Bentonite Clay Pond Liner: A Comprehensive Guide

Bentonite clay pond liners have become a cornerstone of sustainable water management systems due to their remarkable sealing properties, environmental compatibility, and cost-effectiveness. Derived from natural volcanic ash, bentonite clay forms an impermeable barrier when hydrated, making it an ideal solution for ponds, reservoirs, and wastewater containment. Unlike synthetic liners, bentonite not only provides a natural, eco-friendly alternative but also offers unique self-sealing capabilities, ensuring long-term functionality. This guide delves into the science, benefits, and practical applications of bentonite clay pond liners, bolstered by research-backed data and implementation insights.

What is Bentonite Clay?

Bentonite is a naturally occurring clay composed predominantly of montmorillonite, a type of smectite mineral known for its high swelling capacity and low permeability. When hydrated, bentonite expands to several times its dry volume, creating an impermeable barrier that prevents water leakage.

Key Benefits of Bentonite Clay Pond Liners

Environmental Sustainability

Bentonite is a natural material free from synthetic additives, making it eco-friendly and non-toxic to aquatic life and vegetation.Cost-Effectiveness

Compared to synthetic liners like PVC or HDPE, bentonite clay is often more economical, particularly for large-scale projects.Self-Sealing Properties

Bentonite expands and fills gaps or cracks in the substrate, providing a self-healing mechanism for long-term durability.Adaptability

Suitable for ponds of any shape or size, bentonite clay conforms to the contours of the pond bed, ensuring a snug fit.

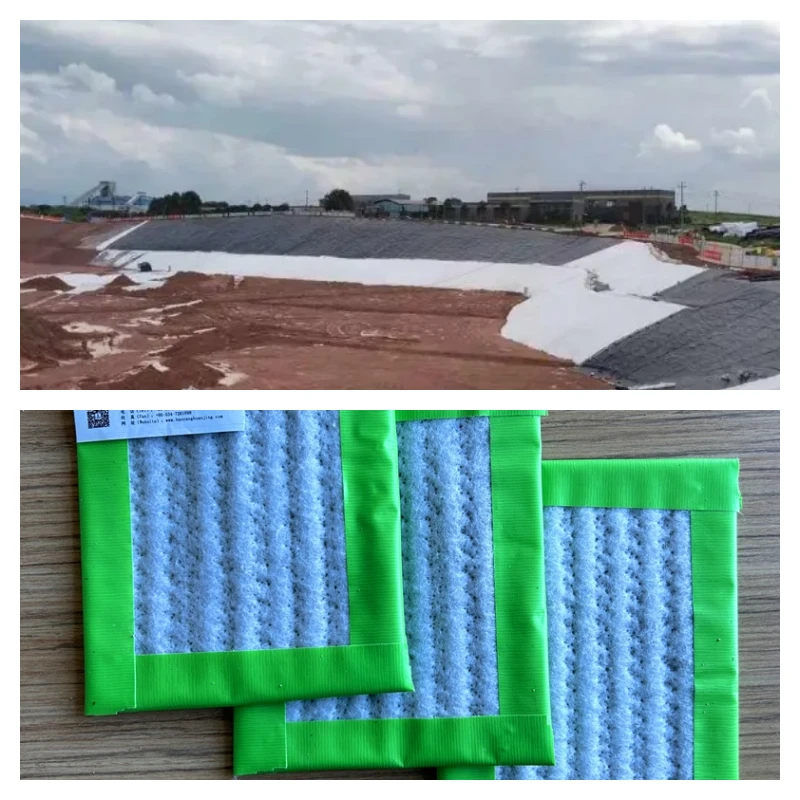

This set of pictures intuitively presents the application and product features of Bentonite Clay Pond Liner through the display of actual scenes and product details. Whether in large-scale water conservancy projects or small pond construction, this material plays an indispensable role in ensuring the effective storage and utilization of water.

Research Data on Bentonite Performance

Key Physical Properties of Bentonite Clay

| Property | Value | Test Method |

|---|---|---|

| Swelling Capacity | 15-20 times dry volume | ASTM D5890 |

| Hydraulic Conductivity | 1 x 10^-9 to 1 x 10^-11 m/s | ASTM D5887 |

| Bulk Density | 0.8-1.1 g/cm³ | ASTM D7263 |

| Plasticity Index | 200-600% | ASTM D4318 |

These properties underline the effectiveness of bentonite as a natural sealant for water containment applications.

