High-Density Polyethylene (HDPE) pipes have become a cornerstone in modern piping systems due to their impressive range of benefits, including durability, flexibility, and resistance to corrosion. These attributes make HDPE pipes an excellent choice for a variety of applications, from water supply to gas distribution and industrial uses. As the demand for HDPE pipes continues to grow, understanding the factors that influence their pricing is crucial for both buyers and suppliers.

What is hdpe pipe?

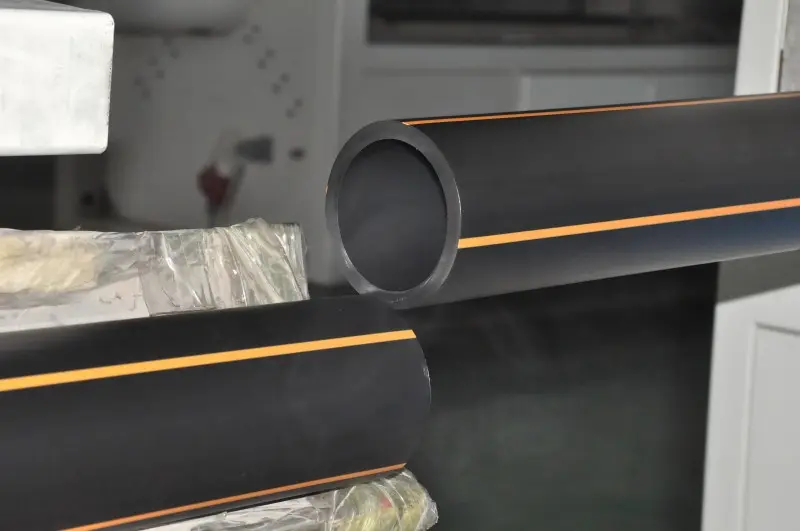

High-Density Polyethylene (HDPE) pipe is a type of plastic piping made from high-density polyethylene material. Known for its durability, flexibility, and versatility, HDPE pipe is widely used in various applications, including water supply, sewage systems, natural gas distribution, irrigation, and industrial piping.

Characteristics of HDPE Pipe

Durability:

HDPE pipes are highly resistant to impact and can withstand heavy loads and harsh environmental conditions. They are less prone to damage from external pressures and impacts compared to other types of piping.

Flexibility:

The flexibility of HDPE pipes allows for easy installation in uneven terrains and areas with complex geometries. They can bend without breaking, reducing the need for joints and fittings.

Corrosion Resistance:

Unlike metal pipes, HDPE pipes are immune to rust and corrosion, making them ideal for transporting water and chemicals. This property extends their lifespan and reduces maintenance costs.

Chemical Resistance:

HDPE pipes can handle a wide range of chemicals without degrading. This makes them suitable for industrial applications where various chemicals are transported.

Leak-Free Joints:

HDPE pipes can be joined using heat fusion methods, creating a homogeneous joint that is as strong as the pipe itself. This reduces the risk of leaks and enhances the overall integrity of the piping system.

Lightweight:

Being lighter than metal pipes, HDPE pipes are easier to handle and install, reducing labor and transportation costs.

Applications of HDPE Pipe

Water Supply:

HDPE pipes are extensively used for potable water distribution due to their non-toxic nature and resistance to bacterial growth. They ensure a safe and reliable supply of drinking water.

Sewage and Wastewater:

Their resistance to corrosion and chemical attack makes HDPE pipes ideal for sewage and wastewater systems. They can handle the aggressive nature of sewage without deteriorating.

