Geocomposite Drainage Layer Cost

In civil engineering, effective drainage is crucial for maintaining the stability and longevity of construction projects. Geocomposite drainage layers are widely used in various applications to facilitate drainage and minimize water-related issues. However, understanding the cost of geocomposite drainage layers can be challenging, as it involves numerous factors, from material composition to installation requirements. This article explores the cost components, benefits, and practical applications of geocomposite drainage layers while offering insights into making cost-effective choices.

What Is a Geocomposite Drainage Layer?

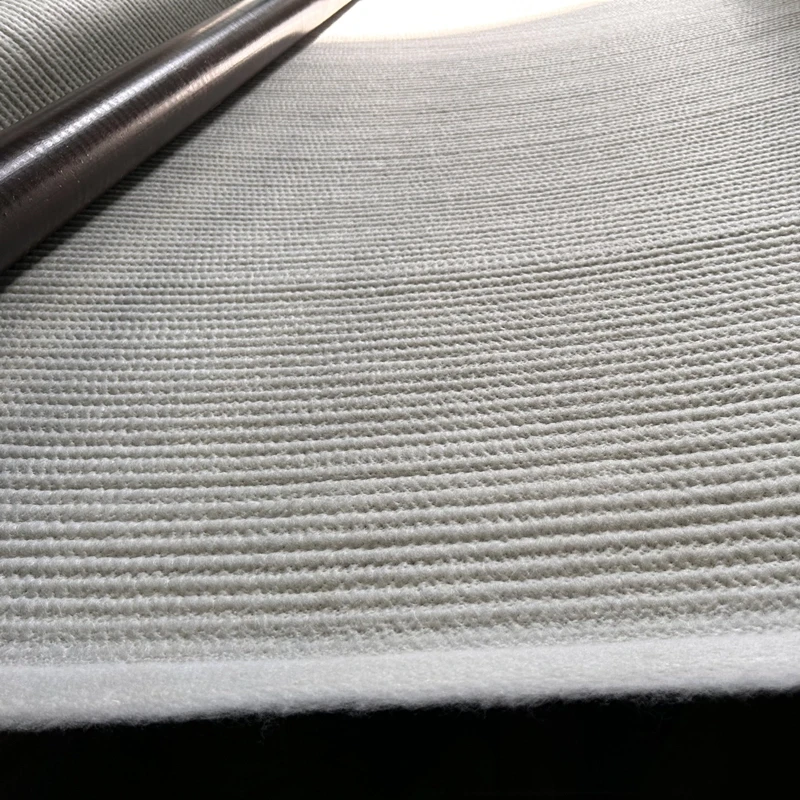

A geocomposite drainage layer combines different materials, typically including geotextiles, geonets, and geomembranes, to create a versatile drainage solution. These layers are designed to improve water flow and manage moisture levels within soil structures. Geocomposite drainage systems are commonly used in road construction, landfills, retaining walls, and roofing to ensure proper water drainage and protect structural integrity.

Key Factors Influencing Geocomposite Drainage Layer Cost

The cost of a geocomposite drainage layer depends on multiple factors, including:

a. Material Type

Geotextiles: Non-woven or woven geotextiles are often integrated with other materials. The cost can vary depending on the material quality, permeability, and durability.

Geonets: Used to provide excellent water flow between layers. The thickness and quality of geonets can influence the overall cost.

Geomembranes: Typically used for waterproofing, geomembranes add to the cost but are essential for projects requiring a high degree of water resistance.

b. Project Size

Larger projects often have higher upfront costs but can benefit from bulk purchase discounts. The cost per square meter decreases as the scale of the project increases.

c. Installation Complexity

Simple, flat surfaces are easier and less expensive to install. In contrast, projects with slopes, curves, or varying elevations might require more labor, driving up the costs.

d. Thickness and Density

The thicker and denser the geocomposite material, the more it will cost. However, thicker materials generally offer better performance in terms of load-bearing and drainage efficiency, making them worth the investment for certain applications.

e. Location and Logistics

The cost of transporting geocomposite materials can also influence overall expenses. Remote locations or challenging terrains may require more logistical planning, which can add to the project cost.

