | 108 lb |

Stress Crack Resistance (2) | 500 hr. |

Carbon Black Content (range) | 2.0-3.0% |

Carbon Black Dispersion | note (4) |

Oxidative Induction Time (OIT) (min. ave.) (5) (a) Standard OIT — or — (b) High Pressure OIT | 100 min. 400 min. |

Oven Aging at 85°C (5), (6) (a) Standard OIT (min. ave.) - % retained after 90 days — or — (b) High Pressure OIT (min. ave.) - % retained after 90 days | 55% 80% |

UV Resistance (7) (a) Standard OIT (min. ave.) — or — (b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (9) | N.R. (8) 50% |

(1) Machine direction (MD) and cross machine direction (XMD) average values should be on the basis of 5 test specimens each direction.

Yield elongation is calculated using a gage length of 1.3 inches

Break elongation is calculated using a gage length of 2.0 in.

(2)The yield stress used to calculate the applied load for the SP-NCTL test should be the manufacturer’s mean valuevia MQC testing.

(3)Other methods such as D 1603 (tube furnace) or D 6370 (TGA) are acceptable if an appropriate correlation to D 4218 (muffle furnace) can be established.

(4)Carbon black dispersion (only near spherical agglomerates) for 10 different views:

9 in Categories 1 or 2 and 1 in Category 3

(5)The manufacturer has the option to select either one of the OIT methods listed to evaluate the antioxidant content in the geomembrane.

(6) It is also recommended to evaluate samples at 30 and 60 days to compare with the 90 day response.

(7)The condition of the test should be 20 hr. UV cycle at 75。C followed by 4 hr. condensation at 60。C.

(8) Not recommended since the high temperature of the Std-OIT test produces an unrealistic result for some of the antioxidants in the UV exposed samples.

(9)UV resistance is based on percent retained value regardless of the original HP-OIT value.

Advantages:

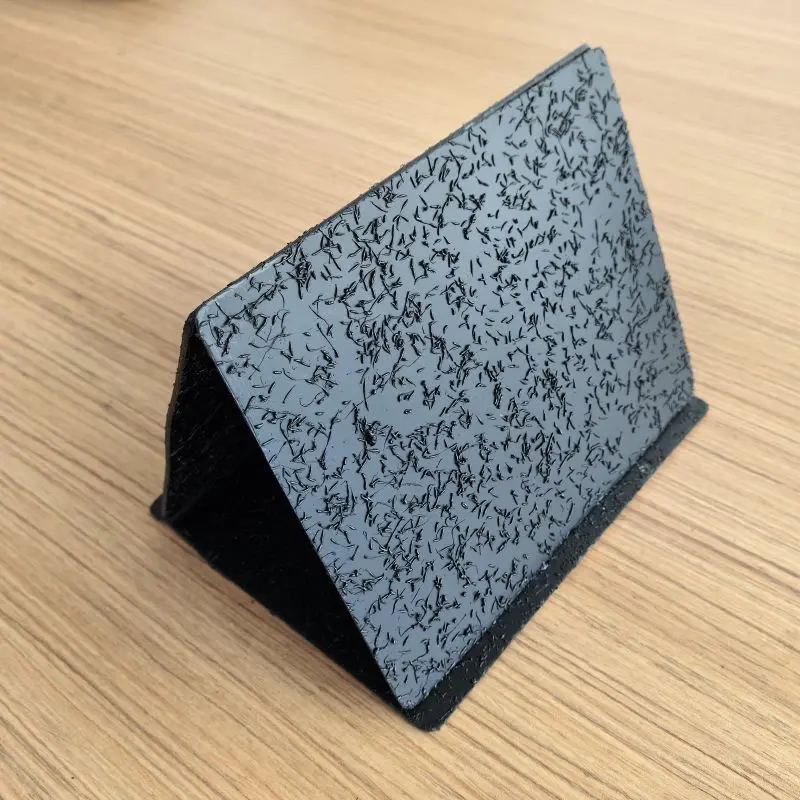

Impermeability: One of the primary advantages of using 2mm HDPE geomembrane liner is its exceptional impermeability. The liner acts as a robust barrier, preventing water seepage and ensuring efficient water retention within the pond.

Durability: HDPE geomembrane liners are known for their durability and resistance to degradation. The 2mm thickness provides added strength and puncture resistance, ensuring long-term performance even in harsh environmental conditions.

Flexibility: The flexibility of HDPE geomembrane allows it to conform to the contours of the pond bed, minimizing wrinkles and ensuring a snug fit. This flexibility also facilitates installation, especially in irregularly shaped ponds.

Chemical Resistance: HDPE geomembrane liners exhibit excellent resistance to chemicals, including acids, alkalis, and organic solvents. This resistance makes them suitable for ponds containing fertilizers, pesticides, or other agricultural chemicals.

UV Resistance: Many HDPE geomembrane liners are formulated with UV stabilizers, enhancing their resistance to degradation from sunlight exposure. This UV resistance prolongs the lifespan of the liner, making it suitable for outdoor applications.

