High-Density Polyethylene (HDPE) geomembranes are essential components in various environmental and civil engineering applications. The choice between utilizing 100% virgin materials and recycled materials in the production of HDPE geomembranes holds significant implications for performance, sustainability, and environmental impact. Lets explore the key differences between these two material choices.

HDPE geomembrane

HDPE geomembrane is a type of geosynthetic material, also known as high-density polyethylene membrane, HDPE geomembrane, or HDPE impermeable membrane. It is a waterproof and barrier material produced using (medium to) high-density polyethylene resin, with a density of 0.94g/cm3 or higher. They serve as effective liners in various applications such as environmental containment, waste management, mining, and water containment.

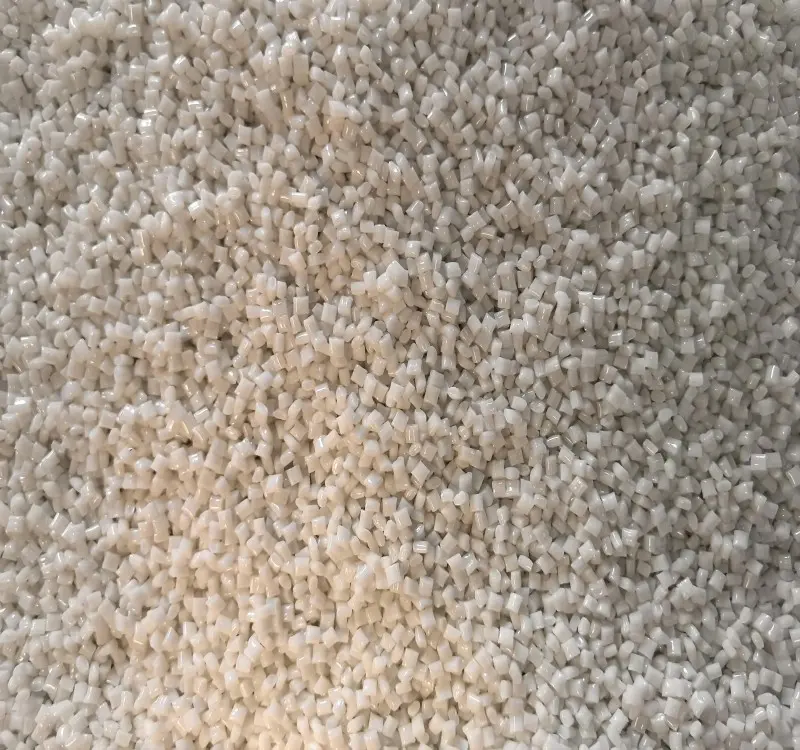

Raw materials of HDPE geomembrane

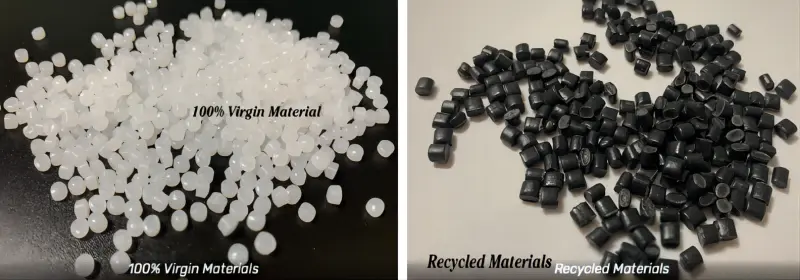

HDPE is a type of high-density polyethylene granule, serving as the primary raw material for the production of impermeable geomembranes. HDPE is a high-crystallinity, non-polar thermoplastic resin. In its original state, HDPE has a milky white appearance, and its thin cross-section exhibits a certain degree of translucency.

“Virgin HDPE geomembrane" refers to a geomembrane manufactured using virgin high-density polyethylene resin granules, while "recycled HDPE geomembrane" denotes a geomembrane produced using recycled and reclaimed polyethylene materials.

