There are many types of geotextiles. Filament spun clay geotextiles and filament woven geotextiles are two types of geotextiles. They are very similar in color and application fields. It is difficult for us to distinguish them in daily use. Below are From several aspects, I would like to introduce to you the characteristics of filament spun clay geotextiles and filament woven geotextiles and their specific differences:

Both filament spunbond needle punched non-woven geotextiles and filament woven geotextiles are filament geotextiles, but one is a non-woven geotextile and the other is a woven geotextile. What are the characteristics and differences between these two geotextiles? The following is an introduction to the differences between filament spunbond needle-punched non-woven geotextiles and filament woven geotextiles:

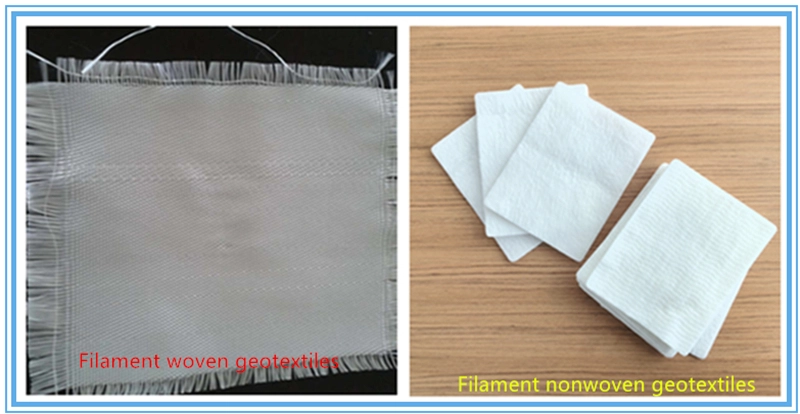

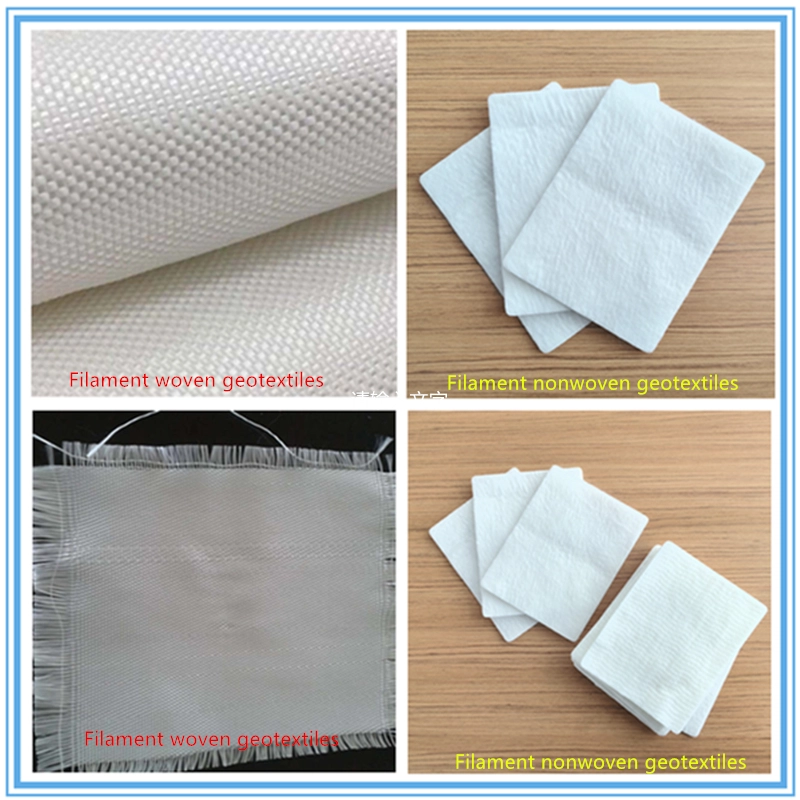

1. Introduction to filament non-woven geotextiles and filament woven geotextiles

Filament spunbond non-woven geotextile: Filament non-woven geotextile is a polyester filament spunbond needle-punched non-woven geotextile. It is an environmentally friendly geotechnical construction material produced from polyester raw materials through a series of processes. . It can replace traditional engineering materials and construction methods, make construction safer, contribute to environmental protection, and solve basic problems in engineering construction more economically and effectively.

