800g Weighted Filament Geotextile

The roadbed is the foundation of the road surface, bearing the weight of vehicles and providing support to prevent deformation and rutting. However, factors such as poor soil quality, erosion and heavy traffic loads can compromise its integrity. This is where filament geotextiles come into play. Filament geotextiles have excellent water permeability and filtration properties, which can protect the soil, slow down soil erosion, and increase the stability and load-bearing capacity of the soil. It is often used in highways, railways, embankments and other projects as reinforcement and protection of soil barriers, with the ability to separate, filter, reinforce, protect or drain. In the field of road construction, stability and longevity are crucial. To achieve this, innovative solutions are constantly sought to strengthen the roadbed and ensure its long-term durability. One solution that is gaining traction is the use of 800 g/m² weighted filament geotextiles.

Haoyang Environmental Protection Co., Ltd. is a manufacturer specializing in the production of geotextiles. Filament non-woven geotextiles are one of our main products. We are also the supplier of the South-to-North Water Diversion Project. Our company has more than ten years of manufacturing experience. I believe you can have a pleasant cooperation with us.

Product Features

1. Uv resistance, acid and alkali resistance.

2. High temperature resistance up to 230℃, maintain structural stability and original physical properties.

3. High strength tear resistance.

4. Resistance to erosion by chemical substances in the soil.

5. It has a high elongation rate, which can adapt to uneven and irregular substrates.

Product application

1. Water conservancy and hydropower engineering.

2. Paving roads and railways.

3. Airports and ports.

4. River protection and tunnel.

5. Environmental protection, etc.

Benefits of 800g/sqm Weighted Filament Geotextile

◢ Enhanced Load Distribution: The 800g/sqm weight of the filament geotextile provides substantial reinforcement to the roadbed, distributing the load of passing vehicles more evenly. This reduces the risk of localized stress concentrations and minimizes rutting and deformation.

◢ Improved Soil Stability: By stabilizing the soil layers within the roadbed, filament geotextile prevents soil erosion and lateral movement. This ensures that the roadbed maintains its integrity under varying weather conditions and traffic loads.

◢ Increased Drainage Efficiency: Despite its weight, filament geotextile remains permeable, allowing water to pass through freely. This prevents water accumulation within the roadbed, reducing the risk of saturation-induced damage such as potholes and pavement deterioration.

◢ Long-Term Durability: Filament geotextile is highly resistant to UV degradation, chemicals, and biological agents, ensuring its longevity even in harsh environmental conditions. Its robust construction provides reliable reinforcement for roadbeds, extending the service life of roads.

◢ Ease of Installation: With its manageable weight and flexible nature, 800g/sqm weighted filament geotextile is relatively easy to handle and install. This facilitates efficient construction processes, saving time and labor costs.

Contact Us

Backed by Haoyang's commitment to quality and innovation, our 800g Weighted Filament Geotextile is certified to meet ISO 9001 quality management standards, ISO 14001 environmental management requirements, and OHSAS 18001 occupational health and safety guidelines. Additionally, it holds CQC environmental product certification, ensuring compliance with the highest industry benchmarks.

Partner with Haoyang Environmental Co., Ltd. and experience the difference that cutting-edge technology and unwavering dedication to environmental stewardship can make. Together, let's build a sustainable future for generations to come.

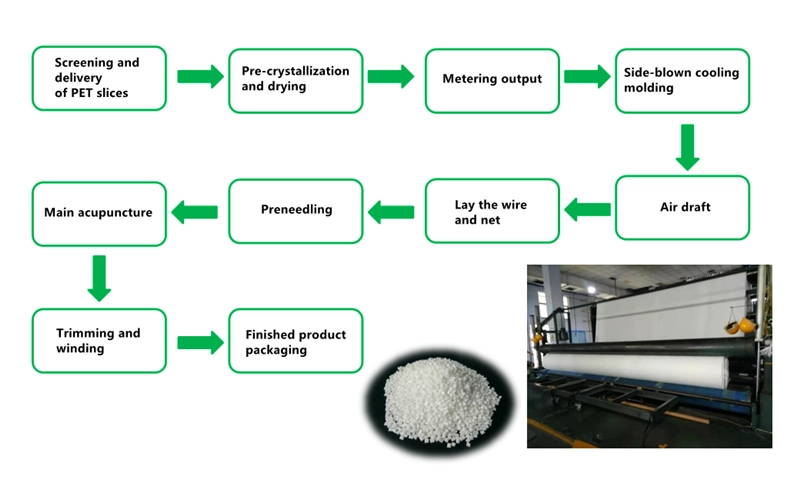

How is Haoyang Filament Geotextile Produced?

The following is the transformation process of our filament geotextiles from polymer particles to formed fibers. Our company has a number of advanced production equipment. Our products have been precision processed and processed in multiple links during the production process, which can ensure that you are satisfied. Strength, durability and stability required during construction.

