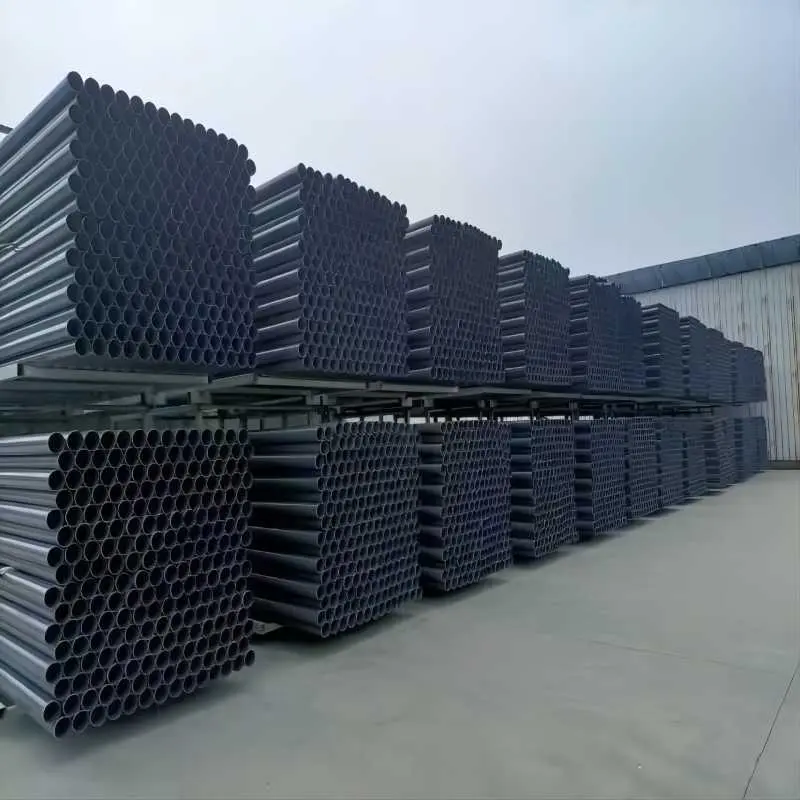

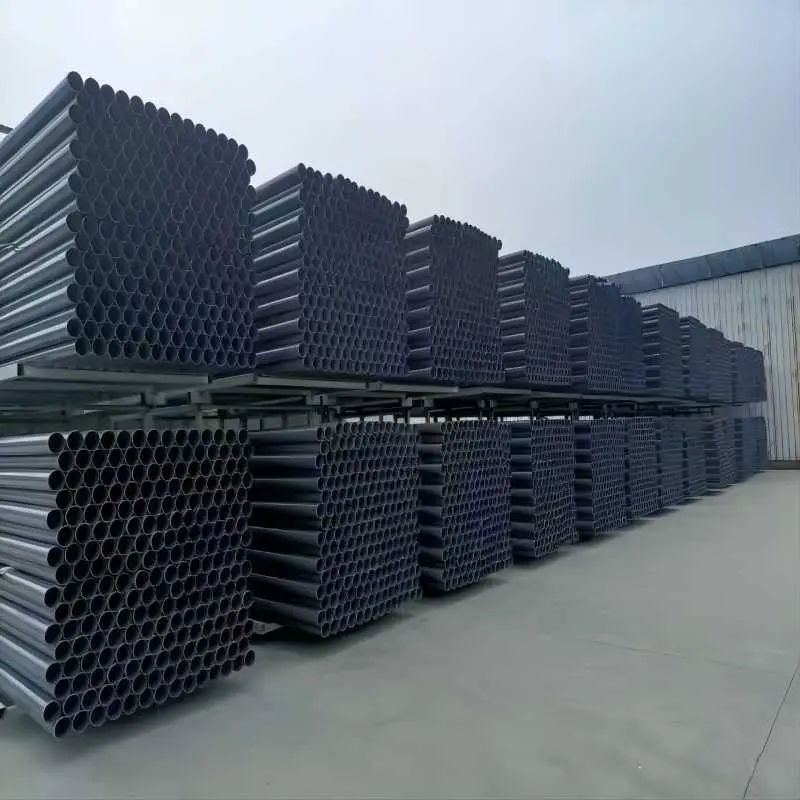

Is HDPE Pipe Safe for Drinking Water?