Average Cost of Geocomposite Drainage Layers

The price for geocomposite drainage layers varies significantly based on the factors mentioned above. On average, costs range from $5 to $15 per square meter, with specialized materials or thicker layers priced higher. Here is a breakdown of estimated costs:

| Type of Geocomposite | Average Cost per Square Meter (USD) |

|---|---|

| Standard Geotextile-Based | $5 - $8 |

| Geonet-Enhanced Layers | $8 - $12 |

| Geomembrane-Integrated | $10 - $15 |

Cost Comparison: Traditional vs. Geocomposite Drainage Layers

Traditional drainage systems often require multiple layers of different materials, such as gravel, sand, and pipes, to achieve similar drainage effects. Geocomposite drainage layers, on the other hand, combine these components into a single, efficient product. Although the initial cost of geocomposites may be higher, they tend to be more cost-effective in the long term due to:

Reduced Material Usage: One product replaces several, saving on material and labor costs.

Lower Installation Costs: Easier and faster installation reduces labor expenses.

Durability: Enhanced lifespan reduces the need for frequent replacements or repairs.

| Cost Component | Geocomposite Drainage Layers | Traditional Drainage Systems |

|---|---|---|

| Material Cost (per sq.m) | $10 - $15 | $8 - $12 |

| Installation Cost (per sq.m) | $3 - $5 | $6 - $8 |

| Maintenance (annual) | Low | Moderate to High |

| Transportation (per load) | $200 | $400 |

| Total Lifecycle Cost (10 years) | $20,000 - $25,000 | $30,000 - $35,000 |

The Cost of Geocomposite Drainage Layers Compare to Traditional Drainage Solutions

The cost of geocomposite drainage layers is often one of the main factors that project managers and engineers consider when deciding between traditional drainage solutions and geocomposites. Although the initial price of geocomposite products might seem higher than that of traditional materials like gravel, sand, and perforated pipes, geocomposites tend to be more cost-effective over the lifespan of a project. Here’s a detailed comparison of the costs associated with geocomposite drainage layers and traditional drainage systems:

1. Initial Material Costs

Traditional drainage systems typically involve multiple components, including pipes, gravel, sand, and filter cloths. The costs of purchasing and transporting these materials can add up, particularly when large volumes are required. In contrast, geocomposite drainage layers combine the functions of these elements into a single product, potentially reducing the total material cost.

For example, a road construction project in Germany that opted for geocomposite layers instead of traditional drainage reduced initial material costs by 20%. This is because the geocomposites integrated filtration, drainage, and protection layers into one product, eliminating the need for separate materials.

2. Installation Costs

One of the significant advantages of geocomposite drainage layers is the reduction in labor and installation expenses. Traditional drainage systems are often labor-intensive to install. They involve digging trenches, laying pipes, and placing aggregate materials, which require more workers and equipment, increasing labor costs. Geocomposites, being lightweight and flexible, can be rolled out quickly, significantly reducing the time and labor required for installation.

For example, an urban infrastructure project in the UK found that using geocomposites reduced installation time by over 40%, leading to a 30% decrease in labor costs compared to traditional methods.

3. Maintenance Costs

Maintenance is a critical aspect that impacts the overall cost of a drainage system. Traditional systems may require regular maintenance to prevent clogging, especially in areas with fine-grained soils that can block pipes. The need for periodic clearing and repair can increase operational costs over time. In contrast, geocomposites have a design that promotes efficient water flow and reduces the risk of blockages. This means that once installed, they typically require less frequent maintenance, resulting in lower long-term expenses.

For instance, in landfill projects, geocomposite drainage systems have demonstrated longer lifespans and fewer maintenance requirements compared to traditional gravel-based systems. This is due to their ability to maintain consistent drainage performance without clogging.

4. Transportation and Storage Costs

Traditional drainage solutions involve the transportation of heavy materials such as gravel, which increases shipping costs. Additionally, these materials take up significant storage space on the construction site, which can be a logistical challenge. Geocomposite drainage layers are relatively lightweight and can be transported and stored more efficiently. They require less space, making it easier to handle and distribute at the construction site.

