What is Tailing Ponds

Tailing ponds also known as tailings dams or storage facilities, are engineered structures designed to contain and manage the waste materials generated from mining operations. These byproducts, commonly referred to as tailings, consist of ground rock and process water that remain after the valuable minerals have been extracted. Proper management of tailings is crucial to prevent environmental contamination and ensure the safety of surrounding ecosystems.

Specifications of HDPE Geomembranes for Tailing Ponds

The specifications of HDPE geomembranes for tailing ponds can vary depending on the project's requirements, such as the type of tailings, environmental conditions, and the required lifespan. Below is a detailed specifications table for common HDPE geomembranes used in tailing pond applications:

| Specification | Details |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Thickness | 0.75 mm to 3.0 mm |

| Width | 5.8 m, 7.0 m, 8.0 m (custom widths available) |

| Length | 50 m to 200 m (custom lengths available) |

| Density | ≥ 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa |

| Elongation at Break | ≥ 700% |

| Puncture Resistance | ≥ 550 N |

| Tear Resistance | ≥ 125 N |

| Environmental Stress Crack Resistance | ≥ 300 hr |

| Carbon Black Content | 2% - 3% (for UV resistance) |

| Water Vapor Transmission | ≤ 1.0 × 10⁻¹³ g.cm/cm².s.Pa |

| Temperature Range | -40°C to 85°C |

| UV Resistance | Excellent (≥ 90% strength retention after 500 hours exposure) |

| Chemical Resistance | Resistant to acids, alkalis, and hydrocarbons |

| Standard Compliance | ASTM D5199, ASTM D6392, ISO 9001, GRI-GM13 |

Pricing of HDPE Geomembranes for Tailing Ponds

The pricing of HDPE geomembranes for tailing ponds depends on factors such as thickness, width, length, and any additional customization required. Below is a general price table based on common specifications:

| Thickness | Width | Length | Price Range (USD/m²) |

|---|---|---|---|

| 0.75 mm | 5.8 m | 100 m | $1.20 - $1.50 |

| 1.0 mm | 7.0 m | 100 m | $1.50 - $1.80 |

| 1.5 mm | 7.0 m | 100 m | $1.80 - $2.20 |

| 2.0 mm | 8.0 m | 50 m | $2.20 - $2.70 |

| 2.5 mm | 8.0 m | 50 m | $2.70 - $3.20 |

| 3.0 mm | 8.0 m | 50 m | $3.20 - $3.80 |

Why Geomembranes Are Widely Used in Tailing Pond Engineering

In the pursuit of sustainable mining practices, the use of geomembranes has emerged as a highly effective solution for lining tailing ponds. Geomembranes, particularly those made from High-Density Polyethylene (HDPE), offer unparalleled impermeability, durability, and chemical resistance, making them ideal for containing and isolating tailings from the environment. By creating a barrier between the tailings and the underlying soil or groundwater, geomembranes significantly reduce the risk of leachate migration and contamination.

