What are geotextiles ?

Geotextiles are synthetic textile materials designed for use in civil engineering, construction, environmental, and geotechnical engineering applications. They are engineered fabrics made from polymers such as polypropylene, polyester, polyethylene, or other synthetic materials. Geotextiles possess unique properties that make them useful in various functions within the construction and infrastructure development sectors.

Characteristics of geotextiles

1. Porosity and Permeability:

Geotextiles have a porous structure that allows water to pass through while retaining soil particles. They aid in drainage by allowing water flow while preventing soil loss.

2. Strength and Durability:

They exhibit high tensile strength and durability, enabling them to withstand loads, stresses, and external forces within construction applications.

3. Filtration and Separation:

Geotextiles act as filters, allowing water to pass through while retaining soil particles. They're used to separate different soil layers, preventing mixing and maintaining structural integrity.

4. Erosion Control:

By stabilizing soil, geotextiles help prevent erosion caused by water flow, wind, or other environmental factors. They are crucial in protecting slopes, embankments, and shorelines from erosion.

5. Reinforcement:

Geotextiles reinforce soil by distributing loads and enhancing soil stability. They are used in soil reinforcement applications to strengthen weak soils and provide structural support.

6. Cushioning and Protection:

In certain applications, geotextiles act as a cushion or protective layer, safeguarding geomembranes, pipes, or other components from damage due to abrasion or puncture.

7. Environmental Benefits:

Some geotextiles are designed to be environmentally friendly, biodegradable, or made from recycled materials, offering sustainable solutions for various applications.

Applications of Geotextiles

539377.webp)

Road Construction: Used in roadways for separation, filtration, and reinforcement in pavement systems.

Drainage Systems: Utilized to aid in subsurface drainage by allowing water flow while preventing soil intrusion.

Landfills: Employed as liners, covers, or drainage layers in landfill construction to contain waste and manage leachate.

Erosion Control: Applied in slope stabilization, riverbanks, and coastal areas to prevent soil erosion.

Civil Engineering Projects: Used in construction of retaining walls, embankments, and foundations to improve stability.

Geotextiles come in various types, such as woven, non-woven, needle-punched, knitted, and specialized variants, each tailored to specific applications. They play a crucial role in modern construction practices by enhancing soil properties, improving infrastructure resilience, and providing environmentally sustainable solutions.

Types

Geotextiles are synthetic textile materials used in civil engineering and various construction projects for their filtration, separation, reinforcement, drainage, and erosion control properties. They are classified into several types based on their specific functions and manufacturing processes. Some common types of geotextiles include:

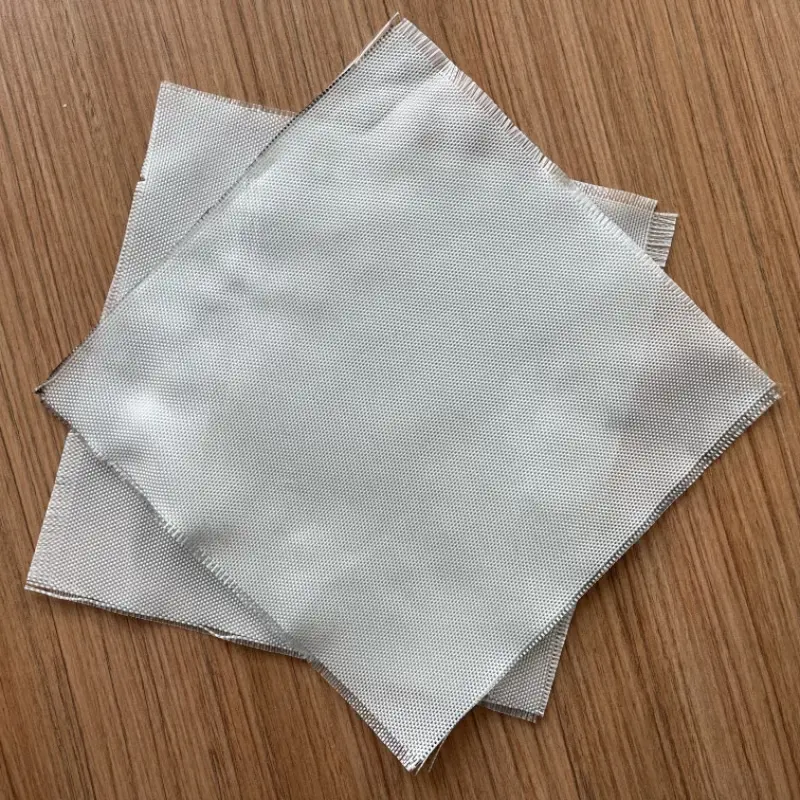

1. Woven Geotextiles

Woven geotextiles are a type of geotextile material constructed by weaving polypropylene, polyester, or other synthetic yarns together to form a stable fabric structure. These geotextiles are manufactured using traditional weaving techniques similar to those used in textile production. The weaving process interlaces individual yarns in a regular pattern to create a strong and durable fabric with distinct characteristics suitable for various civil engineering and construction applications.

Constructed by weaving polypropylene or polyester tapes or yarns together.

High tensile strength and resistance to stretching.

Used for applications requiring strength, filtration, and separation, such as road stabilization, embankment reinforcement, and erosion control.

184321.webp)

2. Non-Woven Geotextiles

Non-woven geotextiles are a type of geotextile material made from synthetic fibers that are mechanically or thermally bonded together, rather than being woven like traditional textiles. These geotextiles are manufactured by layering and bonding fibers using processes such as needle-punching, heat-bonding, or chemical bonding to form a stable fabric structure without traditional weaving.

Made by mechanically bonding or thermally bonding fibers.

Higher permeability and excellent filtration properties.

Ideal for drainage, soil separation, and erosion control in various construction projects.

3. Needle-Punched Geotextiles

Needle-punched geotextiles are a type of non-woven geotextile produced by mechanically bonding synthetic fibers together using a needle-punching process. This manufacturing method involves entangling and interlocking individual fibers using barbed needles without the need for additional binding agents, adhesives, or heat.

Manufactured by mechanically interlocking fibers through needle punching.

Offers good tensile strength and puncture resistance.

Used for drainage, filtration, and protection against soil erosion in different applications.

4. Knitted Geotextiles

Knitted geotextiles are a type of geotextile material manufactured through a knitting process involving interlocking synthetic yarns or fibers to create a stable and flexible fabric structure. Unlike woven geotextiles, which are produced by weaving yarns together, knitted geotextiles are created using knitting machines that form loops of yarn, resulting in a more flexible and conformable fabric.

Created using knitting machines that interlace yarns to form a fabric structure.

Flexible and conformable, providing excellent elongation characteristics.

Commonly used for applications requiring drainage, soil stabilization, and reinforcement.

5. Composite Geotextiles

Composite geotextiles are specialized geotextile materials that combine two or more different types of geotextiles or other materials into a single product to achieve enhanced functionalities and performance. These composites are designed to leverage the beneficial properties of individual geotextiles or materials to address specific engineering or construction challenges.

Combine two or more types of geotextiles or other materials (such as membranes, films, or grids) into a single product.

Offer enhanced functionalities like increased strength, filtration, and drainage capabilities.

Used in various applications where multiple functions are required, such as landfill liners, erosion control, and road construction.

