3D Composite Dranage Net

A 3D composite drainage net, also known as a three-dimensional composite drainage geonet, is a type of geosynthetic material used in various civil engineering and construction applications for drainage purposes. It is designed to effectively drain excess water away from the structure or area where it's installed.

198796.webp)

3D composite drainage net is a very common gesythetic materials used in landfills. It typically consist of multiple layers, incorporating geotextiles, and drainage cores, sometimes, it can also include geomembrane. For Landfill sites, efficient drainage systems are essential to ensure the stability and environmental sustainability of these facilities. One innovative solution that has gained prominence is the application of three-dimensional composite drainage nets.

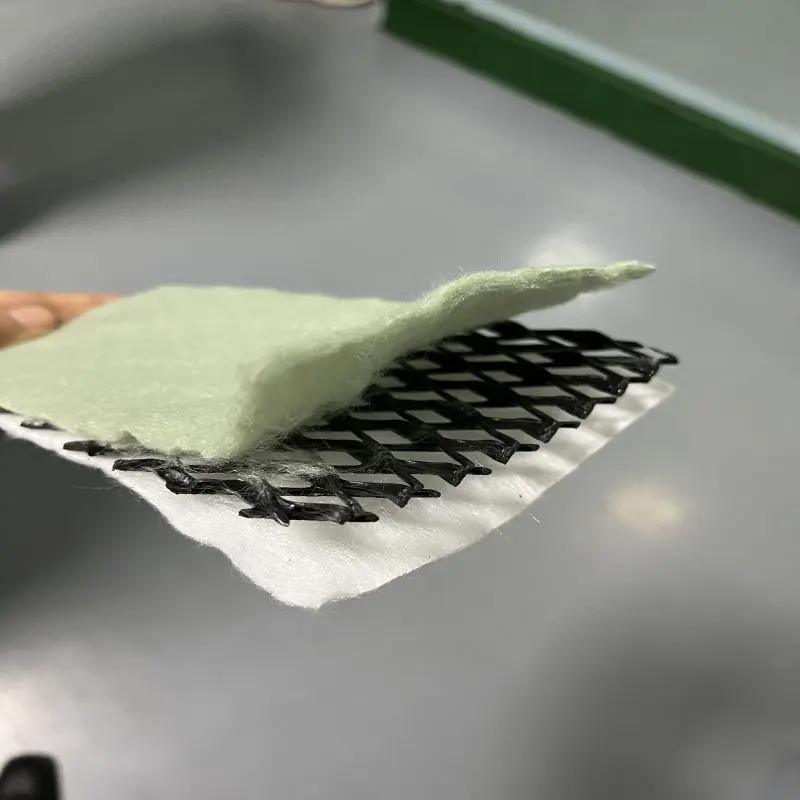

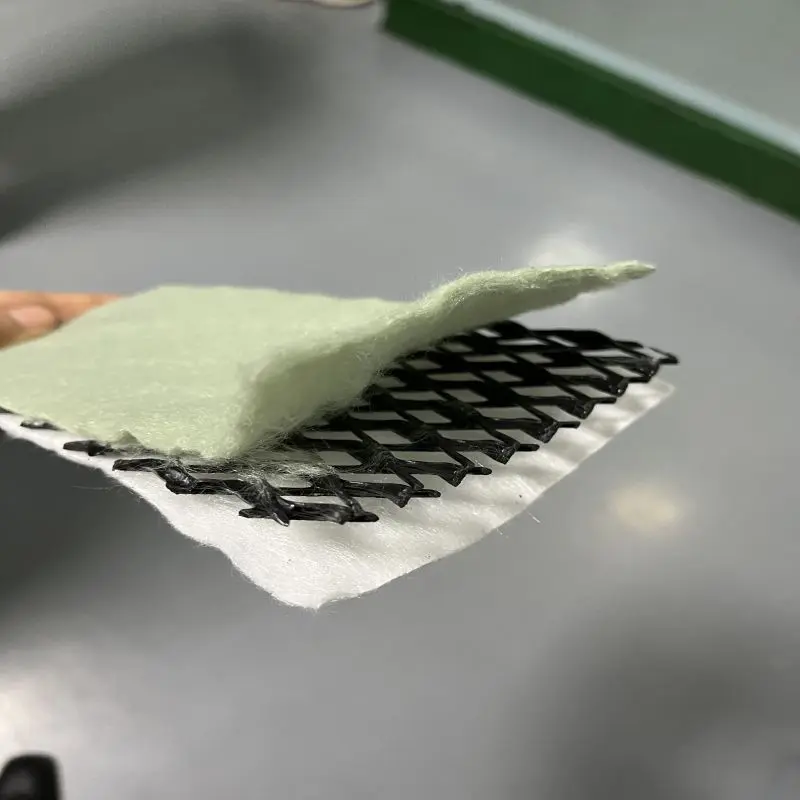

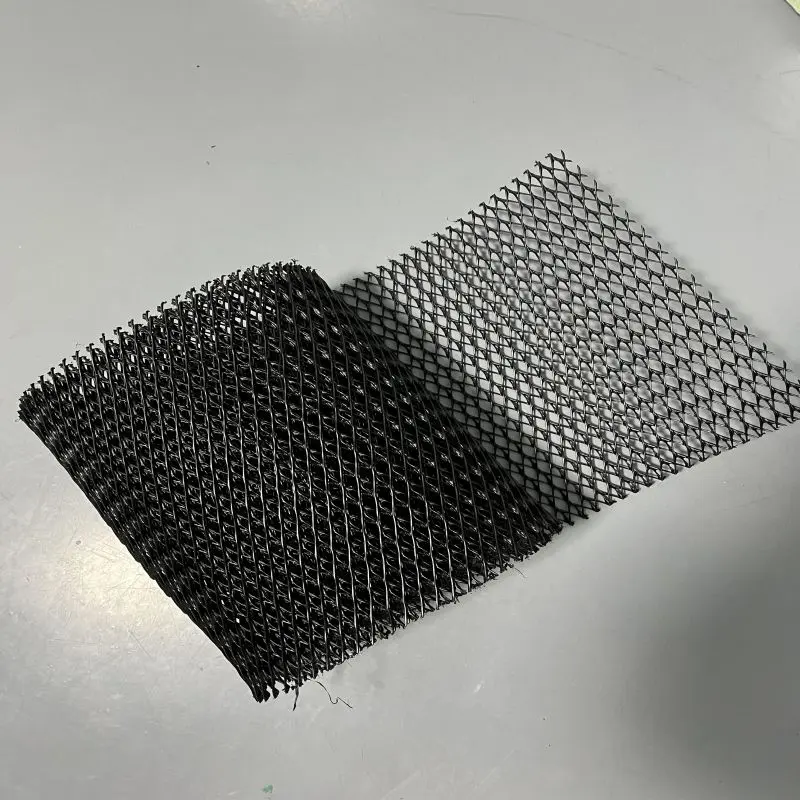

As we can see from the picture, the two sides are filament nonwoven needle punched geofabrics, the colors also can be customized according to your needs. In the middle is 3D drainage net with 6mm thickness, this kind of structure is the most popular choice among our clients. It offers a comprehensive solution to enhance drainage efficiency, and soil stability. This innovative approach aligns with the growing emphasis on sustainable waste management practices, contributing to the overall environmental health and safety of landfill facilities.

Specifications

items | specifications | |

