Landfill Liner Material - Geosynthetic Clay Liner (GCL) Factory Low Price

Haoyang Environmental Co., Ltd., established in 2008, is a leader in high-tech environmental solutions. With extensive experience in geosynthetic material manufacturing, environmental engineering, and innovative solutions, we specialize in producing premium Geosynthetic Clay Liners (GCLs) for landfill applications. Our GCLs deliver excellent sealing performance and cost-effectiveness, making them an ideal choice for landfill projects worldwide.

Product Advantages

Exceptional Sealing Properties:

Engineered with high-quality bentonite and geotextiles, our GCLs provide an impermeable barrier to liquid migration, ensuring long-term environmental safety.Durability and Strength:

Designed to withstand high stress and harsh conditions, GCLs maintain their structural integrity over time.Eco-Friendly Solution:

Our GCLs are an environmentally friendly alternative to traditional compacted clay liners, requiring less material and reducing installation effort.Cost-Effective:

Competitive pricing coupled with reduced transportation and installation costs make our GCLs an economical solution for landfill operators.

Applications

Our GCLs are designed for use in:

Landfill Liners and Caps: Preventing leachate leakage into surrounding soils.

Mining Applications: For tailings storage facilities and leach pads.

Wastewater Treatment Facilities: Providing reliable containment solutions.

Environmental Protection Projects: Ensuring water containment and soil stabilization.