Applications of Bentonite Clay Pond Liners

Fish Ponds and Aquaculture

Bentonite's non-toxic nature ensures the safety of aquatic species. It maintains water levels and prevents seepage, which is vital for fish health.Agricultural Water Storage

Farmers use bentonite-lined ponds to store irrigation water. Its cost-effectiveness and ability to handle large volumes make it ideal for agricultural applications.Industrial Waste Ponds

Industries utilize bentonite for creating containment ponds to store wastewater and other by-products securely, preventing environmental contamination.Landscaping and Ornamental Ponds

Bentonite is also popular for creating aesthetic water features in parks, golf courses, and residential areas due to its natural look.

Installation Process of Bentonite Clay Pond Liners

Step 1: Site Preparation

Clear the area of debris, vegetation, and large rocks to create a smooth substrate for the liner.

Step 2: Soil Compatibility Testing

Ensure the substrate soil has enough clay content to bind with bentonite for optimal performance.

Step 3: Application

Spread bentonite evenly over the surface at a rate of 1 to 2 pounds per square foot, depending on the soil type and pond size.

Step 4: Compaction

Compact the bentonite layer using heavy machinery to ensure a uniform and impermeable seal.

Step 5: Hydration

Introduce water gradually to allow the bentonite to swell and form a watertight barrier.

Recommended Application Rates

| Soil Type | Bentonite Rate (lb/ft²) |

|---|---|

| Sandy Soil | 2.0-2.5 |

| Silty Soil | 1.5-2.0 |

| Clay Soil | 1.0-1.5 |

Comparative Analysis: Bentonite vs. Synthetic Liners

Comparison of Bentonite and Synthetic Liners

| Feature | Bentonite Liner | Synthetic Liner |

|---|---|---|

| Material Cost | Low | High |

| Environmental Impact | Minimal | Moderate to High |

| Installation Complexity | Moderate | High |

| Durability | Self-healing | Prone to punctures |

| Lifespan | 10-20 years (with care) | 20-30 years (maintenance required) |

Bentonite offers clear advantages in cost and sustainability, making it a preferred choice for eco-conscious projects.

Maintenance and Longevity

Proper maintenance ensures the durability and effectiveness of bentonite clay pond liners over the long term. While bentonite has self-healing properties, proactive care significantly extends its lifespan and minimizes water loss. Below are key maintenance practices:

Regular Inspections

Conduct routine checks for signs of erosion, unusual water seepage, or damage to the pond's edges. Over time, factors such as animal activity or heavy rainfall can affect the integrity of the liner. Early identification of issues prevents minor problems from escalating into significant repairs.Vegetation Management

Control the growth of invasive vegetation near the pond. While some ground cover, like grass, protects against erosion, deep-rooted plants can penetrate the bentonite layer, compromising its impermeability.Repair and Reinforcement

In the event of damage, bentonite's self-healing properties can be augmented with targeted application of additional bentonite. For example, sprinkle bentonite over areas with minor leaks and compact the surface to seal it effectively.Water Chemistry Monitoring

Regularly test the pond’s water for pH, salinity, and other chemical factors. Extreme pH levels (below 5 or above 9) can reduce the effectiveness of bentonite over time, necessitating adjustments to maintain optimal conditions.Protection Against Heavy Runoff

Install berms or silt fences around the pond to prevent excessive runoff during heavy rains. This reduces sediment accumulation and maintains the liner's integrity by preventing overburdening.Seasonal Adjustments

Monitor the pond liner during seasonal changes. Freezing temperatures can cause cracks in surrounding soils that might indirectly stress the liner. Proper winterization, such as reducing water levels and inspecting edges, minimizes the risk of damage.

By implementing these measures, a bentonite clay pond liner can maintain its effectiveness for 10-20 years or more, depending on the surrounding environmental conditions and usage. For large-scale applications, consulting with professionals for periodic evaluations ensures long-term success.

Conclusion

Bentonite clay pond liners offer a reliable, sustainable, and cost-effective solution for water containment in a variety of applications, from agricultural irrigation to industrial wastewater management. With their unique self-sealing properties, adaptability, and eco-friendliness, they have become a trusted choice for projects of all sizes.

If you're looking for high-quality bentonite products or expert guidance in geosynthetic solutions, Haoyang Environmental Co., Ltd. is your trusted partner. Established in 2008, Haoyang is a leader in environmental engineering and geosynthetic materials, boasting a professional R&D team and multiple certifications, including ISO 9001 and ISO 14001.

To learn more about our products and services, visit our website or contact us for tailored solutions to your environmental and water management needs.

897.webp)

942.webp)

237.webp)