1、Sodium bentonite composite waterproof blanket (GCL) introduction

Sodium bentonite composite waterproof blanket (GCL) is a new type of geosynthetic material, which can be specially used for impermeable geosynthetic materials such as artificial lake water feature, landfill, underground garage, roof garden, pool, oil depot and chemical plant. The high expansion sodium bentonite is filled between the composite plastic flat silk geotextile and non-woven fabric, and the bentonite particles can not flow unidirectional by acupuncture method, and a uniform and high density rubber waterproof layer is formed in the pad when it meets water to effectively prevent water leakage. Bentonite waterproof blanket not only has all the characteristics of geotechnical materials, but also has excellent waterproof (seepage) performance. It is a kind of impermeable lining between GCL and polymer material (geomembrane).

The waterproof mechanism is that the sodium-based granule bentonite used in the bentonite waterproof blanket expands more than 24 times when it meets water, thus forming a uniform colloidal system, which has the characteristics of high viscosity and low filtration. Under the constraint of two layers of geotextile, bentonite expanded from disorder to order. The result of continuous expansion of water is that the bentonite layer itself becomes dense, thus having a waterproof effect.

Our company mainly produces needled sodium-based swelling moisturizing waterproof blanket and needled coated sodium-based swelling moisturizing waterproof blanket.

Advantages of using bentonite waterproof blankets for landfills

Clay liner bentonite waterproof blankets, also known as Geosynthetic Clay Liners (GCLs), are widely used in landfill applications due to their excellent sealing and barrier properties. Here are some key advantages of using bentonite waterproof blankets for landfills:

Superior Sealing Performance:

Low Permeability: Bentonite has a very low permeability, providing an effective barrier against liquids and gases.

Self-Sealing: Bentonite swells upon contact with water, filling voids and creating a tight seal that enhances the liner's integrity.

Environmental Protection:

Prevent Contaminant Migration: GCLs prevent leachate and other contaminants from migrating into the surrounding soil and groundwater, protecting the environment.

Durability: Resistant to various chemicals and environmental conditions, ensuring long-term protection.

Ease of Installation:

Flexible and Adaptable: The blanket can conform to irregular surfaces and contours, making it easy to install in various landfill geometries.

Quick Installation: Faster and more efficient installation compared to traditional compacted clay liners, reducing labor and equipment costs.

Cost-Effective:

Reduced Material Costs: Less expensive than compacted clay liners, especially when considering the cost of transporting and placing large volumes of clay.

Lower Maintenance: Requires minimal maintenance once installed, leading to long-term cost savings.

Enhanced Performance:

Consistent Quality: Manufactured under controlled conditions, ensuring uniform thickness and quality throughout the liner.

Improved Hydraulic Performance: Provides better hydraulic performance compared to some synthetic liners, especially in preventing fluid migration.

Versatility:

Multiple Applications: Suitable for use in various landfill components, including base liners, cover systems, and secondary containment systems.

Combination with Other Liners: Can be used in conjunction with geomembranes for added protection and redundancy.

Sustainability:

Natural Material: Bentonite is a natural clay material, making GCLs an environmentally friendly choice.

Reduced Carbon Footprint: The efficiency of installation and reduced transportation needs contribute to a lower carbon footprint compared to traditional methods.

Using bentonite waterproof blankets for landfills provides a reliable, efficient, and cost-effective solution for environmental protection and landfill management.

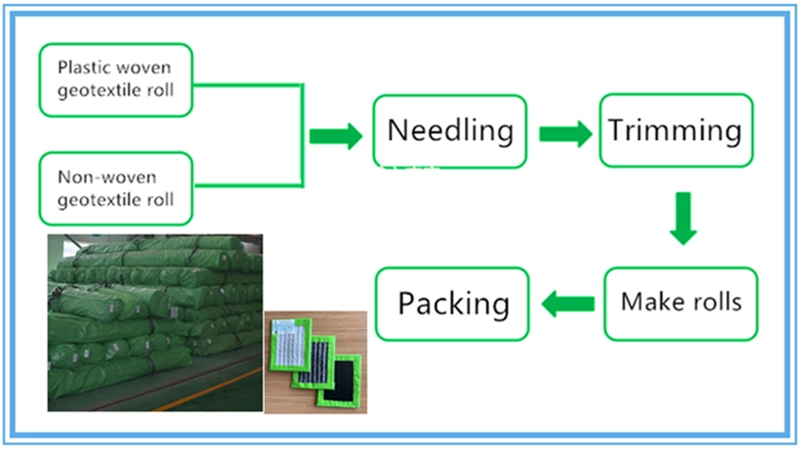

2、How is sodium bentonite waterproof blanket produced?

