Enhancing Roadbed Stability with Filament Geotextile Reinforcement

The construction and maintenance of roads are crucial for ensuring efficient transportation networks. However, various factors such as heavy traffic loads, poor soil conditions, and environmental factors can lead to road deterioration over time. To address these challenges, engineers and infrastructure experts have been exploring innovative solutions, one of which is the utilization of filament geotextiles for roadbed reinforcement.

What is Filament Geotextile?

Filament geotextile is a type of synthetic fabric made from continuous filaments of polyester or polypropylene. These filaments are mechanically bonded together to form a strong, flexible, and permeable material. Filament geotextiles are designed to withstand high tensile loads and provide excellent filtration and drainage properties.

◢ Roadbed Reinforcement:

In road construction, the roadbed serves as the foundation that supports the pavement layers and distributes the traffic loads. Weak or unstable roadbeds can lead to pavement distress, rutting, and ultimately, road failure. Filament geotextiles offer a solution to enhance roadbed stability by providing reinforcement and confinement to the underlying soil.

Key Benefits of Filament Geotextile in Roadbed Reinforcement

◢ Increased Load Bearing Capacity: By distributing the load more evenly across the roadbed, filament geotextiles help reduce the stress on the underlying soil, thereby increasing its load-bearing capacity.

◢ Soil Stabilization: Filament geotextiles act as a barrier that prevents soil particles from migrating and consolidating under heavy traffic loads, thus stabilizing the roadbed and minimizing settlement.

◢ Improved Drainage: The permeable nature of filament geotextiles allows for effective drainage of water from the roadbed, reducing the risk of water-induced damage such as erosion and frost heave.

◢ Longevity and Durability: Filament geotextiles are highly resistant to biological degradation, chemical deterioration, and UV exposure, ensuring long-term performance and durability in various environmental conditions.

◢ Cost-Effectiveness: Implementing filament geotextile reinforcement can extend the service life of roads, reducing the frequency and cost of maintenance and repairs over time.

Case Studies

Several successful applications of filament geotextile reinforcement in road construction have been documented worldwide. For example, in a road widening project in a high-traffic urban area, filament geotextiles were used to improve the subgrade stability and prevent deformation under heavy vehicle loads. Similarly, in rural road projects in areas with expansive soils, filament geotextiles have been instrumental in minimizing soil swelling and shrinkage, thereby preserving the integrity of the roadbed.

Conclusion

Filament geotextiles offer a versatile and effective solution for reinforcing roadbeds and enhancing the performance and longevity of road infrastructure. By addressing issues such as soil instability, drainage problems, and load-bearing capacity, filament geotextiles contribute to the sustainable development of transportation networks, ensuring safer and more resilient roads for communities worldwide. As technology continues to advance, further research and innovation in geosynthetic materials will undoubtedly lead to even more efficient and cost-effective solutions for road construction and maintenance.

