Seepage Treatment of Industrial Solid Waste

The Seepage Treatment of Industrial Solid Waste refers to the process of effectively controlling and managing the liquid permeable components within solid waste generated by industrial activities, utilizing various technologies and engineering measures. This treatment aims to prevent the infiltration of harmful substances from waste into the soil, groundwater, or the surrounding environment, thereby reducing potential impacts on ecosystems and human health.

The significance of solid waste treatment lies in its direct connection to environmental protection and sustainable development goals. With the increasing scale of industrial activities, the volume of industrial solid waste continues to expand, necessitating measures to manage and treat these wastes effectively to avoid potential environmental pollution and resource waste. Efficient seepage treatment is a crucial aspect of solid waste management, helping minimize the spread of toxic substances and safeguarding soil and water resources.

Globally, geotechnical products play a pivotal role in the seepage treatment of industrial solid waste. Ggeotechnical materials such as HDPE geomembranes and nonwoven geofabrics, by constructing robust anti-seepage barriers, effectively isolate hazardous substances, preventing their infiltration into soil and water bodies. These geotechnical products not only offer reliable technical solutions but also drive environmental protection and sustainable development initiatives in the field of solid waste treatment.

Expansion Project of Dahe Dashadi Tailings Storage Facility

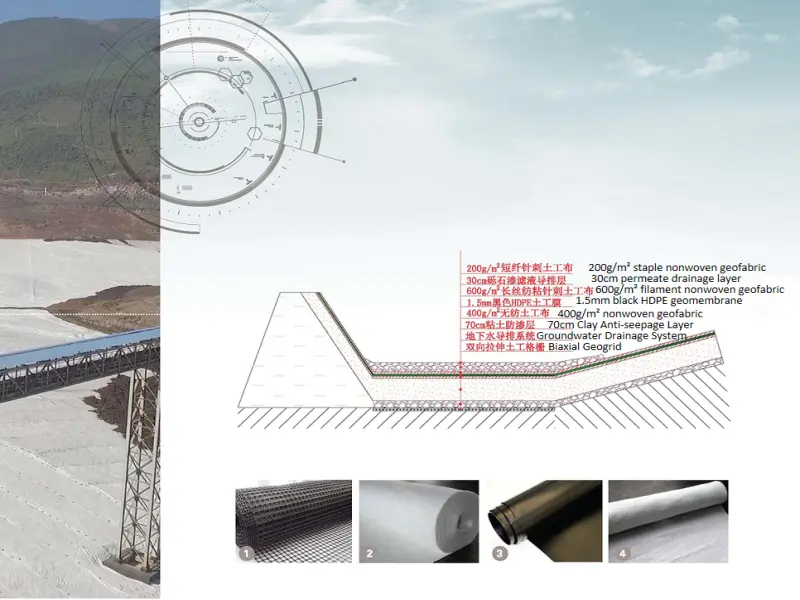

This project involves the treatment of hazardous waste tailings containing cyanide, with a total capacity of approximately 17,000,000 cubic meters and a projected usage period of 12 years. The primary focus of the project is to effectively prevent the leachate from the tailings from polluting the surrounding environment. In accordance with the technical requirements for the safe landfill of hazardous waste, a double artificial liner anti-seepage system must be implemented for the tailings storage facility.

Our company has been invited to oversee the entire project, including the provision of necessary products and construction services.

Problems to be solved

1: Prevention of Cyanide-containing Tailings Seepage

The tailings in Dashadi contain cyanide, classified as hazardous waste. The primary task of the project is to prevent the leachate from these tailings from polluting the surrounding environment.

2: Enhancement of Tailings Storage Facility Foundation Stability

The foundation of the tailings storage facility needs greater stability to withstand the increased pressure and load resulting from the expansion of the facility.

3: Filtration and Drainage

An effective solution is needed for filtration and drainage in the tailings storage facility project to prevent soil erosion and water accumulation.

Our Solutions

1: Prevention of Cyanide-containing Tailings Seepage

Solution: Use three layers of 1.5mm HDPE geomembranes to construct an efficient anti-seepage barrier system, effectively blocking the diffusion of leachate from the tailings and preventing the infiltration of harmful substances into the soil and groundwater.

2: Enhancement of Tailings Storage Facility Foundation Stability

Solution: Utilize a 600g/m² filament nonwoven needle punched geofabric to enhance the foundation's ability to disperse and resist deformation, increase tensile strength, and ensure the overall stability of the project. It can also serve as a long-term effective protection of HDPE geomembranes involves preventing frictional damage caused by sharp objects or sudden uneven loading.

Use biaxial geogrid: Possessing significant tensile strength in both the longitudinal and transverse directions, the biaxial geogrid provides an efficient system for bearing and distributing forces in the soil. It reinforces large area permanent load-bearing foundations by effectively enhancing the capability to withstand and diffuse forces in the soil.

