Composite Geomembrane

The composite geosynthetic membrane is a waterproof material formed by combining geotextiles with a geomembrane. It is primarily used for impermeability. The composite geosynthetic membrane comes in variations such as one fabric and one membrane, as well as two fabrics and one membrane, with a width of 4-6m and a weight ranging from 200-1500g/m2. It exhibits high physical and mechanical performance indicators, including tensile strength, tear resistance, and puncture resistance, making it suitable for various civil engineering applications such as water conservancy, municipal projects, construction, transportation, subway, and tunnels. Due to the use of polymer materials and the addition of anti-aging agents in the production process, it can be employed in unconventional temperature environments.

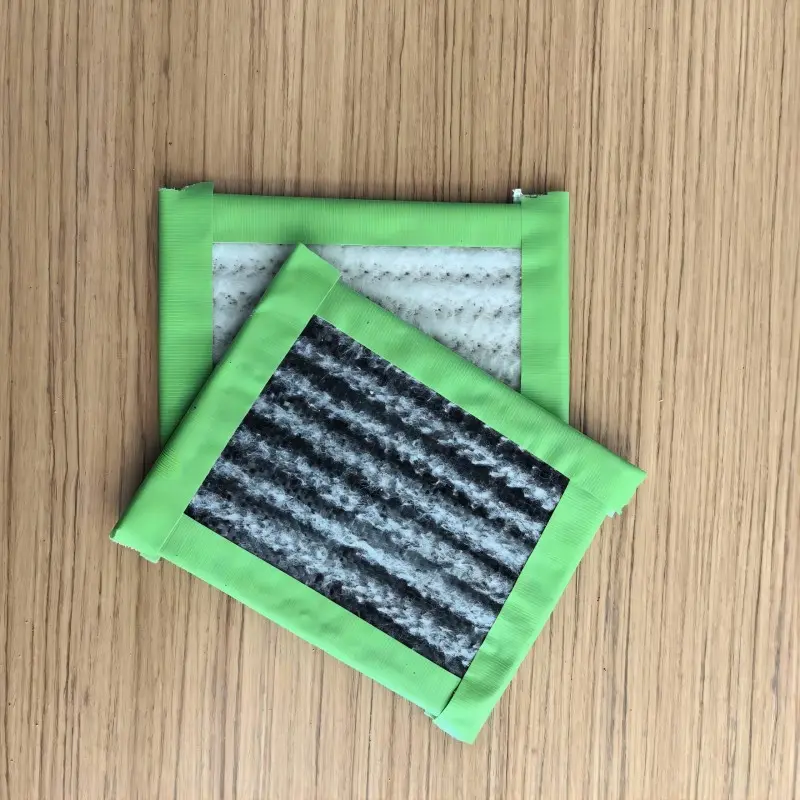

Geosynthetic Clay Liner(GCL)

GCL is a novel composite impermeable material. Geosynthetic clay liner possesses good adhesiveness and expansibility. Its internal structure consists of upper and lower layers of non-woven fabric. After absorbing water, it expands in a limited space, forming a tight colloidal structure, thereby achieving a waterproof effect. Due to its excellent characteristics, it has been designated as the preferred material for ecological pond waterproofing.

This material is composed of naturally graded sodium-based bentonite particles and corresponding additives. Through needle-punching technology and equipment, the bentonite particles are fixed between geotextile and plastic woven fabric to create a blanket-shaped waterproof roll. The bentonite waterproof blanket not only retains all the characteristics of geotechnical materials but also exhibits excellent waterproof (seepage) performance.

Bentonite, with the mineralogical name montmorillonite, is classified into two main types based on chemical composition: sodium-based and calcium-based. Bentonite has the characteristic of expanding upon contact with water. When calcium-based bentonite expands, it only expands to about three times its original volume. In contrast, sodium-based bentonite can adsorb water 8-15 times its own weight, expanding to more than 20-30 times its original volume. By sandwiching sodium-based bentonite between two layers of geosynthetic materials, it serves a protective and reinforcing role, giving the Geosynthetic Clay Liner (GCL) a certain overall shear strength.

When bentonite particles come into contact with water, they expand, forming a uniform colloidal system. Under the restraining effect of two layers of geotextile, the expansion of bentonite transforms from disorderly to orderly, resulting in continuous water absorption and expansion. This process allows the bentonite layer to become compacted, thereby achieving a waterproof effect.

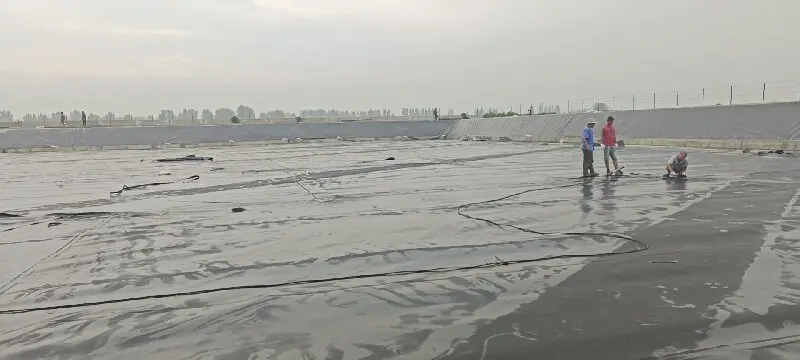

Beautiful Atificial Lake

Artificial lakes or scenic lakes, as a primary means of enhancing urban taste and fostering harmonious coexistence between humans and nature, have become increasingly prominent. With the rapid development of urbanization and the year-by-year improvement of socio-economic levels in China, the improvement of urban living environments is gradually becoming a central focus in the development plans of various small and medium-sized cities. This is especially evident in the construction of water landscape projects in northern cities.

