Bentonite waterproof blanket is a common waterproof material that is usually used for waterproofing in construction projects. Bentonite is a natural mineral with excellent water absorption and swelling properties. Bentonite waterproof blankets utilize these properties of bentonite to achieve waterproofing effects.

The working principle of the bentonite waterproof blanket is that after contact with moisture, the bentonite will quickly absorb water and expand to form a layer of film with higher density and water resistance, thereby effectively preventing moisture penetration. It can be used for waterproofing of various building structures, such as basements, underground garages, roofs, pools, etc.

This waterproof blanket is usually made of materials such as bentonite, plastic flat-filament woven geotextile, short-filament geotextile or filament geotextile. It is flexible and durable and can adapt to surfaces of different shapes and structures. During the construction process, the bentonite waterproof blanket can be laid directly on the surface that needs waterproofing, and the waterproofing effect of the entire surface can be ensured by overlapping and sealing.

In general, bentonite waterproof blanket is an effective waterproof material that can play an important role in waterproof protection in construction projects.

According to different product types, it can be divided into acupuncture method sodium bentonite waterproof blanket, acupuncture coating method sodium bentonite waterproof blanket and adhesive method sodium bentonite waterproof blanket. The installation process is basically similar.

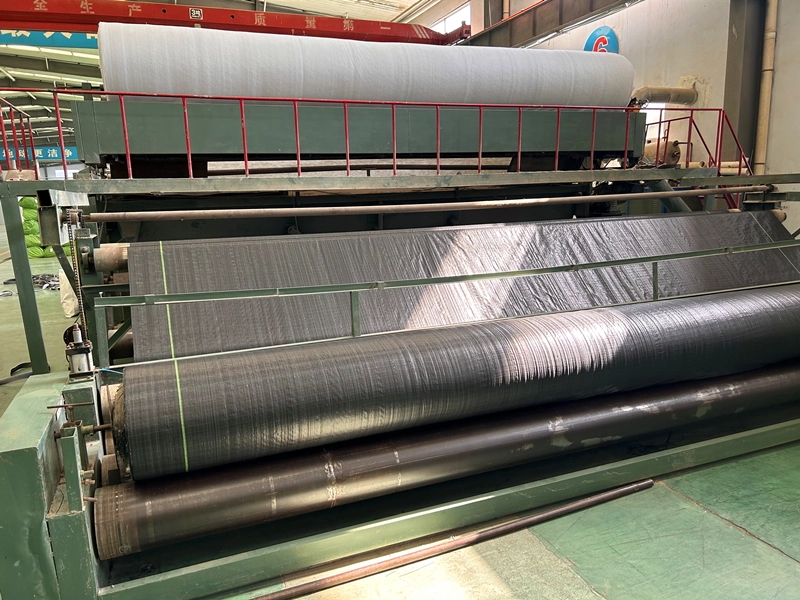

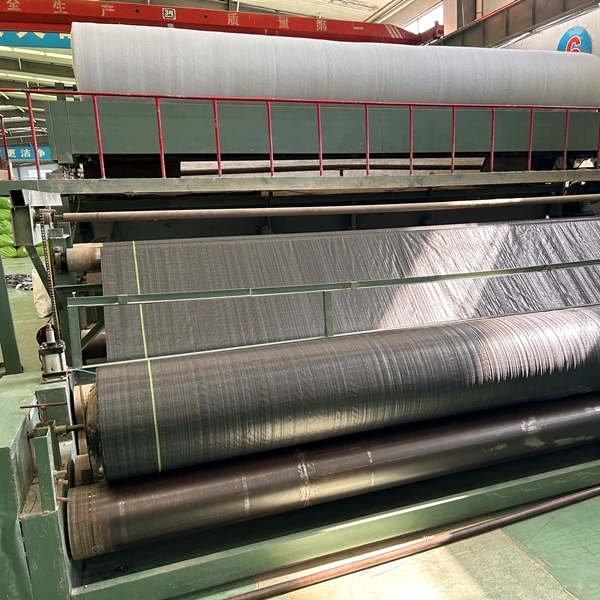

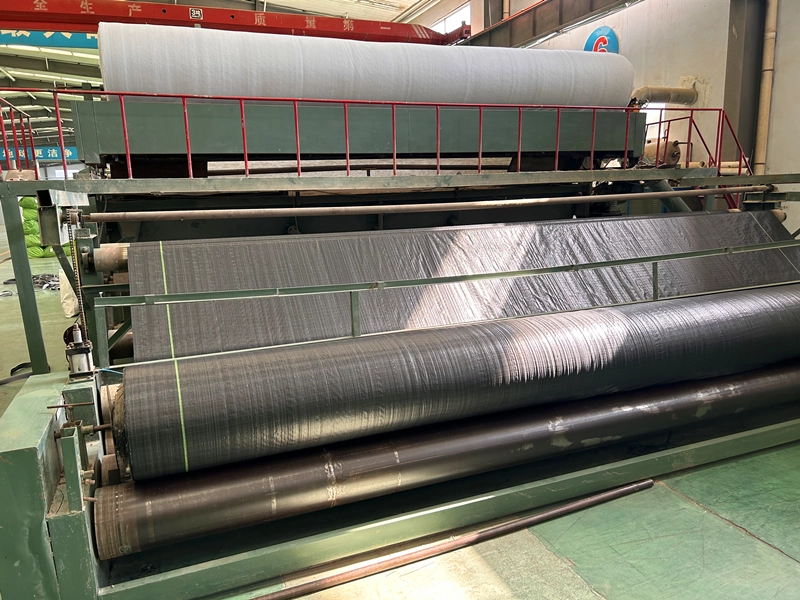

Haoyang sodium bentonite production workshop

The following installation guide is taken from www.astm.org:

1. Scope

1.1 This guide covers directions for the installation of geosynthetic clay liners (GCLs) under field conditions typically present in environmental lining applications.

