Polypropylene Geotextile Fabric: A Comprehensive Guide

Polypropylene geotextile fabric is a versatile and essential material used in the construction, environmental, and civil engineering industries. Known for its strength, durability, and cost-effectiveness, polypropylene fabric is an essential tool for improving the performance and longevity of soil and drainage systems. This article explores the numerous advantages, applications, and performance data of polypropylene geotextile fabric, offering valuable insights into why it has become the material of choice for various industries.

What is Polypropylene Geotextile Fabric?

Polypropylene (PP) geotextile fabric is a type of geosynthetic material made from synthetic polymer fibers. These fabrics are designed to provide filtration, separation, drainage, and reinforcement in various civil engineering and construction applications. PP geotextile is manufactured by weaving or non-woven techniques to create a fabric that is highly durable and resistant to environmental stresses.

Types of Polypropylene Geotextile Fabrics

There are two primary forms of polypropylene geotextile fabric:

Woven Polypropylene Geotextile: Made by weaving individual polypropylene fibers into a tight, interlaced pattern. Woven fabrics typically offer higher tensile strength, making them suitable for reinforcement and load-bearing applications.

Non-woven Polypropylene Geotextile: Produced by bonding polypropylene fibers using heat, chemicals, or mechanical processes. Non-woven fabrics are generally used for filtration, drainage, and separation.

Both types of polypropylene geotextiles offer unique properties depending on the application requirements.

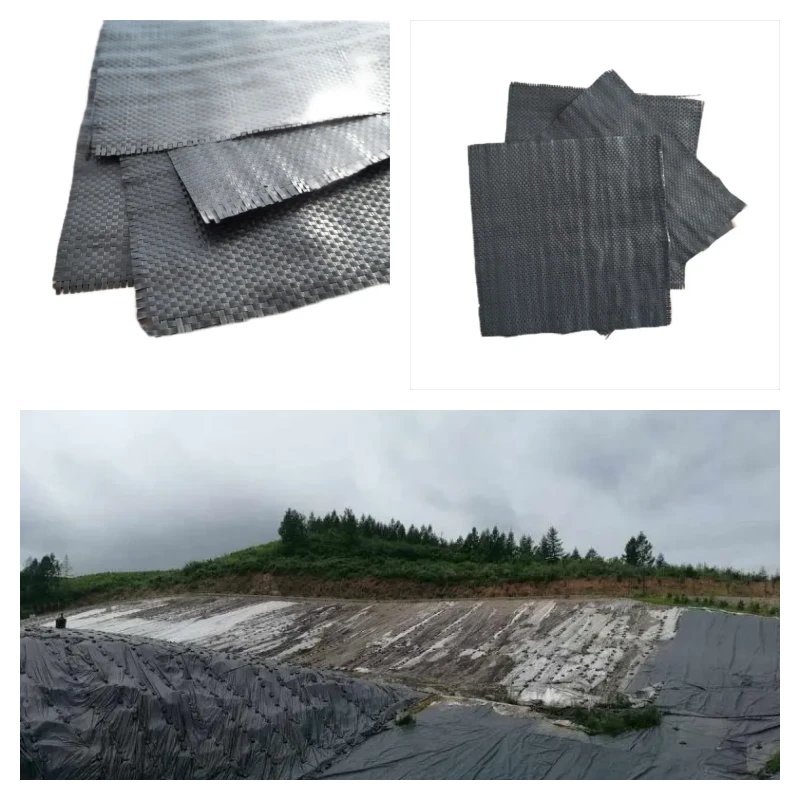

Polypropylene geotextile fabric spread across the ground, playing a crucial role in enhancing the performance of the underlying soil and providing separation and filtration.

Benefits of Polypropylene Geotextile Fabric

1. Strength and Durability

One of the standout features of polypropylene geotextile fabric is its exceptional strength and durability. Polypropylene is inherently resistant to UV degradation, acids, and alkalis, making it ideal for use in harsh environmental conditions. Polypropylene geotextiles are also highly resistant to abrasion and punctures, ensuring a long service life, even in high-traffic areas.

2. Cost-Effectiveness

Polypropylene is a relatively inexpensive material compared to other geosynthetics such as polyester or nylon. This affordability makes polypropylene geotextile fabric an attractive option for large-scale construction projects where cost control is crucial.

3. High Filtration Capacity

Non-woven polypropylene geotextile fabrics are known for their superior filtration properties. They allow water to flow through while preventing the movement of soil particles. This characteristic is vital for drainage applications, such as behind retaining walls or in road construction, where effective water drainage is essential to prevent soil erosion.

4. Environmental Friendliness

Polypropylene geotextile fabrics are made from synthetic polymers, but they are often used in environmentally conscious applications. In addition to their longevity, they can be recycled and repurposed, reducing waste in landfills. Their ability to aid in soil stabilization and erosion control also contributes to environmental sustainability.