Specifications

| Specification | Details |

|---|---|

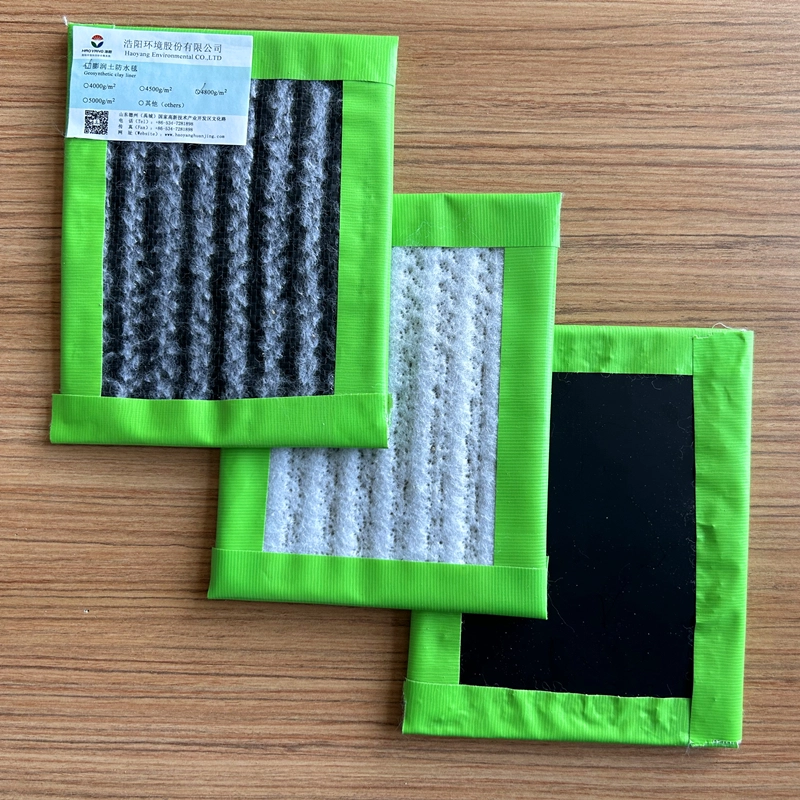

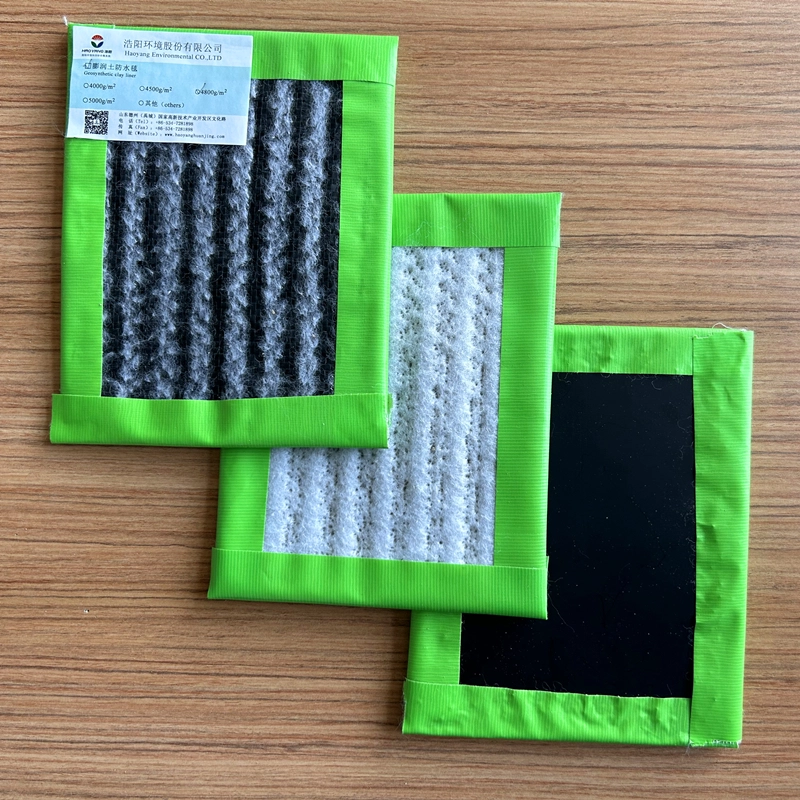

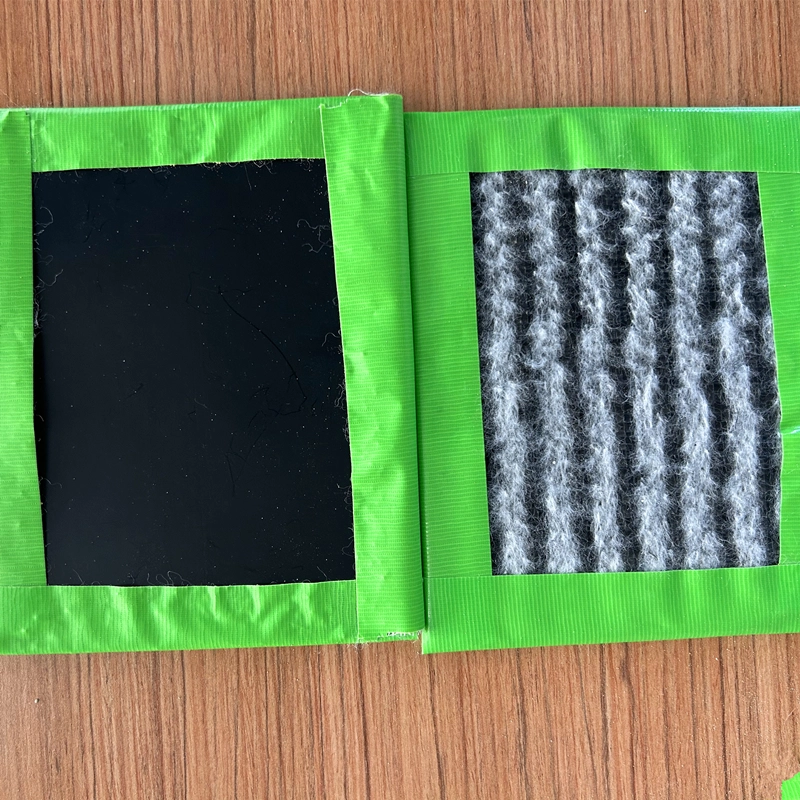

| Material Composition | High-quality sodium bentonite, reinforced with geotextiles (woven and non-woven). |

| Bentonite Thickness | 3mm |

| Width of Roll | Customizable (standard options: 4m-6m). |

| Roll Length | 30m (or customizable based on requirements). |

| Weight | ~4.5-5.0 kg/m² (depending on configuration). |

| Permeability | ≤ 5 × 10⁻¹² m/s |

| Tensile Strength | ≥ 500N/10cm (ASTM D4595) |

| Peel Strength | ≥ 65N (ASTM D6496) |

| Hydraulic Conductivity | ≤ 1 x 10⁻⁹ m/s |

| Application Temperature | -40°C to +85°C |

| Chemical Resistance | Resistant to a wide range of chemicals; specific resistance available on request. |

| Installation Overlap | Recommended overlap: 300mm-500mm |

| Compliance Standards | ASTM D5887, ASTM D6102, and other global standards. |

| MOQ (Minimum Order Quantity) | 1000m² |

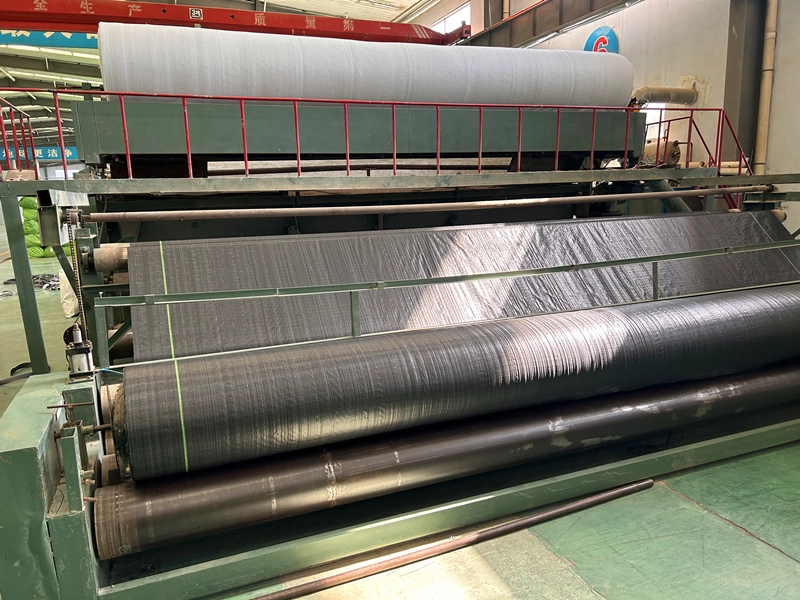

Production workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

|  |

|  |

Company Advantages

Certifications & Recognitions:

Haoyang holds ISO 9001, ISO 14001, OHSAS 18001 certifications, and the CQC Environmental Product Certification, ensuring top-quality standards.Proven Expertise:

Over 15 years of experience in geosynthetic materials manufacturing with a strong focus on R&D, resulting in 3 invention patents and 32 utility model patents.Comprehensive Solutions:

From consulting and design to manufacturing and installation, we offer end-to-end services tailored to your project needs.Competitive Pricing:

We maintain an optimal balance of quality and price, ensuring that our GCLs provide outstanding value for landfill projects.

Upgrade your landfill projects with premium Geosynthetic Clay Liners at factory-direct prices! Let Haoyang be your trusted partner in environmental protection and landfill solutions! Contact us now!

Mode of Transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

Below are our other geoproducts, you can click on the link if you want.

503.webp)

759.webp)

855.webp)

161.webp)

927.webp)