Haoyang Filament Geotextile Features

1. Uv resistance, acid and alkali resistance.

2. High temperature resistance up to 230℃, maintain structural stability and original physical properties.

3. High strength tear resistance.

4. Resistance to erosion by chemical substances in the soil.

5. It has a high elongation rate, which can adapt to uneven and irregular substrates.

Our Filament Geotextile Application

1. Water conservancy and hydropower engineering.

2. Paving roads and railways.

3. Airports and ports.

4. River protection and tunnel.

5. Environmental protection, etc.

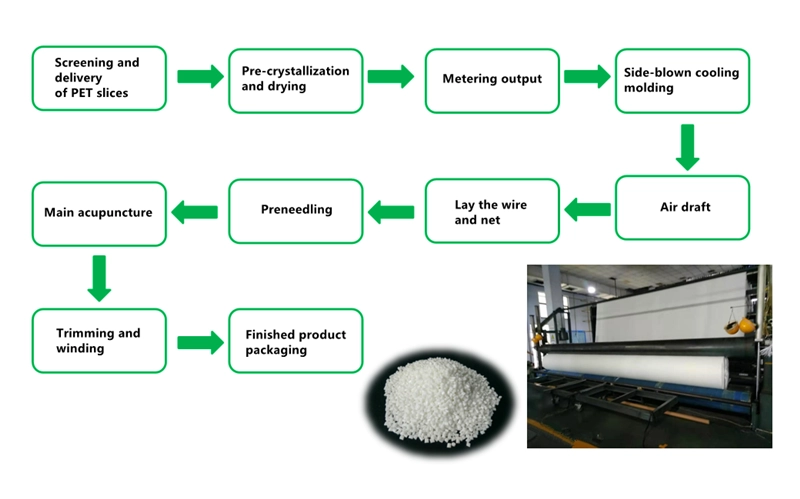

How is Filament Geotextile Produced?

Below is the entire process from PET slice screening and delivery to finished product packaging.

◢ Screening and delivery of PET slices: First, the PET (polyethylene terephthalate) slices are screened to ensure that their quality meets production requirements. Qualified slices are then delivered to the next production stage.

◢ Pre-crystallization and drying: At this stage, the slices undergo pre-crystallization and drying to remove moisture and other impurities to ensure the purity and stability of the material.

◢ Metering output: The pre-processed PET slices are accurately metered and output to control the amount of raw materials used in the production process.

◢ Side-blow cooling molding: Next, the PET slices go through the side-blow cooling molding process to form the desired shape or structure.

◢ Main Needling: In this step, the material is reinforced and finished through a needling process to increase its strength and durability.

◢ Pre-needle punching: Pre-needle punching is a process to further strengthen the material. Pre-needle punching is used to increase the interweaving points between fibers, thereby enhancing the overall performance of the material.

◢ Laying Wires and Netting: During this stage, wires and netting are laid over the material to provide additional support and functional properties.

◢ Air flow combing: Through the air flow combing process, the structure and performance of the material are further organized and optimized.

◢ Trimming and Coiling: Finally, the material is trimmed and coiled in preparation for the next stage of processing.

◢ Finished product packaging: After completing all processing steps, the product is packaged into its final form, ready for shipping and sale.

About Haoyang Environmental Co., Ltd.

Established in June 2008, Haoyang Environmental Co., Ltd. is a leading player in the realm of geosynthetic materials. We specialize in a wide range of services encompassing research and development, manufacturing, environmental engineering consulting, design, construction, soil remediation, and comprehensive solid waste treatment and disposal. With certifications including ISO 9001, ISO 14001, OHSAS 18001, and CQC environmental product certification, we maintain the highest standards of quality, environmental responsibility, and occupational health and safety. Additionally, our recognition as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory" underscores our commitment to innovation and excellence.

Technical Data Sheet of Polyester Geotextile

Our products are manufactured to the highest standards

Item | Unit | Index | |||||||||

Nominal breaking strength | Kn/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

1 | Longitudinal and transverse fracture strength | Kn/m | ≥4.5 | ≥7.5 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 |

2 | Vertical and horizontal standard strength corresponds to elongation | % | 40~80 | ||||||||

3 | CBR bursting strength(Kn/m) | Kn/m | ≥0.8 | ≥1.6 | ≥1.9 | ≥2.9 | ≥3.9 | ≥5.3 | ≥6.4 | ≥7.9 | ≥8.5 |

4 | Vertical and horizontal tearing strength | Kn | ≥0.14 | ≥0.21 | ≥0.28 | ≥0.42 | ≥0.56 | ≥0.7 | ≥0.82 | ≥1.1 | ≥1.25 |

5 | Equivalent aperture O90(o95) | mm | 0.05~0.20 | ||||||||

6 | Vertical permeability coefficient | cm/s | K*(10-1~10-3) K=1.0~9.9 | ||||||||

7 | Thickness | mm | ≥0.8 | ≥1.2 | ≥1.6 | ≥2.2 | ≥2.8 | ≥3.4 | ≥4.2 | ≥5.5 | ≥6.8 |

8 | Amplitude deviation | % | -0.5 | ||||||||

9 | Mass deviation per unit area | % | -5 | ||||||||

Partner with Haoyang

By collaborating with Haoyang Environmental Co., Ltd., you gain access to state-of-the-art technology, extensive expertise, and a proven track record in geosynthetic materials. Together, we can establish a world-class filament geotextile factory dedicated to meeting the evolving needs of road construction and infrastructure development projects worldwide. Join us in paving the way for safer, more resilient, and sustainable transportation networks of the future. Contact us now!

