Geotextile Fabric in Malaysia: A Key Element in Soil Engineering

Geotextile fabric has gained significant popularity in Malaysia, playing a crucial role in various soil engineering applications. This versatile material, often referred to as geosynthetics or geomembranes, offers numerous advantages over traditional methods, making it a preferred choice for numerous projects.

(Black HPDE geomembrane)

Geotextile fabric is primarily used in Malaysia for erosion control, soil stabilization, and separation functions. In erosion control projects, the fabric acts as a barrier, preventing soil particles from being washed away by rainwater or other external forces. This is particularly important in Malaysia, where tropical rains and monsoon seasons can lead to heavy runoff and erosion. By using geotextile fabric, engineers can effectively mitigate these risks and protect slopes, embankments, and other structures from damage.

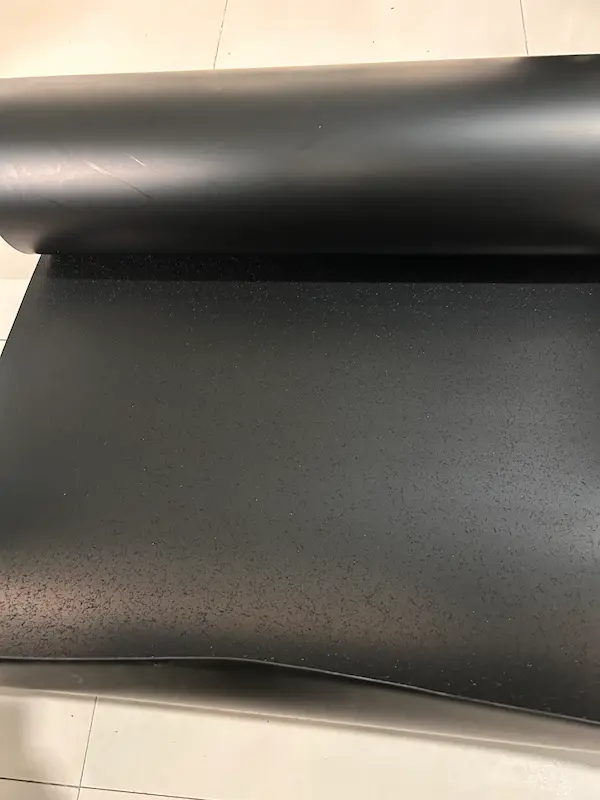

(Black single sided rough geomembrane)

Moreover, geotextile fabric is also used for soil stabilization. It is often placed between soil layers to enhance the overall structural integrity of the soil mass. The fabric provides a reinforcement mechanism, improving the shear strength and bearing capacity of the soil. This is crucial in Malaysia, where soil conditions can vary significantly, ranging from soft clays to sandy soils. By utilizing geotextile fabric, engineers can ensure that soil structures are stable and able to withstand external forces.

(Site construction drawing)

In addition to erosion control and soil stabilization, geotextile fabric is also used for separation functions. It is often placed between different soil layers or between soil and other materials to prevent mixing and ensure proper drainage. This is particularly important in Malaysia, where the tropical climate can lead to high moisture content in the soil. By using geotextile fabric, engineers can create a separation layer that allows water to drain effectively while preventing soil particles from migrating.

The popularity of geotextile fabric in Malaysia is also attributed to its durability and ease of installation. These fabrics are made from high-quality synthetic materials that are resistant to degradation from UV radiation, chemicals, and biological agents. This ensures that they can withstand the harsh tropical conditions in Malaysia and maintain their performance for extended periods. Additionally, the installation process is relatively simple and can be completed quickly, reducing the overall cost and time required for soil engineering projects.

In summary, geotextile fabric plays a crucial role in soil engineering in Malaysia. Its versatility, durability, and ease of installation make it the preferred material for erosion control, soil stabilization, and isolation functions. As Malaysia continues to develop and advance its infrastructure, the demand for geotextile fabric is expected to grow, further strengthening its position in the field of soil engineering.