When it comes to the infrastructure of modern water supply systems, the choice of piping material plays a crucial role in ensuring the safety and quality of drinking water. Among the various materials available, High-Density Polyethylene (HDPE) pipes have gained widespread acceptance due to their durability, flexibility, and cost-effectiveness. But a fundamental question remains: Is HDPE pipe safe for drinking water? In this article, we will explore the safety of HDPE pipes in water supply systems, examining their chemical composition, regulatory approvals, performance in real-world applications, and any associated health concerns. We'll also discuss the environmental impact of HDPE pipes and conclude with an introduction to Haoyang Environmental Co., Ltd., a leading provider of environmental engineering materials.

Understanding HDPE Pipes

HDPE, or High-Density Polyethylene, is a thermoplastic polymer made from petroleum. Known for its high strength-to-density ratio, HDPE is commonly used in the production of plastic bottles, corrosion-resistant piping, and geomembranes. The material's robustness and resistance to chemicals make it an ideal candidate for various applications, including drinking water pipelines.

HDPE pipes are manufactured through a process called extrusion, where molten HDPE is shaped into pipes of various diameters and thicknesses. These pipes are then subjected to rigorous testing to ensure they meet the required standards for use in potable water systems.

Chemical Composition and Safety

The primary concern with any material used in drinking water systems is whether it can leach harmful substances into the water. HDPE pipes are made from virgin polyethylene resin, which is chemically stable and inert. This means that under normal conditions, HDPE does not release harmful chemicals into the water.

In fact, HDPE pipes are known for their excellent chemical resistance, which is why they are widely used in transporting not only drinking water but also chemicals, wastewater, and other fluids. They are free from lead, phthalates, and other harmful substances that can be found in some older piping materials such as polyvinyl chloride (PVC) or metal pipes.

Regulatory Approvals and Certifications

HDPE pipes used for drinking water applications must meet stringent safety standards set by various regulatory bodies around the world. In the United States, for example, HDPE pipes must comply with the standards set by the American Water Works Association (AWWA) and be certified by the National Sanitation Foundation (NSF) for potable water use.

In Europe, HDPE pipes are required to meet the European Union's directives on drinking water safety, specifically the Drinking Water Directive (98/83/EC). These pipes must also be certified by national certification bodies, such as the German Technical and Scientific Association for Gas and Water (DVGW), to ensure they are safe for drinking water applications.

Performance in Real-World Applications

One of the key advantages of HDPE pipes is their long service life, which can exceed 50 years under normal operating conditions. This longevity is partly due to the material's resistance to corrosion, scaling, and biological growth, which are common issues in metal and other types of plastic pipes.

In addition to their durability, HDPE pipes are also highly flexible, allowing them to withstand ground movements, such as earthquakes or soil subsidence, without cracking or breaking. This flexibility reduces the likelihood of leaks and ensures a consistent supply of clean drinking water.

Studies and field data have shown that HDPE pipes perform exceptionally well in both cold and hot water applications. Their low thermal conductivity minimizes heat loss in hot water systems and prevents the water from freezing in cold climates.

Health Concerns and Research Findings

While HDPE pipes are generally considered safe for drinking water, some concerns have been raised regarding the potential leaching of additives used in the manufacturing process. For instance, antioxidants and stabilizers are often added to HDPE to enhance its performance and longevity. There is ongoing research to determine whether these additives can migrate into drinking water and, if so, at what levels.

So far, studies have indicated that any migration of these substances is minimal and well within the safety limits established by regulatory agencies. Moreover, the water quality testing conducted by utility companies consistently shows that water transported through HDPE pipes meets all health and safety standards.

It is also worth noting that HDPE pipes have been used in water distribution systems for decades, with no widespread reports of adverse health effects. This long track record of safe use further supports the conclusion that HDPE pipes are a safe choice for drinking water applications.

Environmental Impact

In addition to being safe for drinking water, HDPE pipes are also environmentally friendly. They have a lower carbon footprint compared to metal pipes, both in terms of manufacturing and transportation. HDPE is also recyclable, which means that at the end of their service life, the pipes can be reprocessed into new products, reducing the need for virgin materials.

