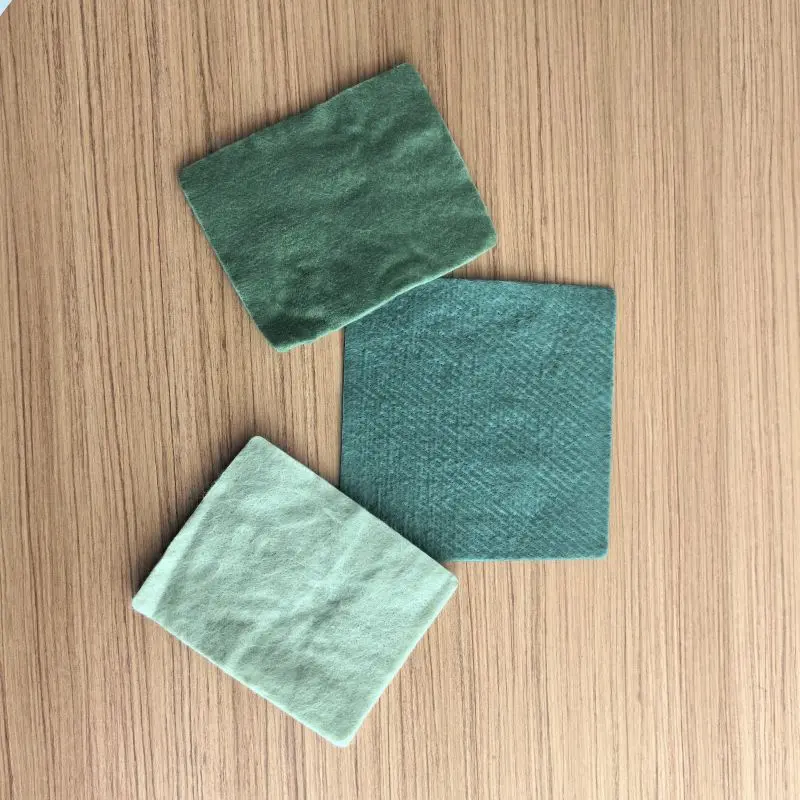

Black, Green, and White Needle Punched Nonwoven Geotextile

Haoyang Environmental Co., Ltd. proudly presents our high-quality needle punched nonwoven geotextile, available in black, green, and white. Engineered for versatility and durability, our geotextiles are ideal for a variety of applications including erosion control, drainage, and soil stabilization. With a focus on sustainability and advanced technology, we ensure that our products meet the highest industry standards.

Classification and Difference of Needle Punched Nonwoven Geotextile

Needle punched nonwoven geotextile is a nonwoven fabric reinforced by needling with fibers, which has the advantages of lightweight, high efficiency, durability, and environmental protection. Depending on different applications and process requirements, needle punched nonwoven geotextile can be made from various types of fibers, such as natural fibers and chemical fibers.

The classification of needle punched nonwoven geotextile can be divided based on their raw materials, weight, and process characteristics. According to the different raw materials, needle-punched nonwovens can be divided into natural fiber needle-punched nonwovens and chemical fiber needle-punched nonwovens. Natural fiber needle-punched nonwovens are usually made of natural fibers such as cotton, hemp, and wool, and have advantages such as environmental protection, comfort, and breathability. Chemical fiber needle-punched nonwovens are made of man-made fibers and have high strength, durability, and water resistance. Our company mainly produces man-made fiber needle-punched nonwovens, which are divided into filament needle-punched nonwovens and staple fiber needle-punched nonwovens based on different fibers.

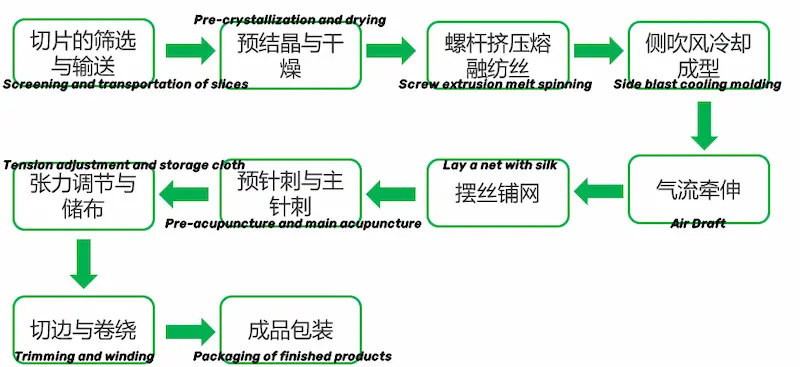

Needle-punched Non-woven Geotextile Process

The following is their process manufacturing process.