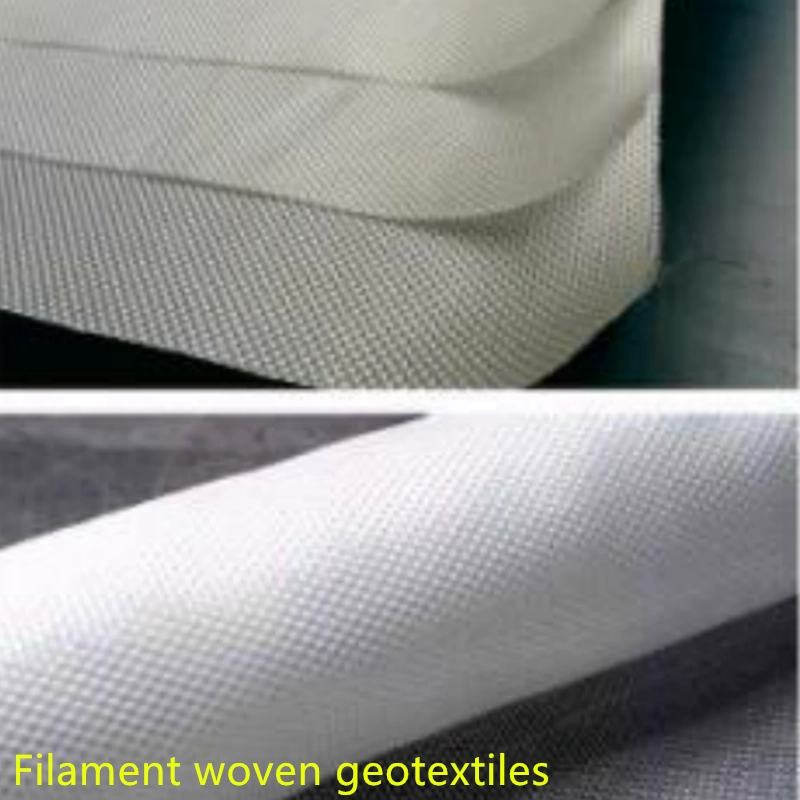

Filament woven geotextile: Filament woven geotextile is a fabric woven from two sets of silk shuttles. The varieties are divided into single-layer woven geotextile (also known as geofilter cloth) and double-layer woven geotextile (also known as geofilter cloth) according to their uses. Also known as geomembrane bag cloth) and woven anti-seepage cloth. It is mainly made of high-strength, low-elongation polypropylene, polyester and other synthetic fiber filaments.

2. The difference between filament non-woven geotextile and filament woven geotextile

(a) From the appearance

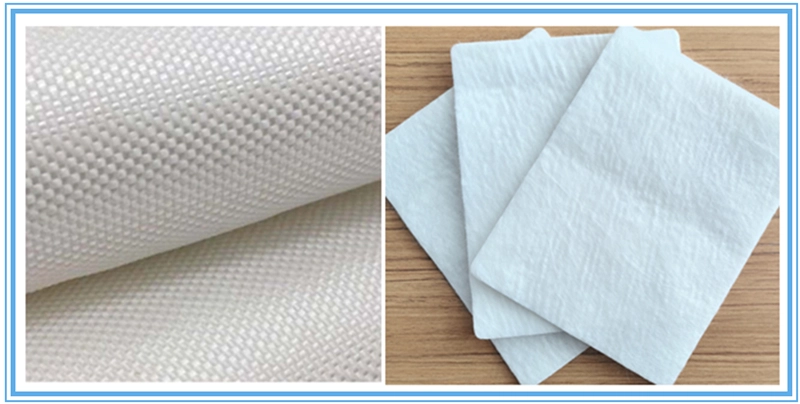

Filament spunbond non-woven geotextiles are generally white and shiny geotextiles with a dense and seamless structure; filament woven geotextiles are generally white and shiny, but because they are warp and weft woven geotextiles, they have pores. This is also the biggest difference between the two.

(b) Applicable standards

The applicable standard for filament spun clay textiles is GBT17639-2023

The applicable standard for filament woven geotextiles is GBT17640-2008

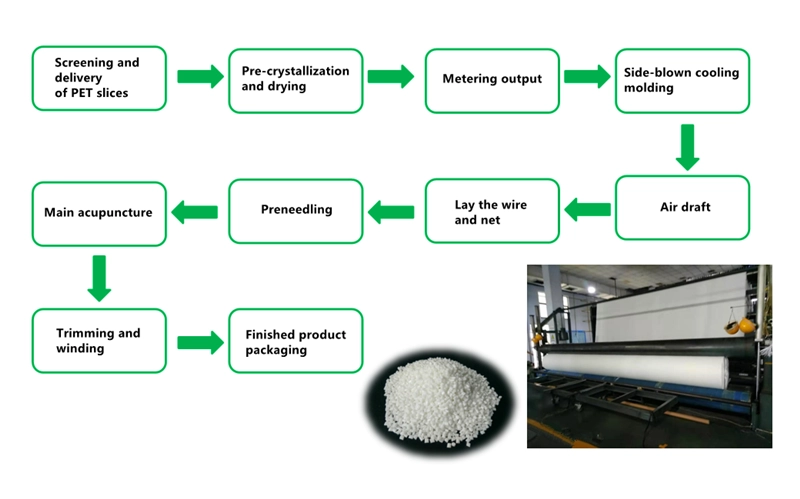

(c) In terms of process flow

The production process of filament spun clay nonwoven fabrics: The production process of filament spun clay woven fabrics mainly includes raw material screening, extrusion melting, cooling, netting, needle punching, reeling, cutting, packaging, etc.;

