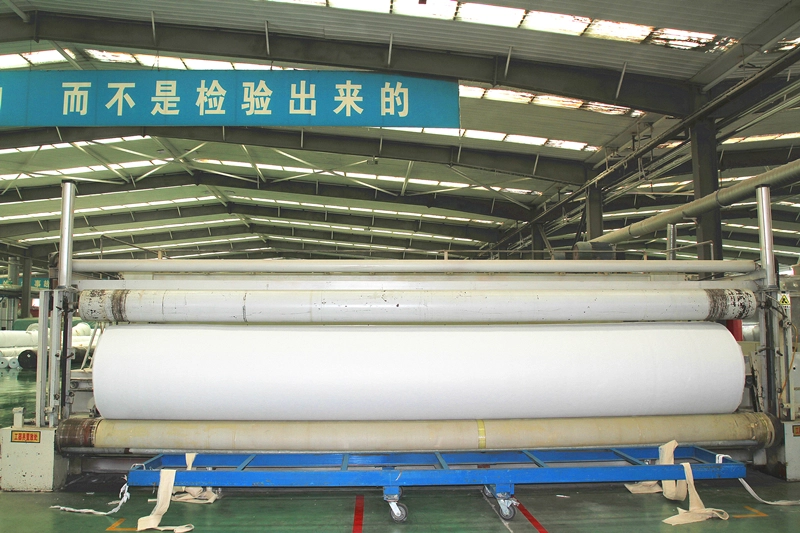

Haoyang staple fiber non-woven geotextile production line

Geotextiles have many advantages and specific details in highway construction, mainly reflected in the following 7 aspects:

1、Reinforce soil stability: Geotextiles can effectively reinforce soil and improve soil stability. In highway construction, especially under weak foundation conditions, the use of geotextiles can increase the anti-deformation and anti-settlement capabilities of the roadbed.

The main method used by geotextiles to reinforce land stability in highway construction is by enhancing the tensile strength and deformation resistance of the soil. The following are specific reinforcement methods:

(1)Foundation treatment: Before carrying out roadbed construction, the foundation needs to be treated first. This may include removal of loose or organic material, proper filling and compaction. Ensure that the base layer is uniform and tight, which is conducive to the effective application of geotextiles.

(2)Laying geotextiles: Geotextiles are usually laid between the various layers of the subgrade, especially between the fill layer and the base layer. The fabric must be smooth and wrinkle-free, and the coverage area must match the design requirements. When laying, be careful to avoid sharp objects to avoid damaging the geotextile.

(3)Cross-Lamination: For requirements requiring greater strength and stability, multiple layers of geotextile can be laid in a cross-lamination manner. Cross-lamination increases overall tensile strength and stability.

(4)Fastening and Attachment: Geotextiles need to be securely fastened to the foundation, usually using ground nails or other fastening devices. The connection points between the fabrics also need to be strong and reliable to ensure that each layer of geotextile forms an integral structure.

(5)Combination with soil: One of the main functions of geotextile is to combine with soil to form a whole. This requires maintaining sufficient soil penetration at the interface between the fabric and the soil to ensure that the geotextile and soil are closely combined to form a strong composite.

(6)Construction management: Strict management and monitoring are required during the construction process to ensure the correct use and effectiveness of geotextiles. Reasonable construction sequence and construction quality assurance are crucial to the reinforcement effect of geotextile.

Through the above reinforcement measures, geotextiles can effectively improve the tensile strength, deformation resistance and overall stability of the subgrade soil, thereby enhancing the stability of the land and extending the service life of the subgrade.

Haoyang filament non-woven geotextile laying during highway construction

2、Anti-erosion and prevention of soil loss: Geotextile has anti-erosion properties, which can effectively prevent soil erosion by water flow and rainwater, and reduce the risk of soil loss. This is critical to protecting highway slopes and maintaining the integrity of the roadbed.

The main role of geotextile in resisting erosion and preventing soil loss in highway construction is to slow down water flow, stabilize soil, and prevent soil from being washed away and eroded through its protective and filtering functions. Here are ways geotextiles can resist erosion and prevent soil loss in highway construction:

(1)Covering bare land: During construction or repair, if there is exposed land surface, it can be covered with geotextile to form a protective layer. This can effectively prevent wind and water erosion from eroding the soil.

(2)Prevent water erosion: Geotextiles can be placed on slopes and ditches to prevent water erosion. It slows the flow of water and reduces its impact on the soil, thereby reducing the potential for erosion.

