What is HDPE liner?

HDPE liner, or High-Density Polyethylene liner, is a flexible membrane product made from High-Density Polyethylene (HDPE) material. HDPE is a thermoplastic plastic with excellent physical and chemical properties, which has led to the wide application of HDPE liner in multiple fields.

Characteristics of HDPE liner

Excellent anti-seepage performance: HDPE liner has outstanding anti-seepage capabilities, effectively preventing the penetration of liquids or gases and protecting groundwater and other sensitive environments from pollution.

High durability: HDPE material has good weather resistance and chemical corrosion resistance, allowing it to be used in harsh environments for long periods without easily aging or damaging.

Easy construction: HDPE liner is lightweight and flexible, making it convenient for transportation and installation. It can form a continuous waterproof layer through hot-melt welding and other methods, resulting in high construction efficiency.

Environmentally friendly and non-toxic: HDPE material is non-toxic and odorless, does not contain harmful substances, meets environmental protection requirements, and can be widely used in drinking water ponds, fish ponds, and other occasions where water quality safety needs to be ensured.

Application areas of HDPE liner

Environmental engineering: Used for anti-seepage treatment of the bottom and sidewalls of environmental protection facilities such as refuse landfills, sewage treatment ponds, and hazardous waste disposal sites.

Water conservancy projects: Used for anti-seepage treatment of water conservancy projects such as reservoirs, dams, and channels, enhancing the stability and safety of the projects.

Construction engineering: Used for waterproof and moisture-proof treatment of basement, tunnels, subways, and other construction projects, ensuring the stability and durability of the building structure.

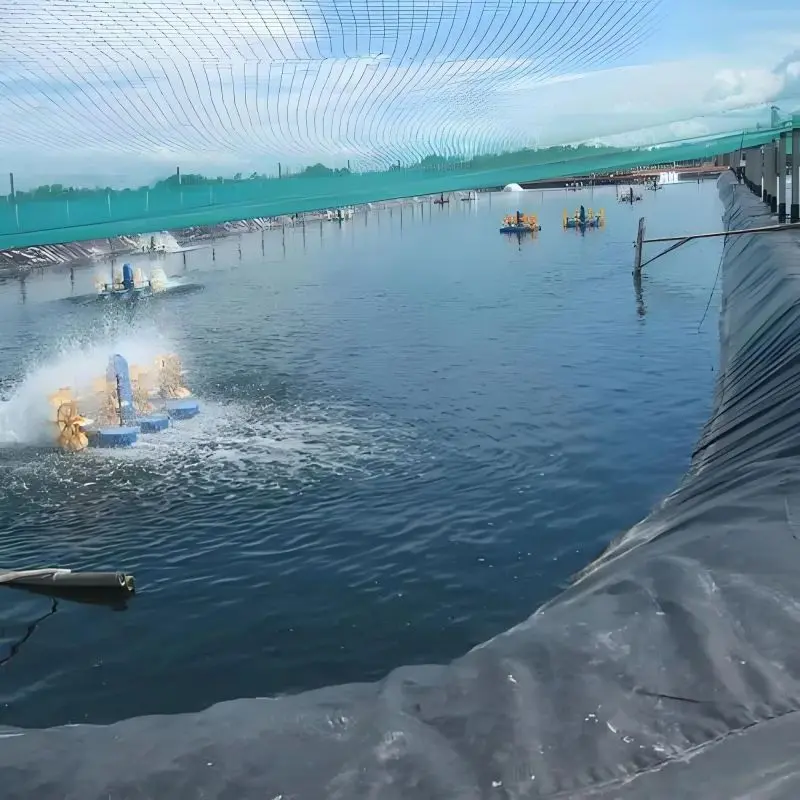

Agricultural engineering: Used for anti-seepage treatment of the bottom and sidewalls of aquaculture facilities such as fish ponds and shrimp ponds, improving aquaculture efficiency and production.

