Both offer distinct advantages and are suitable for various applications, but understanding their differences is crucial for making informed decisions.

1. Material Properties:

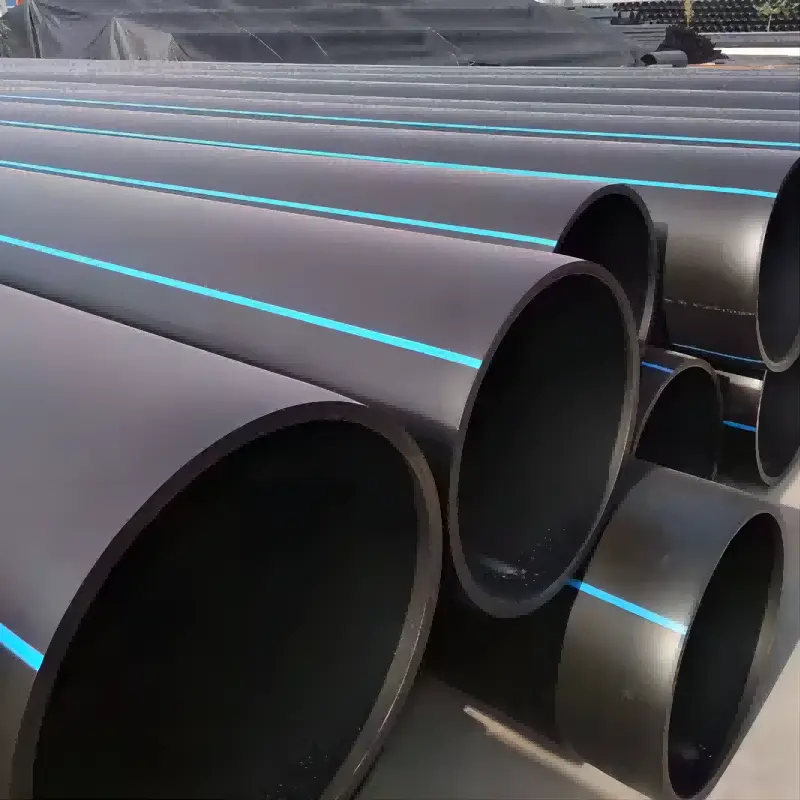

HDPE (High-Density Polyethylene):

Density: HDPE is known for its high density, typically ranging from 0.93 to 0.97 g/cm³.

Flexibility: It exhibits high flexibility and toughness, making it suitable for applications requiring resistance to impact and stress cracking.

Chemical Resistance: HDPE is highly resistant to chemicals, including acids, bases, and alcohols.

Temperature Range: It can withstand temperatures ranging from -50°C to +80°C (-58°F to 176°F).

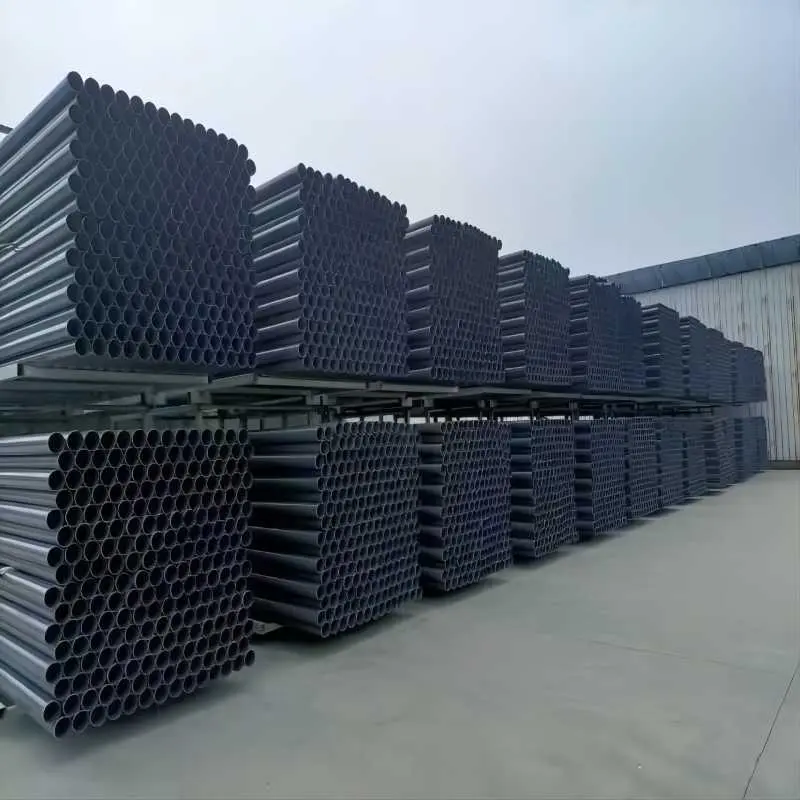

PVC (Polyvinyl Chloride):

Density: PVC has a lower density compared to HDPE, generally ranging from 1.3 to 1.45 g/cm³.