A case study from a large-scale landscaping project in Canada highlighted that using geocomposites reduced transportation costs by 25%, as fewer truckloads were needed compared to traditional gravel drainage systems.

Practical Applications of Geocomposite Drainage Layers

Geocomposite drainage layers are versatile products used in various construction applications, ranging from civil engineering projects to environmental protection initiatives. Their ability to provide efficient drainage, filtration, and protection makes them suitable for multiple scenarios where managing water flow is critical. Here are some common applications of geocomposite drainage layers:

1. Road and Highway Construction

One of the most prevalent uses of geocomposite drainage layers is in road and highway construction. Effective drainage is crucial for maintaining road stability and preventing water damage to the subgrade layers. Geocomposites help in managing water by directing it away from the road structure, thus reducing the risk of pavement erosion, cracking, and potholes. They also enhance the longevity of the road by maintaining the integrity of the foundation.

For example, in a highway expansion project in Texas, the use of geocomposite drainage layers resulted in improved road durability by efficiently managing sub-surface water, leading to lower maintenance costs over time.

2. Retaining Walls and Embankments

Retaining walls and embankments are essential structures in projects like roadways, bridges, and railway lines. These structures need reliable drainage solutions to relieve hydrostatic pressure, which can cause instability or failure. Geocomposite drainage layers are installed behind retaining walls to channel water away from the structure, preventing water buildup that can compromise stability.

A railway embankment project in India used geocomposite layers to manage water drainage effectively, resulting in reduced soil erosion and enhanced embankment stability, ensuring safety and longevity of the railway line.

3. Landfill Liners and Caps

In landfill applications, controlling the flow of leachate (liquid that drains from a landfill) is critical for environmental safety. Geocomposite drainage layers are used as part of landfill liner systems to collect and transport leachate to treatment facilities. They are also used in landfill caps to manage rainwater infiltration, preventing it from mixing with waste and generating leachate.

For instance, in a landfill site in the Netherlands, geocomposite drainage systems significantly reduced the occurrence of leachate seepage, ensuring compliance with environmental regulations and minimizing the impact on surrounding water bodies.

4. Green Roof Systems

Green roofs are becoming increasingly popular in urban areas as they provide insulation, reduce energy consumption, and enhance urban aesthetics. Effective drainage is vital to prevent waterlogging and maintain healthy plant growth. Geocomposite drainage layers are used in green roofs to manage water, allowing excess water to drain away while retaining enough moisture for plant roots.

A green roof project in New York City integrated geocomposite drainage layers, which facilitated proper water management and contributed to the overall success of the rooftop garden by ensuring adequate root aeration and drainage.

5. Tunnel and Underground Construction

Tunnels and underground structures are often at risk of water ingress, which can lead to structural damage and safety hazards. Geocomposite drainage layers are installed in tunnels to provide a continuous drainage path that prevents water from seeping into the structure. They also serve as protective layers, reducing the risk of damage during construction and over the life of the tunnel.

A metro construction project in Japan used geocomposite layers to manage water infiltration, ensuring the tunnels remained dry and safe for daily operations. This application was crucial in extending the lifespan of the infrastructure.

| Project Type | Traditional System Installation (days) | Geocomposite System Installation (days) | Time Saved (%) |

|---|---|---|---|

| Highway Drainage | 15 | 9 | 40% |

| Landfill Leachate System | 20 | 12 | 40% |

| Tunnel Waterproofing | 30 | 18 | 40% |

| Green Roof Setup | 10 | 6 | 40% |

Benefits of Using Geocomposite Drainage Layers

Geocomposite drainage layers have become increasingly popular in civil engineering and construction projects due to their numerous advantages over traditional drainage systems. Unlike conventional methods, which often rely on a combination of gravel, sand, and perforated pipes, geocomposite drainage layers offer a more efficient and cost-effective solution. Below, we explore the key benefits of geocomposite drainage layers and why they are often preferred in modern engineering projects.