Filament nonwoven geotextile production process diagram

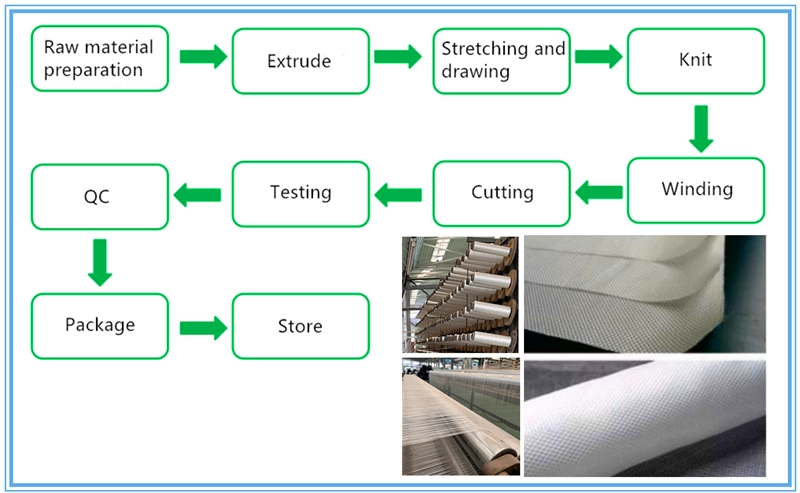

The production process of filament woven geotextiles mainly includes yarn production, warp and weft weaving, reeling, finishing and cutting, etc.

Filament woven geotextile production process diagram

The difference in the process flow of the two determines the difference in structure and performance, so selection needs to be made when applying in different engineering fields.

(d) In terms of characteristics

Performance characteristics of filament spun clay fabric: It can replace traditional engineering materials and construction methods, make construction safer, contribute to environmental protection, and solve basic problems in engineering construction more economically, effectively and permanently. Filament geotextile has good mechanical properties, good water permeability, corrosion resistance, and anti-aging. It has the functions of isolation, filtering, drainage, protection, stabilization, reinforcement, etc. It can adapt to uneven base layers and resist external construction forces. It has little damage and creep, and can still maintain its original functions under long-term load.

Characteristics of filament woven geotextile: high mechanical strength such as tensile resistance, tear resistance, burst resistance, puncture resistance, etc., which is more than double that of short fiber geotextiles of the same weight, especially the burst resistance and puncture resistance reaching More than 2200 Newtons, in stone slope protection, it can effectively prevent the impact of irregular stones on the cloth surface; it has good elongation performance, fast stress dispersion and transmission, so that the load can be evenly distributed; the friction coefficient is large, and it is not easy to slip during construction; it is resistant to Excellent chemical properties; strong corrosion resistance.

Comparison chart of filament non-woven geotextiles and filament woven geotextiles

(e) In application fields

Application areas of filament spun clay fabrics: Suitable for soil protection and stabilization, and can be used in road foundations, slope protection, and water conservancy projects. Provides anti-seepage function and can be used to prevent liquids from penetrating into the soil, such as ponds, reservoirs and other anti-seepage projects. It is suitable for scenes that require soil permeability to help water penetration, drainage and maintain soil structure stability.

Application areas of filament woven geotextiles:

Large-scale foundation projects: Usually used for larger foundation projects that require greater strength and stability, such as bridge foundations, tunnel projects, etc.

Geotechnical Engineering: Used in geotechnical engineering to provide higher tensile strength and stability, helping the surface structure to be more stable.

Coastal protection: Used in coastal protection projects to provide higher weather resistance and durability to prevent seawater erosion and soil loss.

These differences mainly depend on the characteristics and performance of the two geotextiles, and the appropriate geotextile is selected according to the specific needs and environmental conditions of the project.

The following are the product links of Haoyang Environment's specific filament non-woven geotextiles and filament woven geotextiles, you can click for reference.

Filament non-woven waterproofing reinforced drainage geotextiles

Porous filament woven geotextile as raw material for mold bags

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

897.webp)

942.webp)

237.webp)