Production Process:

Specific operating procedures:

(1) Prepare the woven fabric and non-woven fabric in advance, put them in your position, and let the woven fabric and non-woven fabric two layers pass through the acupuncture part;

(2) Prepare the bentonite to the feed bucket, and transport the bentonite to the horizontal conveyor by the angled cage to control the feeding speed;

(3) The bentonite flow rate is adjusted by adjusting the position of the lower plate and cylinder;

(4) The needling machine thrusting and pulling the three through the hook barbed needle at a high speed to become a body intertwined with each other, in which the spindle and the net roller linkage drive, the barbed waterproof blanket transported to the next process;

(5) Cut the GCL waterproof blanket vertically and horizontally and roll it, adjust the meter to make it reach the length and automatically cross cut and check the package.

3、Bentonite waterproof blanket Physical properties:

Comparison of the national standard of physical and mechanical properties of sodium bentonite waterproof blanket by in-needling method and by needling coating method. It conforms to the national standard JG/T 193-2006 issued by the Ministry of Construction of China.

No. | Item | Unit | Index | ||

GCL-NP | GCL-OF | ||||

1 | Bentonite waterproof blanket weight per unit area | g/m2 | ≧4000 and ≧RV | ≧4000 and ≧RV | |

2 | Bentonite expansion index | ml/2g | ≧24 | ≧24 | |

3 | Blue absorption capacity | g/100g | ≧30 | ≧30 | |

4 | Tensile strength | N/10mm | ≧600 | ≧700 | |

5 | Elongation under maximum load | % | ≧10 | ≧10 | |

6 | Peel strength | Nonwovens and woven fabrics | N/100mm | ≧40 | ≧40 |

7 | PE film and nonwovens | - | ≧30 | ||

8 | Permeability coefficient | m/s | ≦5.0*10-11 | ≦5.0*10-12 | |

9 | Hydrostatic pressure resistance | - | 0.4MPa,1h, NO leakage | 0.6MPa,1h, NO leakage | |

10 | Filtration loss | ml | ≦18 | ≦18 | |

11 | Bentonite durability | ml/2g | ≧20 | ≧20 | |

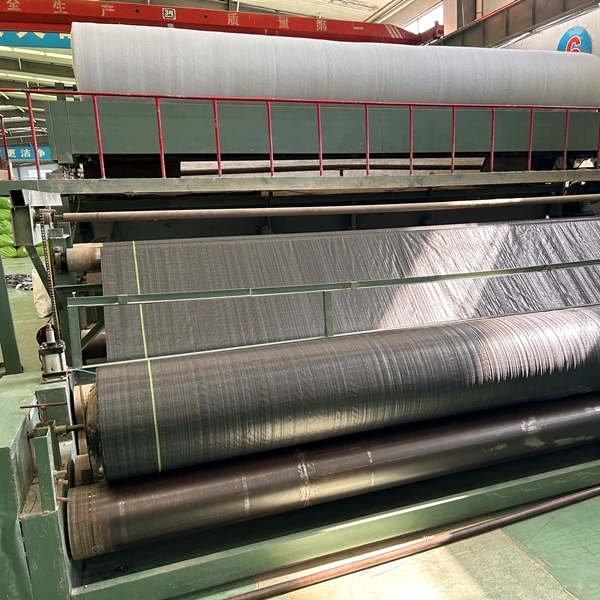

4、Production workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

5、Bentonite waterproof blanket classification

(1) Classification by product type:

a) Sodium bentonite moistened waterproof blanket by needling method is a blanket material formed by needling two layers of geotextile wrapped with bentonite particles, expressed by GCL-NP.

b) The needle-coated sodium-based-swelling waterproof blanket is composed of a layer of high-density polyethylene film on the outer surface of the nonwoven geotextile of the needle-coated sodium-based-swelling waterproof blanket, expressed by GCL-OF.

c) Adhesive method sodium bentonite waterproof blanket, is a kind of sodium bentonite waterproof blanket produced by using an adhesive to bond bentonite particles to a high polyethylene plate, and is expressed by GCL-AH.

(2) Classification according to bentonite varieties:

Artificial sodium bentonite is represented by A; Natural sodium bentonite is denoted by N.

