In the construction of modern landfills, ensuring proper containment and environmental protection is paramount. Among the key components of landfill liner systems, staple fiber needled non-woven geotextiles play a crucial role in providing structural integrity, filtration, and drainage capabilities. Let's delve into the significance and characteristics of this essential material in landfill liner construction.

Features

1. Structural Integrity:Staple fiber needled non-woven geotextiles serve as a foundational layer in landfill liner systems, providing structural support to the overall containment structure. These geotextiles are engineered with high-strength fibers and a dense needling process, ensuring exceptional tensile strength and puncture resistance. This structural integrity is essential for withstanding the stresses exerted by the landfill contents and maintaining the integrity of the liner system over time.

2. Filtration and Separation:In landfill applications, preventing the migration of fine particles while allowing for the efficient passage of water is crucial. Staple fiber needled non-woven geotextiles act as effective filtration and separation barriers, preventing soil intrusion into the landfill while facilitating the drainage of leachate. By effectively filtering out fines and maintaining proper soil-geotextile interface friction, these geotextiles help uphold the hydraulic performance of the landfill liner system.

3. Hydraulic Properties:Hydraulic conductivity is a critical factor in landfill liner design, as it influences the drainage efficiency and overall stability of the containment system. Staple fiber needled non-woven geotextiles are engineered to possess optimal hydraulic properties, striking a balance between permeability and filtration. This allows for the controlled passage of water through the liner system, preventing pore clogging and ensuring efficient leachate collection and removal.

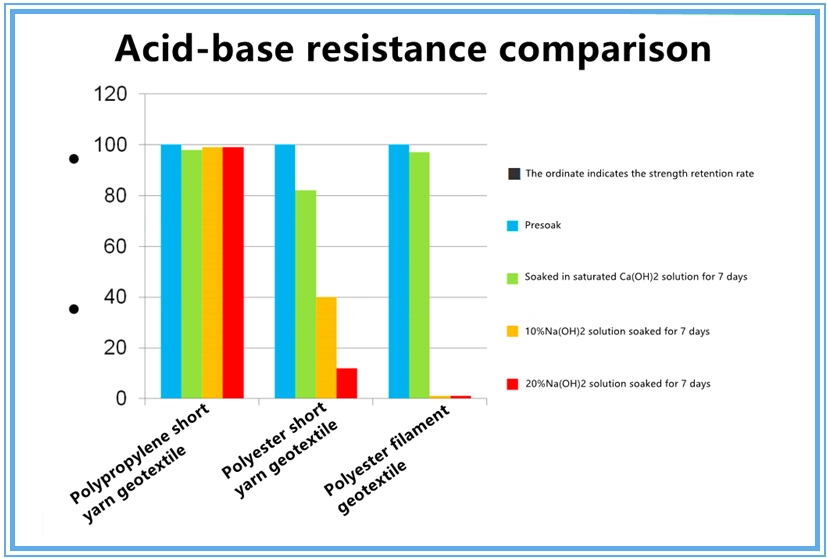

4. Chemical Resistance:Landfills often contain a diverse range of chemical constituents, including aggressive leachate from decomposing waste materials. Staple fiber needled non-woven geotextiles are designed to withstand exposure to these chemicals, offering excellent resistance to degradation and maintaining their mechanical properties over time. This chemical resistance ensures the long-term performance and durability of the landfill liner system in challenging environmental conditions.

5. Environmental Compatibility:As with all geosynthetic materials used in landfill construction, environmental compatibility is a key consideration. Staple fiber needled non-woven geotextiles are manufactured using materials that are inert and non-toxic, ensuring minimal environmental impact. Additionally, these geotextiles are designed for ease of installation and are compatible with various soil types, making them versatile and cost-effective solutions for landfill liner applications.

Specifications of Staple Fiber Needle-Punched Non-Woven Geotextile

| Parameter | Details |

|---|---|

| Material | Polypropylene (PP) or Polyester (PET) |

| Weight | 200gsm - 1200gsm |

| Thickness | 1mm - 10mm |

| Width | 1m - 6m |

| Length per Roll | 50m - 200m |

| Tensile Strength | >20 kN/m |

| Puncture Resistance | >400 N |

| Permeability | 0.1 - 0.5 cm/s |

| UV Resistance | Up to 5 years |

Applications in Landfill Systems

Base Liners:

Installed above or below geomembrane liners to protect them from punctures and facilitate drainage.

Capping Systems:

Used in final cover systems to control water infiltration and direct runoff while preventing erosion.