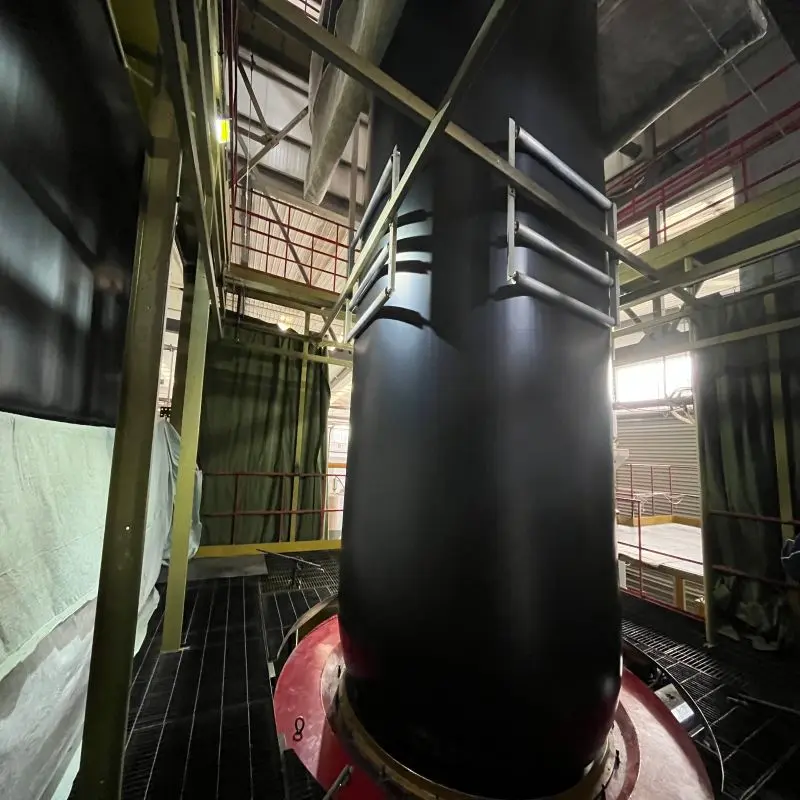

What is HDPE geomembrane

HDPE geomembrane, also known as High-Density Polyethylene geomembrane, is a type of geosynthetic material primarily made from High-Density Polyethylene (HDPE) resin. With a density typically greater than or equal to 0.940 g/cm³, it exhibits exceptional physical-mechanical properties and chemical stability.

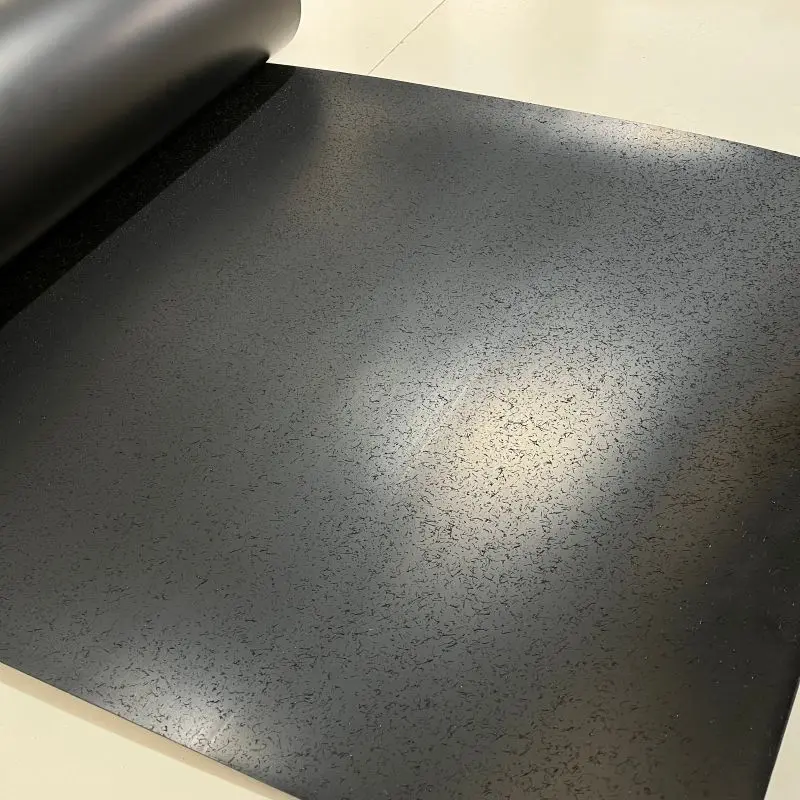

Smooth surface and textured surface type

Smooth-surfaced Geomembrane:

A smooth-surfaced geomembrane, as the name suggests, features a smooth, non-textured surface. It is manufactured primarily from synthetic polymers such as High-Density Polyethylene (HDPE) or other advanced materials that offer high impermeability and resistance to chemicals, punctures, and tears. Smooth-surfaced geomembranes are renowned for their ease of installation, particularly in large-scale applications where a seamless, uniform barrier is required.

Key Applications:

Lining of Liquid Containment Structures: Smooth-surfaced geomembranes are widely used to line ponds, reservoirs, lagoons, and other liquid containment structures. They effectively prevent leakage and seepage, ensuring the integrity of the stored liquid.

Landfill Lining: In landfills, these geomembranes create a barrier between waste materials and the underlying soil or groundwater, minimizing the risk of environmental contamination.

