1. Overview of Geomembranes

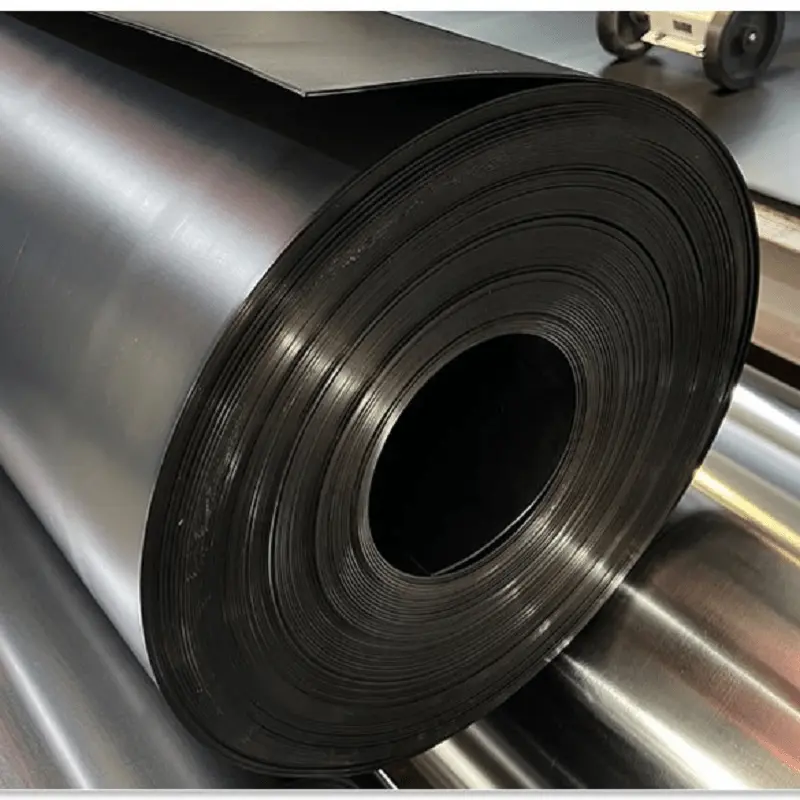

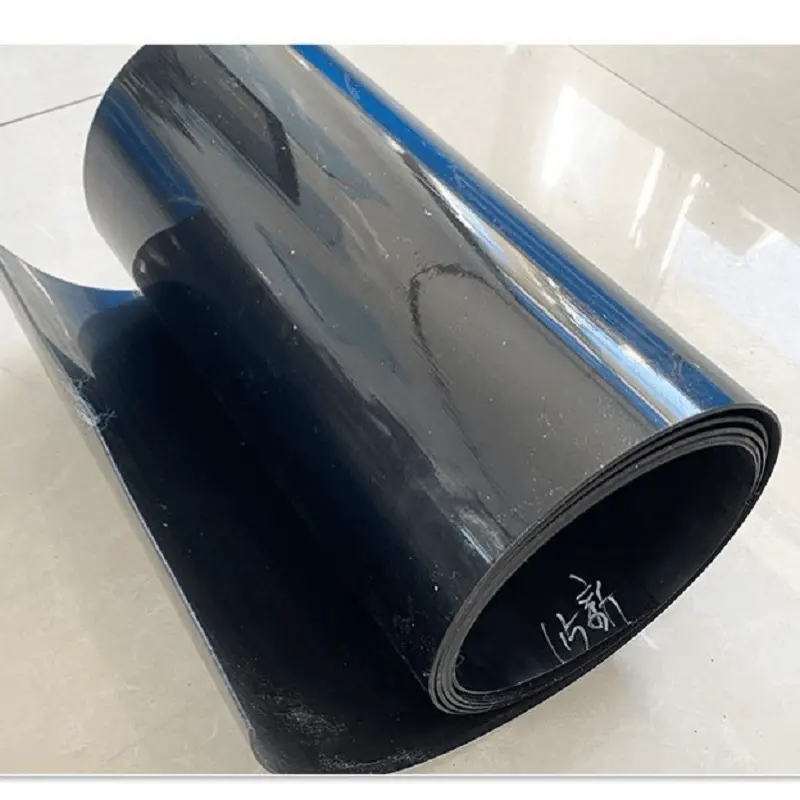

A geomembrane is a synthetic polymer material typically made from high-density polyethylene (HDPE), polyvinyl chloride (PVC), or other synthetic materials. Geomembranes possess excellent impermeability, puncture resistance, and chemical stability, making them suitable for various applications such as landfills and wastewater treatment sites. The primary role of a geomembrane is to form a robust barrier that prevents leachate from penetrating into the groundwater, thus protecting the environment.