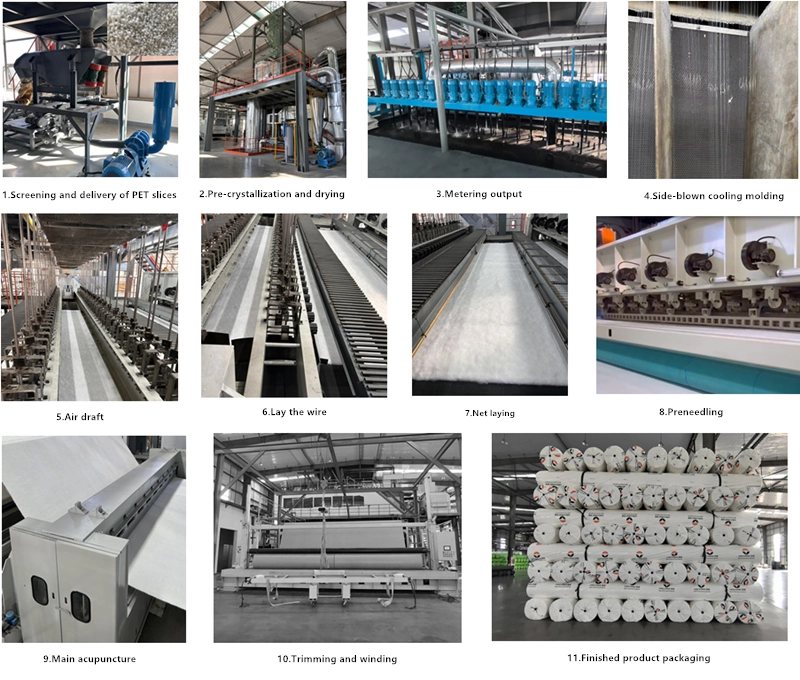

Project Construction Photo

Below are photos of the construction site of our project.

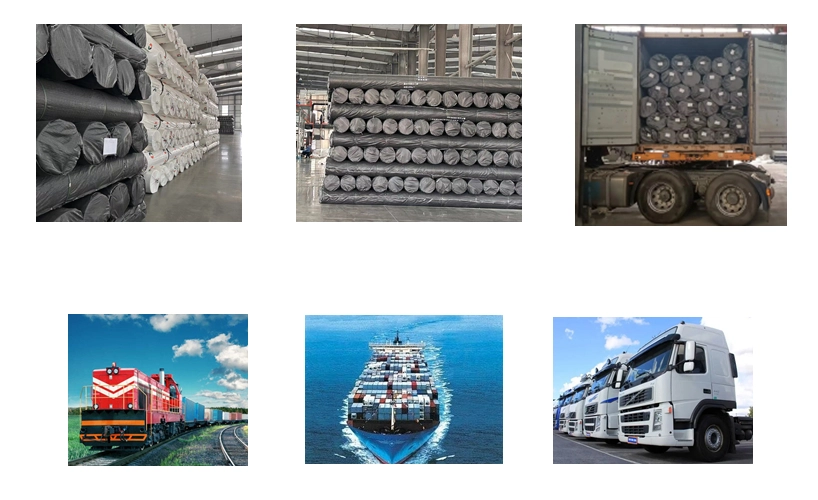

Mode of Transport

FAQ

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q: Where is your factory located? How do I get there?

A: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q: Could you please send the sample before confirming the order?

A: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q: What is the lead time?

A: Usually 5-10 working days after receiving the deposit.

Q: Can you produce according to the customer's requirements?

A: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q: How do you guarantee the quality testing of your products?

A: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)

597.webp)

411.webp)