(3) Classification by unit area quality:

Bentonite waterproof blanket unit area quality: 4000g/㎡, 4500g/㎡, 5000g/㎡, 5500g/㎡, with 4000, 4500, 5000, 5500 and so on.

(4) Classification according to product specifications:

The main specifications of the product are differentiated by length and width; The length of the product is m, expressed by 20, 30, etc. The width of the product is m, expressed by 4.5, 5.0, 5.85, etc. Special needs can be designed on request.

6、Identification method of natural and artificial sodium bentonite

1) The pH value of bentonite aqueous solution is measured by test paper. The pH value of natural sodium bentonite is 8 ~ 9, and the pH value of artificial sodium bentonite is above 9 ~ 10;

2) After adding water to both the natural sodium bentonite and the artificial sodium bentonite, the artificial sodium bentonite has a stronger viscosity than the natural sodium bentonite because Na2CO3 is attached to the surface of the artificial sodium bentonite;

3) Can be used to "see, taste, pinch, pour, wash" method identification;

4) Trace the source of bentonite used by GCL.

7、Mode of transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

Installation Steps for Clay Liner Bentonite Waterproof Blanket for Landfill

Site Preparation:

Surface Preparation: Ensure the subgrade surface is smooth, clean, and free of sharp objects. Remove any stones, roots, or other items that could damage the bentonite blanket.

Subgrade Compaction: Compact the subgrade soil to provide a stable foundation and good contact surface.

Material Preparation:

Inspect Materials: Inspect the bentonite blanket on-site to ensure it is undamaged, and cut and mark it according to project requirements.

Storage and Handling: Store the materials in a dry, flat area, protected from water and direct sunlight.

Laying the Bentonite Blanket:

Laying Direction: Determine the laying direction according to the design requirements, usually laying down the slope from top to bottom.

Unroll the Bentonite Blanket: Carefully unroll the bentonite blanket, avoiding any wrinkles or folds.

Seam Treatment: Overlap the seams between the blankets by at least 30 cm. Use bentonite powder or paste for sealing in special areas (such as corners or edges).

Securing the Bentonite Blanket:

Anchoring: Secure the blanket at the edges and seams with anchor pins or other methods to prevent movement.

Cover Soil Layer: Place a layer of cover soil on top of the bentonite blanket, typically 30-60 cm thick, to protect the blanket and increase its stability.

Compacting the Cover Soil: Use light compaction equipment to compact the cover soil to ensure good contact and reduce air gaps.

Quality Control:

Inspection and Repair: Regularly inspect the quality of the bentonite blanket installation. Repair any damaged or non-compliant areas promptly.

Testing: After installation and covering, conduct permeability tests or other quality checks to ensure the bentonite blanket's performance meets design standards.

Ongoing Maintenance:

Monitoring: Regularly monitor the condition of the bentonite blanket, especially after rainfall or other extreme weather, to ensure it has not moved or been damaged.

Maintenance: Promptly address any issues found to ensure the long-term effectiveness of the bentonite blanket.

Important Considerations

Weather Conditions: Perform installation in dry, mild weather conditions, avoiding high winds or rain.

Safety Measures: Ensure all personnel wear appropriate personal protective equipment and follow safety protocols during installation.

Environmental Measures: Implement measures to prevent waste or pollutants from the construction process from impacting the environment.

With careful planning and proper installation methods, bentonite waterproof blankets can provide effective waterproofing and sealing, ensuring the environmental safety and stability of landfills.

8、FAQ

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q2: Could you please send the sample before confirming the order?

A2: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q3: Can you produce according to the customer's requirements?

A3: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q4: How is the permeability and waterproof performance of bentonite waterproof blanket tested and guaranteed?

A4: Our products pass strict quality inspection procedures, including water tightness test and pressure resistance test, to ensure that their waterproof performance meets the standard.

Q5: What is the main material used for bentonite waterproof blanket? Are there any environmentally harmful ingredients?

A5: Our products mainly use bentonite and environmentally friendly additives, no harmful ingredients to the environment, in line with national environmental standards.

Q6: Is bentonite waterproof blanket suitable for basement, tunnel and other different structures? How does it work in different soil conditions?

A6: Our products are suitable for underground structures, including basements, tunnels, etc., and have good adaptability under different soil and environmental conditions.

503.webp)

759.webp)

927.webp)

109.webp)