Green Filament Geotextile Suitable for Highway Roadbed

Traditional highway construction often comes with serious environmental drawbacks. Soil erosion, sedimentation and degradation of surrounding ecosystems are common problems. In addition, traditional materials used in roadbed construction increase carbon emissions and lack sustainability. Our green filament geotextiles can be used as a solution to these cutting-edge challenges. Our geotextiles are made of PET material and processed using methods such as hot-melt extrusion, and are carefully crafted with attention to environmental impact and performance, providing a sustainable alternative for highway roadbed construction. Haoyang Environmental Co., Ltd. is a manufacturer specializing in the production of geotextiles. Filament non-woven geotextiles are one of our main products. We are also a supplier of large-scale projects such as the South-to-North Water Diversion Project. We look forward to cooperating with you.

Product Features

◢ Our green filament geotextile has high strength and tear resistance, and the longitudinal and transverse breaking strength can exceed 50.

◢ It has the characteristics of UV resistance. At the same time, geotextiles with different vertical permeability can be manufactured according to your actual application, and the manufacturing range can be 1.0-9.9.

◢ High temperature resistance, it can maintain structural stability and original physical properties at high temperatures of 230°C.

◢ The thickness can exceed 6.8mm and can resist the erosion of chemical substances in the soil, making the life of roads and foundations longer.

◢ High elongation, the productivity corresponding to the vertical and horizontal standard strength can reach 80%, and it can adapt to uneven and irregular substrates.

Technical Data Sheet of Polyester Geotextile GBT17639-2008

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

Item | Unit | Index | |||||||||

Nominal breaking strength | Kn/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

1 | Longitudinal and transverse fracture strength | Kn/m | ≥4.5 | ≥7.5 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 |

2 | Vertical and horizontal standard strength corresponds to elongation | % | 40~80 | ||||||||

3 | CBR bursting strength(Kn/m) | Kn/m | ≥0.8 | ≥1.6 | ≥1.9 | ≥2.9 | ≥3.9 | ≥5.3 | ≥6.4 | ≥7.9 | ≥8.5 |

4 | Vertical and horizontal tearing strength | Kn | ≥0.14 | ≥0.21 | ≥0.28 | ≥0.42 | ≥0.56 | ≥0.7 | ≥0.82 | ≥1.1 | ≥1.25 |

5 | Equivalent aperture O90(o95) | mm | 0.05~0.20 | ||||||||

6 | Vertical permeability coefficient | cm/s | K*(10-1~10-3) K=1.0~9.9 | ||||||||

7 | Thickness | mm | ≥0.8 | ≥1.2 | ≥1.6 | ≥2.2 | ≥2.8 | ≥3.4 | ≥4.2 | ≥5.5 | ≥6.8 |

8 | Amplitude deviation | % | -0.5 | ||||||||

9 | Mass deviation per unit area | % | -5 | ||||||||

Product Application

The vertical permeability coefficient of our green filament geotextiles ranges from 1.0-9.9, and you can choose according to your specific design requirements and construction conditions. A vertical permeability coefficient of 9.9 has a strong ability to allow moisture to pass vertically and is suitable for engineering applications that require better drainage and filtration functions. Those with a vertical permeability coefficient of 1.0, although not as good as high-permeability materials, still have a certain water permeability and can be used in certain situations where moderate drainage is required while preventing the loss of fine-grained soil. Our green filament geotextiles usually have the following application scenarios:

☉ Water conservancy and hydropower engineering.

☉ Paving roads and railways.

☉ Airports and ports.

☉ River protection and tunnel.

☉ Environmental protection, etc.

Why Choose Haoyang Environmental Co., Ltd.?

◢ Proven Expertise: With a track record of excellence in geosynthetic materials and environmental engineering, we bring unparalleled expertise to every project.

◢ Certified Quality: Our commitment to quality is reflected in our ISO certifications and recognition as a leader in environmental innovation.

◢ Research and Development: Backed by a dedicated R&D team and numerous patents, we continuously strive to push the boundaries of environmental sustainability and technological advancement.

◢ Comprehensive Support: From initial consultation to project implementation, we provide comprehensive support tailored to meet the unique needs of each client.

Join Us in Building a Sustainable Future

Together, let's pave the way for a greener, more resilient infrastructure. Choose Haoyang Environmental Co., Ltd. and embrace the future of highway construction with Green Filament Geotextile. Contact us today to learn more about how our innovative solutions can transform your projects.

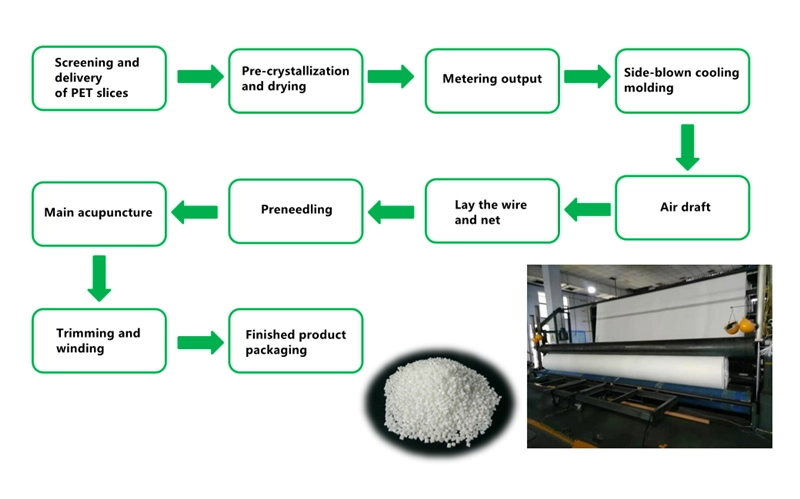

How is filament geotextile produced?