1. Cost Efficiency

One of the primary advantages of geocomposite drainage layers is their cost-effectiveness. Traditional drainage systems require multiple materials—such as aggregate, sand, and pipes—which increases both material and labor costs. By contrast, geocomposites combine the functions of these components into a single product. This simplification reduces installation time and labor expenses, ultimately lowering the total cost of the project. For example, a study comparing traditional drainage systems with geocomposites found that geocomposite layers reduced overall costs by approximately 30% due to faster installation and fewer materials.

2. Improved Installation Efficiency

Traditional drainage systems can be labor-intensive to install, often involving multiple steps, such as digging trenches, laying pipes, and backfilling with gravel. Geocomposite drainage layers are designed for easy and quick installation, as they are lightweight and can be rolled out over the required area without complex machinery or extensive labor. This efficiency not only reduces installation time but also allows projects to be completed faster. For instance, in a highway construction project in Europe, the use of geocomposite drainage reduced installation time by nearly 40%, enabling the project to stay ahead of schedule.

3. Lightweight and Flexible Design

The lightweight nature of geocomposite drainage layers makes them easier to transport and handle compared to traditional systems, which often require large volumes of heavy aggregate. This flexibility is particularly beneficial in projects located in remote or difficult-to-access areas. Additionally, the ability to cut and shape geocomposite layers allows for better adaptability to varying site conditions, including uneven terrain or complex designs, without compromising the drainage system's effectiveness.

4. Superior Drainage Performance

Geocomposites offer enhanced drainage performance by providing high permeability and efficient water flow paths. Traditional systems can sometimes clog over time, especially in fine-grained soils where sediment may obstruct pipes. Geocomposites, however, feature a combination of materials (e.g., geotextiles and geonets) that allow water to flow freely while filtering out soil particles. This ensures continuous drainage and reduces the risk of system failure. For example, landfill sites using geocomposite layers have reported lower incidents of leachate buildup due to the efficient drainage pathways provided by these materials.

5. Environmental Benefits

Another advantage is the environmental sustainability of geocomposites. By using fewer raw materials, geocomposite systems reduce the environmental footprint of construction projects. Traditional drainage solutions require the extraction, transportation, and installation of large quantities of aggregate, which can have a significant environmental impact. In contrast, geocomposites are designed to achieve the same or better drainage efficiency with less material, resulting in lower carbon emissions. Additionally, many geocomposites are made from recycled or recyclable materials, further enhancing their eco-friendly profile.

Real-World Cost Savings: Case Study Data

In a project where a 10,000 square meter area required drainage, the following comparison was observed:

| System Type | Material Cost (USD) | Installation Cost (USD) | Total Cost (USD) |

|---|---|---|---|

| Traditional System | $100,000 | $50,000 | $150,000 |

| Geocomposite System | $80,000 | $30,000 | $110,000 |

Result: The geocomposite system resulted in a 26.7% cost reduction, primarily due to easier installation and reduced material costs.

Tips for Reducing Geocomposite Drainage Layer Costs

a. Buy in Bulk

Purchasing materials in bulk can significantly reduce the cost per square meter. Suppliers often offer discounts for larger orders, making this an economical choice for extensive projects.

b. Choose the Right Supplier

Opt for reputable manufacturers who can guarantee quality while offering competitive prices. Suppliers with a proven track record are more likely to provide products that perform well over time, reducing the risk of costly repairs or replacements.

c. Optimize Design

Work with experienced engineers to design a system that optimizes material use. Proper planning and design can help eliminate unnecessary costs by ensuring that the drainage system is as efficient as possible.

Selecting a Geocomposite Drainage Layer for Your Project

Choosing the right geocomposite drainage layer for a project involves considering several critical factors that can affect both the performance and cost-efficiency of the system. Below, we explore the key aspects that should guide the selection process to ensure optimal drainage performance and project success.

1. Project Requirements and Conditions

The specific requirements of the project, including the type of application (e.g., road construction, landfill, or roofing), site conditions, and expected water load, are essential in determining the appropriate geocomposite drainage layer. For example, a project involving high traffic loads may require a geocomposite with enhanced compressive strength to withstand heavy loads without deformation. Similarly, applications in areas with high water flow will benefit from geocomposites with higher permeability to ensure efficient drainage.

