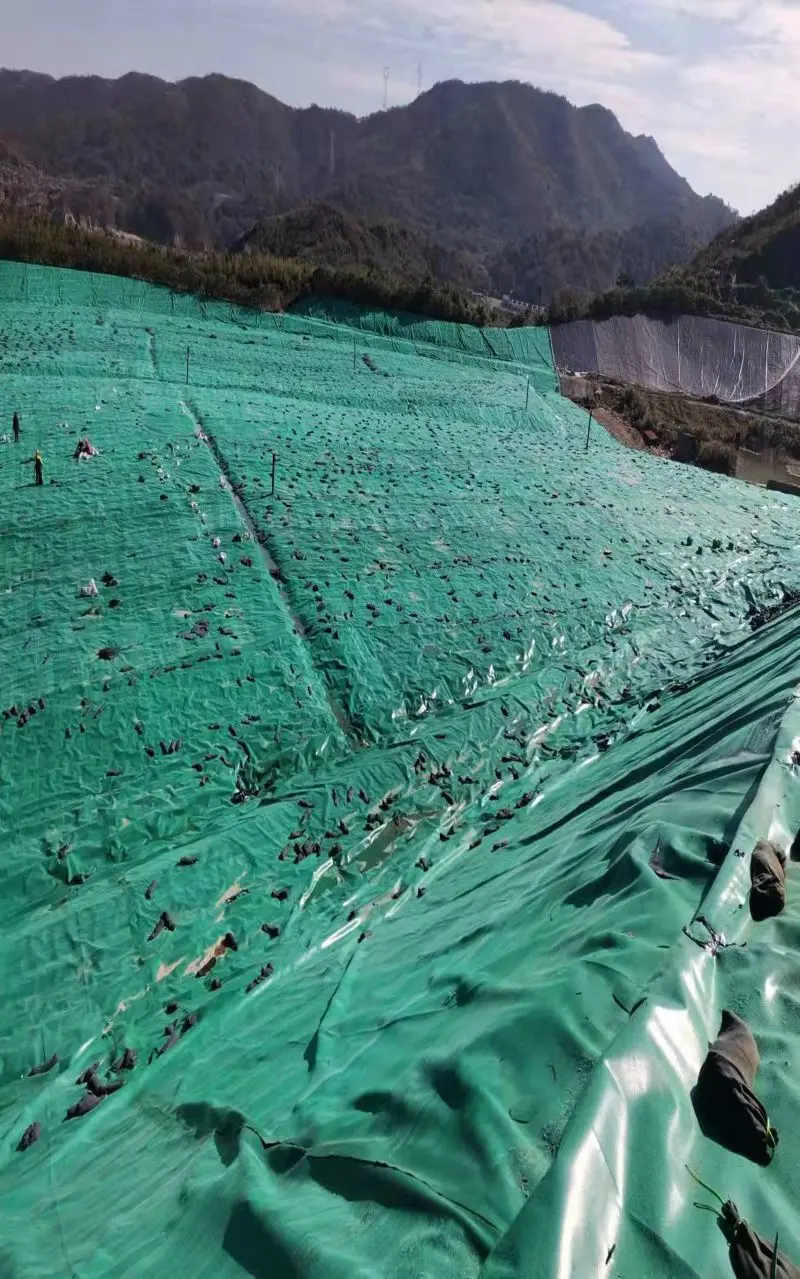

Black and Green Geomembrane

A green geomembrane, also known as a black-green dual-color geomembrane, is a type of geomembrane usually made of high-density polyethylene (HDPE), It is commonly used in landfill closure and rainwater and sewage diversion projects.One side of the geomembrane is black. A certain carbon black content can ensure the anti-aging performance of the geomembrane. One side is green. Green can ensure the environmental protection and beauty of the landfill.

965809.webp)

Specifications

The specifications of our geotextile are as follows:

| Items | 0.3mm | 0.5mm | 0.75mm | 1.0mm | 1.25mm | 15mm | 2.0mm | 2.5mm | 3.0mm |

| Density, g/cm3 | ≥0.94 | ||||||||

| Yield strength,N/mm | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

| Break strength.N/mm | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Yield elongation,% | ≥11 | ||||||||

Break elongation,% | ≥600 | ||||||||

| Tear Resistance(min.ave.),N | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture resistance,N | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

| carbon black content(range)% | 2.0-3.3 | ||||||||

Why Peoppe Choose Green and Black Geomembrane

After the operation of a landfill, with the continuous deposition of waste, various issues such as leachate, landfill gases, and pest infestations may arise to varying degrees. Therefore, it is necessary to temporarily cover the landfill to address these concerns.

