v Basic definition

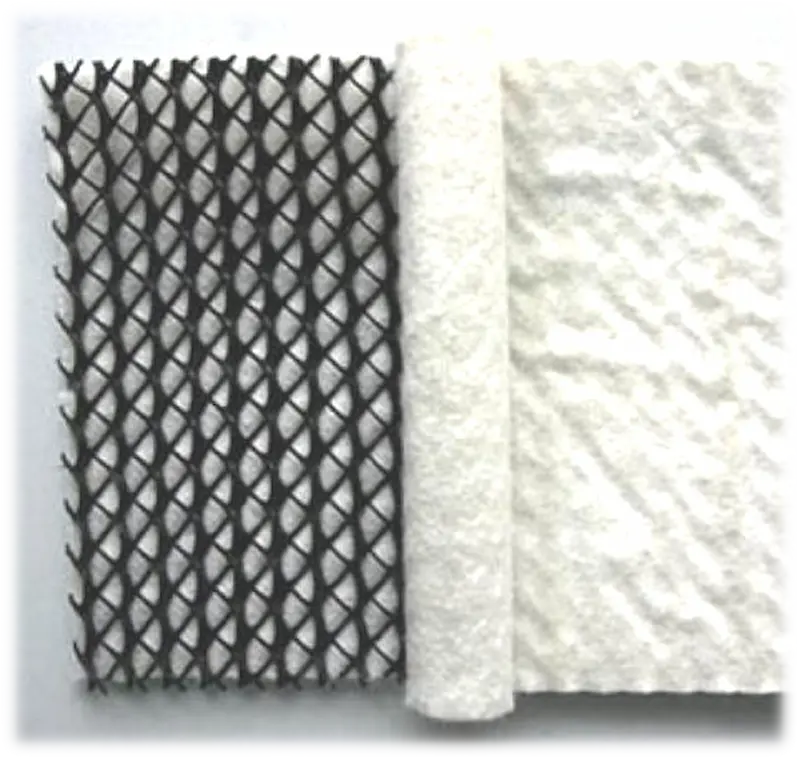

Composite drainage network is a composite material composed of a variety of geomaterials. It usually includes high-strength geomesh and other functional

materials, such as geotextiles (geotextiles) or geomembranes

(The following picture shows the composite drainage network)

v Performance characteristics

1、Excellent drainage performance: The special structure of the mesh core forms a drainage channel with high vertical and horizontal drainage capacity, which can quickly and effectively discharge groundwater or other water bodies, and maintain good drainage performance under high loads.

2、High tensile strength: has a high vertical and horizontal tensile strength, can withstand high tensile stress and compressive stress, can play a certain reinforcement reinforcement role, improve the stability of the soil.

3、Good filtration effect: the external composite permeable geotextile has a filtration function, which can prevent the loss of soil particles, and allow water to pass freely to ensure the smooth drainage.

4、Strong corrosion resistance: the core material generally has good acid and alkali resistance and corrosion resistance, and can maintain good performance and service life under harsh environmental conditions.

v Material composition

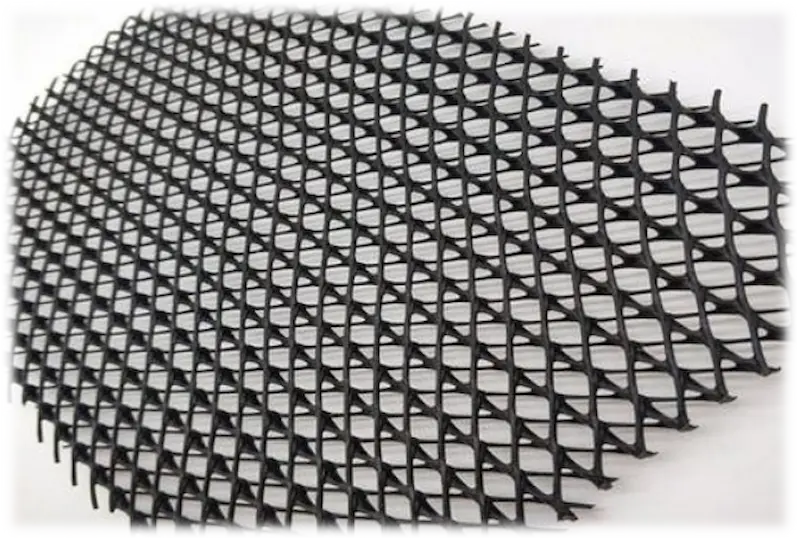

1、drainage network core

Drain core is usually made of high polymer (such as polyethylene, etc.). It has a special three-dimensional structure, which provides an efficient drainage path. For example, the shape may consist of a series of interconnected ribs that form a honeycomb or grill-like structure in space, allowing water to flow rapidly through it. Parameters such as the thickness of the core of the drainage network and the shape and spacing of the ribs will vary according to the specific engineering requirements, thus affecting the drainage capacity of the drainage network.

Polyethylene particle Black mother

2、Geotextiles

2、Geotextiles

Geotextiles are generally made of synthetic fibers (such as polyester fibers) by needling or weaving. It is attached to both sides of the drainage core, and its main function is backfiltration. When water from the soil penetrates into the drainage network, the geotextile can prevent soil particles from entering the drainage channel along with the water flow. Geotextiles have certain pores that are small enough to hold back soil particles but allow water to pass through smoothly, like a fine sieve, ensuring the long-term effectiveness of the drainage system.

Geotextiles are generally made of synthetic fibers (such as polyester fibers) by needling or weaving. It is attached to both sides of the drainage core, and its main function is backfiltration. When water from the soil penetrates into the drainage network, the geotextile can prevent soil particles from entering the drainage channel along with the water flow. Geotextiles have certain pores that are small enough to hold back soil particles but allow water to pass through smoothly, like a fine sieve, ensuring the long-term effectiveness of the drainage system.