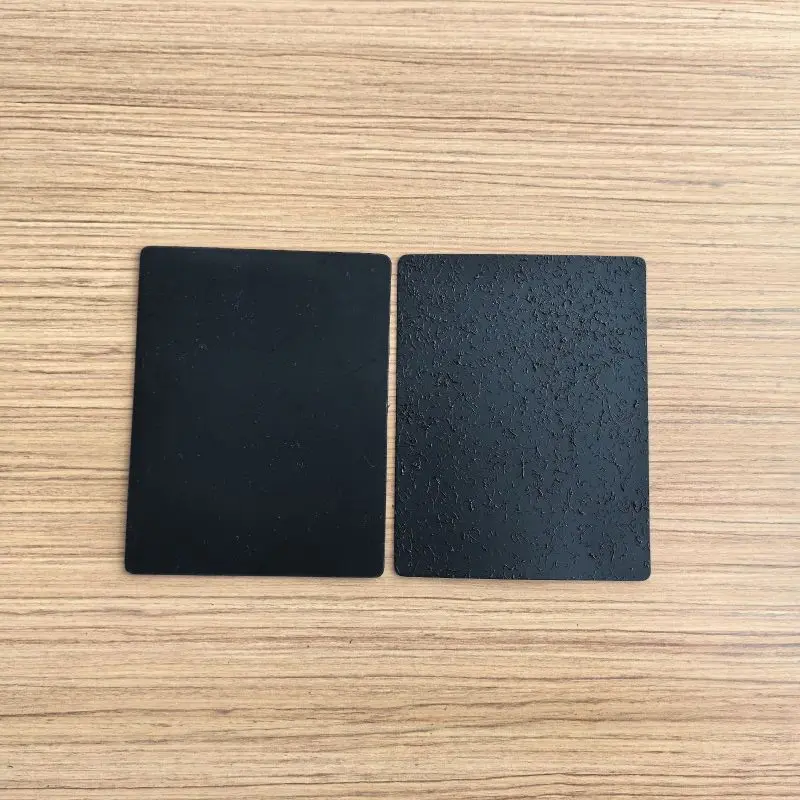

The difference between 100% virgin hdpe geomembrane and recycled HDPE geomembrane

The primary distinction between 100% virgin HDPE geomembrane and recycled HDPE geomembrane lies in the source of the raw materials used in their production:

1, Raw Material:

100% virgin hdpe geomembrane produced using exclusively virgin high-density polyethylene (HDPE) resin granules. Domestically produced virgin materials are typically sourced from major petrochemical enterprises within the country, such as Sinopec, Qilu Petrochemical, Yanshan Petrochemical, Kunlun Petrochemical, and others. Imported virgin materials, on the other hand, are primarily sourced from Middle Eastern countries like Iran and Saudi Arabia.

Recycled hdpe geomembrane are usually manufactured using recycled and reclaimed polyethylene materials, which may come from post-consumer or post-industrial sources.

2, Quality:

100% virgin hdpe geomembrane are typically considered to have higher purity and consistency compared to recycled materials.

Recycled hdpe geomembrane may have variations in composition depending on the source and processing of recycled materials.

3, Properties:

The mechanical properties of HDPE geomembranes encompass factors such as tensile strength, yield strength, puncture resistance, and right angle tear strength. When comparing these characteristics between 100% virgin HDPE geomembranes and regrind HDPE geomembranes, it becomes evident that the physical attributes of geomembranes crafted from pure virgin materials surpass those derived from recycled sources.

4, price:

Due to certain disparities in raw material costs, the cost of 100% virgin HDPE geomembranes with equivalent thickness is higher than that of recycled HDPE geomembranes. This price difference is determined by the production costs and quality distinctions between the two.

5, applications:

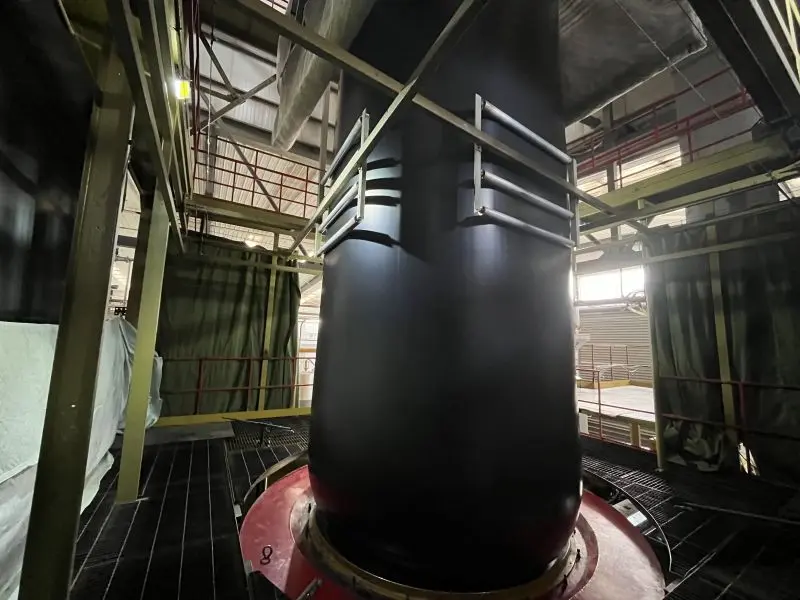

Generally, due to the relatively higher procurement cost, 100% virgin HDPE geomembranes are commonly used in projects with stringent quality requirements. These projects include landfill impermeability, tunnel impermeability, tailings pond impermeability, oil tank area impermeability, large-scale wastewater treatment plant impermeability, and impermeability for large-scale breeding facilities such as biogas tanks.

On the other hand, recycled HDPE geomembranes are suitable for lower construction cost civil projects. These may include impermeability for fish ponds, aquaculture, lotus ponds, reservoirs, and small biogas tanks.

Construction attentions

309614.webp)

Attention should be paid to the following aspects during the construction of HDPE geomembrane:

1, Minimization of Weld Seams: Strive to minimize the number of weld seams while ensuring quality, aiming to conserve raw materials. This approach also facilitates the assurance of quality.

2, Seam Overlap Width: The overlap width of seams between geomembranes should generally be no less than 10cm. Align the direction of welding seams parallel to the maximum slope.

3, Length of Seams in Corners and Irregular Sections: In corners and irregular sections, minimize the length of seams. Avoid placing weld seams on slopes greater than 1:6 within a 1.5-meter range from the top slope or stress concentration area, unless special requirements dictate otherwise.

4, Avoiding Artificial Wrinkles: During HDPE geomembrane installation, avoid creating artificial wrinkles. In lower temperatures, pull and flatten the geomembrane as much as possible.

5, Minimization of Traffic on Installed Geomembrane: After the installation is complete, minimize walking on the geomembrane surface and moving tools. Avoid placing objects on or walking upon the geomembrane that could cause harm, preventing accidental damage to the impermeable membrane.

These construction considerations aim to ensure the effectiveness, durability, and quality of the HDPE geomembrane in various applications.

FAQ

1. What is the primary difference between 100% Virgin Materials HDPE Geomembranes and Recycled Materials HDPE Geomembranes?

The key difference lies in the source of raw materials. Virgin HDPE geomembranes use new high-density polyethylene resin, while recycled HDPE geomembranes are made from reclaimed and recycled polyethylene materials.

2. How do the mechanical properties compare between 100% Virgin Materials and Recycled Materials HDPE Geomembranes?

Generally, the mechanical properties of geomembranes crafted from 100% virgin materials are higher than those made from recycled materials. This includes factors such as tensile strength, yield strength, and puncture resistance.

3. Are there differences in application suitability between the two types of HDPE geomembranes?

Yes, there are application differences. Virgin HDPE geomembranes, due to higher procurement costs, are commonly used in projects with stringent quality requirements (e.g., landfill impermeability), while recycled HDPE geomembranes are suitable for cost-effective civil projects (e.g., fish ponds, reservoirs).

4. How does the pricing of 100% Virgin Materials HDPE Geomembranes compare to Recycled Materials HDPE Geomembranes?

The cost of virgin HDPE geomembranes with equivalent thickness is generally higher than that of recycled HDPE geomembranes. This cost difference is influenced by variations in raw material costs and production processes.

5. What environmental considerations are associated with the use of Recycled Materials HDPE Geomembranes?

Recycled HDPE geomembranes are considered more environmentally friendly as they utilize recycled materials, contributing to waste reduction. This can be a significant factor in projects with sustainability objectives.

897.webp)

942.webp)

237.webp)