Furthermore, the production of HDPE pipes requires less energy and generates fewer greenhouse gases compared to traditional materials like steel or concrete. This makes HDPE an attractive option for municipalities and water utilities looking to reduce their environmental impact.

HDPE Pipes Compare to Other Materials Like PVC and Copper for Drinking Water

HDPE (High-Density Polyethylene) pipes have become a popular choice for drinking water distribution systems due to their numerous advantages over traditional materials like PVC (Polyvinyl Chloride) and copper. Understanding the key differences between these materials can help you make an informed decision about which type of pipe is best suited for your needs.

Durability and Longevity

One of the primary advantages of HDPE pipes is their durability. HDPE pipes are highly resistant to corrosion, scaling, and biological growth, which can be significant issues with metal pipes like copper. Copper pipes, while known for their longevity, can corrode over time, especially in areas with acidic or mineral-laden water. Corrosion can lead to leaks, water contamination, and the need for frequent maintenance or replacement.

PVC pipes, on the other hand, are also resistant to corrosion but are less flexible and durable compared to HDPE. PVC pipes are more prone to cracking under stress, such as ground movements or temperature fluctuations. In contrast, HDPE pipes have a high impact resistance and flexibility, allowing them to withstand such stresses without damage. This flexibility is particularly beneficial in seismic zones or areas with unstable soil.

Health and Safety

When it comes to health and safety, HDPE pipes have a strong track record. They are made from virgin polyethylene resin, which is chemically inert and does not leach harmful substances into the drinking water. This makes HDPE pipes a safe option for potable water systems.

PVC pipes, while widely used, contain additives like plasticizers and stabilizers that can potentially leach into the water over time. Some studies have raised concerns about the long-term health effects of these additives, although the levels are generally considered safe by regulatory agencies.

Copper pipes, although naturally antimicrobial, can leach copper into the water, especially if the water is acidic. High levels of copper can lead to health issues, particularly in infants and individuals with Wilson's disease. The EPA has set a maximum contaminant level goal (MCLG) for copper at 1.3 mg/L, and exceeding this limit can be harmful.

Cost and Installation

Cost is another factor where HDPE pipes often have an edge. HDPE pipes are generally more affordable than copper pipes, both in terms of material cost and installation. Copper is a valuable metal, and its price fluctuates significantly, often making it a more expensive option.

HDPE pipes are also easier and less costly to install. They can be joined using heat fusion, which creates a seamless, leak-proof connection. This method reduces the risk of leaks and water loss over time. PVC pipes, while also affordable, require solvent welding or gasketed joints, which may not be as reliable as fusion welding in HDPE.

In contrast, copper pipes require soldering, which can be labor-intensive and requires skilled labor, increasing the installation cost.

Environmental Impact

Environmental considerations are becoming increasingly important in material selection. HDPE pipes have a lower environmental impact compared to copper and PVC. HDPE is recyclable, and the production process requires less energy and generates fewer greenhouse gases than metal pipe production.

PVC production involves the use of chlorine, which has environmental and health concerns, particularly during manufacturing and disposal. Copper mining and production are also energy-intensive and can lead to significant environmental degradation.

Case Study: The City of Palo Alto's Transition to HDPE

A notable example of HDPE's advantages can be seen in the city of Palo Alto, California. The city undertook a major water infrastructure project in which they replaced aging copper and PVC pipes with HDPE. The reasons for the switch included HDPE's longer lifespan, resistance to earthquakes, and lower maintenance costs.

Since the transition, Palo Alto has reported fewer leaks and a significant reduction in maintenance costs. The project also highlighted the ease of installation and the environmental benefits of HDPE, reinforcing the material's growing popularity in municipal water systems.

HDPE pipes offer a compelling alternative to PVC and copper for drinking water systems, with superior durability, safety, cost-effectiveness, and environmental benefits. Whether for residential, commercial, or municipal applications, HDPE stands out as a reliable, long-term solution for clean and safe water distribution.

Are There Any Health Risks Associated with HDPE Pipes for Drinking Water?