Long silk bonded needled nonwovens or other nonwovens

v Application field

1、Landfill site:

It can be used for groundwater drainage layer, leakage detection layer, leachate collection and drainage layer, sealed gas collection and drainage layer, sealed surface water collection and drainage, etc., which can effectively solve the drainage problem of landfill, reduce the pollution of leachate to the environment, and ensure the safety and stability of landfill.

2、Transportation infrastructure:

It is widely used in the subgrade and pavement drainage projects of railways and highways, which can discharge the groundwater in the subgrade or the seepage of the road surface, improve the carrying capacity of the subgrade, prevent the damage of the road due to water, and extend the service life of the road; In tunnel engineering, it can be used for drainage of tunnel inner wall to prevent leakage of tunnel liner due to insufficient drainage performance.

3、Hydraulic engineering:

used for drainage and reinforcement of reservoirs, DAMS and other projects, which can reduce the water pressure inside the dam body, prevent the dam body from being damaged due to excessive water pressure, and improve the stability and safety of the dam body.

4、Other projects:

such as municipal engineering, slope protection engineering, gardens and sports fields will also use geotechnical composite drainage network for drainage and improve the stability of the soil.

v executive standard

Current standard of composite drainage network:

number | standard name | Standard code |

1 | Geotechnical drainage nets for landfills | CJ/T 452-2014 |

2 | Geosynthetic materials for highway engineering - Drainage materials - Part 1: Composite drainage networks | JT/T 1087.1-2016 |

3 | Technical specification for seepage control system engineering of domestic waste landfill | CJJ 113-2007 |

4 | Guide pad | GB/T 40441-2021 |

v Composite drainage network process flow(As shown below)

608895.webp)

v Test items and standards of composite drainage network (refer to CJ/T 452-2014)

number | test project | executive standard |

1 | width | GB/T 6673 |

2 | thickness | GB/T 6672 |

3 | appearance | |

4 | density | GB/T 1033.2 |

5 | Carbon Black Content | GB/T 13021 |

6 | Longitudinal tensile strength | GB/T 15788 |

7 | Longitudinal water conductivity | Standard Appendix A |

8 | peel strength | Standard Appendix B |

9 | Mass per unit area of geotextile | GB/T 13762 |

amount purchased | Price range (for reference only) |

Small lot size (1-99 SQM) | 5 yuan - 15 yuan/square meter |

Medium batch (100-999 m2) | 4 yuan - 10 yuan/square meter |

Large quantities (≥1000 m2) | 2 yuan - 8 yuan/square meter |

The quotation of different regions and different manufacturers may also vary, in the actual purchase, it is recommended to consult multiple suppliers and compare prices and product quality.

v The price of composite drainage network is mainly affected by the following factors:

1、Raw materials:

Types of raw materials: Different raw materials have a greater impact on prices. For example, the price of a composite drainage network using high-density polyethylene (HDPE) as a raw material will be affected by fluctuations in the price of polyethylene market.

2、Raw material quality:

The composite drainage network produced by high-quality raw materials has better performance and longer service life, and its price will be higher than that of ordinary raw materials.

3、Production process:

Production equipment: Advanced production equipment can ensure the production quality and efficiency of the composite drainage network, but the purchase, maintenance and upgrade costs of equipment are high, which will increase the price of the product.

3、Production technology:

Complex and fine production technology can make the structure of the composite drainage network more reasonable and better performance, such as the three-dimensional structure design of the core more scientific, geotextile and the core bond more firmly, etc., which require higher technical costs, resulting in higher product prices.

5、Product specifications:

Core thickness: The larger the thickness of the core, the stronger the drainage capacity and carrying capacity, the more raw materials required for production, and the higher the price. For example, the price of a 6mm thick composite drainage network will be higher than that of a 4mm thick product.

6、Geotextile quality:

The quality of geotextiles on both sides is different, and the price will be different. Geotextiles with large mass per unit area, good filtration performance and strong water permeability have higher costs, which will increase the overall price of the composite drainage network.

Size: Products with larger sizes such as the width and length of the composite drainage network have relatively more production difficulties and raw material consumption, and the price will increase accordingly.

7、Market factors:

Market supply and demand relationship: when the market demand for composite drainage network is strong, and the supply is relatively insufficient, the price will rise; Conversely, when market supply exceeds demand, manufacturers may lower prices in order to compete for market share.

8、Brand effect:

The composite drainage network of well-known brands is usually more guaranteed in terms of product quality and after-sales service, and its brand value will also be reflected in the price of the product, and the price will be relatively high.

9、Transportation and sales costs:

Transportation distance: The distance between the manufacturer and the place of purchase is longer, and the transportation cost will increase, which will be reflected in the price of the product. For example, when purchasing a composite drainage network from another province, the transportation cost will increase the CIF price of the product.

10、Sales channels:

Through different sales channels to buy composite drainage network, the price will be different. In general, the price of purchasing directly from the manufacturer will be relatively low, and buying through the distributor or retailer will increase the price due to the increase in the intermediate link.

v Summary

Composite drainage network is an important geosynthetic material, which is composed of three-dimensional drainage network core and geotextiles on both sides. The drainage network core has a unique three-dimensional structure, forming an efficient drainage channel, geotextiles play a reverse filtration role, the combination of the two makes the composite drainage network has excellent drainage performance, can be quickly drained in the horizontal and vertical directions, but also has a high tensile strength, pressure resistance, corrosion resistance and aging resistance, convenient construction, It is widely used in road, railway, tunnel, water conservancy, landfill and other projects, and plays a key role in ensuring the safety and functional stability of engineering structures.

897.webp)

942.webp)

237.webp)