1.2 This guide contains general installation guidelines. It is not intended to replace project-specific installation requirements as found in the contract drawings or specifications. In the event of a conflict, the requirement of the project specifications will supersede the requirements of this guide.

1.3 This guide does not purport to establish specific procedure for all climatic, geographical, hydraulic, or topographical conditions that may exist at a site. Appropriate installation procedures under atypical field conditions should be modified

as necessary to maintain the integrity of the GCL and adjacent lining system components.

1.4 Different GCLs have different materials of construction with different physical properties. The procedures contained in this guide, therefore, may not be universally applicable to all GCLs under all field conditions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:2

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D4439 Terminology for Geosynthetics

D5888 Guide for Storage and Handling of Geosynthetic Clay Liners

3. Terminology

3.1 Definitions—For definitions of other geosynthetic terms used in this guide, refer to Terminology D4439. For definitions of soils terms, refer to Terminology D653.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 geosynthetic clay liner (GCL), n—a manufactured hydraulic barrier consisting of clay bonded to a layer or layers of geosynthetics.

4. Significance and Use

4.1 For optimum performance, GCLs must be installed in a manner that does not impact their physical, mechanical, or hydraulic properties.

4.2 This guide identifies the proper installation procedures and equipment for use by GCL designers, inspectors, and installers.

5. Procedure

5.1 The methods and equipment used for placement of the GCL can vary, but the primary objective of the process is to minimize the potential for GCL damage. The placement methods and equipment should be evaluated appropriately within this context.

5.2 Subgrade Preparation:

5.2.1 For projects where the GCL is to be placed over an earthen subgrade, the subgrade surface must be prepared and approved prior to installation in accordance either with project specifications or with this guide. The surface should be firm

and unyielding, with no abrupt elevation changes, voids and cracks, ice, or standing water.

5.2.2 The subgrade surface should be smooth and free of vegetation, sharp-edged rocks, stones, sticks, construction debris, and other foreign matter that could contact the GCL.

The subgrade surface shall be compacted in accordance with the project specifications. At a minimum, the subgrade should be rolled with a smooth-drum compactor of sufficient weight to remove any excessive wheel ruts, footprints, or other abrupt grade changes. Excessive rutting should be clearly defined and quantified. In some cases 25 mm is the maximum rut depth allowed. Furthermore, all protrusions extending more than 12 mm from the subgrade surface shall either be removed, crushed, or pushed into the surface with a smooth-drum compactor.

1 This guide is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.04 on Geosynthetic Clay Liners.

Current edition approved Jan. 1, 2006. Published February 2006.

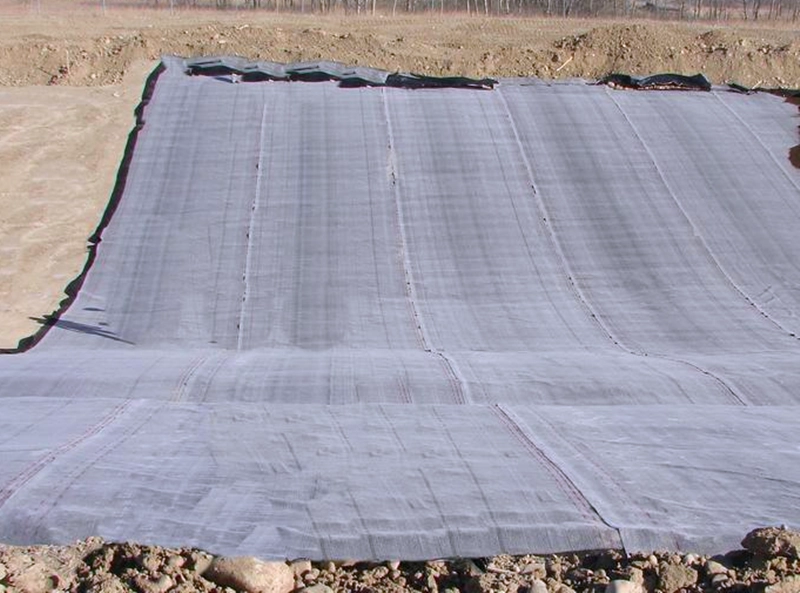

Haoyang sodium bentonite waterproof blanket is being installed

Sodium bentonite waterproof blankets have specific guidance for industry installation, but if a specific installation contract is signed by both installation parties, the installation should be carried out according to the specific contract content. When the two parties have ambiguities on specific issues, they can refer to the industry installation guidelines.

503.webp)

759.webp)

927.webp)

109.webp)