Leachate Collection Layers:

Provides filtration and drainage to manage leachate flow efficiently.

Gas Collection Layers:

Supports the controlled release of landfill gases through the liner system.

Product introduction

Geotextile is a kind of nonwoven and industrial cloth, which is made of polyester crimped staple fiber with fiber density of 6-12 denier and length of 54-64mm.

Through the non-woven production equipment opening, combing, clutter (short fibers interwoven together), laying nets (standardized entanglement fixed), acupuncture and other production processes to make cloth. It is used in railway roadbed reinforcement, highway pavement maintenance, sports hall, dam protection, hydraulic construction isolation, tunnel, coastal beaches, reclamation, environmental protection and other projects.

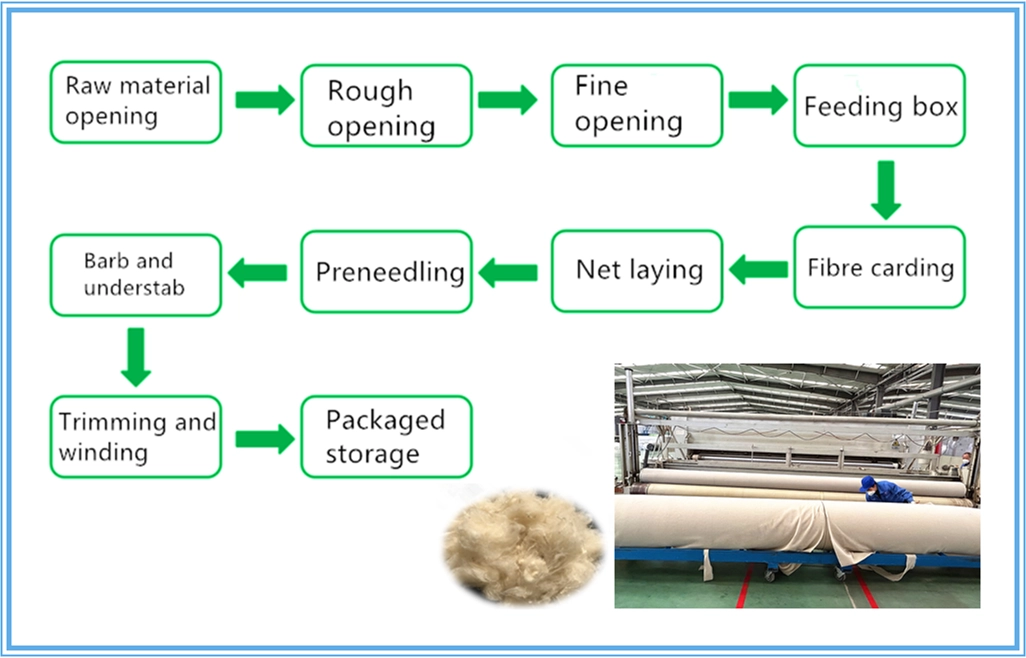

How is staple fiber non-woven geotextile produced?

(1) Raw material unpacking: After unpacking, observe the appearance of raw materials and whether there are other debris.

(2) Raw material loosening: The role of loosening is to change the raw material from large pieces to small pieces or fiber bundles.

(3) Cotton feeding box: The fiber is fully opened and mixed into uniform 筳 cotton fed to the carder.

(4) Fiber carding: The role of the carding machine is to process the fibers through the opening process into a thin fiber net, and after laying and crossing into a net, for the acupuncture machine reinforcement.

(5) Mesh laying: The single-layer fiber net output by the carding machine needs to be repeatedly stacked through the mesh laying mechanism to achieve the product's required unit area quality and width.

(6) Acupuncture: The role of the acupuncture machine is to initially wind and finalize the fiber net formed by combing and laying the net to meet certain technological requirements, reduce the drafting of the formed fiber net as much as possible, and ensure that the direction of the fiber net of the fibril net is unchanged to achieve the best result of the product.

(7) Trimming and winding and finished product packaging.

