1. Introduction to short fiber needle-punched non-woven geotextiles

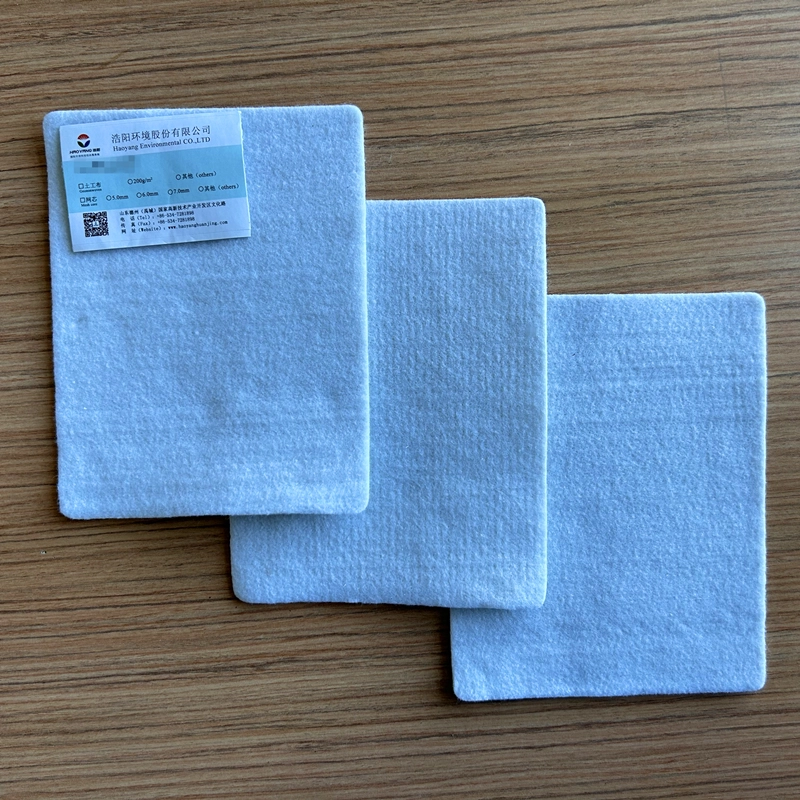

Short fiber needle punched geotextile is a type of nonwoven and industrial fabric. It uses polyester short fiber with a fineness of 6-12 denier and a length of 54-64mm as the raw material. It is made into cloth through non-woven production equipment such as opening, carding, messing (short fibers are intertwined), laying (standardized entanglement and fixation), needle punching and other production processes.

2. Production of short fiber needle-punched non-woven geotextiles

Please refer to the following link for details

Multi-purpose soil management tool of staple fiber needled non-woven geotextile

3. Performance characteristics of short fiber needle-punched non-woven geotextiles

(1) Utilize the good air permeability and water permeability of geotextiles to allow water to pass through, thereby effectively intercepting sand and soil loss;

(2) Geotextile has good water conductivity and can form drainage channels inside the soil to drain excess liquid and gas out of the soil structure;

(3) Use geotextiles to enhance the tensile strength and deformation resistance of the soil and enhance the stability of the building structure to improve the quality of the soil;

(4) Effectively diffuse, transfer or decompose concentrated stress to prevent soil from being damaged by external forces;

(5) Prevent the mixing of sand, soil and concrete between the upper and lower layers;

(6) Because the network structure formed by the amorphous fibrous tissue is adaptable and mobile, the holes are not easily blocked;

(7) It has high water permeability and can still maintain good water permeability under the pressure of soil and water;

(8) Made of polypropylene or polyester and other chemical fibers as raw materials, it is acid and alkali resistant, non-corrosive, non-moth-eaten, and anti-oxidation;

Staple fiber production workshop

4. The role of short fiber needle-punched non-woven geotextile

(1) Isolation function: Used to form an effective isolation layer between different soil layers or materials to prevent mixing and communication between different particles and maintain the stability of the soil layer.

(2) Filtration: Through its uniform pore structure, it can effectively filter water and gas, prevent the penetration of particulate matter, and protect the underlying structure.