Rigidity: PVC pipes are relatively rigid and strong, suitable for applications where structural integrity is critical.

Chemical Resistance: It is resistant to many acids, alkalis, and salts but may degrade with prolonged exposure to certain chemicals.

Temperature Range: PVC pipes can typically handle temperatures from 0°C to +60°C (32°F to 140°F).

353078.webp)

2. Applications:

HDPE Pipes:

Water Supply: HDPE pipes are widely used for potable water distribution due to their non-toxicity and resistance to corrosion.

Gas Distribution: They are suitable for natural gas and propane distribution networks.

Mining: HDPE pipes are used in mining applications due to their resistance to abrasion and chemicals.

PVC Pipes:

Building and Construction: PVC pipes are commonly used in plumbing and drainage systems in residential and commercial buildings.

Irrigation: They are suitable for agricultural irrigation due to their durability and smooth inner surface.

Electrical Conduits: PVC pipes are used for electrical conduits and cable protection due to their insulating properties.

3. Installation and Maintenance:

HDPE:

Ease of Installation: HDPE pipes are lightweight and flexible, allowing for easier installation, especially in trenchless applications.

Jointing: Fusion welding is used for jointing HDPE pipes, ensuring leak-free connections.

Maintenance: HDPE pipes require minimal maintenance due to their resistance to corrosion and chemical degradation.

PVC:

Installation: PVC pipes are rigid and require careful handling during installation to avoid damage.

Jointing: Solvent welding or threading are common methods for jointing PVC pipes, which require skilled labor.

Maintenance: PVC pipes may require periodic inspections for signs of degradation, especially in environments with exposure to sunlight and certain chemicals.

4. Environmental Impact:

HDPE:

Recyclability: HDPE pipes are highly recyclable and have a lower environmental footprint compared to PVC.

Longevity: They have a longer service life, reducing the need for frequent replacements and associated environmental impacts.

PVC:

Recyclability: PVC pipes can be recycled but face challenges due to the presence of additives.

Disposal: Disposal of PVC pipes may involve incineration, which can release harmful substances into the environment.

5. Cost Considerations:

HDPE: Initially, HDPE pipes may have a higher material cost but offer long-term savings due to lower maintenance and replacement costs.

PVC: PVC pipes generally have lower initial material costs but may incur higher maintenance and replacement costs over their lifespan.

Choosing between HDPE and PVC pipes depends on specific project requirements, including application, environmental factors, installation conditions, and budget considerations. HDPE excels in durability, chemical resistance, and environmental friendliness, while PVC offers strength, rigidity, and affordability. By evaluating these factors comprehensively, stakeholders can make informed decisions that align with their project goals and sustainability objectives.

HDPE vs PVC Pipe: Pros and Cons

Choosing between High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) pipes involves weighing their respective advantages and disadvantages. Here’s a detailed comparison:

HDPE Pipes:

Pros:

Chemical Resistance: Highly resistant to acids, alkalis, and other chemicals, making it suitable for a wide range of applications including industrial and municipal water systems.

Durability: HDPE pipes have excellent resistance to impact and stress cracking, offering long-term performance in harsh environments.

Flexibility: They are lightweight and flexible, allowing for easier handling and installation, particularly in trenchless applications.

Low Maintenance: Requires minimal maintenance due to its resistance to corrosion and abrasion, reducing lifecycle costs.

Environmental Impact: HDPE pipes are recyclable and have a lower carbon footprint compared to PVC.

Cons:

Temperature Limitations: Limited to temperatures ranging from -50°C to +80°C (-58°F to 176°F), which may restrict certain applications.

Jointing Methods: Requires specialized fusion welding equipment and trained personnel for jointing, which can increase installation costs.

Initial Cost: Higher initial material costs compared to PVC pipes, though offset by lower maintenance and replacement costs over time.

PVC Pipes:

Pros:

Affordability: PVC pipes are cost-effective in terms of initial material costs, making them popular for residential and light commercial applications.

Rigidity: Offers strong structural integrity, suitable for applications where pipes need to maintain shape and withstand external pressure.

Chemical Resistance: Resistant to many acids, bases, and salts, though not as universally resistant as HDPE.

Ease of Installation: Lightweight and rigid, facilitating straightforward installation processes using solvent welding or threading methods.