Filament:

This technology combines chemical fiber production and nonwoven production into one, with two processes carried out simultaneously on the same production line. The part before the drawing process is basically the same as the production process of synthetic fibers, with screening and transportation of raw materials, drying, screw melting, filtration, melt metering, spinning, and cooling. The drawing process uses air flow drawing process, and after the drawing process, it is a double-swinging wire, which evenly spreads the fiber onto the mesh belt. The fiber arrangement is in a three-dimensional mesh structure, and the fiber web is then subjected to pre-needling machine for fixing, main needle repair and shaping. After that, the product is finally cut by a winder to form a finished product.

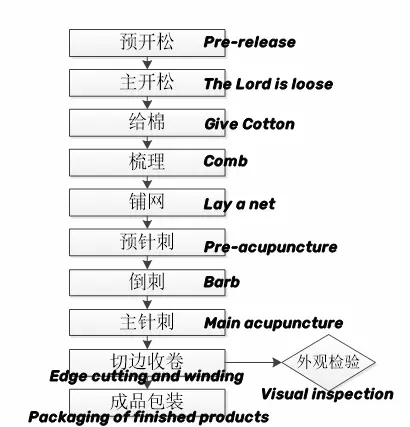

Staple fiber: medium speed staple fiber process flow chart

The production line uses short fibers as raw materials and proceeds through opening, carding, mechanical web formation, pre-needling reinforcement, main needle reinforcement, trimming, and winding to produce finished products.

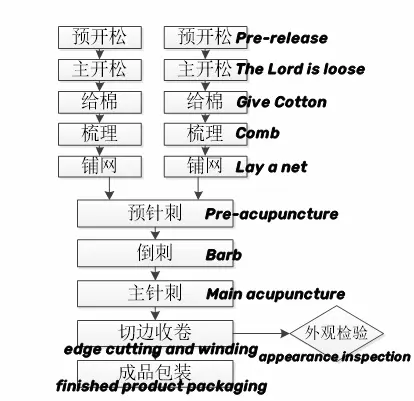

High-speed staple fiber production process

The production line uses short fibers as raw materials, and is made up of two-pass opening, two-pass carding, two-pass mechanical web formation, pre-needling reinforcement, main needling reinforcement, and trimming and winding. The products of this production line can be made with a density of over 1000 grams per square meter, and can be used for the sliding layer of high-speed rail track slabs.

Progressiveness

1. The entire machine is controlled by PLC + touch screen, which ensures high precision in product quality control;

2. The use of a new type of feeding cotton box with a large storage capacity and uniform feeding;

3. Selecting a double-cylinder double-doffer double-random carding machine to achieve multidimensional distribution of fibers in the web and improve the uniformity of each direction;

4. This machine can produce woven composite geotextiles, which are composed of three layers of short-fiber geotextiles: an upper layer of short-fiber geotextiles, a middle layer of woven geotextiles, and a lower layer of short-fiber geotextiles. The three layers are compounded using needle punching technology, which gives them the characteristics of high tensile strength in both the longitudinal and transverse directions, high CBR burst strength, low elongation at break, and the performance of needle punched nonwoven fabrics.

Our high-speed staple fiber production line has two Certificates:

Patent Certificate for Pressing Device of Staple Fiber Equipment and Patent Certificate for Woven Composite Geotextiles

Product Advantages

Superior Filtration: Our needle punched nonwoven geotextiles provide excellent water permeability and soil separation, ensuring effective filtration and preventing soil erosion.

High Strength and Durability: Manufactured using robust synthetic fibers, our geotextiles withstand mechanical stress and environmental factors, offering long-lasting performance in challenging conditions.

Versatile Applications: Available in black, green, and white, our geotextiles can be used in landscaping, civil engineering, and construction projects, providing aesthetic options and functional benefits.

Easy Installation: Lightweight and flexible, our nonwoven geotextiles are easy to handle and install, saving time and labor costs on-site.

Company Advantages

At Haoyang Environmental Co., Ltd., we are committed to quality and innovation. Our certifications, including ISO 9001, ISO 14001, and OHSAS 18001, reflect our dedication to excellence in manufacturing and environmental responsibility. With a professional R&D team and multiple patents, we continuously enhance our products to meet the evolving needs of our clients. Our extensive experience in environmental engineering consulting and waste management positions us as a trusted partner in sustainable solutions.

Contact Us

To learn more about our black, green, and white needle punched nonwoven geotextiles or to discuss your project requirements, please contact us.

Partner with Haoyang Environmental Co., Ltd. for innovative, sustainable geotextile solutions that meet your needs.

172.webp)

503.webp)

759.webp)

861.webp)