(3) Reinforcement and enhancement: It can be used as a reinforcement layer or reinforcing layer to improve the tensile strength and compressive resistance of the soil and increase the stability of the soil.

(4) Drainage function: It has good drainage performance and can quickly remove moisture from the soil, reduce soil saturation, and prevent soil loss and liquefaction.

(5) Protective function: Used as a protective layer in foundation projects to protect underground pipelines and structures from soil erosion and damage.

In general, short-fiber needle-punched non-woven geotextiles play a variety of key roles in projects, helping to maintain the stability of the soil structure and improve the durability and safety of the project.

Application of short fiber needle-punched non-woven geotextile

5. Short fiber needle-punched non-woven geotextiles have a wide range of applications

(1) Short fiber needle-punched non-woven geotextiles have a wide range of applications in the engineering field, including but not limited to the following aspects:

(2) Improvement of soil stability: Used as an isolation layer or reinforcement layer in foundation projects such as roadbeds, railways, airports, and dams to improve soil stability.

(3) Drainage protection: Used in drainage systems of roads, railways, water conservancy projects, etc., as a filter and drainage layer to prevent soil saturation and liquefaction.

(4) Protective covering: In environmental protection and land recycling projects, it is used as a covering layer to protect the soil from erosion and reduce soil erosion and vegetation loss.

(5) Geotechnical filler: As a filler in geotechnical bags, it is used in coastal protection, river management and other projects to enhance structural stability.

(6) Soil solidification and slope protection: Used for slope protection, preventing soil erosion and maintaining slope stability.

(7) Sewage treatment: In sewage treatment projects, it serves as a covering layer for sludge accumulation to prevent gas spillage and sludge loss.

(8) Landscape: Used in landscaping projects to enhance soil structure and promote plant growth.

Short-fiber needle-punched non-woven geotextiles are widely used in various engineering fields due to their versatility and applicability to improve the stability, safety and durability of engineering structures.

6. Specific application fields of short fiber needle-punched non-woven geotextiles

(1) Soil reinforcement and stabilization: Used as a reinforcement layer in infrastructure projects such as roads, railways, and airports to improve the bearing capacity and stability of the soil.

(2) Water conservancy projects: It is used to prevent river embankments and dam bodies from being eroded by erosion. It is widely used in slope protection, anti-seepage and protection of dams, rivers and reservoirs.

(3) Environmental protection and land recycling: As an anti-seepage layer in landfills, it prevents pollutants from penetrating into the soil. It is also used for land restoration and contaminated soil treatment.

(4) Drainage and filtration: Used as drainage layer in road engineering, landscaping and other fields to promote the drainage of water and filter impurities.

(5) Protective covering: Used as a covering layer for slope protection, riverbank protection, coastline restoration and other projects to prevent soil erosion and soil loss.

(6) Ecological environment protection: In wetland restoration and ecological projects, it is used to enhance soil structure and improve plant growth conditions.

These application areas demonstrate the versatility and important role of short-fiber needle-punched non-woven geotextiles in different projects, providing stability, protection and environmental protection for the project.

Specific applications of short fiber needle-punched non-woven geotextiles

7. Laying process of short fiber needle-punched non-woven geotextile

(1) Preparation work: Before laying, clean the laying surface to ensure that it is flat, dry, clean, and free of sharp objects and debris.

(2) Fabric laying: Spread and lay the short fiber needle-punched non-woven geotextile according to the design requirements. Make sure the fabric fits snugly to the surface, leaving no gaps or wrinkles.

(3) Fixing and connection: When laying fabric, the edges need to be fixed and connected, usually using fixing nails, joints or special glue.

(4) Overlap and seam processing: During fabric laying, if multiple pieces of fabric are needed for seaming, ensure that the overlap of the seams has sufficient coverage, and use appropriate seam processing methods, such as hot melting, bonding, etc. Make sure the seams are tight.

(5) Leveling and compaction: After the paving is completed, level and compact the paving area to ensure that the geotextile is in full contact with the ground surface and improve the stability and effect of the geotextile.