(3)Filtration Function: The filtration function of geotextile prevents soil particles from being washed away while allowing moisture to pass through. This helps maintain soil stability and reduces soil erosion.

(4)Strengthening ditches: Along highways or on slopes, geotextiles can be used to strengthen the structure of ditches, prevent water flow from forming cut ditches, and reduce erosion.

(5)Combined with vegetation: Geotextiles can be used in combination with vegetation to form an ecological protection system. The roots of vegetation can be anchored into the soil with geotextiles, providing additional protection against erosion.

Maintain construction sites: On construction sites, use geotextiles to cover construction areas, especially temporary exposed land, to reduce the risk of erosion.

The combination of these methods can effectively reduce soil erosion and loss, protect land resources during highway construction, and maintain the stability of infrastructure.

Flat yarn woven geotextiles are used in the construction of the northern outer ring extension line of Jinan Zero Point Interchange Expressway

3、Improve the bearing capacity of the roadbed: The use of geotextiles can increase the bearing capacity of the roadbed, reduce the settlement of the roadbed, and improve the stability and durability of the road surface. This is crucial for highway projects under high traffic loads.

Geotextiles can be used to improve the bearing capacity of roadbeds in highway construction, mainly through the following methods:

(1)Increase the stability of the roadbed: Geotextiles can be used to enhance the stability of the roadbed and prevent lateral spreading and subsidence of the roadbed material. By laying geotextiles at different levels of the subgrade, the overall stability of the subgrade can be improved.

(2)Dispersed load: The use of geotextiles can effectively disperse the load and reduce the stress concentration on the surface of the roadbed, thereby reducing the subsidence and deformation of the roadbed. This is essential to improve the load-bearing capacity of the roadbed.

(3)Anti-permeability and anti-scouring: Geotextiles have certain anti-permeability and anti-scouring properties, which can prevent moisture from intruding into the interior of the roadbed, slow down the loosening of the soil, and improve the compactness and consistency of the roadbed.

(4)Inhibiting the growth of herbaceous vegetation: Covering the surface of the roadbed with geotextile can effectively inhibit the growth of herbaceous vegetation, prevent its roots from penetrating the roadbed, and reduce the risk of roadbed deformation and loosening.

(5)Prevent differential settlement of roadbed: In roadbed design, geotextiles can be used to build layered structures to prevent differential settlement of different levels of roadbed. This helps maintain the smoothness and load-bearing capacity of the roadbed.

(6)Combining geogrids: The combination of geogrids and geotextiles can form a reinforcement layer that improves the shear strength of the soil, thereby enhancing the overall load-bearing capacity of the roadbed.

In actual construction, it is necessary to select appropriate types and specifications of geotextiles according to specific engineering conditions and requirements, and rationally design construction plans to achieve the effect of improving the bearing capacity of the roadbed.

Haoyang filament non-woven geotextile enhances construction strength in highway construction

4、Drainage and anti-infiltration: Geotextiles can be used to improve the drainage performance of the roadbed and prevent groundwater from penetrating into the roadbed. This helps prevent moisture from damaging the subgrade structure and increases the service life of the pavement.

In highway construction, geotextiles are used for drainage and anti-seepage purposes, which are usually achieved in the following ways:

(1)Choose permeable geotextile: In order to achieve drainage effect, you can choose geotextile with good water permeability. Permeable geotextiles have an open structure that allows water to penetrate and drain away from the geotextile, preventing water from being retained within the subgrade structure.

(2)Applied to different levels of subgrade structure: Geotextiles are usually used at different levels of subgrade structure to meet different engineering needs. For example, geotextiles with good water permeability can be used in the surface structure, while geotextiles with strong anti-penetration properties can be used in the underlying structure to achieve drainage and anti-penetration effects.

(3)Reducing the groundwater level: In some cases, by taking measures to reduce the groundwater level, the drainage burden of the geotextile can be reduced and the drainage effect can be improved. This may include appropriate water table lowering before works begin.

(4)Adopt transverse and longitudinal drainage measures: Combined with geotextiles, transverse and longitudinal drainage measures can be designed. Horizontal drainage removes water laterally through drainage pipes, drainage channels and other structures, while longitudinal drainage removes water longitudinally through the drainage performance and structure of the geotextile itself.

(5)Reasonable design and construction: In actual construction, it is necessary to ensure the correct laying and connection of geotextiles to reduce possible damage and leakage. A properly designed construction plan can give full play to the drainage and anti-seepage effects of geotextiles.

