Road construction is a complex process that requires the use of various materials and technologies to ensure the durability and strength of the pavement. One of these materials is the geogrid. Geogrids are used to reinforce soils and other materials, significantly improving their mechanical properties.

Why Geogrids Are Used in Railway Construction

Geogrids play a crucial role in railway construction due to their ability to enhance the mechanical properties of the soil and the overall stability of the railway structure. Here are the key reasons why geogrids are used in railway construction:

Load Distribution:

Geogrids help distribute the loads from railway tracks more evenly across the underlying soil. This distribution reduces the stress on the subgrade and prevents differential settlement, ensuring a more stable and durable railway track.

Soil Reinforcement:

Geogrids reinforce weak soils by interlocking with the soil particles, thereby increasing the soil’s shear strength. This reinforcement is essential in areas with poor soil conditions, where it helps to improve the load-bearing capacity of the subgrade.

Reduction of Maintenance Costs:

By stabilizing the soil and distributing loads more effectively, geogrids minimize track deformation and settlement. This leads to a reduction in maintenance requirements and costs over the railway's lifespan, as the track remains more stable and less prone to damage.

Prevention of Subgrade Deformation:

Geogrids prevent the deformation of the subgrade by providing additional support and confinement to the soil. This is particularly important in areas subjected to repeated dynamic loads from passing trains, which can cause significant subgrade deformation over time.

Erosion Control:

Geogrids help control erosion by stabilizing slopes and embankments along the railway line. This stabilization prevents soil erosion caused by water runoff and ensures the long-term integrity of the railway embankments.

Improved Drainage:

Geogrids can be used in conjunction with geotextiles to improve drainage around the railway tracks. Proper drainage is essential to prevent water accumulation, which can weaken the subgrade and lead to track instability.

Environmental Benefits:

Using geogrids can reduce the amount of raw materials needed for construction, such as aggregates. This not only lowers construction costs but also has positive environmental impacts by reducing resource consumption and the associated carbon footprint.

Types of Geogrids

Geogrids are classified into several types depending on the material they are made of and their structure. The main types of geogrids include:

1,Polymer Geogrids

2,Fiberglass Geogrids

3,Steel Geogrids

4,Composite Geogrids,

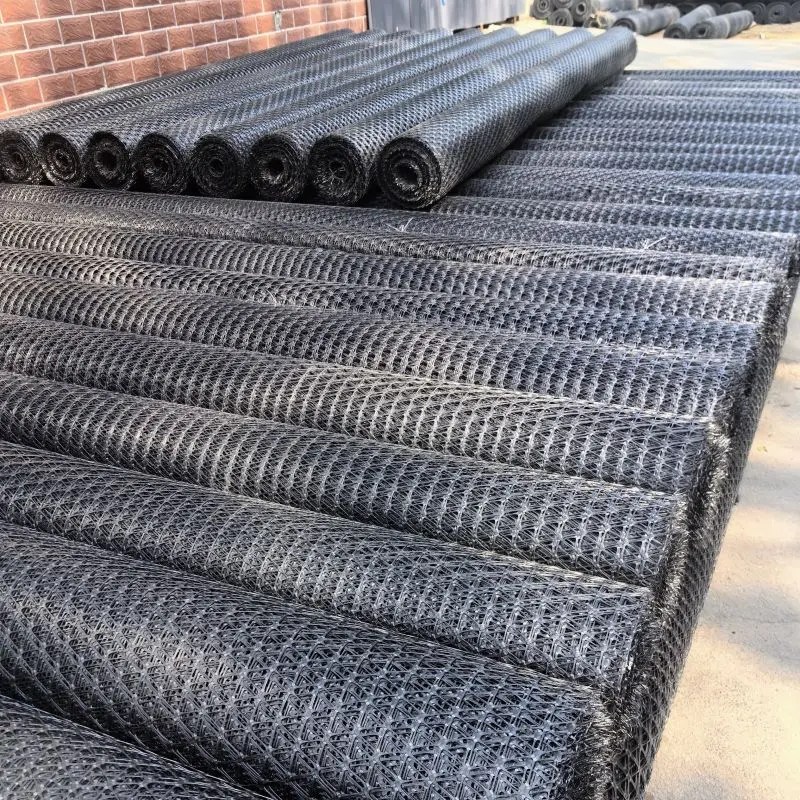

Polymer Geogrids

Polymer geogrids are made from synthetic materials such as polypropylene (PP) or high-density polyethylene (HDPE). They have high tensile strength and resistance to chemical exposure and ultraviolet radiation. Polymer geogrids are widely used for reinforcing weak soils, which increases the load-bearing capacity of the road base and prevents rutting.

Advantages:

High tensile strength

Resistance to chemical and biological exposure

Lightweight and easy to install

Applications:

Road base reinforcement

Slope and embankment stabilization

Erosion control

Fiberglass Geogrids

Fiberglass geogrids are made from fiberglass and have high strength and stiffness. These geogrids are mainly used for reinforcing asphalt concrete pavements, which helps prevent cracking and extends the pavement's lifespan. Fiberglass geogrids also have high resistance to high temperatures.

