Geomembranes are essential materials used in various civil engineering and environmental applications to provide reliable containment and protection against fluid migration or environmental contamination. Understanding their technical properties is crucial for selecting the right geomembrane for specific projects.

Technical values of Geomembrane

The technical values of geomembranes encompass a range of physical, mechanical, hydraulic, and durability properties that determine their suitability for specific applications. Here are some common technical values associated with geomembranes:

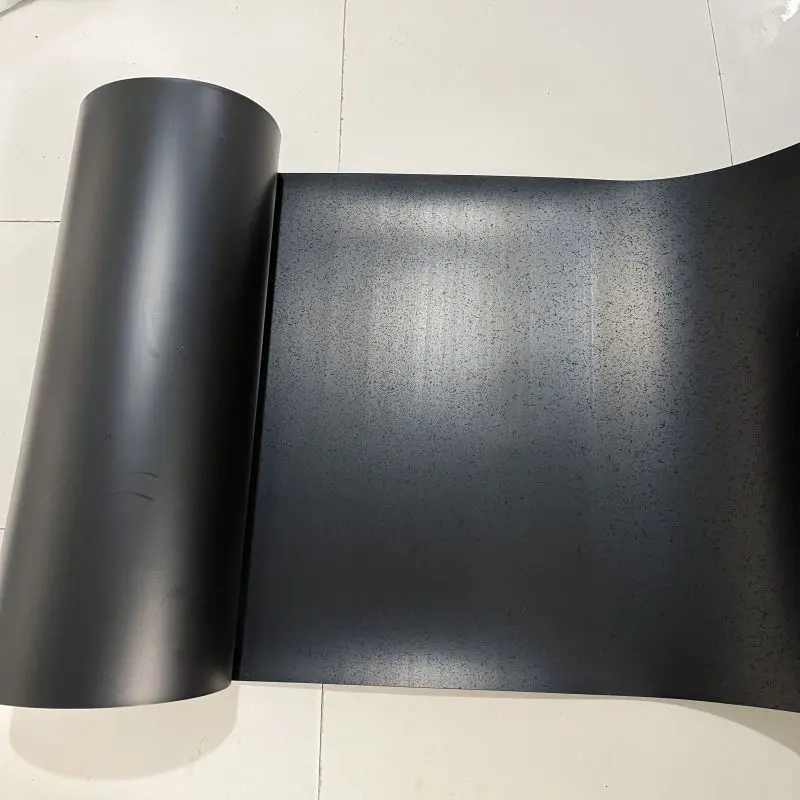

1, Thickness: This refers to the measurement of the thickness of the geomembrane material. It is important as it directly affects the barrier properties of the geomembrane, such as its impermeability and resistance to puncture.

923051.webp)

The thickness of a geomembrane directly impacts its barrier properties. Thicker geomembranes generally provide greater resistance to permeation and puncture, making them suitable for applications where robust containment is required, such as landfill liners or pond liners.

2, Density: Density refers to the mass per unit volume of the geomembrane material. It is a measure of how tightly packed the molecules are within the material. Density can affect various properties of the geomembrane, including its mechanical strength and resistance to environmental factors.

112269.webp)

The density of a geomembrane affects its mechanical properties and overall performance. Higher density geomembranes tend to have better tensile strength and puncture resistance, offering enhanced durability and longevity in demanding environments.

3,Tensile Yield and Ultimate Strength: Tensile strength measures the maximum amount of tensile stress a material can withstand before it fails or breaks. Yield strength is the stress at which a material begins to deform permanently. Ultimate strength is the maximum stress a material can withstand before complete failure. These properties are critical for assessing the ability of the geomembrane to withstand stretching or pulling forces without tearing.

972704.webp)

These properties are crucial for assessing the structural integrity and load-bearing capacity of geomembranes. Geomembranes with higher tensile yield and ultimate strength can withstand greater stretching forces without tearing or failure, making them suitable for applications where high tensile strength is required, such as in retaining walls or floating covers.