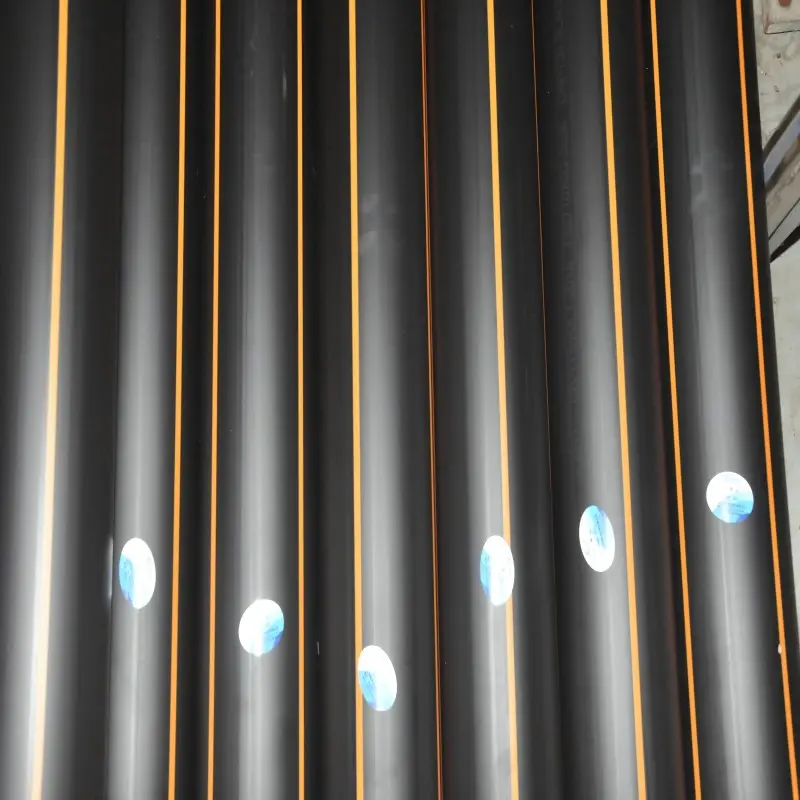

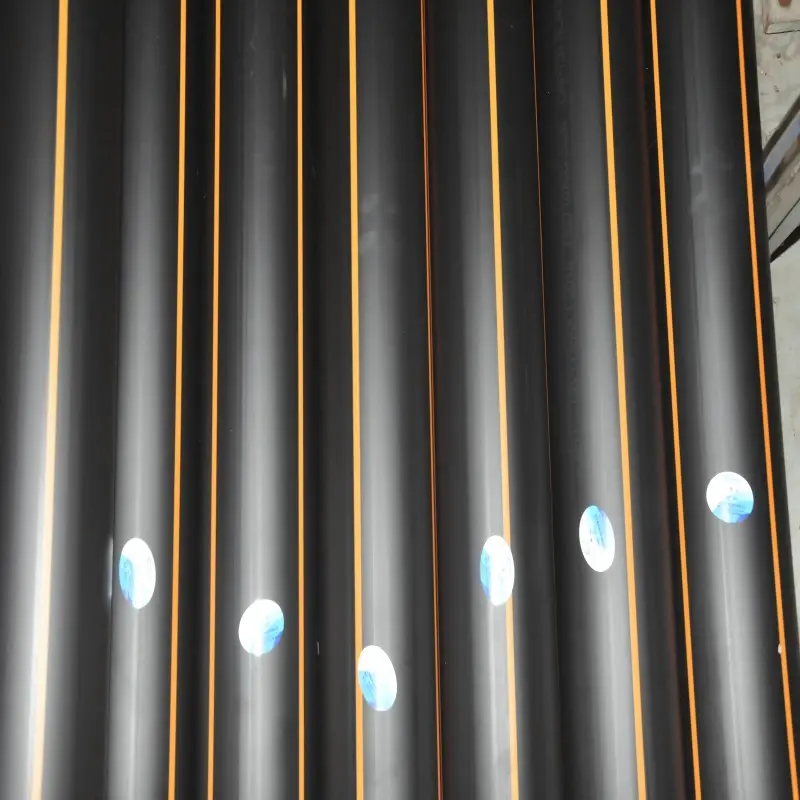

Natural Gas Distribution:

HDPE pipes are commonly used in the natural gas industry because of their strength, flexibility, and resistance to leaks. They provide a safe and efficient means of transporting gas.

Irrigation Systems:

In agriculture, HDPE pipes are used for irrigation due to their flexibility and durability. They can easily be installed in fields and withstand the pressures of irrigation systems.