2. Application of Geomembranes in Landfills

In the construction of landfills, geomembranes are typically used as a lining system to form barriers at the bottom and sides of waste disposal areas. Their main functions include:

Preventing leachate contamination of groundwater: During the landfill process, water and harmful substances in the waste can seep into the groundwater. Geomembranes effectively prevent this leachate from infiltrating and contaminating the groundwater.

Preventing the spread of pollutants: Geomembranes serve as a barrier, preventing harmful substances from spreading into the surrounding environment, thus protecting ecological systems.

Enhancing landfill stability: Geomembranes help reduce the compressive impact of waste on the underlying soil, improving the overall stability of the landfill.

3. Leachate Containment Performance of Geomembranes

The leachate containment performance of geomembranes directly impacts the effectiveness of environmental protection at landfills. The performance varies based on the material, thickness, and installation method of the geomembrane. The table below shows the typical performance of different geomembrane materials:

| Geomembrane Type | Material Characteristics | Permeability Coefficient (cm/s) | Common Applications |

|---|---|---|---|

| HDPE Membrane | High-density polyethylene, chemically resistant | ≤ 1 × 10⁻¹² | Landfills, wastewater treatment plants, etc. |

| LLDPE Membrane | Linear low-density polyethylene, flexible | ≤ 1 × 10⁻¹¹ | Coatings, leachate barriers, water retention |

| PVC Membrane | Polyvinyl chloride, good weather resistance | ≤ 1 × 10⁻¹³ | Drainage systems, groundwater protection |

As shown in the table, HDPE and LLDPE membranes have low permeability coefficients, making them highly suitable for landfill applications to effectively isolate leachate and pollutants.

4. Advantages of Geomembranes

The use of geomembranes in landfills offers several significant advantages, including:

Excellent impermeability: Geomembranes have extremely low permeability, preventing leachate from penetrating and protecting the groundwater from contamination.

Strong resistance to chemical corrosion: Geomembranes are highly resistant to acids, alkalis, salts, and other chemicals, ensuring durability and effectiveness in the harsh landfill environment.

Ease of installation: Geomembrane installation is relatively simple and can be completed quickly over large areas, reducing construction costs and time.

Good weather resistance: Geomembranes can withstand prolonged exposure to ultraviolet (UV) radiation, temperature fluctuations, and other environmental factors, ensuring long-term effectiveness in landfill applications.

5. Considerations during Construction

The quality of geomembrane installation directly affects its leachate containment performance. Therefore, special attention should be paid to the following during installation:

Material selection: Choose the appropriate geomembrane material (e.g., HDPE or LLDPE) based on the specific requirements of the landfill.

Installation method: Ensure the geomembrane is laid flat without wrinkles or air bubbles, which could compromise its impermeability. Joints between sheets should be sealed tightly to prevent leakage.

Quality testing: After installation, it is essential to conduct tests to verify that the geomembrane's thickness, permeability coefficient, and other properties meet the design specifications.

6. Future Trends

With increasing environmental protection requirements, the application of geomembranes in landfills will become more critical. In the future, geomembrane materials are expected to evolve towards higher performance and eco-friendly solutions. For example, biodegradable and non-toxic geomembranes will gradually replace traditional materials, reducing environmental impact. Additionally, the integration of smart monitoring technologies will make leachate containment systems more efficient and safer.

Conclusion

Geomembranes play a vital role in leachate containment and isolation in landfills, offering significant environmental protection. By selecting the appropriate geomembrane materials and ensuring high-quality installation, leachate pollution can be effectively prevented, safeguarding groundwater resources. With ongoing advancements in material technology and monitoring systems, geomembranes will continue to be an essential tool in addressing environmental pollution challenges, ensuring safer and more sustainable landfill management.

![]() 1.5 Double-sided smooth HDPE geomembrane.pdf

1.5 Double-sided smooth HDPE geomembrane.pdf

897.webp)

942.webp)

237.webp)