Ordinary high density polyethylene geomembrane(GB/T 176543-2011 GH-1type)

Number | Ltem | Value | |||||||||||

Thickness mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | ||||

1 | Density g/cm3 | ≥0.940 | |||||||||||

2 | Tensile yield strength (MD andCD) N/mm | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 | |||

3 | Tensile break strength(MD andCD)N/mm | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 | |||

4 | Elongation at yield(MD and CD)N/mm | 一 | 一 | ≥11 | |||||||||

5 | Elongation at break(MD andCD)% | ≥600 | |||||||||||

6 | Tear resistance(MD and CD)% | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 | |||

7 | Puncture strength N | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 | |||

8 | Carbon blank content % | 2.0~3.0 | |||||||||||

9 | Carbon black dispersion | There are no more than 1 in the 10 data,no 4 or 5 | |||||||||||

10 | Normal pressure oxidationinduction time min | ≥60 | |||||||||||

11 | Low temperature impacbrittleness | Get through | |||||||||||

12 | Water vapor permeabilityg-cm/(cm²-s-Pa) | ≤1.0×10-l: | |||||||||||

13 | Dimensional stability % | ±2.0 | |||||||||||

Environmental protection with rough high density polyethylene geomembrane(GB/T 176543-2011 GH-2TI.GH-2T2type) | |||||||||||

| Item | Value | |||||||||

| 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | ||||

1 |

| g/cm3 | ≥0.940 | ||||||||

2 |

| mm | ≥0.25 | ||||||||

3 |

| ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 | |||

4 |

| ≥8 | ≥10 | ≥13 | ≥16 | ≥21 | ≥26 | ≥32 | |||

5 |

| ≥12 | |||||||||

6 |

| ≥100 | |||||||||

7 |

| ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 | |||

8 |

| ≥200 | ≥270 | ≥335 | ≥400 | ≥535 | ≥670 | ≥800 | |||

9 |

| ≥300 | |||||||||

10 |

| 2.0~3.0 | |||||||||

11 |

|

| |||||||||

12 |

|

| |||||||||

| |||||||||||

13 |

| ≥55 | |||||||||

14 | UV Rresistance(High Pressure | ≥50 | |||||||||

Note: Technical performance indicator requirements for thickness specifications not listed in the table shall be implemented in accordance with the interpolation method. | |||||||||||

In the 10 tests for index item 2, the results of 8 tests should be greater than 0.18mm, and the minimum value should be greater than 0.13mm. | |||||||||||

For index items 13 and 15, either the normal pressure OIT (retention rate) or the high pressure OIT (retention rate) can be selected for testing. | |||||||||||

As a prominent geotextile fabric manufacturer and exporter based in China, we take pride in offering high-quality products to customers worldwide, including Malaysia. With a strong focus on innovation, quality, and customer satisfaction, we have established ourselves as a trusted supplier in the geotextile industry.

Our company boasts state-of-the-art manufacturing facilities and a team of skilled professionals dedicated to delivering top-notch geotextile fabric solutions. We adhere to stringent quality control measures throughout the production process to ensure that our products meet the highest standards of performance and durability.

At Haoyang, we offer a comprehensive range of geotextile fabric products tailored to meet the diverse needs of our customers. Whether you require fabrics for soil stabilization, erosion control, drainage, filtration, or any other application, we have the expertise and resources to provide you with the perfect solution.

We understand the importance of reliability and efficiency in today's fast-paced construction and environmental projects. That's why we strive to offer competitive pricing, timely delivery, and exceptional customer service to meet and exceed our customers' expectations.

For customers in Malaysia seeking geotextile fabric solutions, we invite you to choose Haoyang as your trusted partner. With our commitment to quality, reliability, and customer satisfaction, we are confident that we can meet your geotextile needs and contribute to the success of your projects.

Thank you for considering Haoyang. We look forward to serving you and building a long-lasting partnership.

Download

Ordinary high density polyethylene geomembrane specifications and standards.pdf

897.webp)

942.webp)

237.webp)