(6)Use in conjunction with other drainage materials: Geotextiles can be used in conjunction with other drainage materials (such as drainage pipes, drainage boards, etc.) to improve the overall drainage effect. The synergistic effect can further enhance the drainage and anti-seepage properties of the subgrade.

Through the above methods, geotextiles can effectively drain water and prevent seepage during highway construction, ensuring the stability and long-term service life of the roadbed structure.

5、Rapid construction and cost reduction: The use of geotextiles can usually speed up the construction progress, reduce changes to the original terrain, and reduce construction costs. It is a relatively economical and efficient roadbed improvement material.

In highway construction, in order to achieve rapid construction of geotextiles and reduce costs, the following strategies can be adopted:

(1)Pre-planning and design: Before starting the project, carry out detailed planning and design to determine the specific use, laying location and layer of the geotextile. Proper planning can help improve construction efficiency and reduce costs.

Select geotextiles of appropriate specifications: According to specific project needs, select geotextiles of appropriate specifications to avoid overuse or insufficient specifications. Reasonable selection of specifications can help reduce costs and increase construction speed.

(2)Laying in rolls: Using geotextiles in roll form instead of sheets can reduce the number of joints and increase construction speed. The laying of membranes is more efficient and reduces waste during construction.

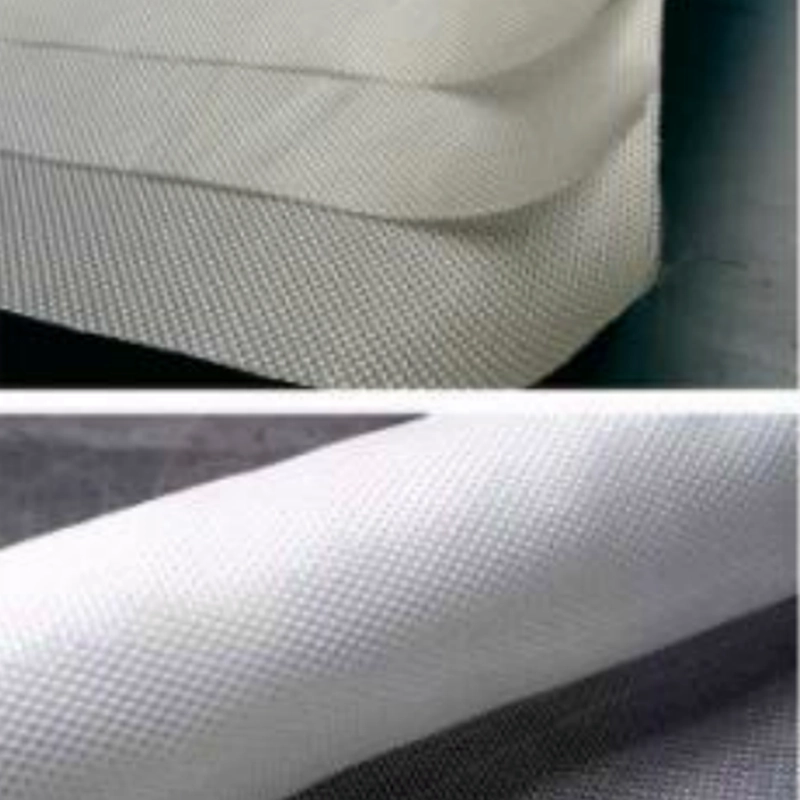

(3)Use non-woven geotextiles: Non-woven geotextiles have better tensile strength and abrasion resistance than woven geotextiles, and are usually cheaper. Therefore, on the premise of meeting engineering needs, choosing suitable non-woven geotextiles can reduce costs.

(4)Introducing mechanical equipment to assist construction: In large-scale highway construction, introducing mechanical equipment (such as spreaders, winches, etc.) to lay geotextiles can greatly increase the construction speed and reduce labor costs.

(5)Precise construction technology: Use precise construction technology to ensure the correct laying and connection of geotextiles, reduce the possibility of damage and re-construction, and improve construction efficiency.

(6)Reasonable procurement and supply chain management: When purchasing geotextile materials, conduct full price comparisons and select suppliers with high cost-effectiveness. Effective supply chain management helps obtain required materials in a timely manner and reduces procurement costs.

(7)Training and skill improvement: Provide professional training for engineering personnel to improve their proficiency in geotextile construction technology and ensure that construction tasks are completed efficiently and safely.