935550.webp)

Problems

Many artificial landscape lakes, waterways, swimming pools, and garden ponds currently face leakage issues. The loss of landscape water leads to unattractive later-stage greening, and water quality treatment proves ineffective. This situation can have repercussions on surrounding structures, posing a significant challenge for property owners and developers.

Artificial lakes exhibit complex structures and diverse forms, often featuring winding watercourses, protruding bridge piers, variously shaped artificial islands, irregular cobblestone retaining walls, and different types of landscaped embankments. When it comes to waterproofing for landscape gardens, employing rigid waterproofing methods may result in issues such as cracking and leakage due to uneven ground settlement. This approach not only fails to achieve optimal waterproofing but also entails high costs and extended construction periods.

Solution of Atificial lake problems

The combination of composite geosynthetic membrane and GCL represents the optimal solution to the above problem.

Using a composite geofilm and geosynthetic clay liner for artificial lake seepage prevention has several advantages:

Synergistic Effect: The combination of the composite geomembrane and GCL leverages their respective strengths, creating a synergistic effect that enhances overall impermeability.

Multilayered Protection: The composite geofilm provides a robust surface layer, effectively preventing external physical damage. Simultaneously, the GCL, upon absorbing water, forms a tight colloidal structure, further increasing impermeability.

High Adaptability: Due to the expansive nature of bentonite, it can adapt to uneven ground settlement, reducing the risk of cracking and leakage associated with foundation settling.

Cost-Effective: Compared to traditional rigid waterproofing methods, this combined solution offers better cost-effectiveness. It provides a longer lifespan and more reliable impermeability, reducing maintenance and repair costs over time.

Shorter Construction Period: The construction period for using a composite geosynthetic membrane and bentonite waterproof blanket is relatively shorter compared to some traditional impermeability methods, contributing to project timeline efficiency.

Choose Haoyang As Your Geomembrane Supplier

Welcome to Haoyang Environmental Co., Ltd., your premier destination for high-quality geomembranes tailored for artificial lakes. With a commitment to excellence and innovation, we specialize in providing durable, reliable, and environmentally friendly solutions for your water containment needs.

At Haoyang, we understand the importance of artificial lakes in various applications, whether for recreational purposes, irrigation, aquaculture, or environmental conservation. Our geomembranes are meticulously engineered to ensure superior performance, longevity, and protection against leaks, seepage, and contamination.

Backed by years of experience and expertise, we leverage cutting-edge technology and stringent quality control measures to manufacture geomembranes that meet and exceed industry standards. Our products are designed to withstand harsh environmental conditions, including UV exposure, temperature fluctuations, and chemical exposure, ensuring the integrity of your artificial lake projects for years to come.

Moreover, we prioritize sustainability in our manufacturing processes, utilizing eco-friendly materials and practices to minimize our environmental footprint. By choosing Haoyang, you not only invest in top-notch geomembranes but also contribute to a greener and more sustainable future.

Whether you're constructing a small decorative pond or a large-scale reservoir, Haoyang is your trusted partner for premium geomembrane solutions. Explore our range of products and let us help you realize your artificial lake projects with confidence and peace of mind.

Factory Display

Haoyang Environmental Co., Ltd. stands as the foremost manufacturer of geofabrics in China, boasting over 15 years of unwavering expertise. Our state-of-the-art factory houses more than 20 advanced environmental engineering material production lines. Among these, we proudly feature the nation's inaugural 10-meter-wide blown film geotextile production line, the pioneering twin-screw filament geotextile production line, and internally developed innovations such as the high-strength reinforced geotextile production line, high-strength composite geotextile production line, and ultra-wide woven geotextile production line.

Our diverse product portfolio encompasses HDPE geotextile, composite geotextile, polyester spunbond filament geotextile, high-strength woven geotextile, short fiber geotextile, three-dimensional composite drainage net, bentonite waterproof blanket, single and double-directional geogrid, and an array of other environmentally conscious engineering materials. These offerings serve multifaceted functions including waterproofing, impermeability, reinforcement, isolation, and filtration.

With applications spanning various environmental engineering domains such as water conservancy, transportation, urban solid waste treatment, industrial tailings ponds, and environmental pollution control, our materials have become indispensable solutions driving sustainability and efficacy in diverse projects.

Our Clients

Our clients are from all over the world, due to our high quality of the products and service, we have been estabished a reliable and long-term development relationships with each of our customers.If you are engaging in geofabric products, or you are interested in geosynthetics, feel free to contact us, and welcom to our factory!

FAQ

Q1: Are you factory or trading company?

A: We are factory with ten years of experience. You can visit our factory online through video.

Q2: What’s your payment term?

A: 30% TT in advance and the balance before shipment or 100% Irrevocable L/C at sight.

Q3: How about the minimum order quantity?

A: We have no MOQ limited for the sample order and regular products.

The MOQ for special customized products is 5000 sqm.

Q4: How long is your delivery time?

A: It depends on the quantity of you quantity.

Usually, it takes 7-10 days upon we receive your deposit.

Q5: How can I get samples?

A: Sample can be sent by DHL or FedEx , etc.

Sample is free and freight collect. We promise we will definitely return the postage to you when we first cooperate.

Q6: Can you advise our pond liner installation and project design?

A: Welding machine is available for your installation.

If necessary, our welder can fly to your project site and install the pond liner. About the project design, we can also give you our rough advice.

658.webp)

503.webp)

759.webp)