Rough-surfaced Geomembrane: An Efficient Solution for Anti-seepage

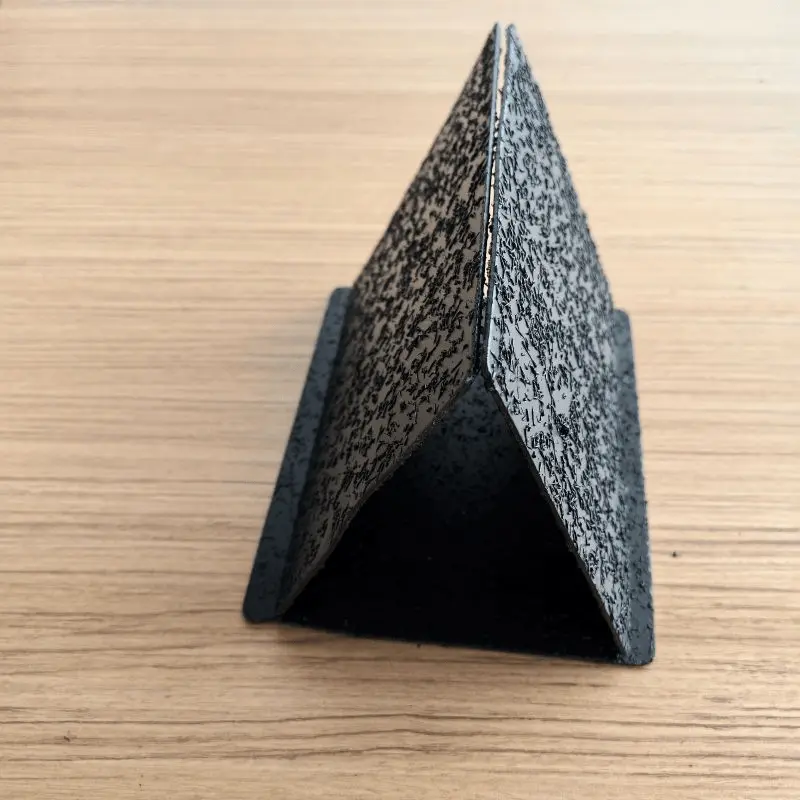

Rough-surfaced geomembrane, a type of HDPE geomembrane with a unique rough texture, has been widely used in various anti-seepage projects in recent years. Its excellent anti-slip, drainage, and bonding properties make it an ideal choice in many engineering fields. This article will delve into the advantages of rough-surfaced geomembrane and its applications in different scenarios to showcase its vital role in anti-seepage engineering.

Advantages:

Anti-slip Performance: The rough texture of rough-surfaced geomembrane provides it with superior anti-slip properties. When applied to slopes, dams, or other scenarios that require increased stability, the texture of the geomembrane can provide better anti-slip effects, reducing the risk of instability caused by soil sliding.

Drainage Performance: The rough texture of the geomembrane increases the contact area with the soil and forms tiny channels, facilitating the drainage of moisture from the soil. This drainage capability helps reduce hydraulic pressure within the soil, preventing shear sliding between the geomembrane and the soil. Therefore, it has advantages in scenarios where strong drainage performance is required.

Bonding Performance: The rough texture of rough-surfaced geomembrane enhances its bonding strength with the soil. When used in soil reinforcement and slope protection projects, this bonding performance can strengthen the close connection between the geomembrane and the soil structure, improving overall stability and resistance to erosion.

Anti-aging Performance: Rough-surfaced geomembrane exhibits excellent anti-aging, anti-UV, and anti-decomposition properties. It can be used exposed to the elements, with a material lifespan of up to 50 to 70 years, providing a reliable guarantee for environmental anti-seepage.

Chemical Stability: Rough-surfaced geomembrane boasts exceptional chemical stability, making it widely applicable in scenarios such as sewage treatment, chemical reaction tanks, and landfills. It can withstand high temperatures, resist asphalt, oil, tar, and is corrosion-resistant to over 80 types of strong acids and alkalis.

High Mechanical Strength: Rough-surfaced geomembrane possesses excellent mechanical strength, elasticity, and deformation capabilities, making it particularly suitable for use on expanding or contracting substrates. It can effectively cope with uneven settlement of the substrate.

Applications:

Due to its unique advantages, rough-surfaced geomembrane is widely used in various anti-seepage engineering applications, including but not limited to:

Anti-seepage treatment for underground works, mining engineering, landfills, sewage or waste treatment facilities.

Anti-seepage treatment for river dikes, lake dams, tailings dams, sewage dams, reservoirs, channels, and liquid storage ponds (pits, mines).

Anti-seepage lining for subways, basements, tunnels, and tunnel excavations.

Salt-resistant anti-seepage for roadbeds and other foundations.

Horizontal anti-seepage blankets and vertical anti-seepage layers for dams and embankments, construction cofferdams, and waste yards.

Anti-seepage treatment for marine and freshwater aquaculture ponds.

Waterproof layers for road, highway, and railway foundations, as well as expansive and collapsible soils.

Roof anti-seepage treatment.

Overall, rough-surfaced geomembrane plays a significant role in various anti-seepage scenarios due to its excellent performance. For more information, please feel free to consult us. Our 10-meter blown geomembrane production line belongs to China's advanced production technology.It can produce up to 10 meters wide wide geotextile.This production line adopts PLC + touch screen control, high degree of automation.We have the patent certificates are: blowing film air ring cooling device, blowing film equipment with the touch frame, two-way coiler.

776.webp)