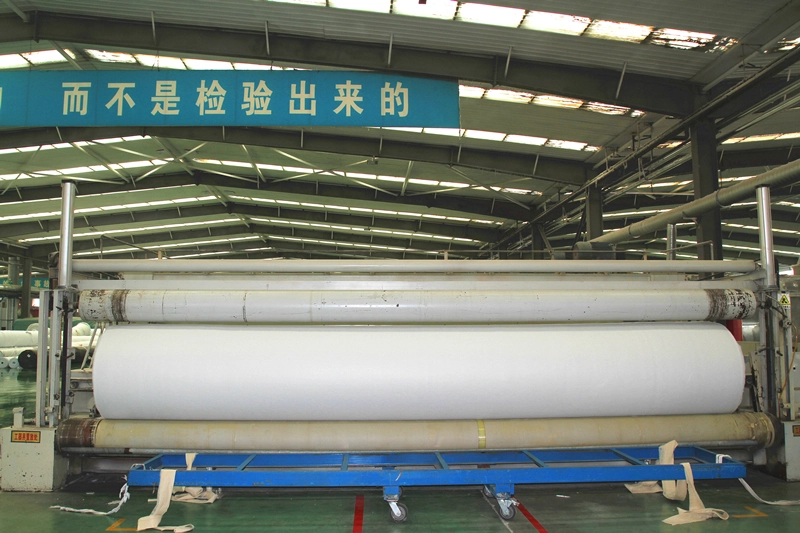

Production workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

309476.webp)

Short fiber needled nonwoven geotextile quality technical index

The technical requirements of the basic internal quality of geosynthetic materials staple fiber needled nonwoven geotextiles are shown in the table, which conforms to the new national standard GB/T 17638-2017 in China.

No. | Item | Unit | Nominal breaking strength | ||||||||

3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | |||

1 | Longitudinal and transverse fracture strength | Kn/m | ≧3.0 | ≧5.0 | ≧ 8.0 | ≧10.0 | ≧15.0 | ≧20.0 | ≧25.0 | ≧30.0 | ≧40.0 |

2 | Nominal breaking strength corresponds to elongation | % | 20~100 | ||||||||

3 | Bursting force | Kn | ≧0.6 | ≧1.0 | ≧1.4 | ≧1.8 | ≧2.5 | ≧3.2 | ≧4.0 | ≧5.5 | ≧7.0 |

4 | Mass deviation rate per unit area | % | ±5 | ||||||||

5 | Width deviation rate | % | -0.5 | ||||||||

6 | Thickness deviation rate

| % | ±10 | ||||||||

7 | Equivalent aperture O90(O95) | mm | 0.07-0.20 | ||||||||

8 | Vertical permeability coefficient | cm/s | K*(10-1~10-3) ,K=1.0~9.9 | ||||||||

9 | Vertical and horizontal tearing force | Kn | ≧ 0.10 | ≧ 0.15 | ≧ 0.20 | ≧ 0.25 | ≧ 0.40 | ≧ 0.50 | ≧ 0.65 | ≧ 0.80 | ≧ 1.00 |

10 | Acid and alkali resistance (Strength guarantee ratio) | % | ≧80 | ||||||||

11 | Antioxidant property(Strength guarantee ratio) | % | ≧80 | ||||||||

12 | Ultraviolet resistance(Strength guarantee ratio) | % | ≧80 | ||||||||

Pricing for Staple Fiber Needle-Punched Non-Woven Geotextile

Prices vary based on weight, material type, and order quantity. Below are approximate ranges in USD:

| Weight (GSM) | Price per Square Meter (USD) |

|---|---|

| 200gsm - 300gsm | $0.30 - $0.50 |

| 400gsm - 600gsm | $0.60 - $1.00 |

| 800gsm - 1200gsm | $1.00 - $2.00 |

Example:

For a 5,000 sq.m order of 400gsm PP geotextile, the cost ranges from $3,000 - $5,000.

Construction site display

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

Staple fiber punched geotextile function

(1) The use of squat geotextile good air permeability and water permeability, so that water flow through, so as to effectively intercept the loss of sand.

(2) Geotextile has good water conductivity, it can form a drainage channel inside the soil, the excess liquid and gas in the soil structure out.

(3) The use of geotextiles to enhance the tensile strength and deformation resistance of the soil, enhance the stability of the building structure, and improve the quality of the soil.

(4) Effectively diffuse, transfer or decompose the concentrated stress to prevent the soil from being damaged by external forces.

Prevent mixing between upper and lower layers of sand, soil and concrete.

(5) The mesh is not easy to block - the network structure formed by the amorphous fiber tissue has anisotropy and motility.

(6) High permeability - under the pressure of soil and water, it can still maintain good water permeability.

(7) Corrosion resistance - polypropylene or polyester and other chemical fiber as raw materials, acid and alkali resistance, no corrosion, no moth, anti-oxidation.

Mode of transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

The staple fiber needle-punched non-woven geotextile is a critical component in landfill liner systems, offering superior protection, filtration, and drainage. With customizable specifications and competitive pricing, it ensures cost-effective and sustainable landfill management. For optimized solutions, work with trusted manufacturers and suppliers that can meet your specific project requirements and provide reliable technical support.