Specifications and prices of HDPE liner

HDPE liner comes in various specifications, including different thicknesses, widths, and lengths. The specific specifications need to be selected based on the usage occasion and engineering requirements. In terms of price, due to factors such as market supply and demand relationships and fluctuations in raw material prices, the price of HDPE liner may vary. Generally, retail prices are relatively higher, while factory prices or bulk purchase prices are more competitive.

In summary, HDPE liner is a flexible membrane product with excellent anti-seepage performance, high durability, easy construction, and environmental friendliness and non-toxicity. It has been widely used in multiple fields such as environmental protection, water conservancy, construction, and agriculture. When selecting HDPE liner, it is essential to choose the appropriate specifications and suppliers based on specific usage occasions and engineering requirements to ensure engineering quality and economic benefits.

HDPE liner Specifications

HDPE (High-Density Polyethylene) liners are used in various applications, such as landfills, water reservoirs, canals, and ponds, due to their excellent impermeability and resistance to chemical reactions. Here are some common specifications for HDPE liners:

Thickness:

0.5 mm (20 mil)

0.75 mm (30 mil)

1.0 mm (40 mil)

1.5 mm (60 mil)

2.0 mm (80 mil)

2.5 mm (100 mil)

3.0 mm (120 mil)

Width:

5.8 meters (19 feet)

7.0 meters (23 feet)

Length:

Customizable based on project requirements, typically in rolls of 50 meters (164 feet) or 100 meters (328 feet).

Density:

0.94 g/cm³ to 0.96 g/cm³

Tensile Strength:

27 MPa to 33 MPa

Elongation at Break:

700% to 900%

Carbon Black Content:

2% to 3%

Standards and Certifications:

ASTM D1505 (Density)

ASTM D638 (Tensile Properties)

ASTM D1004 (Tear Resistance)

ASTM D746 (Low Temperature Impact)

ASTM D1238 (Melt Flow Index)

Applications:

Landfill liners and covers

Water reservoirs

Pond liners

Canal liners

Wastewater treatment plants

Mining

Agriculture

These specifications can vary depending on the manufacturer and specific application requirements. Always consult with the supplier or manufacturer to ensure the HDPE liner meets the project’s needs.

The Cost of HDPE Liners: Market, Distributor, and Factory Prices

High-Density Polyethylene (HDPE) liners are essential in numerous industries due to their exceptional impermeability, chemical resistance, and durability. They are commonly used in landfills, water reservoirs, canals, and ponds, providing an effective barrier against leaks and contamination. Understanding the cost of HDPE liners is crucial for budgeting and project planning. This article will explore the different pricing tiers of HDPE liners, including market prices, distributor prices, and factory prices.

Market Prices

The market price of HDPE liners varies widely depending on several factors, including thickness, width, length, and specific application requirements. As of the current market trends, HDPE liners typically range from $0.50 to $2.50 per square foot. This broad range is influenced by the liner's specifications, the quality of the material, and the brand. Thicker liners with higher tensile strength and elongation at break tend to be more expensive due to their enhanced performance and durability.

For instance, a 1.0 mm (40 mil) thick HDPE liner might cost around $0.75 per square foot, while a 2.0 mm (80 mil) thick liner could be priced at approximately $1.50 per square foot. Customization options, such as specific widths and lengths tailored to project needs, can also affect the final market price. It is advisable to consult multiple suppliers to get accurate quotes and compare prices to find the best deal.

Distributor Prices

Distributors play a crucial role in the supply chain by bridging the gap between manufacturers and end-users. They purchase HDPE liners in bulk from factories and sell them to contractors, businesses, and consumers. Distributor prices are generally lower than market prices but higher than factory prices due to the added value of inventory management, customer service, and logistical support.

Typically, distributor prices for HDPE liners can range from $0.40 to $2.00 per square foot. Distributors often offer discounts for large volume purchases, making them a cost-effective option for sizeable projects. For example, purchasing a bulk order of 1.5 mm (60 mil) thick HDPE liners from a distributor might cost around $1.20 per square foot, compared to a higher market price.

Additionally, distributors may provide technical support, installation services, and warranty options, which add value beyond just the product cost. When considering distributor prices, it is essential to factor in these additional services and benefits.