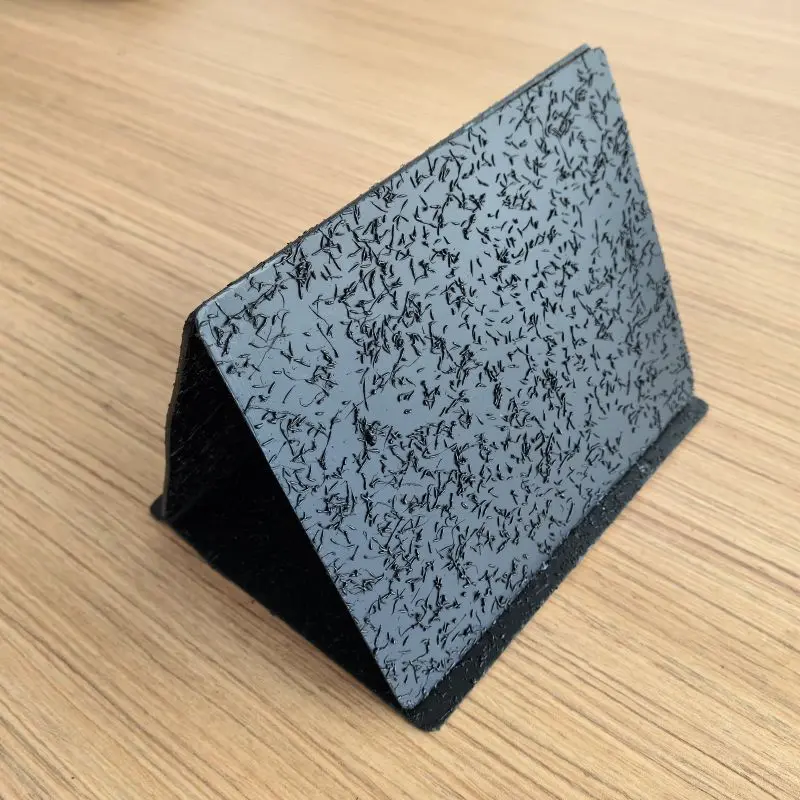

6. Geogrids

Geogrids are specialized geosynthetic materials consisting of a grid-like structure typically made from polymers, fiberglass, or other high-strength materials. These materials are manufactured in the form of intersecting ribs or strands, creating apertures or openings within the grid structure. Geogrids are designed to provide soil reinforcement, improve stability, and reduce soil movement in various civil engineering and construction applications.

Although not technically geotextiles, geogrids are often grouped with geotextiles.

Made of polymer or other materials and characterized by large open spaces or apertures.

Used primarily for soil reinforcement, providing stability, and reducing soil movement in structures like retaining walls, slopes, and roadways.

7. Silt Fence Geotextiles

Silt fence geotextiles, also known as erosion control fabric or silt barriers, are specialized geotextile materials designed to control sediment runoff and soil erosion on construction sites, particularly during earthwork, grading, or land development activities. These geotextiles are deployed as barriers to contain sediment-laden runoff while allowing water to pass through.

Specifically designed to control sediment runoff and erosion on construction sites.

Typically made of woven or non-woven materials and used as barriers to trap sediment while allowing water to flow through.

8. Coir Geotextiles

Coir geotextiles are natural geotextile materials made from coconut fibers extracted from the husk of coconut fruits. These biodegradable and environmentally friendly geotextiles are derived from a renewable resource and find various applications in erosion control, soil stabilization, landscaping, and environmental projects.

Made from natural coconut fibers and used in erosion control, slope stabilization, and landscaping applications.

Biodegradable and environmentally friendly alternative to synthetic geotextiles in certain applications.

These different types of geotextiles offer a wide range of properties and functionalities, allowing engineers and construction professionals to choose the most suitable material based on the specific requirements of their projects.

9. High-Strength Geotextiles

High-strength geotextiles are specialized geotextile materials engineered to possess exceptionally high tensile strength, durability, and robustness. These geotextiles are designed to withstand heavy loads, high stresses, and demanding conditions in various civil engineering, construction, and infrastructure applications where superior strength properties are required.

Geotextiles designed with exceptionally high tensile strength for applications requiring heavy loads or structural support.

Used in road construction, reinforcement of soft soils, and stabilization of steep slopes.

