Understanding the Price of Geotextile Fabric: A Comprehensive Analysis

Geotextile fabrics are essential components in modern civil engineering and construction projects, offering solutions for soil stabilization, erosion control, and drainage. Understanding the pricing dynamics of geotextile fabrics is crucial for project planning and budgeting. This article delves into the factors influencing geotextile fabric costs, provides current market price ranges, and presents data tables for clarity.

Factors Influencing Geotextile Fabric Prices

Several key factors affect the pricing of geotextile fabrics:

Type of Geotextile: The primary categories are woven and non-woven geotextiles. Woven geotextiles, known for their strength and durability, are typically more expensive than non-woven varieties, which are valued for their filtration capabilities.

Material Composition: Geotextiles are commonly made from polypropylene or polyester. Material choice impacts properties like tensile strength and UV resistance, influencing cost.

Weight and Thickness: Measured in grams per square meter (GSM), heavier and thicker geotextiles generally cost more due to increased material usage.

Roll Size and Dimensions: Standard roll widths and lengths can vary. Custom sizes may lead to price adjustments.

Manufacturing Processes: Advanced manufacturing techniques or treatments (e.g., UV resistance, chemical stabilization) can add to production costs.

Market Conditions: Fluctuations in raw material prices, supply chain dynamics, and regional demand can cause price variations.

Purchase Volume: Bulk purchases often come with discounted rates.

Current Market Price Ranges

As of recent data, the following price ranges are observed for geotextile fabrics:

Price Range by Geotextile Type

| Geotextile Type | Price per Square Foot | Price per Square Meter |

|---|---|---|

| Non-Woven | $0.15 - $0.50 | $1.50 - $5.40 |

| Woven | $0.30 - $0.70 | $3.20 - $7.50 |

Price Range by Material Composition

| Material | Price per Square Meter |

|---|---|

| Polypropylene | $0.20 - $2.50 |

| Polyester | $0.40 - $0.50 |

Price Range by Weight (GSM)

| Weight (GSM) | Price per Square Meter |

|---|---|

| 100 - 800 | $0.20 - $0.70 |

| 1000 | $0.40 - $0.50 |

Price Range by Geotextile Product

| Product Type | Price per Square Foot | Price per Square Meter |

|---|---|---|

| Geotextile Tubes/Bags | $0.50 - $5.00 | $5.40 - $54.00 |

| Specialty Geotextiles | Varies | Varies |

Note: Prices are approximate and subject to change based on market conditions and supplier.

Regional Price Variations

The price of geotextile fabric can vary significantly based on location. Factors such as labor costs, import/export duties, and the availability of raw materials influence regional pricing. Below are some examples of how pricing differs across regions:

North America: Higher labor costs and stricter environmental regulations contribute to higher prices.

Europe: Import duties and environmental standards influence costs.

Asia: Lower production costs in China and India lead to competitive pricing.

Middle East & Africa: Higher transportation costs can increase overall prices.

Environmental Impact and Sustainability

Sustainability in geotextile manufacturing is gaining importance. Many manufacturers are now producing eco-friendly geotextiles using recycled materials. Some key considerations include:

Recycled Materials: Reducing dependency on virgin polypropylene and polyester.

Biodegradable Options: Developing alternatives that break down naturally.

Sustainable Manufacturing Practices: Lowering carbon footprints through energy-efficient production.

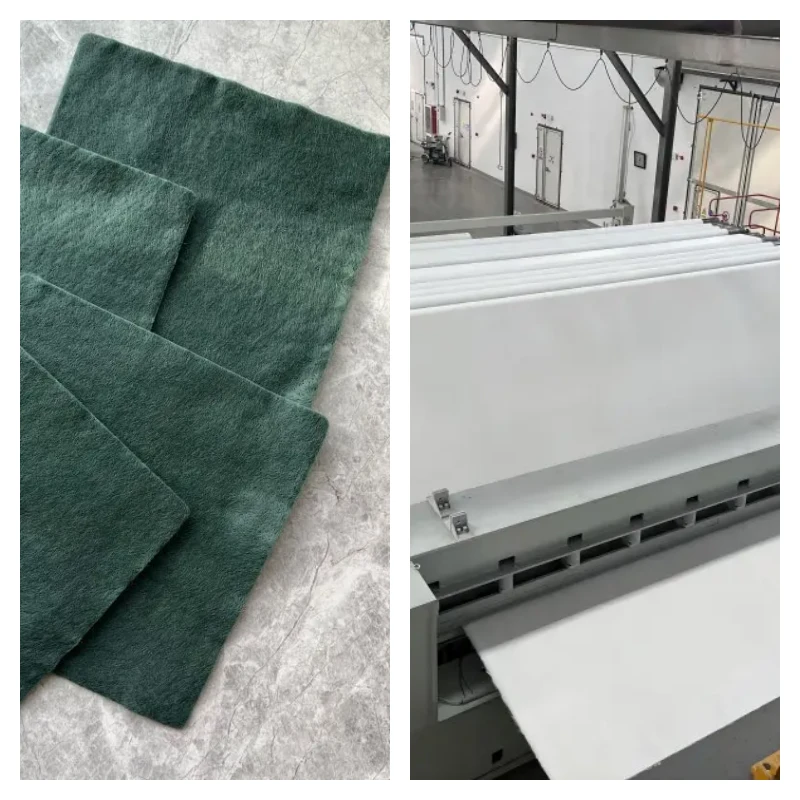

The picture shows Geotextile Fabric. The left picture shows the appearance of the finished geotextile, with a dark green material and a thick texture; the right picture shows the scene of the geotextile on the factory production line, with the white geotextile being processed by the equipment, reflecting its industrialized production process.

Practical Considerations for Budgeting

When planning for geotextile fabric procurement, consider the following:

Project Specifications: Determine the exact requirements regarding type, material, weight, and dimensions to avoid over-specification, which can lead to unnecessary costs.

Supplier Selection: Engage with reputable suppliers who can provide quality certifications and competitive pricing.

Bulk Purchasing: If feasible, purchasing in larger quantities can reduce the unit cost.

Logistics: Factor in shipping costs, especially for large orders or if sourcing from distant suppliers.

Installation Costs: Account for labor and equipment required for installation, as these can significantly impact the overall budget.

Conclusion

Understanding the various factors that influence geotextile fabric prices is essential for effective project planning and budgeting. By considering the type, material, weight, and current market conditions, stakeholders can make informed decisions that align with both technical requirements and financial constraints. Regular consultation with suppliers and market analysis will ensure access to the most accurate and competitive pricing available.

About Haoyang Environmental Co., Ltd.

Haoyang Environmental Co., Ltd. is a leading provider of high-quality geosynthetic materials, specializing in R&D, manufacturing, and environmental engineering solutions. With ISO and CQC certifications, Haoyang ensures superior product quality and innovative solutions for soil stabilization, erosion control, and infrastructure projects. Contact us today to learn more about our premium geotextile products and how they can enhance your project’s efficiency and durability.

897.webp)

942.webp)

237.webp)