Factory Prices

Factory prices, also known as ex-factory prices, are the lowest in the supply chain. These prices represent the cost of the HDPE liners directly from the manufacturing facility, excluding any additional distribution or retail markups. Factory prices are typically reserved for large-scale buyers, such as wholesalers, contractors, and industrial clients who can purchase in bulk.

Factory prices for HDPE liners can range from $0.30 to $1.50 per square foot, depending on the specifications and order quantity. For instance, a 2.5 mm (100 mil) thick HDPE liner might be available for around $1.00 per square foot when purchased directly from the factory in large quantities. However, it is essential to consider the logistics, such as shipping and handling costs, when calculating the total expenditure.

Purchasing directly from the factory offers the advantage of the lowest per-unit cost and the possibility of customizing products to meet specific project requirements. However, it also requires significant upfront investment and often involves longer lead times compared to buying from distributors or the market.

Conclusion

The cost of HDPE liners varies across market, distributor, and factory prices, each offering different benefits and trade-offs. Market prices provide convenience and accessibility but at a higher cost. Distributor prices offer a balance between cost and added services, making them suitable for medium to large-scale projects. Factory prices are the most cost-effective for bulk purchases, ideal for large industrial applications.

When budgeting for HDPE liners, it is crucial to consider not only the per-square-foot cost but also the overall value, including quality, service, and logistical factors. By thoroughly researching and comparing different suppliers, project managers can make informed decisions that optimize both cost and performance for their specific needs.

How to use HDPE Liners

Using HDPE liners involves a series of steps to ensure proper installation and functionality. Below is a step-by-step guide on how to use HDPE liners, accompanied by an illustrative example.

Step-by-Step Guide to Using HDPE Liners

Preparation and Planning:

Site Assessment: Conduct a thorough assessment of the site where the HDPE liner will be installed. Identify any potential obstacles or areas of concern.

Design and Specification: Determine the required specifications for the HDPE liner, including thickness, width, and length, based on the specific application and engineering requirements.

Material Procurement: Order the HDPE liner from a reputable supplier, ensuring it meets all relevant standards and specifications.

Surface Preparation:

Clearing and Leveling: Clear the installation area of any debris, rocks, or vegetation. Level the surface to ensure a smooth foundation for the liner.

Compaction: Compact the soil to provide a stable base for the HDPE liner. This is especially important for areas with soft or loose soil.

Liner Laying:

Unrolling: Carefully unroll the HDPE liner onto the prepared surface. Use a roller or other equipment to smooth out any wrinkles or folds.

Overlapping: If necessary, overlap sections of the liner to ensure complete coverage. Follow the manufacturer's recommendations for the minimum overlap length.

Seaming and Welding:

Seam Marking: Mark the areas where seams will be created using a suitable marker.

Welding Equipment: Prepare the hot-air welding equipment according to the manufacturer's instructions.

Welding: Perform hot-air welding along the marked seams, creating a strong and continuous bond between the liner sections. Ensure that the welding temperature and speed are adjusted correctly for the specific HDPE liner material.

Anchoring and Securing:

Anchoring System: Install an anchoring system to secure the edges of the HDPE liner in place. This could involve using anchor trenches, sandbags, or other methods.

Inspection: Thoroughly inspect the entire liner installation for any defects, punctures, or areas of concern.

Backfilling and Finalization:

Backfilling: Backfill the area around the HDPE liner with suitable material, such as soil or gravel. Compact the backfill material as needed to provide additional support and stability.

Final Inspection: Conduct a final inspection to ensure that the installation meets all design and engineering requirements.

Illustrative Example

Application: A fish pond in a residential backyard

Steps:

Preparation and Planning: The homeowner assesses the site, measures the dimensions of the proposed fish pond, and orders a HDPE liner with the appropriate specifications from a local supplier.

Surface Preparation: The homeowner digs out the area for the fish pond, levels the bottom, and compacts the soil to create a stable base.

Liner Laying: The homeowner carefully unrolls the HDPE liner into the pond area, using a roller to smooth out any wrinkles. No overlapping is required as the liner is large enough to cover the entire pond.