10. Geomembranes

Geomembranes are synthetic liners or barriers used in various engineering, environmental, and containment applications to control the movement of liquids, gases, and pollutants. They are impermeable sheets or membranes made from synthetic materials like high-density polyethylene (HDPE), polyvinyl chloride (PVC), polypropylene (PP), ethylene propylene diene monomer (EPDM), and other polymer-based materials.

Impermeable sheets or liners used as barriers to prevent fluid migration or seepage.

Often made of materials like HDPE (High-Density Polyethylene) or PVC (Polyvinyl Chloride).

Commonly used in landfill liners, containment ponds, and liquid containment areas.

11. Paving Geotextiles

Paving geotextiles, also known as paving fabrics or asphalt overlays, are specialized geotextile materials used in pavement systems to enhance performance, durability, and longevity of roads, highways, and parking lots. These geotextiles are placed between pavement layers to improve structural integrity, reduce cracking, and prolong the lifespan of the pavement.

Geotextiles specifically engineered to be placed between pavement layers to reduce cracking and enhance structural integrity.

Helps in distributing loads and preventing reflective cracking in roads, highways, and parking lots.

12. Root Barrier Geotextiles

Root barrier geotextiles are a type of geotextile designed specifically to control the growth of roots in certain areas, preventing their intrusion into structures, utilities, or sensitive zones. These geotextiles act as a barrier to restrain root growth, directing roots away from particular areas where their penetration could cause damage or interference.

Root barrier geotextiles are typically made from durable and impermeable materials, often utilizing high-density polyethylene (HDPE), polypropylene (PP), or other synthetic polymers. Their primary function is to obstruct and redirect root growth, providing a physical barrier that discourages roots from spreading into restricted zones, such as building foundations, sidewalks, roads, utilities, or landscaping areas where root penetration could cause structural damage or disrupt infrastructure.

The geotextile's structure is designed to inhibit root penetration while allowing adequate water and oxygen permeability to sustain healthy root growth in other desired areas. Root barrier geotextiles are commonly used in urban landscapes, construction sites, and infrastructure projects to protect structures and utilities from the potential damage caused by invasive root systems.

Geotextiles designed to control the growth of roots in specific areas.

Used in landscaping and construction to prevent root intrusion into structures, pavement, and underground utilities.

13. Prefabricated Vertical Drains (PVDs)

Prefabricated Vertical Drains (PVDs), also known as wick drains, are geotechnical engineering solutions used to accelerate the consolidation process of soft and compressible soils, such as clay or silt, in land reclamation, ground improvement, and soil consolidation projects.

Narrow geotextile strips used for accelerating the consolidation of soft, compressible soils by enhancing drainage.

Installed vertically into the ground to provide pathways for water to escape, speeding up soil consolidation.

14. Soil Erosion Control Blankets/Mats

Soil erosion control blankets are a type of geotextile, also known as erosion control mats or blankets, are geosynthetic products used to mitigate and prevent soil erosion in areas prone to erosion, such as steep slopes, embankments, construction sites, or areas affected by wildfire or landscaping activities. These blankets act as protective covers over soil surfaces, offering stabilization, erosion control, and vegetation establishment.

Geotextile blankets or mats combined with seed and mulch used to prevent soil erosion on slopes, banks, or disturbed areas.

Aids in vegetation growth and stabilization while protecting soil from erosion due to water runoff.

15. Agricultural Geotextiles

Agricultural geotextiles are a type of geotextile fabric specifically designed and used in agricultural applications to improve soil health, control erosion, facilitate drainage, and aid in crop growth. These geotextiles are employed in various agricultural practices to enhance soil structure, protect crops, and improve water management.

Geotextiles used in agriculture for weed control, moisture retention, and protection of crops.

They come in various forms, including woven, non-woven, or mulch films, to cater to different agricultural needs.