Versatility: Widely used in plumbing, irrigation, and electrical conduit systems due to its versatility and ease of handling.

Cons:

Environmental Concerns: PVC production involves the use of chlorine and may release harmful substances during disposal or incineration.

Limited Longevity: Prone to degradation over time, especially when exposed to sunlight (UV radiation) and certain chemicals.

Brittleness: Compared to HDPE, PVC pipes can be more susceptible to impact damage, requiring careful handling during installation.

Temperature Limitations: Limited to temperatures ranging from 0°C to +60°C (32°F to 140°F), which may restrict use in certain industrial applications.

When deciding between HDPE and PVC pipes, it's essential to consider factors such as application requirements, environmental impact, installation conditions, and lifecycle costs. HDPE pipes excel in durability, chemical resistance, and environmental sustainability, while PVC pipes offer affordability, rigidity, and ease of installation. By evaluating these pros and cons in the context of specific project needs, stakeholders can make informed decisions that optimize performance, longevity, and cost-effectiveness.

948066.webp)

Choosing Between HDPE and PVC Pipes

Selecting the right pipe material, whether High-Density Polyethylene (HDPE) or Polyvinyl Chloride (PVC), depends significantly on the specific application requirements. Here’s a guideline based on various application scenarios:

1. Water Supply Systems:

HDPE Pipes:

Advantages: Ideal for potable water distribution due to its non-toxicity, high chemical resistance, and long-term durability against corrosion.

Recommendation: Choose HDPE pipes for municipal water supply networks, irrigation systems, and industrial water conveyance where reliability and longevity are critical.

PVC Pipes:

Advantages: Cost-effective for residential and light commercial water supply systems, plumbing, and non-potable water applications.

Recommendation: Suitable for indoor plumbing, wastewater drainage, and agricultural irrigation where the operating temperatures and chemical exposure are within PVC’s limits.

2. Gas Distribution Networks:

HDPE Pipes:

Advantages: Excellent resistance to chemicals and abrasion, making them suitable for natural gas and propane distribution.

Recommendation: Opt for HDPE pipes where underground installation and resistance to soil movement and external stresses are critical, ensuring safe and efficient gas distribution.

PVC Pipes:

Advantages: Cost-effective and suitable for low-pressure gas distribution in residential and light commercial settings.

Recommendation: Use PVC pipes for indoor gas piping and where specific codes and regulations permit the use of PVC in gas applications.

3. Industrial Applications:

HDPE Pipes:

Advantages: Superior durability, impact resistance, and chemical resilience make HDPE ideal for industrial applications such as mining slurries, chemical processing, and industrial effluent disposal.

Recommendation: Select HDPE pipes where resistance to abrasion, chemicals, and environmental factors (UV exposure, temperature fluctuations) is crucial for long-term performance.

PVC Pipes:

Advantages: Rigid structure and affordability make PVC suitable for industrial water transport, drainage systems, and non-critical industrial applications.

Recommendation: Use PVC pipes in industrial settings where cost-effectiveness and ease of installation are prioritized over extreme durability requirements.

4. Environmental Considerations:

HDPE Pipes:

Advantages: Highly recyclable, lower environmental impact due to longer lifespan and resistance to degradation.

Recommendation: Prefer HDPE pipes in environmentally sensitive areas, sustainable construction projects, and applications requiring LEED certification or environmental compliance.

PVC Pipes:

Advantages: Recyclable but may release harmful substances during production and disposal.

Recommendation: Use PVC pipes in applications where short-term use, cost efficiency, and specific project constraints outweigh long-term environmental concerns.

5. Infrastructure and Construction Projects:

HDPE Pipes:

Advantages: Flexible, durable, and resistant to impact and abrasion, making them suitable for underground utilities, trenchless installations, and infrastructure projects.

Recommendation: Opt for HDPE pipes in infrastructure projects such as sewer systems, stormwater management, and subsoil drainage where long-term performance and resistance to ground movement are critical.

PVC Pipes:

Advantages: Rigid structure and ease of handling make PVC pipes suitable for building and construction applications, including plumbing, drainage, and electrical conduits.

Recommendation: Use PVC pipes in residential and commercial construction where cost efficiency, ease of installation, and compatibility with building codes are important considerations.

990716.webp)

6. Agricultural and Irrigation Systems:

HDPE Pipes:

Advantages: Resistant to chemicals and abrasion, suitable for irrigation systems, agricultural water distribution, and irrigation pivot systems.

Recommendation: Choose HDPE pipes for agricultural applications where resistance to weather elements, chemicals in fertilizers, and longevity are essential for efficient water management.