Advantages:

High stiffness and strength

Resistance to high temperatures

Durability

Applications:

Asphalt concrete pavement reinforcement

Crack prevention

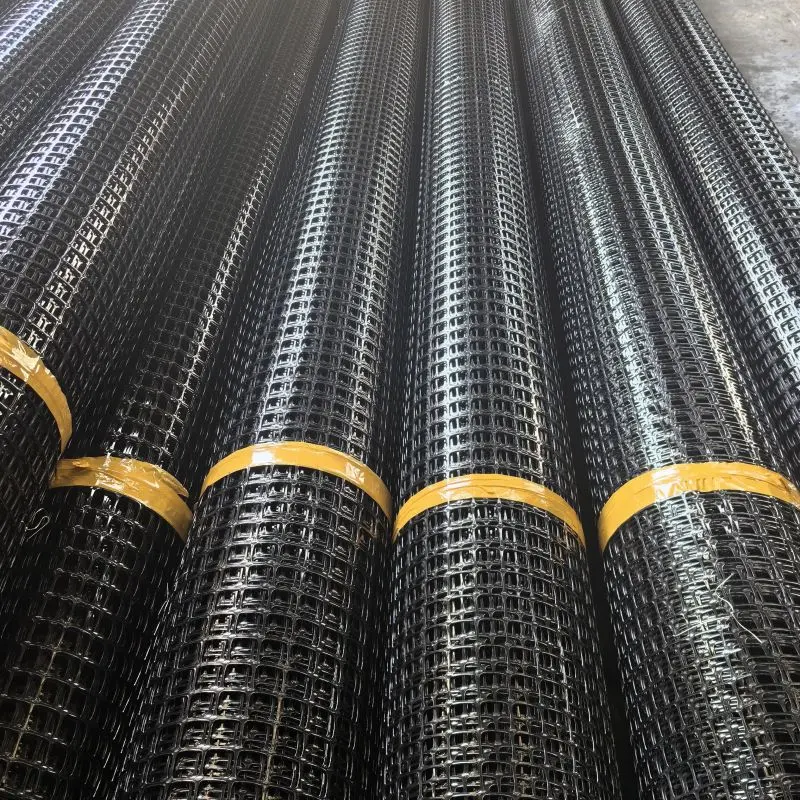

Steel Geogrids

Steel geogrids are made from high-strength steel wire and have exceptional strength and stiffness. They are used to reinforce soils under high loads, such as in the construction of highways and railways, as well as for slope and embankment stabilization. Steel geogrids have high resistance to mechanical damage and durability.

Advantages:

High strength and stiffness

Resistance to mechanical damage

Durability

Applications:

Soil reinforcement under high loads

Slope and embankment stabilization

Highway and railway construction

Composite Geogrids

Composite geogrids combine the properties of various materials, allowing for optimal characteristics for specific operating conditions. For example, geogrids made from polymer and fiberglass elements have high tensile strength and resistance to high temperatures, making them ideal for reinforcing asphalt concrete pavements.

Advantages:

Combination of the best properties of different materials

High strength and resistance to various exposures

Versatility in applications

Applications:

Reinforcement of various types of road pavements

Slope and embankment stabilization

Erosion control

Common specification used for different road parts

Treatment area | types of geogrids |

Roadbed (high embankment) | Bidirectional plastic geogrid, with a longitudinal and transverse tensile strength of ≥40 kN/m. |

treatment of steep slope embankments and cut-fill transitions | Bidirectional plastic geogrid with a longitudinal and transverse tensile strength of ≥40 kN/m. |

bridge abutment backfill | Unidirectional geogrid with a tensile strength of ≥80 kN/m. |

special foundation treatment | Bidirectional steel-plastic geogrid with a longitudinal and transverse tensile strength of ≥80 kN/m. |

culvert foundation and abutment backfill | Bidirectional steel-plastic geogrid with longitudinal and transverse tensile strength of ≥80 kN/m |

Geogrids play an essential role in road construction by improving the mechanical properties of soils and pavements. Depending on the operating conditions and project requirements, different types of geogrids can be used: polymer, fiberglass, steel, and composite. Each of these types of geogrids has its unique characteristics and advantages, allowing for the optimal choice for specific situations. The use of geogrids in road construction contributes to extending the lifespan of roads, reducing maintenance costs, and enhancing traffic safety.

Haoyang's stength

Haoyang is a leading supplier all kinds of geogrids, we pride ourselves on offering premium quality products that meet the highest industry standards. Our plastic steel geogrids are engineered with advanced materials and innovative designs, ensuring exceptional strength, durability, and flexibility for a wide range of civil engineering and infrastructure projects.

As a trusted partner, we specialize in providing customized solutions tailored to our clients' specific requirements. Whether it's for soil reinforcement, retaining walls, slope stabilization, or pavement reinforcement, our geogrids deliver unparalleled performance and cost-effectiveness.

Backed by a team of experienced engineers and a state-of-the-art manufacturing facility, we ensure every product undergoes rigorous quality control checks to maintain consistency and reliability. Our commitment to excellence extends beyond product delivery, with exceptional customer service and timely support throughout the project lifecycle.

Choose us as your geogrid supplier and experience the difference of working with a company that values quality, innovation, and customer satisfaction above all else. Let's collaborate to build stronger, more sustainable infrastructures together.

If you need any help, please contact Echo:

Phone/whataspp: 0086-18853127527

Email: export@hygeosynthetics.com

897.webp)

942.webp)

237.webp)