16. Coated Geotextiles

Coated geotextiles refer to a type of geotextile fabric that has undergone a coating process, where a layer of material is applied onto the surface of the geotextile. This coating provides additional functionalities and characteristics to the geotextile, enhancing its performance in various engineering and construction applications.

Geotextiles with specialized coatings or treatments to enhance specific properties such as UV resistance, chemical resistance, or waterproofing.

Used in applications where additional protection or durability is required.

These diverse types of geotextiles cater to a wide array of engineering, construction, environmental, and agricultural needs, offering tailored solutions for various soil stabilization, drainage, filtration, and erosion control applications.

17. Hydrophilic Geotextiles

Hydrophilic geotextiles are a type of geotextile fabric designed with an inherent ability to attract and absorb water. These geotextiles are engineered to be water-attracting or moisture-absorbing, allowing them to efficiently manage water flow, drainage, and filtration in various civil engineering and construction applications.

Geotextiles designed to absorb and retain water, aiding in drainage, filtration, and erosion control.

Used in areas where moisture management and groundwater control are essential, such as landfills, drainage systems, and landscaping.

18. Geotextile Tubes/Bags

Geotextile tubes or bags, also known as geotextile containers, geotextile dewatering bags, or geotextile tubes, are specialized geotextile materials designed in the form of large, tubular bags or tubes used for dewatering, containment, or shoreline protection in various civil engineering, environmental, or hydraulic applications.

Geotextile containers used for dewatering, sediment control, and shoreline protection.

Filled with sludge, sediment, or other materials, and employed in construction, environmental remediation, and coastal restoration projects.

19. Thermally Bonded Geotextiles

Thermally bonded geotextiles are a type of geotextile fabric produced through a manufacturing process that involves heat and pressure to bind synthetic fibers together without the use of additional adhesives or binders.

Geotextiles produced by using heat to bond fibers together, providing strength and stability.

Suitable for separation, filtration, and reinforcement in road construction, railways, and embankment stabilization.

Thermally bonded geotextiles are favored for their consistent quality, reliability, and versatility in civil engineering, construction, and environmental projects where geotextiles are employed for filtration, separation, reinforcement, or other geotechnical functions. Their ability to offer a stable and durable fabric without additional binding agents makes them suitable for various geotechnical applications.

20. Biodegradable Geotextiles

Biodegradable geotextiles are a type of geotextile material designed to degrade naturally over time when exposed to environmental conditions, ultimately breaking down into simpler, harmless substances. These geotextiles are made from biodegradable materials such as natural fibers (e.g., jute, coir) or biodegradable polymers that decompose through biological processes, contributing to reduced environmental impact.

Geotextiles made from natural materials or biodegradable polymers that break down over time.

Used in erosion control, temporary applications, and environmentally sensitive areas where degradation is desired.

21. Floating Geotextiles

Floating geotextiles, also known as floating turbidity curtains or silt curtains, are specialized geotextile barriers used in water bodies to control the movement of sediment, silt, or pollutants while allowing water to pass through. These curtains float on the surface of water bodies and are employed in various aquatic settings for environmental protection, sediment control, and water quality management.

Geotextiles designed to float on water surfaces, offering protection, erosion control, and habitat improvement in water bodies.

Used in applications such as shoreline protection, restoration of wetlands, and reservoir covers.

22. Antistatic Geotextiles

Antistatic geotextiles are a specialized type of geotextile fabric engineered to control or dissipate static electricity that may build up within certain environments or applications. These geotextiles are designed to prevent the accumulation of electrical charges and minimize the risk of electrostatic discharge in specific situations where static electricity can pose hazards or interfere with sensitive equipment or materials.

Geotextiles with antistatic properties used in applications where static electricity buildup needs to be prevented.

Employed in specialized construction projects or areas sensitive to electrostatic discharge.