| drainage net | composite drainage net | |

| density(g/㎡) | ≥0.939 | ----- |

| carbon black content(%) | 2-3 | ----- |

| tensile strength in the longitudinal direction(KN/m) | ≥8.0 | ≥16.0 |

| longitudinal hydraulic conductivity(%) | ≥3.0x10-3 | ≥3.0x10-4 |

| peel strength(KN/m) | ----- | ≥0.17 |

| unit areal mass of geotextile(g/㎡) | ----- | ≥200 |

Specifications Table for 3D Composite Drainage Net

| Specification | Description |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Structure | 3D Geonet core with double-sided non-woven geotextile layers |

| Geonet Thickness | 5mm - 10mm |

| Geotextile Weight | 200gsm - 400gsm (grams per square meter) |

| Tensile Strength | ≥ 15 kN/m (geotextile layer), ≥ 30 kN/m (geonet core) |

| Flow Capacity | 1.5 x 10⁻³ m²/s - 5 x 10⁻³ m²/s (depends on thickness) |

| Permeability | ≤ 1 x 10⁻⁷ cm/s |

| Roll Width | 2m - 4m (custom widths available) |

| Roll Length | 30m - 50m (varies based on thickness and application) |

| Compression Strength | 250 kPa - 600 kPa (varies with thickness) |

| UV Resistance | UV-stabilized for outdoor use |

| Applications | Landfill drainage, tunnel drainage, slope drainage, retaining walls |

| Compliance | ISO 9001, ASTM D4716, EN 13252 standards for drainage materials |

| Lifespan | Up to 30 years in buried conditions |

These nets are available in different sizes, thicknesses, and configurations to suit specific project needs. They are often supplied in rolls for ease of transportation and installation on-site.