The safety of drinking water is a top priority for any community, and the materials used in water distribution systems play a critical role in maintaining that safety. HDPE (High-Density Polyethylene) pipes are widely regarded as safe for drinking water applications, but like any material, they come under scrutiny.

Chemical Stability and Inertness

HDPE pipes are made from virgin polyethylene resin, which is known for its chemical stability and inertness. This means that HDPE does not react with the substances it comes into contact with, including drinking water. As a result, HDPE pipes do not leach harmful chemicals or contaminants into the water, making them a safe choice for potable water systems.

Numerous studies have confirmed the safety of HDPE in drinking water applications. For instance, a study by the National Sanitation Foundation (NSF) found that HDPE pipes used in potable water systems do not release harmful levels of any substances that would compromise water quality. The NSF has certified HDPE pipes for potable water use, further affirming their safety.

Concerns About Additives

One area of concern with HDPE pipes is the potential for leaching of additives used in the manufacturing process. To enhance the performance and longevity of HDPE pipes, manufacturers often add antioxidants, UV stabilizers, and other additives. The question arises: can these additives migrate into the drinking water, and if so, are they harmful?

Research indicates that while some additives may leach into the water, the levels are extremely low and well within safety limits established by regulatory bodies like the Environmental Protection Agency (EPA) and the European Union (EU). For example, a study published in the Journal of Water Supply: Research and Technology-AQUA found that the migration of additives from HDPE pipes was minimal and did not pose a risk to human health.

Moreover, the additives used in HDPE pipes are carefully selected and regulated to ensure they are safe for use in drinking water systems. These additives are typically tested for their potential to leach and for any health risks they might pose before being approved for use.

Biofilm Formation and Bacterial Growth

Another concern with plastic pipes, including HDPE, is the potential for biofilm formation. Biofilms are colonies of bacteria that can develop on the interior surfaces of pipes. If not properly managed, biofilms can harbor harmful pathogens and compromise water quality.

However, studies have shown that HDPE pipes are less prone to biofilm formation compared to other materials like PVC. This is because HDPE’s smooth surface and chemical resistance make it difficult for bacteria to adhere and multiply. Additionally, HDPE pipes can be treated with disinfectants like chlorine, which effectively controls biofilm growth.

For example, a study conducted by the Water Research Foundation found that HDPE pipes in water distribution systems exhibited lower levels of biofilm growth compared to other plastic materials. The study concluded that HDPE is a safe and reliable material for drinking water systems, with no significant risk of bacterial contamination.

Regulatory Oversight and Certification

HDPE pipes are subject to rigorous testing and certification processes to ensure they are safe for drinking water. In the United States, the NSF certifies HDPE pipes for potable water use, ensuring they meet the standards set by the American Water Works Association (AWWA) and other regulatory bodies. In Europe, HDPE pipes must comply with the Drinking Water Directive (98/83/EC) and obtain certification from national agencies like the DVGW in Germany.

These certifications involve testing for chemical leaching, taste and odor, and other factors that could impact water quality. The fact that HDPE pipes consistently meet these stringent standards is a strong indicator of their safety for drinking water applications.

Case Study: Flint, Michigan Water Crisis

The Flint, Michigan water crisis is a stark reminder of the importance of using safe materials in drinking water systems. In Flint, the use of corrosive water caused lead to leach from aging pipes into the drinking water, leading to widespread contamination and health problems.

In response to the crisis, the city of Flint began replacing its lead pipes with safer alternatives, including HDPE. The decision to use HDPE was based on its corrosion resistance, chemical stability, and proven safety in other municipal water systems. The new HDPE pipes have helped restore safe drinking water to the residents of Flint, demonstrating the material’s effectiveness in preventing contamination.

HDPE pipes are widely recognized as a safe and reliable choice for drinking water systems. While concerns about additive leaching and biofilm formation exist, the evidence overwhelmingly supports the conclusion that HDPE pipes pose minimal health risks. Rigorous testing, regulatory oversight, and real-world case studies all reinforce the safety of HDPE for potable water applications, making it a trusted material for ensuring clean and safe drinking water.