Seaming and Welding: In this case, no seaming or welding is necessary as the liner fits perfectly into the pond area without the need for seams. However, if seams were required, the homeowner would have used a hot-air welding machine to create strong bonds between the liner sections.

Anchoring and Securing: The homeowner installs an anchoring system around the edges of the pond to hold the HDPE liner in place. This involves digging small trenches and filling them with soil or gravel to anchor the liner edges.

Backfilling and Finalization: The homeowner backfills the area around the pond with soil, taking care not to damage the HDPE liner. After backfilling, the homeowner performs a final inspection to ensure that the liner installation is complete and free of defects. The fish pond is now ready for use.

Detailed usage and example description of HDPE Liners

I. Detailed usage

Design planning:

Design the size, thickness and performance requirements of HDPE liners according to specific project requirements (such as reservoirs, landfills, aquaculture ponds, etc.).

Take into account the long-term stability of the project and the impact of environmental factors (such as groundwater level, soil pH, etc.) on HDPE liners.

Material procurement and inspection:

Purchase HDPE liners that meet project requirements from reliable suppliers.

Inspect the quality of the HDPE liners that arrive to ensure that they are free of damage, cracks, and meet relevant standards.

Foundation treatment:

Remove debris from the laying area to ensure that the foundation is flat and solid.

Compact the foundation as needed to improve the bearing capacity and stability of HDPE liners.

Laying and welding:

Before laying HDPE liners, lay a layer of protective material (such as sand, geotextile, etc.) underneath them to prevent sharp objects from piercing the HDPE liners.

Carefully lay the HDPE liners to the predetermined position, taking care to avoid folding and excessive stretching.

If you need to splice HDPE liners, use a professional hot melt welding machine for welding. Before welding, make sure the welding surface is clean, dry, and free of oil and impurities. When welding, control the welding temperature and speed to ensure the quality of the weld.

Anchoring and fixing:

Anchor trenches or anchor points are set around the HDPE liners, and anchors (such as anchor nails, pressure strips, etc.) are used to fix them to the ground.

Ensure that the anchoring system is firm and reliable to prevent the HDPE liners from shifting or floating during subsequent use.

Backfilling and covering:

After the HDPE liners are laid and fixed, backfilling should be carried out in time. The backfilling material should be granular materials without sharp edges (such as sand, gravel, etc.) to avoid piercing the HDPE liners.

During the backfilling process, it should be compacted layer by layer to ensure the density and stability of the backfilling material.

As needed, one or more protective layers (such as geomembranes, vegetation layers, etc.) are laid on top of the HDPE liners to improve their anti-aging performance and aesthetics.

Post-maintenance:

Inspect and maintain HDPE liners regularly to ensure they are intact and function properly.

If damage or aging is found, they should be repaired or replaced in time.

II. Example

Example: Use of HDPE liners in a landfill

Project background: A new landfill was built in a city. In order to prevent leachate from polluting groundwater, it was decided to use HDPE liners as an anti-seepage layer.

Design and planning: According to the scale of the landfill, daily processing volume, groundwater level and other factors, the thickness of the HDPE liners is designed to be 2.0mm, and the width is customized according to the shape of the bottom of the landfill. At the same time, considering the gas pressure that may be generated during the landfill process, the HDPE liners are designed to have a certain puncture resistance and tensile strength.

Material procurement and inspection: Purchase materials that meet the design requirements from well-known domestic HDPE liners manufacturers and conduct strict quality inspections.

Foundation treatment: Remove stones, tree roots and other debris at the bottom of the landfill, and level and compact them. Before laying the HDPE liners, lay a layer of sand cushion with a thickness of not less than 30cm as a protective layer.

Laying and welding: Use large mechanical equipment to transport the HDPE liners to the landfill site and carefully lay them to the predetermined location. During the laying process, be careful to avoid contact between the HDPE liners and sharp objects. If you need to splice the HDPE liners, use a professional hot melt welding machine for welding to ensure that the weld quality meets the relevant standards.