23. Microbial Geotextiles

Microbial geotextiles, sometimes referred to as bioremediation geotextiles or bio-geotextiles, incorporate microorganisms or microbial additives within geotextile materials to facilitate biodegradation or biological processes. These specialized geotextiles are designed to promote microbial activity and aid in the breakdown or treatment of pollutants, organic matter, or contaminants in soil or water environments.

Geotextiles integrated with microbes or bioactive components to aid in environmental remediation or soil improvement.

Used in soil bioengineering, bioremediation, and ecological restoration projects.

These specialized geotextiles cater to specific requirements in various industries and applications, offering solutions for unique challenges related to soil stabilization, erosion control, drainage, and environmental sustainability.

Purchasing Considerations

Project Requirements: Assess your project needs for filtration, drainage, separation, or reinforcement.

Site Conditions: Consider environmental factors like soil type, water flow, and load-bearing requirements.

Material Specifications: Evaluate tensile strength, permeability, thickness, and durability to align with project demands.

Regulatory Compliance: Ensure geotextiles meet relevant industry standards and regulations for quality and performance.

By understanding the characteristics, applications, and considerations for different types of geotextiles, you can make an informed decision when purchasing, ensuring that the selected material aligns with your project's specific requirements and offers optimal performance and durability.

Geotextile manufacturing standards

The manufacturing standards for geotextiles typically encompass various criteria and specifications established to ensure the quality, performance, and suitability of these materials for diverse applications. Some of the key standards applicable to geotextile manufacturers include:

ASTM International Standards:

ASTM D5261: Standard Test Method for Measuring Mass per Unit Area of Geotextiles.

ASTM D4533: Standard Test Method for Trapezoid Tearing Strength of Geotextiles.

ASTM D4354: Standard Practice for Sampling of Geosynthetics for Testing.

ASTM D4751: Standard Test Methods for Determining Apparent Opening Size of a Geotextile.

ISO (International Organization for Standardization) Standards:

ISO 10319: Geosynthetics - Wide-width tensile test.

ISO 12956: Geotextiles and geotextile-related products - Determination of water permeability characteristics.

ISO 13433: Geotextiles and geotextile-related products - Determination of thickness.

European Standards (EN):

EN 13249: Geotextiles and geotextile-related products - Determination of the tensile strength and elongation.

EN ISO 12958: Geotextiles and geotextile-related products - Determination of water flow capacity in their plane.

Geosynthetic Materials Association (GMA) Guidelines:

GMA GC8: Recommended Specification for Woven Monofilament Geotextiles.

GMA GC9: Recommended Specification for Woven Slit-Film Geotextiles.

Geotechnical Engineering Standards:

Geotechnical Fabrics Report: Specifications and recommendations by engineering associations, focusing on geotextile usage in civil engineering, soil stabilization, drainage, and erosion control.

These standards encompass a range of testing methods, performance criteria, and quality control measures aimed at evaluating characteristics such as tensile strength, durability, permeability, thickness, and other essential properties of geotextile materials. Manufacturers often adhere to these standards to ensure their geotextile products meet industry requirements and perform reliably in various geotechnical and civil engineering applications.

About Haoyang Environmental

Haoyang Environmental Protection is a leading name in the realm of geotextile manufacturing, known for its commitment to quality, innovation, and sustainable solutions in the geotechnical industry. With a strong focus on producing high-performance geotextiles, Haoyang has established itself as a reliable partner for various engineering and environmental projects worldwide.

As a reputable geotextile manufacturer, Haoyang Environmental Protection stands at the forefront of innovation, quality, and sustainability. Their dedication to producing high-quality geotextiles tailored to diverse project requirements makes them a trusted choice for geotechnical solutions globally.

For more information about Haoyang Environmental Protection and its range of geotextile offerings, visit company website to explore their comprehensive product line and innovative solutions.

If you want to purchase in bulk please contact us

+8613156125717

info@hygeosynthetics.com

897.webp)

942.webp)

237.webp)