The Environmental Benefits of Using HDPE Pipes for Drinking Water

As environmental concerns continue to shape infrastructure decisions, the choice of materials used in water distribution systems has become increasingly important. HDPE (High-Density Polyethylene) pipes are not only safe and durable but also offer significant environmental benefits compared to traditional materials like copper, steel, and PVC.

Lower Carbon Footprint

One of the most significant environmental benefits of HDPE pipes is their lower carbon footprint. The production of HDPE requires less energy compared to the production of metal pipes like copper and steel. According to a study by the Plastics Pipe Institute (PPI), the energy required to produce HDPE pipes is about 50-75% lower than that required for metal pipes. This translates to a reduction in greenhouse gas emissions, contributing to the fight against climate change.

Furthermore, HDPE pipes are lightweight, which reduces the energy required for transportation and installation. The reduced weight also means that less fuel is needed to transport HDPE pipes to the installation site, further lowering their carbon footprint.

Longer Lifespan and Reduced Waste

HDPE pipes have a longer lifespan than many traditional materials, often lasting 50-100 years or more under normal operating conditions. This longevity means that HDPE pipes need to be replaced less frequently, resulting in less waste over time. In contrast, metal pipes like copper may corrode or degrade more quickly, leading to more frequent replacements and greater environmental impact.

The durability of HDPE also reduces the likelihood of leaks and breaks, which can lead to significant water loss and environmental degradation. Water loss through leaking pipes is a major issue in many parts of the world, and the use of HDPE can help mitigate this problem.

Recyclability and Reuse

HDPE is a fully recyclable material, and recycled HDPE can be used to produce new pipes or other products. This recyclability is a key environmental advantage, as it reduces the need for virgin materials and helps keep plastic waste out of landfills and oceans.

According to a report by the Association of Plastic Recyclers, HDPE is one of the most commonly recycled plastics, with a recycling rate of around 30% in the United States. Recycled HDPE pipes perform similarly to those made from virgin materials, making recycling a viable option for reducing environmental impact.

Moreover, the process of recycling HDPE is less energy-intensive than producing new plastic, leading to further reductions in greenhouse gas emissions.

Case Study: Green Infrastructure in Denmark

Denmark is a leading example of how HDPE pipes can be used to create environmentally sustainable water infrastructure. The country has implemented green infrastructure projects that use HDPE pipes to improve water management and reduce environmental impact.

In one project, the city of Copenhagen replaced old, leaking pipes with HDPE to improve the efficiency of its water distribution system. The new HDPE pipes have significantly reduced water loss, leading to a more sustainable water supply. Additionally, the use of recycled HDPE in the project minimized the environmental impact of the construction process.

Denmark’s success with HDPE pipes demonstrates the material’s potential for contributing to sustainable infrastructure and reducing the environmental footprint of water distribution systems.

Water Conservation

HDPE pipes contribute to water conservation efforts by reducing leaks and improving the efficiency of water distribution systems. In the United States, the Environmental Protection Agency (EPA) estimates that water utilities lose about 16% of their treated water annually due to leaks in the distribution system. By using HDPE pipes, which are less prone to leaks than metal or PVC pipes, utilities can significantly reduce water loss and conserve this precious resource.

For example, the Los Angeles Department of Water and Power (LADWP) implemented a program to replace aging water pipes with HDPE. The program resulted in a significant reduction in water loss, helping the city conserve water during times of drought and reduce its overall environmental impact.

HDPE pipes offer a range of environmental benefits that make them an excellent choice for drinking water systems. Their lower carbon footprint, recyclability, and contribution to water conservation efforts make them a sustainable alternative to traditional materials like copper and PVC. As more communities and utilities prioritize environmental sustainability, HDPE pipes are likely to play an increasingly important role in building greener, more resilient infrastructure.

The Safety Considerations When Using HDPE Pipes for Drinking Water Systems

Chemical Resistance and Safety

HDPE (High-Density Polyethylene) pipes are widely recognized for their excellent chemical resistance, making them a safe choice for drinking water systems. Unlike some other materials, HDPE does not react with a wide range of chemicals, ensuring that the water transported through these pipes remains uncontaminated. The non-reactive nature of HDPE means that it doesn’t leach harmful substances into the water, a critical factor when considering long-term exposure to drinking water.