By comprehensively applying the above strategies, rapid construction of geotextiles and effective cost control can be achieved in highway construction.

6、Strong adaptability: Geotextiles have strong adaptability and can be applied to various geological conditions and different types of roadbeds. It can adapt to complex terrain and climate conditions.

Improving the adaptability of geotextiles in highway construction mainly involves selecting appropriate geotextile types, specifications and construction methods to meet different engineering environments and requirements. Here are some suggestions for improving the adaptability of geotextiles:

(1)Suitable geotextile type: Select the appropriate type of geotextile based on project requirements and land conditions. For example, woven geotextiles and non-woven geotextiles have different adaptability in different situations, and the choice can be made according to specific needs.

(2)Diverse specification selection: Geotextiles come in different specifications and thicknesses. Choose the appropriate specifications to adapt to different engineering environments. For high-load areas, thicker geotextiles can be selected, while for low-load areas, relatively thinner specifications can be selected.

(3)Anti-UV performance: Consider the anti-UV performance of geotextile, especially in places exposed to the sun for a long time outdoors. Choose geotextiles with good UV resistance to ensure long service life.

(4)Chemical resistance: In environments where resistance to chemical corrosion is required, choose geotextiles with good chemical stability. This is particularly important in areas where chemicals may be involved in road construction.

(5)Strong tensile strength: Consider the tensile strength of geotextile to ensure that it can cope with the challenges of land deformation, load and other external forces and improve its adaptability.

(6)Reasonable construction methods: Use reasonable construction methods, such as correct connection and fixation methods, to ensure the integrity and stability of the geotextile. Different construction environments may require different fixing methods.

(7)Comprehensive consideration of project needs: Comprehensive consideration of geological conditions, load requirements, hydrological conditions and other factors of highway projects, and select geotextiles with strong adaptability. Different engineering environments require different adaptability.

(8)Professional advice: When selecting and using geotextiles, seek the advice of a professional geotechnical engineer or consultant to ensure the adaptability of the geotextile meets the requirements of the specific project.

By comprehensively considering these factors, the adaptability of geotextiles in highway construction can be improved to ensure that they can perform optimally in various environments.

The use of flat yarn woven geotextiles in Jinan high-speed extension lines

7、Environmental protection and sustainability: Geotextiles are usually made of environmentally friendly materials and are recyclable. In highway construction, the use of geotextiles can reduce the impact on the natural environment and embody the concept of sustainable development.

The environmental protection and sustainability of geotextiles in highway construction mainly involve the following considerations:

(1)Raw material selection: Choose environmentally friendly and sustainable raw materials to manufacture geotextiles. Some advanced geotextiles are made from recyclable materials, reducing reliance on natural resources.

(2)Production process optimization: By optimizing the production process, energy consumption and waste emissions are reduced, and the environmental protection of the production process is improved. Adopt more environmentally friendly production technologies and equipment to reduce the impact on the environment.

(3)Biodegradable properties: Some geotextiles have degradable properties and can degrade naturally after a certain period of time, reducing long-term impact on the environment. This is very beneficial for engineering scenarios that require temporary support.

(4)Long-term stability: Choose geotextiles with long-term stability to reduce the frequency of replacement and maintenance. This helps reduce waste of resources and improves service life.

(5)Recycling: Some geotextiles can be cleaned, repaired or reused after completing a project, reducing resource consumption. This recycling practice helps improve sustainability.

(6)Project Design and Planning: During the design and planning stages of highway projects, consider the rational use of geotextiles to minimize damage to land and water resources. Scientific and rational design helps achieve sustainability goals.

(7)Environmental certification: Choose geotextile products that have passed environmental certification to ensure that they comply with relevant environmental standards and regulations. This helps verify the environmental performance of the product.

(8)Monitoring and evaluation: During the use of geotextiles, a monitoring and evaluation system should be established to track and evaluate the performance and environmental impact of geotextiles. Identify problems promptly and take measures to ensure project sustainability.

By comprehensively considering these aspects, geotextiles can better achieve environmental protection and sustainability in highway construction. This requires the joint efforts of the entire supply chain and project implementers to ensure that the use of geotextiles has minimal impact on the environment.

Enhanced environmental protection in Haoyang filament non-woven geotextile highway construction

Takenthe top 7 together, the application of geotextiles in highway construction has comprehensive advantages and specific details. It can improve the engineering performance of the roadbed, extend the service life of the road surface, and improve the overall quality and sustainability of the highway project.

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)

241.webp)

191.webp)