3: Filtration and Drainage

Solution: Employ a 400g/m² and 200g/m² short fiber needle-punched geofabric. This product, with its needle-punched structure, provides effective filtration, preventing soil particles and fine materials from entering the leachate, while maintaining good drainage performance.

Products We Use

1, 1.5mm HDPE geomembrane

1.5mm HDPE geomembrane is a high-density polyethylene (HDPE) liner designed for various environmental and civil engineering applications. This geomembrane is 1.5mm thick, providing a robust barrier against liquid seepage and preventing the migration of contaminants into the soil and groundwater. Its durable and impermeable properties make it suitable for applications such as landfill lining, tailings storage facilities, pond liners, and other containment systems where effective seepage control is crucial. The geomembrane is known for its flexibility, chemical resistance, and resistance to UV degradation, making it a reliable solution for projects requiring long-term environmental protection and containment.

2, 600g/m² filament nonwoven needle punched geofabric

The 600g/m² filament nonwoven needle-punched geofabric is a geotechnical material with a weight of 600 grams per square meter. This geofabric, produced using filament spinning and needle-punching processes, forms a robust and sturdy structure. Its primary applications include:

1), Foundation Reinforcement: Due to its high weight and robust structure, this geofabric is used in civil engineering to reinforce and strengthen foundations, improve soil tensile strength, mitigate foundation deformation, and enhance overall project stability.

2), Soil Protection: Used as a soil cover or protective layer, it effectively shields the soil surface from erosion, scouring, and other natural factors, helping to maintain soil structure and quality.

3), Filtration and Drainage: With its fiber structure, the geofabric provides effective filtration, preventing the entry of particulate matter into the soil, while maintaining relatively good drainage performance to prevent soil erosion and water accumulation.

4), Hydraulic Engineering: In hydraulic engineering, the geofabric can be applied to riverbank protection, channel dredging, and other applications involving soil protection and reinforcement.

3, 400g/m² short fiber needle-punched geofabric

The 400g/m² geofabric is a heavy-duty material manufactured using short fibers through a needle-punching process. This results in a durable and robust geotextile with a weight of 400 grams per square meter. Its Functions:

1), Filtration: The geofabric serves as an effective filtration layer, preventing the migration of fine particles and soil into drainage systems or other areas. This is crucial in applications where water flow needs to be controlled while allowing for proper drainage.

2),Erosion Control: Used in soil erosion control applications, the geofabric helps stabilize the soil by preventing surface runoff and the detachment of soil particles, maintaining the integrity of slopes and embankments.

3),Drainage: Its needle-punched structure facilitates water drainage, making it suitable for applications where efficient drainage is required to avoid waterlogging and maintain soil stability.

4, 200g/m² short fiber needle-punched geofabric

The 200g/m² geofabric is a lighter variant of the needle-punched geotextile, weighing 200 grams per square meter. It is designed for applications where a lower weight geotextile is appropriate. Its Functions:

1), Separation: The geofabric acts as a separation layer, preventing the mixing of different soil layers. This is particularly useful in road construction and other projects where distinct layers need to be maintained.

2), Protection: It provides a protective barrier, minimizing damage to underlying materials or structures caused by sharp objects or uneven loads. This protection is essential for extending the lifespan of various construction elements.

3), Vegetation Support: In some applications, the geofabric supports vegetation growth by providing a stable environment for roots, preventing soil erosion, and promoting plant establishment.

FAQ

1. What is the role of a 1.5mm HDPE geomembrane in seepage treatment for industrial solid waste?

The 1.5mm HDPE geomembrane serves as a robust anti-seepage barrier, preventing the infiltration of harmful substances from industrial solid waste into the surrounding environment, ensuring effective containment.

2. How does a nonwoven geofabric contribute to seepage treatment in industrial solid waste applications?

The nonwoven geofabric, through its filtration and reinforcement capabilities, enhances the stability of the system. It aids in preventing soil erosion, filtering contaminants, and providing additional support to the geomembrane.

3. Can a 1.5mm HDPE geomembrane withstand the harsh conditions often associated with industrial solid waste treatment?

Yes, the 1.5mm HDPE geomembrane is designed to be durable and chemically resistant, making it well-suited for the challenging conditions present in industrial solid waste treatment facilities.

4. What are the key advantages of using nonwoven geofabric alongside HDPE geomembrane in seepage treatment?

The nonwoven geofabric enhances overall stability, provides additional reinforcement, and facilitates filtration and drainage, complementing the HDPE geomembrane's anti-seepage properties for comprehensive seepage treatment.

5. How does the combined system of 1.5mm HDPE geomembrane and nonwoven geofabric contribute to environmental protection in industrial solid waste management?

The integrated system creates a reliable and sustainable solution by preventing the migration of pollutants, ensuring proper containment, and minimizing the environmental impact of industrial solid waste treatment practices.

437.webp)

897.webp)

942.webp)

237.webp)