In a study conducted by the Water Research Foundation, HDPE pipes were shown to have a low potential for contaminant leaching compared to other plastic materials. The study emphasized that HDPE pipes meet the stringent standards set by the National Sanitation Foundation (NSF) for potable water applications. These standards ensure that HDPE pipes do not impart any taste or odor to the water, maintaining water quality and safety.

Durability and Reliability

The durability of HDPE pipes is another safety consideration that sets them apart. HDPE pipes are highly resistant to corrosion, which is a significant concern with metal pipes such as copper or galvanized steel. Corroded pipes can introduce harmful metals into drinking water, leading to potential health risks. In contrast, HDPE’s corrosion-resistant properties ensure that the integrity of the pipe is maintained over its long lifespan, reducing the likelihood of contamination.

Additionally, HDPE pipes are flexible and can withstand ground movements, such as those caused by earthquakes or soil shifts, without breaking. This flexibility reduces the risk of pipe bursts or leaks, which can compromise water quality and safety. For example, in the aftermath of the 2011 Christchurch earthquake in New Zealand, HDPE pipes were noted for their resilience compared to traditional materials, with significantly fewer failures.

Resistance to Biofilm Formation

Biofilm formation is a concern in any water distribution system, as it can harbor harmful bacteria and other microorganisms. HDPE pipes have a smooth interior surface, which minimizes the potential for biofilm development. The smooth surface reduces friction, allowing water to flow more freely and minimizing areas where bacteria can attach and grow.

A study published in the Journal of Water and Health demonstrated that HDPE pipes had a lower tendency to support biofilm formation compared to other materials like PVC or steel. This is particularly important for drinking water systems, where preventing bacterial contamination is paramount.

Installation and Jointing Safety

The safety of a drinking water system also depends on the integrity of its joints and connections. HDPE pipes can be joined using heat fusion, a process that creates a homogenous joint that is as strong as the pipe itself. This method reduces the risk of leaks, which are common in systems with mechanical joints, such as those found in metal or PVC pipes.

Heat fusion has been widely adopted in the gas industry for decades due to its reliability, and its application in water systems further ensures that joints remain secure over the long term. This reduces the risk of water contamination due to joint failures, enhancing the overall safety of the drinking water system.

Case Study: Safety in Flint, Michigan

The city of Flint, Michigan, became infamous for its water crisis, where lead leaching from corroded pipes led to widespread contamination. In response to this disaster, the city embarked on a massive pipe replacement project, opting for HDPE pipes to replace the corroded lead and galvanized steel pipes. The choice of HDPE was driven by its resistance to corrosion and the assurance that it would not contribute to further contamination of the water supply.

The successful implementation of HDPE pipes in Flint has since been cited as a model for other cities facing similar challenges, highlighting the safety benefits of HDPE in maintaining clean and safe drinking water.

How do HDPE Pipes Contribute to Reducing Water Loss in Distribution Systems?

Leak-Free Performance

Water loss in distribution systems is a significant issue worldwide, with some estimates suggesting that up to 30% of treated water is lost due to leaks and inefficiencies. HDPE pipes contribute to reducing water loss through their leak-free performance. Unlike traditional pipe materials that rely on mechanical joints, which are prone to leaking over time, HDPE pipes are typically joined using heat fusion, creating a seamless, leak-proof joint.

According to a report by the American Water Works Association (AWWA), systems using HDPE pipes have been found to experience significantly lower rates of leakage compared to those using materials like cast iron or PVC. This reduction in leaks not only conserves water but also reduces the energy and costs associated with treating and pumping additional water to compensate for losses.

Flexibility and Resilience to Ground Movement

One of the primary causes of leaks in water distribution systems is ground movement, which can cause pipes to shift, crack, or break. HDPE pipes are known for their flexibility and ability to withstand ground movements without compromising their integrity. This flexibility allows HDPE pipes to absorb and distribute stress caused by soil shifts, temperature changes, or seismic activity, which would otherwise lead to leaks in more rigid materials.

In areas prone to earthquakes, such as Japan and California, HDPE pipes have been increasingly used in water distribution systems due to their resilience. A study by the Japan Water Works Association found that HDPE pipes had a significantly lower failure rate during earthquakes compared to traditional materials, resulting in less water loss and a quicker restoration of water services.

