Enhancing Drainage with Filament Geotextile

Drainage is a critical aspect of various construction projects, ranging from roadways and railways to retaining walls and landfills. Effective drainage ensures the stability and longevity of these structures by preventing water buildup and soil erosion. One innovative solution gaining traction in the construction industry is the use of filament geotextile for enhanced drainage. In this article, we will explore the benefits and applications of filament geotextile in improving drainage systems.

Understanding Filament Geotextile

Filament geotextile is a synthetic material composed of continuous filaments spun together to form a durable, porous fabric. This geotextile is engineered to have high tensile strength, puncture resistance, and permeability, making it ideal for various civil engineering applications. Unlike traditional non-woven geotextiles, filament geotextile offers superior filtration properties and greater water flow capacity, making it particularly effective in drainage systems.

Enhanced Drainage Performance

One of the primary advantages of filament geotextile is its ability to enhance drainage performance in geotechnical applications. By incorporating filament geotextile into drainage systems, engineers can achieve improved water flow rates, reduced soil erosion, and enhanced soil stabilization. The high permeability of filament geotextile allows water to pass through freely while retaining soil particles, preventing clogging and ensuring long-term functionality.

Applications

Filament geotextile finds wide-ranging applications in civil engineering projects where drainage optimization is essential. Some common applications include:

◢ Roadway Construction: Filament geotextile is used in roadbeds and subgrade stabilization to enhance drainage and prevent water-induced damage.

◢ Retaining Walls: Filament geotextile is installed behind retaining walls to promote efficient drainage and reduce hydrostatic pressure.

◢ Landfills: Filament geotextile is employed in landfill liners and leachate collection systems to facilitate proper drainage and minimize environmental impact.

◢ Athletic Fields: Filament geotextile is utilized in sports field drainage systems to maintain optimal playing conditions and prevent waterlogging.

◢ Railway Tracks: Filament geotextile is incorporated into railway track beds to improve drainage and prevent track settlement.

Benefits

The use of filament geotextile offers several benefits for drainage applications:

◢ Improved Water Management: Filament geotextile enhances water flow and reduces the risk of water accumulation, thereby mitigating the potential for erosion and slope instability.

◢ Longevity: Filament geotextile is highly durable and resistant to degradation, ensuring long-term performance and minimizing maintenance requirements.

◢ Environmental Sustainability: By promoting efficient drainage and soil stabilization, filament geotextile helps preserve natural resources and minimize the environmental impact of construction activities.

◢ Cost-Effectiveness: Despite its initial investment, filament geotextile offers cost savings over the lifespan of a project by minimizing the need for costly repairs and replacements associated with poor drainage.

Conclusion

Filament geotextile represents a versatile and effective solution for enhancing drainage in various civil engineering applications. Its high permeability, durability, and superior filtration properties make it an invaluable component of modern drainage systems. By leveraging the benefits of filament geotextile, engineers can optimize water management, improve project longevity, and ensure the sustainability of infrastructure development.

Features of Haoyang Geotextile

UV Resistance, Acid, and Alkali Resistance:The filament geotextile boasts excellent UV resistance, ensuring prolonged durability even when exposed to harsh sunlight. Additionally, its resistance to acid and alkali substances safeguards against degradation, maintaining structural integrity over time.

High Temperature Resistance up to 230°C:Withstanding temperatures of up to 230°C, the filament geotextile retains its structural stability and original physical properties even in extreme heat conditions. This resilience ensures reliable performance in environments with elevated temperatures.

High Strength Tear Resistance:The geotextile is engineered with high-strength properties, providing exceptional tear resistance. This feature enhances its ability to withstand mechanical stresses and ensures longevity in demanding applications.

Resistance to Erosion by Chemical Substances in the Soil:Designed to resist erosion caused by chemical substances present in the soil, the filament geotextile offers reliable protection against deterioration, preserving its effectiveness in drainage systems and soil stabilization projects.

High Elongation Rate:Featuring a high elongation rate, the geotextile can adapt flexibly to uneven and irregular substrates. This characteristic enables it to conform to varying terrain conditions, ensuring optimal performance and effective water management across diverse landscapes.