Industrial Applications:

HDPE pipes are used in various industrial applications for transporting chemicals, compressed gases, and other substances. Their chemical resistance and durability are key advantages in these settings.

Mining:

The mining industry utilizes HDPE pipes for slurry and tailings transport, water supply, and dewatering applications. Their robustness and resistance to abrasion make them suitable for these demanding environments.

Factors Influencing HDPE Pipe Prices

Raw Material Costs:

The primary component of HDPE pipes is polyethylene resin. The cost of this raw material is subject to fluctuations based on global oil prices, as polyethylene is a derivative of petroleum. Therefore, any significant changes in crude oil prices directly impact the cost of HDPE pipes. Additionally, the quality of the polyethylene resin, whether it is virgin or recycled, also plays a role in determining the price.

Manufacturing Process:

The production of HDPE pipes involves several stages, including extrusion, cooling, and quality control. The efficiency and technological advancement of the manufacturing process can affect the overall cost. Modern manufacturing techniques that enhance production speed and reduce waste can lead to lower prices. Conversely, outdated or less efficient processes may increase production costs.

Pipe Specifications:

HDPE pipes come in various sizes, thicknesses, and pressure ratings. These specifications are tailored to meet specific application requirements. Generally, larger diameter pipes and those with higher pressure ratings require more raw material and a more rigorous manufacturing process, thereby increasing the cost. Additionally, special additives used to enhance the pipe’s properties, such as UV resistance or improved flexibility, can also impact the price.

Market Demand:

Like any other product, the law of supply and demand significantly influences HDPE pipe prices. High demand in construction, agriculture, and industrial sectors can drive up prices. Conversely, a market downturn or reduced demand can lead to lower prices. Seasonal variations also play a role; for example, construction activities often peak during certain times of the year, leading to increased demand and higher prices.

Geographical Factors:

The location of the manufacturer and the buyer can affect the cost due to transportation and logistical expenses. Pipes are bulky and heavy, making transportation a considerable part of the total cost. Manufacturers located closer to raw material sources or major markets can often offer more competitive prices.

Economic Conditions:

Broader economic factors, such as inflation rates, currency exchange rates, and economic policies, can impact the cost structure of HDPE pipes. For instance, inflation can lead to higher prices for raw materials and labor, which in turn increases the overall cost of the pipes. Currency fluctuations can affect international trade prices, making imports either cheaper or more expensive.

Typical Price Range

The price of HDPE pipes can vary widely depending on the factors mentioned above. On average, the cost for standard HDPE pipes can range from $1.50 to $10 per meter for pipes with a diameter of 20mm to 110mm. For larger diameters, such as 200mm to 500mm, the price can range from $10 to $50 per meter. These prices are indicative and can vary based on market conditions and regional factors.

Market Trends and Future Outlook

The HDPE pipe market is poised for significant growth, driven by increasing infrastructure development, urbanization, and the need for efficient water management systems. Technological advancements in manufacturing processes and the development of new grades of HDPE resin are expected to enhance the performance and cost-effectiveness of HDPE pipes.

Sustainability is another key trend influencing the market. There is a growing emphasis on using recycled materials and developing eco-friendly products. This trend not only helps in reducing the environmental footprint but also offers cost benefits, as recycled HDPE can be cheaper than virgin resin.

Moreover, the adoption of HDPE pipes in emerging economies is expected to rise, fueled by government initiatives to improve water supply and sanitation infrastructure. These markets offer significant growth opportunities for HDPE pipe manufacturers.

Understanding the HDPE pipe price requires a comprehensive analysis of various factors, including raw material costs, manufacturing processes, pipe specifications, market demand, geographical considerations, and economic conditions. By keeping these factors in mind, buyers and suppliers can make informed decisions and navigate the market more effectively. As the demand for sustainable and high-performance piping solutions continues to grow, the HDPE pipe market is set to experience robust growth, offering numerous opportunities for industry stakeholders.

897.webp)

942.webp)

237.webp)