Canal Lining: For irrigation and drainage canals, smooth-surfaced geomembranes provide a durable, impermeable lining that resists wear and tear from water flow and debris.

Rough-surfaced Geomembrane:

In contrast, a rough-surfaced geomembrane is designed with a textured or embossed surface to improve its interface properties. This surface treatment enhances the bond between the geomembrane and the underlying soil, geotextile, or other supporting layer, creating a more stable and secure installation. Rough-surfaced geomembranes are often used in applications where a strong, reliable connection to the substrate is crucial.

Key Applications:

Slope Stabilization: In areas prone to slope failures or landslides, rough-surfaced geomembranes are used to reinforce soil structures and promote stability. The textured surface improves the friction between the geomembrane and the soil, helping to resist sliding forces.

Foundation Waterproofing: For buildings and structures requiring foundation waterproofing, rough-surfaced geomembranes provide a robust barrier that can be securely anchored to the foundation material, ensuring long-term protection against moisture infiltration.

Landfill Covers: As landfill covers, rough-surfaced geomembranes not only prevent the escape of gas and leachate but also provide a stable surface for the placement of final cover materials, such as soil or vegetation.

In tailings pond engineering, the simultaneous need for both smooth-surfaced and rough-surfaced geomembranes arises from their unique properties and the specific requirements of the project. Here are the key reasons:

Functional Differences:

Smooth-surfaced Geomembrane: Known for its high impermeability and seamless installation, smooth-surfaced geomembranes are ideal for creating a waterproof barrier within the tailings pond. They effectively prevent the seepage of contaminants, such as wastewater, chemicals, and heavy metals, into the surrounding soil and groundwater.

Rough-surfaced Geomembrane: The textured surface of rough-surfaced geomembranes enhances friction and adhesion with the underlying soil or geotextile layers. This is crucial for slope stabilization, as it provides a more secure interface that resists sliding and erosion.

Slope Stability:

Tailings ponds often involve steep slopes that require special attention to prevent slope failures. Rough-surfaced geomembranes are preferred for slope areas due to their ability to anchor securely and resist sliding forces. They help maintain the stability of the slope, especially during extreme weather conditions or seismic events.

Compatibility and Design Flexibility:

Projects may require a combination of both types of geomembranes to address different aspects of the tailings pond's design and functionality. Smooth-surfaced geomembranes can be used in areas where a high level of impermeability is the primary concern, while rough-surfaced geomembranes can be applied to slopes for enhanced stability.

Long-term Durability and Maintenance:

Both types of geomembranes are designed for long-term durability, but they serve different purposes within the tailings pond system. Smooth-surfaced geomembranes ensure continuous containment of contaminants, while rough-surfaced geomembranes contribute to the overall structural integrity of the slope. This combination helps minimize maintenance requirements and prolongs the lifespan of the tailings pond.

Primary Functions of hdpe in tailing ponds:

Impermeability: The primary function of HDPE geomembranes is to provide a complete barrier against liquid and gas permeation. This ensures that toxic or harmful substances within the tailings are contained, minimizing the risk of groundwater contamination.

Durability: The material's resilience and ability to withstand extreme conditions ensure long-term performance, reducing the need for frequent maintenance or replacement.

Chemical Resistance: HDPE geomembranes are highly resistant to a wide range of chemicals commonly found in tailings, including acids, alkalis, and salts, ensuring their integrity over time.

Flexibility: The material's flexibility allows it to conform to the contours of the tailing pond, eliminating gaps or weaknesses that could compromise the barrier's effectiveness.

Environmental Protection: By preventing the release of contaminants, HDPE geomembranes contribute significantly to environmental stewardship, ensuring mining operations align with sustainable development goals.

HDPE geomembranes play a pivotal role in the safe and environmentally responsible management of tailing ponds. Their unparalleled impermeability, durability, and chemical resistance make them the material of choice for lining these critical structures. By containing tailings and preventing the migration of contaminants, HDPE geomembranes safeguard groundwater resources, protect ecosystems, and support sustainable mining practices. As the mining industry continues to evolve, the importance of incorporating HDPE geomembranes into tailing pond engineering cannot be overstated.

897.webp)

942.webp)

237.webp)