Disadvantages:

Temperature Sensitivity: HDPE geomembrane liners may become stiff and brittle in cold temperatures, which can affect their flexibility and handling during installation. Proper precautions, such as warming the material before installation, can mitigate this issue.

Seaming Complexity: Achieving watertight seams with HDPE geomembrane liners requires specialized equipment and skilled labor. Improper seaming can compromise the integrity of the liner and lead to leaks.

Puncture Risk: While HDPE geomembrane liners offer good puncture resistance, they are not entirely immune to damage from sharp objects or abrasive materials. Care must be taken during installation and maintenance to avoid punctures.

Principles:

The underlying principle of using 2mm HDPE geomembrane liner for pond construction lies in creating a reliable barrier to control water movement. The impermeable nature of the liner prevents seepage into or out of the pond, maintaining desired water levels and preserving water quality. Proper installation techniques, including surface preparation, seaming, and anchoring, are essential to ensure the integrity of the liner. Additionally, considerations such as slope stability, hydraulic design, and environmental regulations play crucial roles in the design and implementation of pond projects utilizing HDPE geomembrane liners.

In conclusion, the use of 2mm HDPE geomembrane liner offers significant advantages for pond construction, including impermeability, durability, and chemical resistance. However, careful attention to installation practices and potential limitations is necessary to maximize the effectiveness of the liner and ensure the success of pond projects.

What are the construction requirements?

When installing a 2mm (60 mil) HDPE geomembrane liner for a pond, there are several construction requirements to follow to ensure proper installation and avoid non-compliant practices. Here are the construction requirements and precautions to avoid violations:

Construction Requirements:

Surface Preparation:

Ensure the pond bed is properly graded and compacted to provide a smooth and stable surface for the geomembrane liner.

Unrolling and Placement:

Carefully unroll the geomembrane liner over the prepared pond bed, ensuring it lies flat and without wrinkles or creases.

Overlap adjacent rolls according to manufacturer specifications and securely bond them.

Seaming:

Use appropriate seaming techniques recommended by the manufacturer to join adjacent rolls of geomembrane liner.

Ensure seams are properly welded or bonded to maintain integrity and prevent leakage.

Anchoring and Fixing:

Anchor the geomembrane liner along the edges and at regular intervals to prevent movement during and after installation.

Avoid excessive tension on the liner, as it may lead to stress concentrations and potential failure.

Protection and Covering:

Cover the installed geomembrane liner with protective layers, such as geotextile or soil, to shield it from UV exposure and physical damage.

Minimize traffic over the liner to prevent punctures or tears.

Quality Control:

Conduct thorough inspections throughout the installation process to ensure compliance with design specifications and manufacturer guidelines.

Inspect for wrinkles, tears, and other defects, and address them promptly.

Documentation:

Maintain detailed records of the installation process, including installation logs, inspection reports, and as-built drawings.

Document any deviations from the design plan and corrective actions taken.

Precautions to Avoid Non-compliant Practices:

Avoid Overstretching: Do not stretch the geomembrane liner excessively during installation, as it may compromise its integrity and lead to premature failure.

Prevent Damage during Handling: Handle the geomembrane liner with care to avoid punctures, tears, or other damage during transportation, storage, and installation.

Follow Manufacturer Guidelines: Adhere to the manufacturer's recommended installation procedures and specifications to ensure proper performance and warranty coverage.

Avoid Improper Seaming: Use proper welding or bonding techniques for seaming to maintain the integrity of the liner and prevent leaks.

Minimize Disturbance: Minimize disturbances to the geomembrane liner during installation and subsequent activities to prevent damage and ensure long-term performance.

Ensure Proper Anchoring: Ensure anchors and fasteners are installed correctly and securely to prevent liner movement and displacement.

By following these construction requirements and precautions, contractors can ensure the successful installation of a 2mm HDPE geomembrane liner for a pond while avoiding non-compliant practices that could compromise its effectiveness and durability.

How to calculate dosage?

To calculate the quantity of 2mm (60 mil) HDPE geomembrane liner required for a pond construction project, you can use the following formula:

Area of Pond Surface (in square meters or square feet) = Length of Pond (in meters or feet) × Width of Pond (in meters or feet)

Then, considering the desired thickness of the geomembrane liner (2mm or 60 mil), you can calculate the volume of material required using the following formula:

Volume of Geomembrane Liner (in cubic meters or cubic feet) = Area of Pond Surface × Thickness of Geomembrane Liner

To convert the volume into rolls of geomembrane liner, divide the volume by the area covered by a single roll of liner. The area covered by a roll can be determined by multiplying the roll width by the roll length.

Number of Rolls = Volume of Geomembrane Liner / (Roll Width × Roll Length)

Ensure to consider any overlaps or waste factor when estimating the quantity of geomembrane liner needed for the project.

By using these formulas, you can accurately calculate the quantity of 2mm HDPE geomembrane liner required for the pond construction project, enabling efficient material planning and procurement.

Design life

The design lifespan of HDPE geomembrane liners for ponds can vary depending on several factors, including material quality, installation practices, environmental conditions, and intended use of the pond. However, in general, HDPE geomembrane liners are designed to have a lifespan ranging from 20 to 30 years under typical environmental conditions and proper installation.