4, Right Angle Tear Load: This measures the resistance of the geomembrane to tearing when a force is applied at a right angle to a pre-cut slot in the material. It indicates the material's tear resistance under specific conditions.

The right angle tear load indicates the resistance of the geomembrane to tearing under specific conditions. Higher tear resistance is desirable in geomembranes used in environments where sharp objects or abrasive materials may be present, reducing the risk of punctures and tears that could compromise containment integrity.

5,Puncture Resistance: Puncture resistance measures the ability of the geomembrane to withstand penetration by sharp objects or puncturing forces. It is crucial for applications where the geomembrane is exposed to potential puncture hazards, such as landfill liners.

Puncture resistance is critical for geomembranes employed in applications where they may be exposed to puncture hazards, such as industrial storage facilities or wastewater treatment plants. Geomembranes with superior puncture resistance can effectively withstand penetration by sharp objects or debris, minimizing the risk of leaks or contamination.

6, Environmental Stress Cracking Resistance: This property measures the ability of the geomembrane to resist cracking when subjected to environmental stresses such as chemicals, temperature variations, and UV radiation. Cracking can compromise the integrity of the geomembrane and lead to leaks or failure.

The ability of a geomembrane to resist environmental stress cracking is essential for long-term performance in harsh conditions. Geomembranes with high environmental stress cracking resistance can maintain their structural integrity and barrier properties when exposed to chemicals, temperature fluctuations, and UV radiation, ensuring reliable containment over time.

7, Carbon Black Content: Carbon black is often added to geomembranes as a UV stabilizer and to enhance their durability. The carbon black content indicates the concentration of carbon black in the material, which directly influences its resistance to UV degradation and overall longevity.

8, Carbon Black Dispersion: This refers to how uniformly the carbon black particles are distributed within the geomembrane material. A uniform dispersion of carbon black ensures consistent UV protection and durability throughout the geomembrane.

801637.webp)

Carbon black serves as a UV stabilizer in geomembranes, providing protection against degradation caused by sunlight exposure. Geomembranes with higher carbon black content offer increased UV resistance, making them suitable for outdoor applications where prolonged exposure to sunlight is expected, such as in reservoirs or irrigation channels.

9, Oxidation Induction Time: This measures the resistance of the geomembrane to oxidation, which can degrade the material over time. A longer oxidation induction time indicates better resistance to oxidative degradation.

A longer oxidation induction time indicates better resistance to oxidative degradation, which can prolong the service life of geomembranes in challenging environments. Geomembranes with higher oxidation induction times are less prone to deterioration from exposure to oxygen, ozone, or other oxidizing agents, ensuring reliable performance in a range of applications.

10, Oven Aging: This test subjects the geomembrane to accelerated aging conditions, such as elevated temperatures, to simulate long-term exposure to environmental factors. It helps assess the material's durability and performance over time.

The oven aging test provides insights into the long-term durability and stability of geomembranes under accelerated aging conditions. Geomembranes that exhibit minimal changes in properties after oven aging are more likely to maintain their performance characteristics over time, offering reliable containment and protection in demanding applications.

11, Ultraviolet Resistance Strength: This measures the ability of the geomembrane to resist degradation caused by exposure to ultraviolet (UV) radiation from sunlight. UV resistance is crucial for outdoor applications to prevent premature aging and deterioration of the geomembrane.

Geomembranes exposed to sunlight can degrade over time due to UV radiation. Geomembranes with high ultraviolet resistance strength can withstand prolonged exposure to sunlight without significant deterioration, ensuring long-term performance and durability in outdoor applications such as reservoirs, landfills, or agricultural ponds.

In summary, the technical values of geomembranes encompass a range of parameters that impact their performance and suitability for specific applications. By considering these factors carefully, engineers and environmental professionals can ensure the successful implementation of geomembrane systems for containment and protection needs.

If you are interested in geomemrbrane products, fell free to contact Echo:

Phone/Whatsapp: 0086-18853127527

email: export@hygeosynthetics.com

897.webp)

942.webp)

237.webp)