Anchoring and fixing: Set up anchor trenches around the HDPE liners and use anchors to fix them to the ground. At the same time, set up cofferdams and infiltration systems around the landfill to prevent rainwater from flowing into the landfill.

Backfilling and covering: After the HDPE liners are laid and fixed, backfilling work should be carried out in time. The backfill materials should be sand, gravel and other materials without sharp edges, and compacted layer by layer. During the landfill process, pay attention to controlling the height and speed of the landfill to avoid excessive pressure on the HDPE liners. After the landfill is completed, a geomembrane is laid on top of the HDPE liners as a protective layer to improve its anti-aging performance.

Through the implementation of the above steps, the landfill successfully used HDPE liners as an anti-seepage layer, effectively preventing the pollution of groundwater by leachate. At the same time, the excellent performance of HDPE liners also ensures the long-term stability and safety of the landfill.

Do you have to choose the lowest-priced HDPE liner?

When choosing HDPE liners, you don't necessarily have to choose the lowest-priced one. Although price is one of the considerations, it is more important to ensure that the HDPE liners can meet the specific needs of the project and long-term stability. Here are some key factors to consider when choosing HDPE liners:

Project requirements:

First, it is necessary to clarify what project the HDPE liners will be used for, such as landfills, reservoirs, aquaculture ponds, etc. Different projects may have different performance requirements for HDPE liners, such as anti-seepage performance, puncture resistance, tensile strength, etc.

Material quality:

The quality of HDPE liners directly affects its anti-seepage effect and service life. Therefore, products with reliable quality and in compliance with relevant standards should be selected. This usually means choosing a well-known brand, a supplier with a good reputation, and checking the quality inspection report of the product.

Thickness and size:

Choose the appropriate thickness and size of HDPE liners according to the specific needs of the project. Thicker HDPE liners usually have better anti-seepage performance and puncture resistance, but they will also increase costs. Therefore, it is necessary to reasonably control costs while meeting the needs of the project.

Durability: Consider the durability of HDPE liners, including their anti-aging properties, UV resistance, etc. These properties will directly affect the service life and maintenance cost of HDPE liners.

Construction and maintenance: Choose HDPE liners that are easy to construct and maintain. For example, some HDPE liners have hot-melt welding interfaces, which are usually more solid and reliable than mechanical interfaces, but professional welding equipment and technology are required during construction. Therefore, when choosing HDPE liners, construction conditions and technical requirements also need to be considered.

Price and cost-effectiveness: Although price is one of the considerations, it should not be the only factor. When comparing the prices of different suppliers and products, the above factors need to be considered comprehensively to select the most cost-effective HDPE liners.

After-sales service: High-quality after-sales service can ensure that problems encountered during use can be solved in a timely manner. Therefore, when choosing HDPE liners, the supplier's after-sales service capabilities and commitments should also be considered.

In summary, when choosing HDPE liners, multiple factors such as project requirements, material quality, thickness and size, durability, construction and maintenance, price and cost-effectiveness, and after-sales service should be considered comprehensively. While price is important, it should not be the only deciding factory.

About Haoyang Environmental

Haoyang Environmental is a well-known HDPE liner (high-density polyethylene anti-seepage membrane) production factory in China, dedicated to providing high-quality environmentally friendly anti-seepage solutions. As an enterprise focusing on the field of environmental protection, Haoyang Environmental has advanced production technology and rich industry experience, and its products are widely used in landfills, reservoirs, aquaculture ponds and other fields. The factory pays attention to material quality and uses high-quality high-density polyethylene raw materials to ensure that the HDPE liner has excellent anti-seepage performance, puncture resistance and durability. At the same time, Haoyang Environmental also pays attention to technological innovation and product research and development, and continuously launches new products that meet market demand to meet the specific requirements of different projects. With excellent product quality and high-quality customer service, Haoyang Environmental enjoys a good reputation in the HDPE liner market in China and Southeast Asia, and is committed to providing customers with the best anti-seepage solutions and environmental protection support.

Because the price needs real-time quotation, please give me your most detailed specifications and requirements, our experts will give you the most cost-effective ex-factory HDPE liners price

897.webp)

942.webp)

237.webp)