The specific design and composition of a 3D composite drainage net may vary based on the manufacturer, intended application, and required performance specifications for a particular project.

Funtions of the 3D Composite Drainage Net in Landfills

Drainage Function: The unique structure of the 3D composite drainage net provides excellent drainage performance. It effectively guides and accelerates the flow of infiltrating water, preventing water retention within the landfill waste. This reduces the accumulation of leachate, aiding in maintaining the stability of the landfill and preventing environmental issues such as groundwater pollution.

Gas Emission and Control: The structure of the 3D composite drainage net allows for effective handling of gases produced during the landfill process, such as methane. By enabling gas circulation, the drainage net helps slow the accumulation of gases, reducing gas pressure within the landfill and mitigating potential safety risks. This also decreases the impact of toxic gases on the environment.

Soil Stability: Since the 3D composite drainage net typically includes various geosynthetic materials such as geotextiles and geomembranes, it plays a positive role in soil stability. This helps reduce erosion on the slopes of the landfill, enhances the soil's resistance to sliding, and strengthens the overall structural stability of the landfill.

Resistance to Biodegradation: 3D composite drainage nets are usually made from materials resistant to biodegradation, capable of withstanding microbial and chemical erosion. This ensures their long-term durability in landfill applications.

Environmental Sustainability: By improving drainage, gas control, and soil stability, the 3D composite drainage net contributes to increased environmental sustainability of the landfill. It minimizes adverse impacts on the surrounding environment, aligning with the principles of sustainable development in modern waste management.

Products Often Used in Landfills

Commonly used geosynthetic products in landfill burial projects include:

1,Geomembranes: Used to cover landfill areas and prevent waste leakage into groundwater.

2,Geotextiles: Used for soil separation, filtration, and reinforcement to enhance the stability of landfill areas.

3,Geogrids: Used to reinforce soil, preventing soil slippage and deformation.

4,Drainage Pipe Systems: Used for drainage and preventing the accumulation of moisture in landfill areas.

5,Biodegradable Covering Materials: Used to cover waste, slowing down the decomposition process and reducing leakage risks.

6,Slope Protection Materials: Used to prevent erosion and collapse on landfill slopes.

7,Monitoring Systems: Include leak detection systems, gas monitoring systems, etc., for real-time monitoring of the environmental conditions in the landfill area.

Proven Expertise and Innovation

With a professional R&D team dedicated to environmental engineering design and consulting, Haoyang has pioneered numerous innovations in pollution control and hazardous waste treatment. We hold three invention patents and 32 utility model patents, reflecting our commitment to cutting-edge technology and continuous improvement.

Commitment to Quality

Certified under ISO 9001, ISO 14001, and OHSAS 18001, Haoyang ensures that every product meets the highest standards of quality, environmental management, and occupational health and safety. Our rigorous testing and quality control processes guarantee reliable and effective solutions for our clients.

Price List for 3D Composite Drainage Net

| Thickness (mm) | Geotextile Weight (gsm) | Roll Dimensions (m) | Factory Price (USD per Square Meter) | Factory Price (USD per Roll) | Application |

|---|---|---|---|---|---|

| 5mm | 200gsm | 2m x 30m (60m²) | $2.00 - $2.50 | $120 - $150 | Slope and wall drainage |

| 6mm | 250gsm | 2m x 30m (60m²) | $2.20 - $2.80 | $132 - $168 | Landfill and tunnel drainage |

| 7mm | 300gsm | 2m x 30m (60m²) | $2.50 - $3.00 | $150 - $180 | Retaining walls, leachate management |

| 8mm | 350gsm | 2m x 40m (80m²) | $2.80 - $3.30 | $224 - $264 | Landfill drainage systems |

| 10mm | 400gsm | 2m x 50m (100m²) | $3.00 - $3.80 | $300 - $380 | High-capacity drainage projects |

Note: Prices may vary based on order quantity, location, and specific project requirements. Bulk purchase discounts are available.