Durability and Long-Term Reliability

HDPE pipes have a long lifespan, often exceeding 50 years, and are resistant to corrosion, scaling, and chemical attacks that can weaken pipes and cause leaks. This durability ensures that the pipes remain intact and functional over long periods, reducing the need for frequent repairs or replacements that can disrupt water supply and lead to losses.

The long-term reliability of HDPE pipes is evident in their widespread use in regions with harsh environmental conditions. For instance, in the Middle East, where water is a scarce and valuable resource, HDPE pipes have been used extensively in water distribution systems to minimize losses and ensure reliable delivery of water. The reduced maintenance requirements and extended service life of HDPE pipes contribute to the overall efficiency and sustainability of these systems.

Case Study: Leak Reduction in London

London, one of the oldest cities in the world, has faced significant challenges with water loss due to its aging infrastructure. To address this, Thames Water, the utility responsible for the city’s water supply, embarked on a massive pipe replacement project, with a focus on using HDPE pipes.

The project, known as the London Ring Main, involved replacing old cast iron and lead pipes with HDPE. The results were remarkable, with the city seeing a 36% reduction in water loss within the first few years of the project. The seamless joints and corrosion-resistant properties of HDPE played a crucial role in achieving this reduction, demonstrating the material’s effectiveness in leak prevention.

Impact on Water Conservation Efforts

Reducing water loss is a critical component of global water conservation efforts. With increasing concerns about water scarcity, especially in arid regions, the use of HDPE pipes in distribution systems represents a practical solution to preserve this vital resource. By minimizing leaks, HDPE pipes not only help conserve water but also reduce the energy required for water treatment and pumping, contributing to overall environmental sustainability.

In California, a state frequently affected by drought, the use of HDPE pipes has been promoted as part of water conservation strategies. Municipalities that have upgraded to HDPE in their distribution systems have reported significant reductions in water loss, helping to alleviate the pressure on already strained water resources.

What are The Cost Benefits of Using HDPE Pipes Over Traditional Materials in Water Systems?

Lower Installation Costs

One of the primary cost benefits of using HDPE pipes is their lower installation costs compared to traditional materials such as cast iron, steel, or PVC. HDPE pipes are lightweight and flexible, which makes them easier and faster to install. This reduces the labor costs associated with handling and installing heavy, rigid pipes.

Trenchless installation methods, such as horizontal directional drilling (HDD), are particularly well-suited for HDPE pipes due to their flexibility and strength. These methods reduce the need for extensive excavation, further lowering installation costs. A study by the U.S. Environmental Protection Agency (EPA) found that using HDPE pipes with trenchless technology can reduce installation costs by up to 50% compared to traditional open-trench methods.

Reduced Maintenance and Repair Costs

HDPE pipes are highly resistant to corrosion, scaling, and chemical attacks, which are common issues with metal and concrete pipes. This resistance reduces the need for maintenance and repairs over the life of the system. In contrast, traditional materials often require regular maintenance to prevent leaks, corrosion, and other issues that can compromise the system’s integrity.

A cost analysis by the American Society of Civil Engineers (ASCE) highlighted that HDPE pipes have significantly lower maintenance costs over their lifespan compared to cast iron or steel pipes. The report noted that while the initial material cost of HDPE might be comparable to or slightly higher than traditional materials, the long-term savings in maintenance and repairs make HDPE a more cost-effective choice over time.

Longer Lifespan and Investment Value

The longer lifespan of HDPE pipes—often exceeding 50 years—translates to a better return on investment for water utilities and municipalities. Traditional materials like galvanized steel or concrete may need replacement after 20-30 years, leading to higher overall costs when considering the entire lifecycle of the system.

In a case study from the City of Calgary, Canada, the transition to HDPE pipes in their water distribution system was driven by the desire to maximize long-term investment. The city’s analysis showed that while the initial costs of HDPE were slightly higher, the extended lifespan and reduced need for replacement meant that HDPE offered the best value over the 50-year projected lifespan of the system.