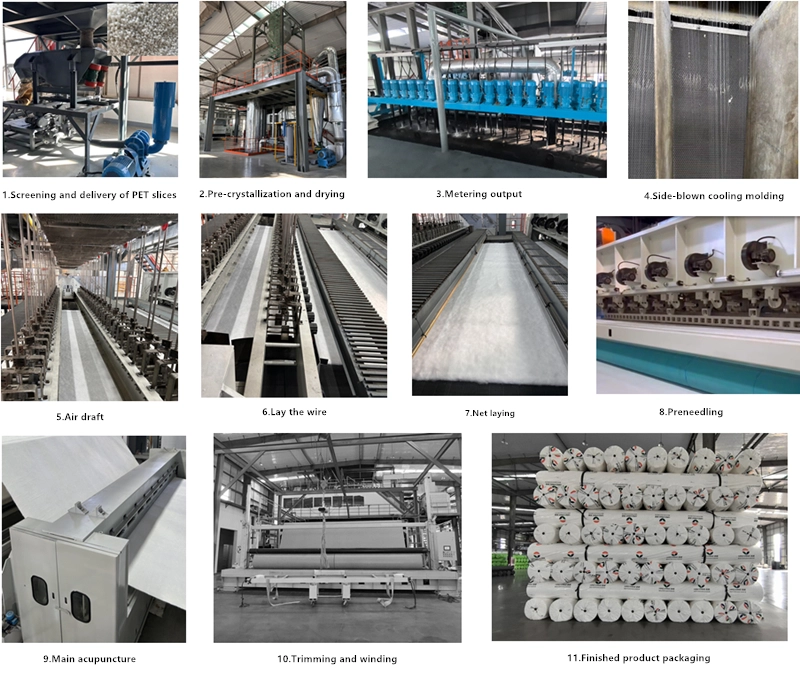

Factory display

We sincerely welcome you to our filament geotextile production workshop. Our filament geotextile workshop is a modern and efficient production base. State-of-the-art facilities using the latest technology and production processes to ensure superior quality and consistency of products. As one of the leading geotechnical materials manufacturers, we are committed to providing high quality, innovative and reliable geotechnical materials to meet a wide range of engineering and construction needs.

This is the filament geotextile device.

This is the filament geotextile device.

This is filament geotextile feeding equipment.

Technical Data Sheet of Weighted Filament Geotextile

Our company's filament geotextile products are manufactured in strict accordance with national standards or even exceed national standards. The quality control standards are higher than national standards. Each batch of our products undergoes strict laboratory instrument testing before they can be sold. You can be completely assured of our quality.

Item | Unit | Index | |||||||||

Nominal breaking strength | Kn/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

1 | Longitudinal and transverse fracture strength | Kn/m | ≥4.5 | ≥7.5 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 |

2 | Vertical and horizontal standard strength corresponds to elongation | % | 40~80 | ||||||||

3 | CBR bursting strength(Kn/m) | Kn/m | ≥0.8 | ≥1.6 | ≥1.9 | ≥2.9 | ≥3.9 | ≥5.3 | ≥6.4 | ≥7.9 | ≥8.5 |

4 | Vertical and horizontal tearing strength | Kn | ≥0.14 | ≥0.21 | ≥0.28 | ≥0.42 | ≥0.56 | ≥0.7 | ≥0.82 | ≥1.1 | ≥1.25 |

5 | Equivalent aperture O90(o95) | mm | 0.05~0.20 | ||||||||

6 | Vertical permeability coefficient | cm/s | K*(10-1~10-3) K=1.0~9.9 | ||||||||

7 | Thickness | mm | ≥0.8 | ≥1.2 | ≥1.6 | ≥2.2 | ≥2.8 | ≥3.4 | ≥4.2 | ≥5.5 | ≥6.8 |

8 | Amplitude deviation | % | -0.5 | ||||||||

9 | Mass deviation per unit area | % | -5 | ||||||||

Project Construction Photo

The following is a picture of the construction status of our products at the project site

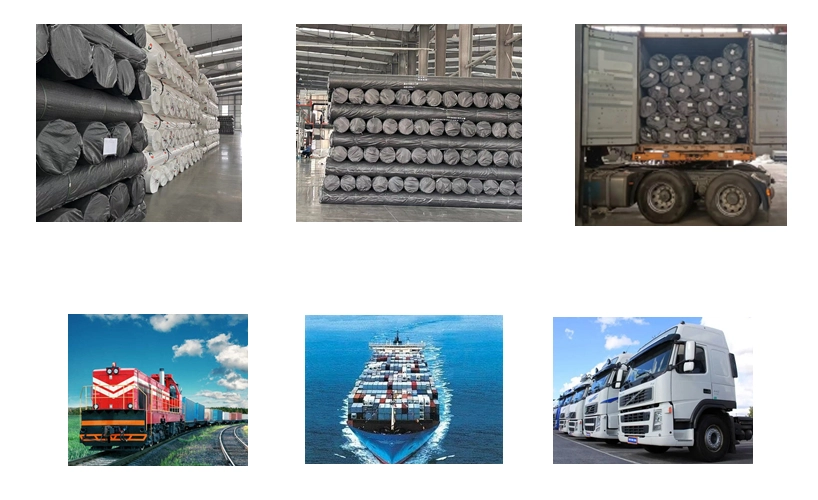

Mode of Transport

FAQ

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q: Where is your factory located? How do I get there?

A: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q: Could you please send the sample before confirming the order?

A: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q: What is the lead time?

A: Usually 5-10 working days after receiving the deposit.

Q: Can you produce according to the customer's requirements?

A: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q: How do you guarantee the quality testing of your products?

A: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

In summary, the utilization of 800g/sqm weighted filament geotextile offers significant benefits in road construction. From enhancing load distribution and soil stability to improving drainage efficiency and ensuring long-term durability, this innovative material plays a crucial role in reinforcing roadbeds and prolonging the lifespan of roads. As the transportation industry continues to evolve, filament geotextile remains a reliable solution for achieving resilient and sustainable infrastructure.

In the journey towards safer, smoother, and more durable roads, 800g/sqm weighted filament geotextile emerges as a key ally, paving the way for a smoother ride ahead.

Download

Filament geotextile for roadbed.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

503.webp)

759.webp)

597.webp)

411.webp)