2. Material Composition

Geocomposite drainage layers are typically made from a combination of geotextiles, geonets, and geomembranes. Each component serves a different purpose, and the material composition should be chosen based on the project's specific needs. For example:

Geotextiles: Provide filtration and separation. Non-woven geotextiles are preferred for areas requiring high permeability, while woven geotextiles offer better strength.

Geonets: Facilitate water flow between layers. The thickness and structure of the geonet will determine the drainage capacity.

Geomembranes: Used for applications requiring waterproofing. Geomembrane-integrated layers are ideal for projects where preventing water infiltration is critical.

3. Installation Complexity and Cost

The ease of installation is another factor that should be considered. Geocomposite drainage layers that are lightweight and flexible can be installed more easily, reducing labor costs and project timeframes. For example, projects involving steep slopes or complex geometries may require specialized geocomposites that can be easily shaped and installed without compromising drainage performance.

4. Longevity and Maintenance

The durability and maintenance requirements of geocomposite drainage layers are also crucial considerations. A high-quality geocomposite should provide long-term performance without frequent maintenance. Projects with a long expected lifespan, such as highways or building foundations, will benefit from choosing geocomposites that offer enhanced durability and resistance to environmental factors like UV exposure, chemical degradation, and biological growth.

5. Environmental Impact

Considering the environmental impact of the chosen materials is increasingly important in modern construction projects. Opting for geocomposites made from recycled or recyclable materials can help achieve sustainability goals. Additionally, selecting systems that minimize the disturbance of the surrounding ecosystem (e.g., by reducing soil erosion) contributes to more environmentally friendly project outcomes.

Making Cost-Effective Decisions

When considering the cost of geocomposite drainage layers, it is essential to account for both the initial investment and long-term savings. While the upfront cost may appear higher than traditional systems, geocomposites offer numerous benefits that result in overall cost savings, including easier installation, reduced material usage, and extended durability. Additionally, they contribute to sustainability, making them an excellent choice for projects prioritizing environmental responsibility.

By understanding the factors influencing the cost of geocomposite drainage layers and implementing smart purchasing strategies, project managers can achieve efficient and cost-effective drainage solutions. Choosing the right materials and suppliers can further ensure that the investment in geocomposites will deliver reliable performance for years to come.

Promote Your Project’s Success with Haoyang Environmental Co., Ltd.

If you're looking for reliable and high-quality geocomposite drainage layers, Haoyang Environmental Co., Ltd. is your go-to solution. Established in 2008, Haoyang is a leading high-tech provider specializing in the research, development, and manufacturing of geosynthetic materials. With extensive experience in environmental engineering design, soil remediation, and solid waste treatment, Haoyang delivers comprehensive solutions tailored to meet the specific needs of each project.

Here’s why you should choose Haoyang for your geocomposite drainage layer needs:

Certified Excellence: Haoyang has obtained ISO 9001, ISO 14001, and OHSAS 18001 certifications, ensuring the highest standards in quality management, environmental protection, and occupational health and safety. Additionally, the company holds the CQC environmental product certification, reflecting its commitment to sustainable and eco-friendly practices.

Advanced R&D Capabilities: Recognized as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory," Haoyang is at the forefront of innovation in geosynthetic material technology. With a professional R&D team, the company focuses on developing cutting-edge solutions that address the most challenging environmental engineering issues.

Proven Track Record: Haoyang's expertise is backed by three invention patents and 32 utility model patents, along with two provincial-level scientific and technological achievement certifications. These accolades highlight the company’s leadership in creating effective and reliable geocomposite products.

Customized Solutions: Whether you need geocomposite drainage layers for road construction, landfills, or green roofs, Haoyang can provide customized solutions designed to optimize performance and cost-efficiency for your specific project requirements.

By choosing Haoyang Environmental Co., Ltd., you’re not just investing in a product; you're partnering with a team dedicated to providing innovative, high-performance, and environmentally conscious solutions. Contact Haoyang today to learn how our geocomposite drainage layers can contribute to the success of your next project.

897.webp)

942.webp)

237.webp)