FAQ

1. What is a staple fiber needled non-woven geotextile?

Staple fiber needled non-woven geotextile is a synthetic fabric made from polypropylene (PP) or polyester (PET) fibers. It is manufactured through a needle-punching process that creates a strong, durable, and permeable fabric, ideal for landfill applications like protection, filtration, separation, and drainage.

2. Why is non-woven geotextile used in landfill liners?

Non-woven geotextiles are used in landfill liners for the following reasons:

Protection: Shields geomembranes from punctures and mechanical damage.

Filtration: Allows water and leachate to flow through while retaining soil particles.

Separation: Prevents intermixing of materials, maintaining liner integrity.

Drainage: Facilitates leachate flow to collection systems.

3. What materials are used in staple fiber non-woven geotextiles?

These geotextiles are made from:

Polypropylene (PP): Lightweight, chemical-resistant, and cost-effective.

Polyester (PET): Higher tensile strength, ideal for high-stress environments.

4. What are the standard specifications for landfill geotextiles?

| Parameter | Details |

|---|---|

| Material | Polypropylene (PP) or Polyester (PET) |

| Weight | 200gsm - 1200gsm |

| Thickness | 1mm - 10mm |

| Tensile Strength | >20 kN/m |

| Puncture Resistance | >400 N |

| Permeability | 0.1 - 0.5 cm/s |

5. What is the primary function of this geotextile in landfill systems?

The primary functions include:

Protecting the geomembrane liner from sharp objects.

Acting as a filtration layer for leachate.

Facilitating drainage while preventing soil clogging.

Stabilizing the landfill structure by separating layers.

6. How does the geotextile protect geomembranes in landfills?

It serves as a cushion layer between the geomembrane and rough subsoil or aggregate, absorbing pressure and preventing punctures from sharp objects.

7. What thickness and weight are recommended for landfill applications?

200gsm - 400gsm: Suitable for light-duty landfill applications.

400gsm - 800gsm: Ideal for heavy-duty liners with significant loads.

1000gsm - 1200gsm: Used for highly demanding projects with aggressive environments.

8. Is this geotextile resistant to chemicals and UV radiation?

Yes, it is:

Chemical Resistance: Resistant to acids, alkalis, and hydrocarbons commonly found in landfill leachates.

UV Resistance: UV-treated variants can withstand prolonged exposure to sunlight.

9. How long does staple fiber geotextile last in landfill applications?

When properly installed, it can last 20-50 years, depending on environmental conditions and material quality.

10. How is the geotextile installed in landfill systems?

Surface Preparation: Clear and level the subgrade.

Roll Out the Geotextile: Unroll it over the prepared area, ensuring smooth placement.

Overlap Edges: Overlap adjacent sheets by 300mm to 600mm.

Secure the Geotextile: Use ballast or clamps to keep it in place.

Add Protection Layers: Install geomembranes or drainage layers as required.

11. What are the benefits of using needle-punched geotextiles in landfills?

Enhanced Liner Protection: Prevents punctures, extending liner lifespan.

Efficient Drainage: Manages leachate flow and reduces hydraulic pressure.

Reduced Maintenance: Ensures long-term landfill stability.

Environmental Compliance: Meets regulatory standards for waste containment.

12. How much does staple fiber non-woven geotextile cost?

Prices depend on weight, material, and quantity:

200gsm - 300gsm: $0.30 - $0.50 per square meter.

400gsm - 600gsm: $0.60 - $1.00 per square meter.

800gsm - 1200gsm: $1.00 - $2.00 per square meter.

13. Can geotextiles be customized for specific landfill needs?

Yes, customization options include:

Adjusting weight, thickness, and permeability.

Offering UV-treated or chemically enhanced variants.

Custom roll widths and lengths.

14. Are staple fiber geotextiles eco-friendly?

Yes, they are made from recyclable materials and contribute to sustainable landfill management by reducing environmental leakage and contamination risks.

15. What standards should landfill geotextiles meet?

ASTM D4491: Water permeability testing.

ASTM D4833: Puncture resistance.

ISO 10319: Tensile strength testing.

EN 13257: Geotextile use in solid waste containment.

16. How can I source high-quality geotextiles for landfill projects?

Choose manufacturers with certifications like ISO 9001 and proven expertise in geosynthetics.

Verify product specifications and request test reports.

Opt for bulk orders to secure competitive pricing.

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

826.webp)

509.webp)

769.webp)