Application

Water Conservancy and Hydropower Engineering:

Examples include dams, reservoirs, irrigation systems, and hydroelectric power plants. Filament geotextile plays a crucial role in such projects by providing effective drainage solutions, erosion control measures, and soil stabilization techniques, ensuring the longevity and efficiency of water-related infrastructure.

Road and Railway Construction:

Filament geotextile finds extensive application in the construction of roads and railways, where it contributes to the stability, durability, and longevity of the transportation network. By enhancing soil reinforcement, improving drainage systems, and preventing soil erosion, geotextile solutions help ensure the smooth and safe operation of roadways and railways, reducing maintenance costs and enhancing overall infrastructure resilience.

Airports and Ports:

The construction and maintenance of airports and ports demand robust and resilient infrastructure capable of withstanding heavy loads, dynamic forces, and environmental stresses. Filament geotextile is employed in these projects to reinforce soil, improve drainage systems, and enhance subgrade stability, thereby ensuring the integrity and functionality of runways, taxiways, aprons, quays, and container yards.

River Protection and Tunneling:

In river protection projects, filament geotextile serves as a critical component in erosion control measures, bank stabilization techniques, and flood mitigation strategies. Moreover, in tunneling applications, geotextile solutions provide temporary and permanent support systems, facilitating excavation, groundwater control, and soil stabilization, thereby ensuring the safety and efficiency of tunnel construction projects.

Environmental Protection:

Filament geotextile plays a vital role in environmental protection initiatives, including soil remediation, landfill containment, wetland restoration, and coastal erosion management. By providing effective filtration, containment, and erosion control, geotextile solutions help mitigate the impact of human activities on the environment, preserve ecological habitats, and promote sustainable development practices.

Join Us

At Haoyang Environmental Co., Ltd., we envision a world where sustainability and innovation converge to create a brighter future for generations to come. Join us in our mission to redefine environmental protection through cutting-edge technologies and solutions. Together, we can build a greener, more sustainable tomorrow.

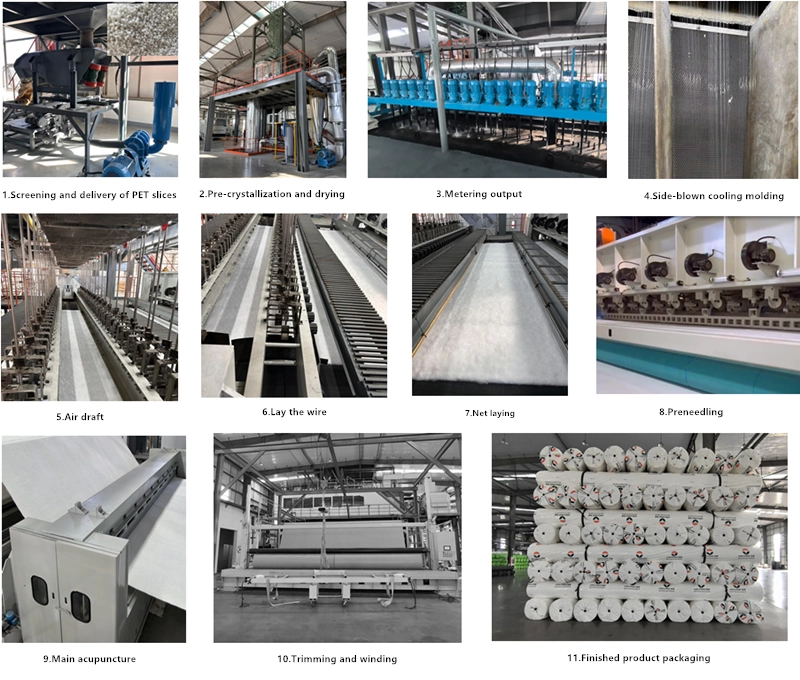

Haoyang Nonwoven Production Process

◢ Screening and delivery of PET slices: First, the PET (polyethylene terephthalate) slices are screened to ensure that their quality meets production requirements. Qualified slices are then delivered to the next production stage.

◢ Pre-crystallization and drying: At this stage, the slices undergo pre-crystallization and drying to remove moisture and other impurities to ensure the purity and stability of the material.

◢ Metering output: The pre-processed PET slices are accurately metered and output to control the amount of raw materials used in the production process.

◢ Side-blow cooling molding: Next, the PET slices go through the side-blow cooling molding process to form the desired shape or structure.