Filament is one of the important raw materials for geotextile manufacturing, and its production process goes through multiple links of precision processing and treatment to ensure that the final product has the required strength, durability and stability. The following diagram will show the filament production process, detailing the conversion process from polymer particles to formed fibers. The high-quality preparation of filament has an important impact on the quality and performance of geotextiles, so our company has introduced a number of advanced production equipment for the quality of filament products to improve and upgrade. Take an in-depth look at the filament production process and its key role in geotextile manufacturing.

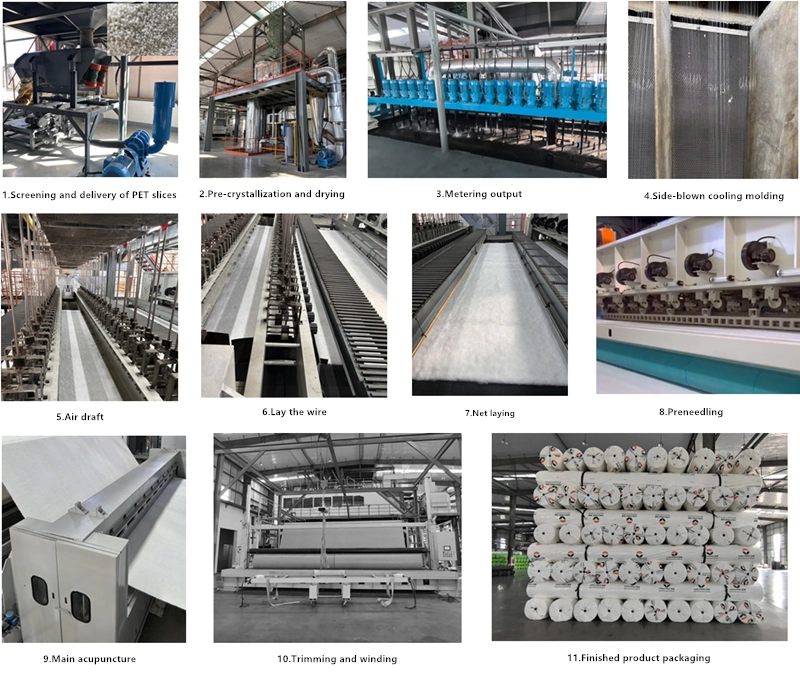

Factory Display

We sincerely welcome you to our filament geotextile production workshop. As one of the leading producers of geomaterials, we are committed to providing high quality, innovative and reliable geomaterials to meet a wide range of engineering and construction needs.

Our filament geotextile workshop is a modern and efficient production base. State-of-the-art facilities, using the latest technology and production processes to ensure excellent quality and consistency of products.

111767.webp) | 533305.webp) |  |

157122.webp) |  | 763278.webp) |

Project Construction Photo

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

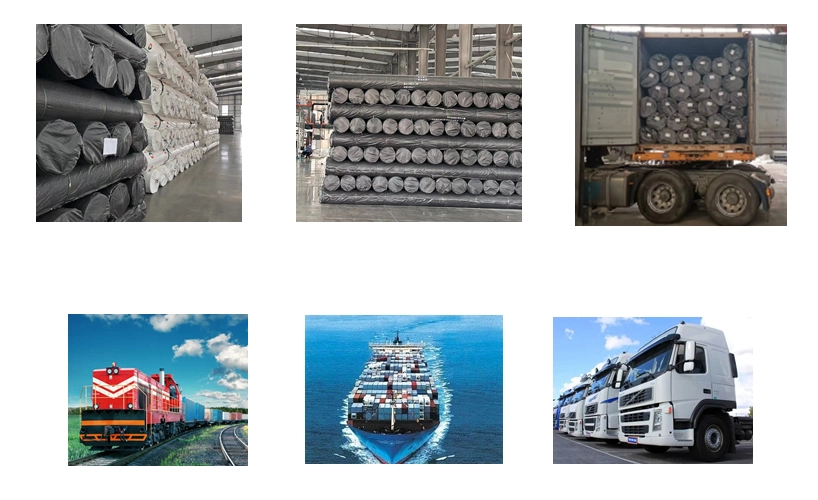

Mode of Transport

FAQ

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q: Where is your factory located? How do I get there?

A: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q: Could you please send the sample before confirming the order?

A: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q: What is the lead time?

A: Usually 5-10 working days after receiving the deposit.

Q: Can you produce according to the customer's requirements?

A: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q: How do you guarantee the quality testing of your products?

A: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)

597.webp)

411.webp)