The 3D Composite Drainage Net by Haoyang Environmental Co., Ltd.: Revolutionizing Environmental Engineering Solutions

At Haoyang Environmental Co., Ltd., innovation and sustainability are at the heart of our mission. Established in 2008, we have grown into a leading high-tech service provider in environmental engineering, backed by certifications in ISO 9001, ISO 14001, and OHSAS 18001, as well as the esteemed CQC environmental product certification. Our commitment to excellence has also been recognized by the National Laboratory, earning us accolades as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory". Welcome to contact us.

Sucessfule Case

917537.webp)

The first phase of the town domestic garbage landfills in Jingbian County covers an area of 62,476 square meters, and the capacity of the landfill area is 104 square meters.

The effective capacity is 10.29 million square meters, the landfill scale is 300 tons per day, the designed serviceable life of the landfill is 10 years.

The waste landfill adopts sanitary landfill technology, which can improve the environmental conditions of the original garbage dump point , make the residential environment beautiful and clean, save a lot of land, and improve the space utilization coefficient. At the same time, the project adopts artificial horizontal anti -seepage, and the anti -seepage project at the bottom of the warehouse area adopts a composite lining anti -seepage system. It can avoid the pollution of water, groundwater, and soil by using polyester filament spunbond nonwoven needle punched geotextiles layer+HDPE artificial anti -infiltration layer+GCL geosynthetic clay liner+geocomposite drainage net+compact soil for anti –seepageit, which also can reduce damage to human health, save pollution treatment costs, reduce economic losses caused by pollution, and improve the level of satisfaction of residents. The project brings good environmental economic and social benefits.

The project covers an area of about 60,000 square meters. The anti -seepage project of the reservoir area is constructed by our company and adopts a composite lining layer. We use three -dimensional composite drainage net to drain and collect the leachate, in this way, it can effectively avoid pollution of surface water, groundwater and soil.

Three-dimensional composite drainage net: It has a comprehensive role in strengthening the foundation and "anti-filter-drainage-breathable-protection". At the same time, it can also reduce the thickness of the drainage layer, increase the effective capacity of the landfill, reduce the construction cost of the project and make it durable.

Factory Display

301736.webp)

Our factory covers an area of over 230 acres with more than 40,000 square meters of standardized industrial workshops. The company boasts over 26 modern production lines for geosynthetic materials, with a total annual production capacity of 73,500 tons.The facilities include:

The world's only 10-meter-wide, five-layer co-extrusion, online dual-sided roughening, and nitrogen-enhanced blown film production line for geosynthetic membranes.

PP/PE dual-component ultra-wide high-strength geotextile production line.

The first domestically established 6-meter-wide drainage net production line.

The first domestically established dual-screw intelligent biaxial geogrid production line with long filament.

Powdered bentonite waterproof blanket production line.

These state-of-the-art production lines highlight our commitment to advanced technology and innovation in the field of geosynthetic materials

At the Exhibition

Every year,we will attend exhibitions, we will showcase our latest products and technologies at a captivating booth. Our team will personally introduce our solutions, establishing connections with clients and partners.

We look forward to meeting you at the exhibition, sharing our innovative achievements, understanding your needs, and exploring future collaboration opportunities together.

FAQ

Q1: Are you factory or trading company?

A: We are factory with ten years of experience. You can visit our factory online through video.

Q2: What’s your payment term?

A: 30% TT in advance and the balance before shipment or 100% Irrevocable L/C at sight.

Q3: How about the minimum order quantity?

A: We have no MOQ limited for the sample order and regular products.

The MOQ for special customized products is 5000 sqm.

Q4: How long is your delivery time?

A: It depends on the quantity of you quantity.

Usually, it takes 7-10 days upon we receive your deposit.

Q5: How can I get samples?

A: Sample can be sent by DHL or FedEx , etc.

Sample is free and freight collect. We promise we will definitely return the postage to you when we first cooperate.

Q6: Can you advise our pond liner installation and project design?

A: Welding machine is available for your installation.

If necessary, our welder can fly to your project site and install the pond liner. About the project design, we can also give you our rough advice.

169.webp)

733.webp)

483.webp)

214.webp)

934.webp)