Benefits of temporary covering for a landfill site:

1,Rainwater and sewage diversion, reducing the volume of leachate to be treated.

2,Encapsulation, facilitating the collection of landfill gas.

3,Encapsulation, covering odors, facilitating environmental maintenance.

4,Reducing the use of clay layers, increasing storage capacity.

So, green geomembrane are primarily used for daily cover, intermediate cover, and final closure of landfill sites, it can also be applied in projects such as landscape lakes, swimming pools, water channels, and aquaculture reservoirs.

Funtions of Black and Green Geomembrane

A high-quality black-green dual-color geomembrane not only exhibits excellent anti-seepage effects but also possesses high puncture resistance, strong tensile strength, extended aging resistance, weather resistance, and chemical stability. It can withstand high temperatures up to 110°C and low temperatures down to -70°C, making it a reliable anti-seepage material. Additionally, it is resistant to corrosion from strong acids, alkalis, and oils.

This standard black-green geomembrane demonstrates robust tensile strength and elongation at break, allowing HDPE dual-color anti-seepage geomembranes to be used in various challenging geological and climatic conditions.

Issues to be Mindful of During Construction

When working with black-green dual-color geomembranes, attention should be given to the following issues during construction:

Substrate Preparation: Ensure the substrate is smooth, clean, and free from sharp or protruding objects to prevent damage to the geomembrane.

Seam Treatment: Proper treatment of seams between rolls of geomembrane is crucial. Employ professional seam methods to ensure secure and leak-free joints.

Temperature Control: Monitor ambient temperatures during construction to ensure proper laying and bonding of the geomembrane. Avoid construction in extreme temperatures to prevent adverse effects on the geomembrane's performance. When laying HDPE geomembranes, it is essential to consider the local temperature variations and the performance requirements of the HDPE geomembrane. Allow for the expansion and contraction caused by temperature changes and anticipate the expansion and contraction of the geomembrane based on the site topography and the conditions of geomembrane installation to accommodate uneven foundation settlement.

Protective Measures: Implement necessary protective measures on the construction site to prevent damage to the geomembrane from sharp tools, mechanical equipment, or other potential hazards.

Construction Personnel Training: Ensure construction personnel undergo professional training, understanding the correct construction methods and procedures to ensure effective use of the geomembrane.

Quality Control: Conduct quality control checks during construction to ensure the geomembrane meets specified standards.

Factory Diaplay

Haoyang Environmental Co., Ltd. owns more than 20 modern environmental engineering materials production lines, including the first in China with a width of 10 meters blown film geomembrane production line, the first twin-screw filament geotextile production line, and independently developed high-strength reinforced geomembrane production line, high-strength composite geotextile production line, and ultra-wide woven geotextile production line. The products include HDPE geomembranes, composite geomembranes, polyester spunbond filament geotextiles, high-strength woven geotextiles, short fiber geotextiles, three-dimensional composite drainage nets, bentonite waterproof blankets, single and double-directional geogrids, and other novel environmental engineering materials with functions of waterproofing, anti-seepage, reinforcement, isolation, and filtration. They are widely used in various environmental engineering fields, including water conservancy, transportation, urban municipal solid waste treatment, industrial tailings storage, and environmental pollution control.

Our Team

116328.webp)

Every year, we participate together in international geotechnical engineering exhibitions. At these exhibitions, our high-quality product standards and extensive application cases have earned recognition and favor from numerous clients. We have established cooperative intentions with many international buyers, leveraging our success in the exhibitions.If you are interested in geofabrics, please feel free to contact us, looking forward to establish business relationship with you.

FAQ

Q1: Are you factory or trading company?

A: We are factory with more than ten years of experience. weclome to visit our factory.

Q2: What’s your payment term?

A: 30% TT in advance and the balance before shipment or 100% Irrevocable L/C at sight.

Q3: How about the minimum order quantity?

A: We have no MOQ limited for the sample order and regular products.

The MOQ for special customized products is 5000 sqm.

Q4: How long is your delivery time?

A: It depends on the quantity of you quantity.

Usually, it takes 7-10 days upon we receive your deposit.

Q5: How can I get samples?

A: Sample can be sent by DHL or FedEx , etc.

Sample is free and freight collect. We promise we will definitely return the postage to you when we first cooperate.

Q6: Can you advise our pond liner installation and project design?

A: Welding machine is available for your installation.

If necessary, our welder can fly to your project site and install the pond liner. About the project design, we can also give you our rough advice.

337.webp)

322.webp)

767.webp)

503.webp)

759.webp)

574.webp)

585.webp)

523.webp)