Energy Efficiency and Cost Savings

HDPE pipes also contribute to energy efficiency in water systems. Their smooth interior surface reduces friction, allowing water to flow more freely and requiring less energy for pumping. This efficiency translates to lower operational costs for utilities, as less energy is needed to move water through the system.

For example, a study conducted in the United Kingdom found that water systems using HDPE pipes experienced up to 20% energy savings in pumping costs compared to systems using traditional materials. These energy savings contribute to the overall cost-effectiveness of HDPE pipes, especially in large-scale water distribution networks where pumping costs are a significant portion of operational expenses.

Case Study: Cost Savings in South Africa

In South Africa, the eThekwini Municipality undertook a project to replace aging cast iron and asbestos cement pipes with HDPE pipes in its water distribution network. The project aimed to reduce the high costs associated with frequent repairs and water loss due to leaks.

The municipality reported substantial cost savings following the transition to HDPE pipes. Maintenance costs were reduced by 30%, and the overall water loss decreased by 25%. These savings were reinvested into further infrastructure improvements, demonstrating the long-term economic benefits of using HDPE pipes.

Environmental and Regulatory Benefits

Cost benefits also extend to environmental compliance. HDPE pipes are environmentally friendly, requiring less energy to produce and install compared to traditional materials. They are also fully recyclable, which can reduce disposal costs at the end of their lifespan.

Moreover, HDPE’s durability and resistance to environmental stressors ensure that the pipes meet regulatory standards for water quality and safety, potentially reducing the risk of costly fines or remediation efforts due to system failures or contamination.

In conclusion, while HDPE pipes may have a comparable or slightly higher initial cost than some traditional materials, the long-term cost benefits, including lower installation, maintenance, and operational costs, as well as the extended lifespan and environmental advantages, make HDPE a highly cost-effective choice for modern water systems.

The Role of Haoyang Environmental Co., Ltd. in Promoting Safe and Sustainable Water Systems

At Haoyang Environmental Co., Ltd., we are committed to advancing the safety and sustainability of water supply systems through our high-quality geosynthetic materials and environmental engineering solutions. Established in 2008, Haoyang has grown into a leading provider of innovative environmental products and services, earning recognition for our contributions to environmental protection and sustainable development.

Our comprehensive product portfolio includes HDPE pipes and other geosynthetic materials designed for use in drinking water systems, wastewater management, and environmental remediation projects. All our products are manufactured to the highest standards, with certifications including ISO 9001, ISO 14001, and OHSAS 18001. These certifications attest to our commitment to quality, safety, and environmental responsibility.

At Haoyang, we understand the critical importance of ensuring the safety of drinking water. Our HDPE pipes are engineered to meet and exceed global safety standards, providing a reliable solution for potable water systems. We employ state-of-the-art manufacturing processes and conduct rigorous quality control tests to ensure that our products are free from contaminants and safe for long-term use.

In addition to our products, Haoyang offers a range of services, including environmental engineering consulting, design, and construction. Our experienced technical R&D team is dedicated to developing innovative solutions that address the challenges of modern water supply systems, from soil remediation to comprehensive solid waste treatment and disposal.

With over 32 utility model patents and two provincial-level scientific and technological achievement certifications, Haoyang is at the forefront of research and development in the field of environmental engineering. We are proud to contribute to the safety and sustainability of water supply systems around the world, and we look forward to continuing our work in this vital area.

Conclusion

HDPE pipes have proven to be a safe and effective solution for drinking water systems, offering numerous advantages over traditional materials. Their chemical stability, durability, and environmental benefits make them an excellent choice for municipalities, water utilities, and developers. While ongoing research continues to monitor the safety of HDPE pipes, the overwhelming evidence supports their use in delivering clean and safe drinking water.

As a leader in environmental engineering materials, Haoyang Environmental Co., Ltd. is proud to offer HDPE pipes that meet the highest standards of safety and performance. We are committed to providing innovative, sustainable solutions that protect public health and the environment, ensuring a reliable and safe water supply for generations to come.

For more information about our products and services, please contact Haoyang Environmental Co., Ltd. We are here to assist you with all your environmental engineering needs and to help you achieve your sustainability goals.

897.webp)

942.webp)

237.webp)