◢ Air flow combing: Through the air flow combing process, the structure and performance of the material are further organized and optimized.

◢ Laying Wires and Netting: During this stage, wires and netting are laid over the material to provide additional support and functional properties.

◢ Mesh Laying: This step involves combining multiple layers of material together to form more complex structures.

◢ Pre-needle punching: Pre-needle punching is a process to further strengthen the material. Pre-needle punching is used to increase the interweaving points between fibers, thereby enhancing the overall performance of the material.

◢ Main Needling: In this step, the material is reinforced and finished through a needling process to increase its strength and durability.

◢ Trimming and Coiling: Finally, the material is trimmed and coiled in preparation for the next stage of processing.

◢ Finished product packaging: After completing all processing steps, the product is packaged into its final form, ready for shipping and sale.

Factory Display

We sincerely welcome you to our filament geotextile production workshop. As one of the leading producers of geomaterials, we are committed to providing high quality, innovative and reliable geomaterials to meet a wide range of engineering and construction needs.

Our filament geotextile workshop is a modern and efficient production base. State-of-the-art facilities, using the latest technology and production processes to ensure excellent quality and consistency of products.

|  |  |

|  |  |

Technical Data Sheet of Polyester Geotextile

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

Item | Unit | Index | |||||||||

Nominal breaking strength | Kn/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

1 | Longitudinal and transverse fracture strength | Kn/m | ≥4.5 | ≥7.5 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 |

2 | Vertical and horizontal standard strength corresponds to elongation | % | 40~80 | ||||||||

3 | CBR bursting strength(Kn/m) | Kn/m | ≥0.8 | ≥1.6 | ≥1.9 | ≥2.9 | ≥3.9 | ≥5.3 | ≥6.4 | ≥7.9 | ≥8.5 |

4 | Vertical and horizontal tearing strength | Kn | ≥0.14 | ≥0.21 | ≥0.28 | ≥0.42 | ≥0.56 | ≥0.7 | ≥0.82 | ≥1.1 | ≥1.25 |

5 | Equivalent aperture O90(o95) | mm | 0.05~0.20 | ||||||||

6 | Vertical permeability coefficient | cm/s | K*(10-1~10-3) K=1.0~9.9 | ||||||||

7 | Thickness | mm | ≥0.8 | ≥1.2 | ≥1.6 | ≥2.2 | ≥2.8 | ≥3.4 | ≥4.2 | ≥5.5 | ≥6.8 |

8 | Amplitude deviation | % | -0.5 | ||||||||

9 | Mass deviation per unit area | % | -5 | ||||||||

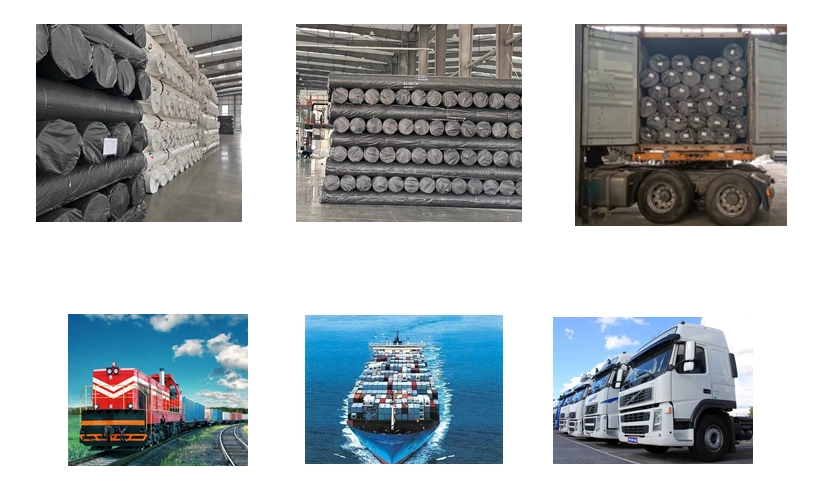

Mode of Transport

FAQ

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q: Where is your factory located? How do I get there?

A: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q: Could you please send the sample before confirming the order?

A: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q: What is the lead time?

A: Usually 5-10 working days after receiving the deposit.

Q: Can you produce according to the customer's requirements?

A: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q: How do you guarantee the quality testing of your products?

A: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)

597.webp)

411.webp)