Applications of Polypropylene Geotextile Fabric

Polypropylene geotextile fabrics are employed across various industries for a range of applications. The primary uses include:

1. Soil Separation and Reinforcement

In road construction, polypropylene geotextiles are often used to separate different layers of soil. This prevents mixing and helps maintain the integrity of the structure. They also improve the load-bearing capacity of weak soils by reinforcing the subgrade, ensuring that roads, railways, and other structures can withstand heavy loads.

2. Erosion Control and Drainage

Geotextiles are widely used for erosion control in construction projects near water bodies, slopes, and other vulnerable areas. Their filtration properties allow water to pass while preventing soil displacement. Polypropylene geotextiles are also used in drainage systems to direct water away from structures, preventing water buildup that can damage foundations.

3. Landfills and Waste Containment

Polypropylene geotextile fabric plays a critical role in the construction and maintenance of landfills. The fabric acts as a separation layer between waste materials and the underlying soil, preventing contamination of groundwater. Additionally, it supports the installation of drainage systems that manage leachate and gas from the waste.

4. Slope Stabilization and Pavement Construction

Polypropylene geotextiles are widely used in the construction of roads and highways to enhance the stability of slopes and pavements. They prevent shifting of soil and reduce the risk of landslides in areas with unstable terrain.

Performance Data of Polypropylene Geotextile Fabric

The performance of polypropylene geotextile fabrics is critical to their selection for specific applications. The following tables provide essential data on the physical properties and performance standards of polypropylene geotextiles.

Key Physical Properties of Polypropylene Geotextile Fabric

| Property | Value Range | Unit |

|---|---|---|

| Tensile Strength | 15 - 60 kN/m | kN/m |

| Puncture Resistance | 500 - 1500 N | Newtons |

| Grab Tensile Strength | 200 - 400 N | Newtons |

| Elongation at Break | 10 - 15% | Percentage |

| Permeability (Flow rate) | 0.01 - 0.2 cm/s | cm/s |

| UV Resistance | 70% after 5000 hours of exposure | % |

| Thickness | 0.5 - 1.5 mm | mm |

| Weight | 100 - 500 g/m² | g/m² |

Performance Standards for Polypropylene Geotextile

| Standard Code | Description | Test Method |

|---|---|---|

| ASTM D4632 | Standard Specification for Nonwoven Geotextiles | ASTM D4632-10 |

| ASTM D4751 | Standard Test Method for Determining the Apparent Opening Size (AOS) | ASTM D4751-12 |

| ISO 10318-1 | Geotextiles - Part 1: Identification and General Characteristics | ISO 10318-1:2000 |

| ISO 9001 | Quality Management Systems | International Standard |

| ISO 14001 | Environmental Management Systems | International Standard |

How to Choose the Right Polypropylene Geotextile

Choosing the correct polypropylene geotextile depends on several factors, such as the specific application, environmental conditions, and load-bearing requirements. Key considerations include:

Tensile Strength: Woven polypropylene geotextiles are typically preferred for applications where high tensile strength is required, such as soil reinforcement and separation in roads.

Permeability: For drainage applications, non-woven geotextiles with higher permeability are necessary to ensure proper water flow and filtration.

UV Resistance: In outdoor applications, selecting a fabric with high UV resistance ensures longevity and reduces the degradation of the material when exposed to sunlight.

Polypropylene Geotextile Fabric and Sustainability

Sustainability is a significant concern in construction and civil engineering. Polypropylene geotextiles contribute to sustainability in several ways:

Durability: Polypropylene fabrics have a long service life, reducing the need for replacement and minimizing waste.

Recyclability: The material is recyclable, which helps reduce the environmental impact when the fabric reaches the end of its life cycle.

Erosion Control: Geotextiles play a vital role in preventing soil erosion, preserving landscapes, and protecting water bodies from pollution.

Future Trends in Polypropylene Geotextile Fabric

As the construction industry moves towards more sustainable practices, the demand for high-performance, environmentally friendly geotextiles will continue to rise. Polypropylene geotextiles are expected to see further advancements in their manufacturing processes, leading to even stronger, lighter, and more durable fabrics. Additionally, increased focus on recycling and reuse will play a crucial role in the future of geosynthetics.

Conclusion

Polypropylene geotextile fabric is a highly effective and cost-efficient solution for a variety of civil engineering and construction applications. Its strength, durability, filtration capacity, and environmental benefits make it a preferred choice for soil separation, erosion control, drainage, and reinforcement projects. The growing demand for sustainable construction materials positions polypropylene geotextiles as a key player in the future of geotechnical engineering.

With a wide range of applications and excellent performance characteristics, polypropylene geotextiles will continue to shape the landscape of modern construction projects for years to come.

About Haoyang

For those looking for top-quality geosynthetic materials, Haoyang Environmental Co., Ltd. offers cutting-edge solutions. Established in 2008, Haoyang specializes in the research, development, and manufacturing of geosynthetic materials, with expertise in environmental engineering, soil remediation, and pollution control. With certifications such as ISO 9001 and ISO 14001, Haoyang provides reliable, high-performance products and services designed to meet the highest industry standards. Let us support your next project with innovative, environmentally sustainable solutions.

Contact us today to learn more about our geosynthetic material offerings.

897.webp)

942.webp)

237.webp)