PVC Pipes:

Advantages: Cost-effective and suitable for surface irrigation, drip irrigation systems, and agricultural drainage.

Recommendation: Use PVC pipes in agricultural settings where affordability, ease of installation, and compatibility with irrigation fittings and accessories are prioritized.

7. Electrical Conduits and Cable Protection:

HDPE Pipes:

Advantages: Non-conductive, resistant to moisture and chemicals, making them ideal for protecting electrical cables in underground and exposed installations.

Recommendation: Opt for HDPE pipes in electrical and telecommunications infrastructure where durability, longevity, and protection against environmental factors are critical.

PVC Pipes:

Advantages: Insulating properties, ease of installation, and affordability make PVC suitable for electrical conduit systems and cable protection in residential and commercial buildings.

Recommendation: Use PVC pipes for indoor electrical wiring and conduit systems where cost efficiency and compliance with electrical codes are important.

8. Marine and Offshore Applications:

HDPE Pipes:

Advantages: Excellent resistance to saltwater, chemicals, and corrosion, making them suitable for marine and offshore environments.

Recommendation: Opt for HDPE pipes in marine applications such as seawater intake and outfall systems, offshore oil and gas platforms, and aquaculture where durability and resistance to harsh marine conditions are critical.

PVC Pipes:

Advantages: Cost-effective and suitable for non-critical marine applications such as shipbuilding, dockside utilities, and recreational boating facilities.

Recommendation: Use PVC pipes in marine environments where cost efficiency and ease of installation outweigh the need for extreme durability and resistance to chemicals and saltwater.

9. Mining and Slurry Transport:

HDPE Pipes:

Advantages: Abrasion-resistant, tough, and chemically inert, making them ideal for mining slurries, tailings transport, and process water conveyance.

Recommendation: Choose HDPE pipes in mining operations where resistance to abrasion, chemicals, and prolonged exposure to sunlight is crucial for reliable and efficient material transport.

PVC Pipes:

Advantages: Suitable for lighter-duty mining applications, including water supply, drainage, and ventilation systems within mining facilities.

Recommendation: Use PVC pipes in mining environments where cost efficiency and compatibility with mining equipment and infrastructure are primary considerations.

10. Renewable Energy Projects (Solar and Geothermal):

HDPE Pipes:

Advantages: Thermal stability, resistance to chemicals, and longevity make HDPE suitable for geothermal heat exchange systems and solar thermal installations.

Recommendation: Opt for HDPE pipes in renewable energy projects where resistance to high temperatures, chemicals, and environmental factors is critical for long-term performance and efficiency.

PVC Pipes:

Advantages: Cost-effective and suitable for low-pressure solar water heating systems, plumbing, and conduit for electrical wiring in renewable energy infrastructure.

Recommendation: Use PVC pipes in renewable energy projects where affordability, ease of installation, and compatibility with solar and geothermal components are essential.

Choosing between HDPE and PVC pipes involves evaluating factors such as durability, chemical resistance, installation requirements, environmental impact, and lifecycle costs. HDPE pipes excel in applications requiring high durability, chemical resistance, and environmental sustainability, while PVC pipes offer affordability, ease of installation, and versatility in less demanding applications. By aligning these considerations with specific project needs, stakeholders can make informed decisions that optimize performance, longevity, and overall project success.

About Haoyang Environmental

Haoyang Environmental is a prominent HDPE pipe manufacturer and factory based in China, specializing in the production of high-quality piping solutions for a wide range of applications. With a commitment to excellence and innovation, Haoyang Environmental leverages state-of-the-art manufacturing techniques and stringent quality control processes to deliver products that meet international standards.

Our HDPE pipes are known for their exceptional durability, flexibility, and resistance to corrosion and chemicals, making them ideal for various sectors including municipal water supply, agricultural irrigation, industrial applications, and more. We prioritize environmental sustainability in our manufacturing practices, ensuring that our products contribute to efficient and eco-friendly infrastructure solutions.

Backed by a dedicated team of professionals and a robust infrastructure, Haoyang Environmental caters to diverse customer needs with customized solutions and reliable service. Whether for large-scale infrastructure projects or everyday plumbing applications, our HDPE pipes offer superior performance and longevity, supported by comprehensive technical support and after-sales service.

As a trusted name in the industry, Haoyang Environmental continues to innovate and expand its product offerings, maintaining a steadfast commitment to quality, reliability, and customer satisfaction. Contact us today to discover how our HDPE pipes can enhance your projects with durability and efficiency.

103.webp)

897.webp)

942.webp)

237.webp)