Factors affecting the design lifespan of HDPE geomembrane liners include:

Material Quality: The quality and formulation of the HDPE geomembrane material play a significant role in determining its lifespan. High-quality HDPE materials with UV stabilizers and antioxidants tend to have longer lifespans.

Installation Practices: Proper installation techniques, including surface preparation, seaming, anchoring, and protection, are essential for maximizing the lifespan of HDPE geomembrane liners. Improper installation can lead to premature failure and reduced lifespan.

Environmental Conditions: Exposure to environmental factors such as sunlight (UV radiation), temperature fluctuations, chemical exposure, and mechanical stresses can impact the durability and longevity of HDPE geomembrane liners.

Pond Use: The intended use of the pond, such as irrigation, aquaculture, stormwater management, or recreational activities, can influence the lifespan of the geomembrane liner. Ponds subjected to heavy traffic or abrasive materials may experience accelerated wear and reduced lifespan.

Maintenance: Regular inspection and maintenance of the geomembrane liner can help identify and address issues early, extending its lifespan. Measures such as repairing damage, removing debris, and monitoring for leaks can contribute to prolonged durability.

It's important to note that while HDPE geomembrane liners are designed for long-term performance, environmental and usage factors can impact their actual lifespan. Therefore, proper consideration of these factors during design, installation, and maintenance is essential for ensuring the desired lifespan of HDPE geomembrane liners used in pond construction projects.

HDPE geomembrane liners manufacturer

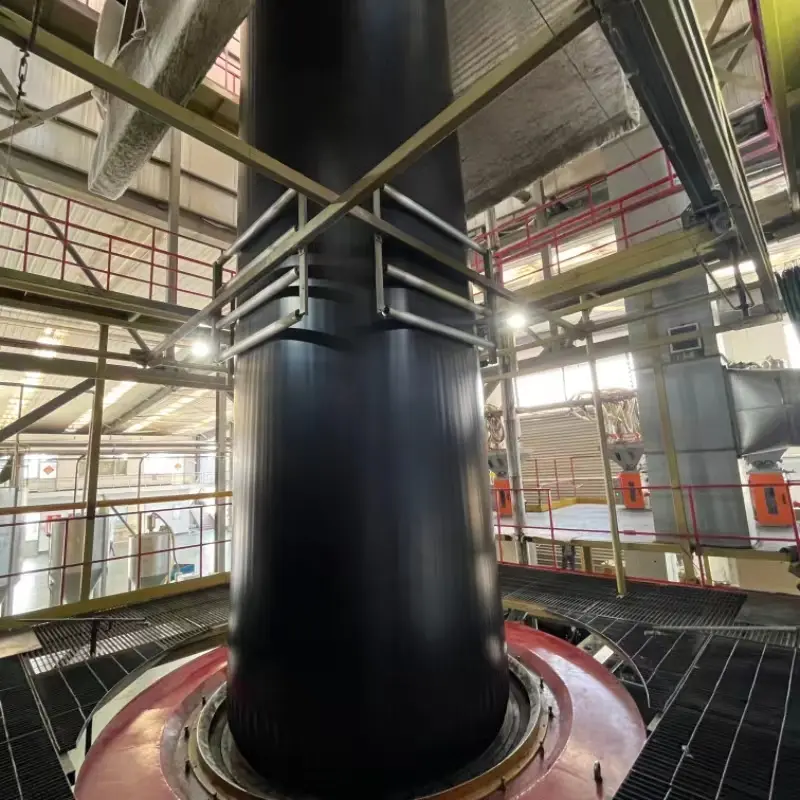

Haoyang Environmental is a leading manufacturer of HDPE geomembrane liners, committed to providing high-quality solutions for a wide range of environmental and engineering applications. With our state-of-the-art manufacturing facility and dedication to innovation, we have established ourselves as a trusted partner for clients worldwide.

Quality Assurance:

At Haoyang Environmental, quality is our top priority. We adhere to strict quality control measures at every stage of the manufacturing process, from raw material selection to final product inspection. Our HDPE geomembrane liners are manufactured using premium-grade materials and advanced production techniques, ensuring superior performance, durability, and reliability.

Global Reach:

With our global distribution network and strategic partnerships, Haoyang Environmental serves clients across the globe, delivering high-quality HDPE geomembrane liners to diverse industries and sectors. Whether it's landfill construction, pond lining, mining, or wastewater treatment, our products have been trusted by engineers, contractors, and environmental professionals worldwide.

Conclusion:

When it comes to HDPE geomembrane liners, Haoyang Environmental is your trusted partner for quality, reliability, and performance. With our cutting-edge manufacturing capabilities, customized solutions, and unwavering commitment to customer satisfaction and environmental stewardship, we are poised to meet the evolving needs of the industry and deliver lasting value to our clients. Choose Haoyang Environmental for all your HDPE geomembrane liner needs, and experience the difference of excellence.

503.webp)

759.webp)

897.webp)

942.webp)

237.webp)