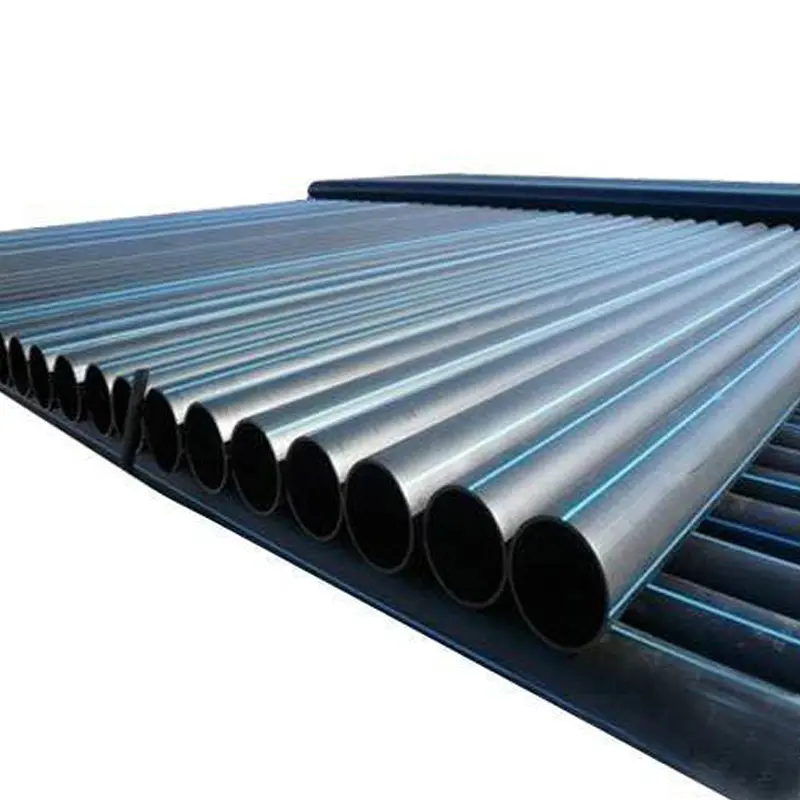

High-Density Polyethylene (HDPE) pipes have become a popular choice for various piping applications due to their unique properties and performance characteristics. They are commonly used in water supply, sewage systems, gas distribution, and industrial piping. However, like any material, HDPE pipes come with their own set of advantages and disadvantages.

Advantages of HDPE Pipes

Durability and Long Service Life:

HDPE pipes are known for their exceptional durability. They can last for over 50 years under optimal conditions. Their resistance to chemical corrosion, abrasion, and other environmental factors contributes to this longevity. Unlike metal pipes, HDPE pipes do not rust, corrode, or rot, making them suitable for a wide range of environments, including highly corrosive soils and saline water applications.

Flexibility:

One of the standout features of HDPE pipes is their flexibility. This characteristic allows them to be installed in a variety of terrains, including areas with unstable ground conditions or seismic activity. HDPE pipes can bend without cracking, which reduces the need for joints and fittings, thereby minimizing potential weak points in the piping system. This flexibility also makes HDPE pipes easier to install in difficult or uneven terrains.

Lightweight and Easy to Handle:

HDPE pipes are much lighter than traditional materials like steel or concrete, which makes them easier to transport and install. This reduces labor costs and installation time, especially in remote or difficult-to-access areas. The lightweight nature of HDPE pipes also minimizes the need for heavy machinery during installation, which can be particularly beneficial in environmentally sensitive areas.

Leak-Free Joints:

HDPE pipes are typically joined using heat fusion, which creates a joint that is as strong as or stronger than the pipe itself. This method eliminates the possibility of leakage at the joints, which is a common problem with other types of pipes, especially those joined by mechanical fittings. Leak-free joints are particularly important in water and gas distribution systems, where even small leaks can lead to significant losses and safety hazards.

Chemical Resistance:

HDPE pipes are highly resistant to a wide range of chemicals, including acids, alkalis, and organic solvents. This makes them ideal for industrial applications where the piping system may be exposed to harsh chemicals. The chemical resistance of HDPE also ensures that the pipes do not degrade or contaminate the fluids they are transporting, making them safe for potable water applications.

Environmental Sustainability:

HDPE pipes are considered environmentally friendly. They have a low carbon footprint during production, and their long service life reduces the need for frequent replacements, which minimizes waste. Additionally, HDPE is recyclable, and the pipes can be repurposed at the end of their life cycle, contributing to a circular economy.

Disadvantages of HDPE Pipes

Susceptibility to UV Degradation:

While HDPE pipes are resistant to many environmental factors, prolonged exposure to ultraviolet (UV) radiation can degrade the material. This is a significant disadvantage for above-ground installations where the pipes are exposed to direct sunlight. To mitigate this issue, HDPE pipes used in such applications often require UV stabilizers or protective coatings, which can add to the overall cost.

High Initial Cost:

The initial cost of HDPE pipes can be higher than that of traditional materials like PVC or metal, especially when factoring in the cost of specialized equipment required for heat fusion joining. While the long-term savings in maintenance and longevity often justify the initial investment, the upfront cost can be a barrier for some projects.

Thermal Expansion:

HDPE pipes have a high coefficient of thermal expansion, meaning they expand and contract significantly with temperature changes. This can cause issues in systems where temperature fluctuations are common, potentially leading to joint failure or deformation of the piping system. In such cases, additional measures, such as expansion joints or anchors, may be required to manage thermal movement, adding complexity and cost to the installation.

Potential for Mechanical Damage:

Despite their durability, HDPE pipes can be susceptible to mechanical damage during handling, installation, or from external impacts after installation. Sharp objects or excessive force can cause gouges or cracks in the pipe, compromising its integrity. Careful handling and proper installation practices are essential to prevent such damage.

Limited Temperature Range:

HDPE pipes have a relatively limited operating temperature range compared to some other materials. They can become brittle in extremely cold temperatures and soften at high temperatures, which can limit their use in certain applications. For instance, HDPE pipes may not be suitable for hot water systems or environments where the temperature regularly drops below freezing without adequate insulation.

Complex Installation Techniques:

While HDPE pipes are generally easier to handle and install due to their lightweight and flexibility, the specialized equipment and techniques required for heat fusion joining can be a disadvantage. The process requires skilled labor and precision to ensure a leak-free, strong joint. Inadequate fusion can lead to weak joints, which may fail over time, causing leaks or system failures.

Conclusion

HDPE pipes offer numerous advantages, including durability, flexibility, chemical resistance, and environmental sustainability, making them an excellent choice for a wide range of applications. However, their susceptibility to UV degradation, thermal expansion, and the need for specialized installation techniques are notable disadvantages that must be considered. Understanding these pros and cons is crucial for selecting the appropriate piping material for any given project. While HDPE pipes are not without their challenges, their long-term benefits often outweigh the drawbacks, making them a popular choice in modern infrastructure projects.

As a leading manufacturer specializing in HDPE pipes in China, we offer a comprehensive range of high-quality pipes in various specifications, directly from our factory to ensure unparalleled reliability and cost-effectiveness. Our commitment to excellence in production, combined with rigorous quality control measures, guarantees that every pipe meets international standards for durability, strength, and environmental sustainability. We are eager to forge partnerships with clients across the globe, leveraging our extensive experience and expertise to meet your unique piping needs. Whether it's for water supply, sewage disposal, irrigation systems, or industrial applications, we have the solution tailored to your requirements. Contact us to discuss your project and discover how our HDPE pipes can contribute to your success.

897.webp)

942.webp)

237.webp)