(6) Acceptance and maintenance: After the laying is completed, acceptance is carried out to check whether it meets the design requirements. At the same time, perform maintenance to ensure that the geotextile remains in good condition during use.

These steps can ensure the effective laying and use of short-fiber needle-punched non-woven geotextiles and improve their functionality and stability in engineering.

Laying of short fiber needle-punched non-woven geotextiles

8. Short fiber acupuncture can hinder the later maintenance of geotextile

(1) Regular inspection: Regularly check whether there is damage, cracks or deformation on the surface of the geotextile, as well as whether there is water accumulation and debris. Detecting problems in time can prevent further damage.

(2) Keep it clean: Keep the geotextile surface clean, and regularly remove accumulated water and debris to ensure its normal drainage and filtration functions.

(3) Repair damaged parts: For damaged or worn parts, repair them in time. You can use repair materials or special glue to repair them.

(4) Prevent sharp objects: Avoid sharp objects from directly contacting the surface of the geotextile, which may cause scratches and damage.

(5) Prevent ultraviolet radiation: Provide sufficient shade for the geotextile to avoid long-term exposure to the sun and reduce the damage of ultraviolet rays to the geotextile.

(5) Regular maintenance: According to the manufacturer's recommendations, perform regular maintenance and upkeep to extend the service life and performance of the geotextile.

These maintenance measures help ensure the durability and functionality of the staple fiber needle-punched nonwoven geotextile to achieve its best results in the project.

9. Green staple fiber non-woven geotextile

In addition to the production of commonly used white staple fiber non-woven geotextiles, Haoyang Environmental Company also produces special green non-woven geotextiles, the difference between green dust-proof geotextiles and green non-woven fabrics is mainly reflected in the application range, production process, production raw materials, product weight, price, characteristics, size, function and other aspects. The following details the differences between the two aspects:

(1) the difference between the scope of application: green dust-proof geotextile (non-woven geotextile suppliers) is mainly used in construction sites bare soil cover, garbage removal, environmental dust control; Green non-woven fabrics are mainly used in agricultural planting, landscaping, tree insulation, vegetable seedling control and so on.

(2)the difference in the production process: the green dust-proof geotextile is made of polyester staple fiber with a denier of 6-12 denier and a length of 54-64mm, which is made by the production process of opening, combing, handling, laying nets, etc. Green non-woven fabrics are composed of directional or random fibers. It is called cloth because it has the appearance and certain properties of cloth.

(3)the difference of raw materials: the raw materials of green dust-proof geotextile (Chinese geotextile custom) are mainly polypropylene, nylon, polyester and other polymer composite fibers. The main raw material of green non-woven fabric is polypropylene, which is produced by high temperature melting, spinning, laminating, hot rolling and other processes.

(4)product weight difference: the weight of green dust proof geotextiles used in construction sites is mostly 80-150 grams, which can play a good dust suppression effect; The weight of the green non-woven fabric used for agricultural planting is mostly 25g-50g, which can fully meet the use effect of vegetable seedling and garden greening. Choosing the right weight of the product can reduce the cost of use.

(5)the difference in price: the price of environmental protection dust-proof geotextile per ton is relatively cheap, and the price of the two has a lot to do with the raw materials used (new materials or new materials).

(6)product characteristics difference: green dust proof geotextile has the characteristics of light weight, corrosion resistance, good dust proof effect, convenient construction, etc. Green non-woven fabric is characterized by moisture, breathable, flexible, easy to decompose, recyclable and so on.

(7)the difference between the role of the product: the role of green dustproof geotextile (geotextile dealer) is mainly dustproof, cover the soil and sand to press the dust, do not let the dust everywhere; The main function of green non-woven fabric is to increase the germination rate of seeds, prevent the breeding of weeds, increase the surface temperature, and shorten the germination time of seeds.

Please refer to the link for other geosynthetic materials from Haoyang Environmental Company.

300g stable reliable and environmentally friendly staple fiber needled non-woven geotextile

leachate collection system landfill liner material geosythetic clay liner waterproof blanket

1.5mm smooth impermeable HDPE geomembrane in India

White and green mountain protection special composite drainage net hot sale price

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

503.webp)

759.webp)

861.webp)