1. General provisions

(1)Construction operations should be conducted as far away as possible from the windy season. Pay attention to protect all signposts and points to prevent them from being blown down by the wind or buried in the sand.

(2) The principle of construction and protection at the same time should be followed, and earthwork construction, protection projects, and sand control projects should be completed in a supporting manner.

(3)When cleaning the surface, do not arbitrarily damage the vegetation and surface hard shells on both sides of the route, and pay attention to protecting the desert environment.

(4)In mobile desert areas, construction machinery that is efficient and has certain wind and sand resistance should be used. One section of roadbed filling and excavation should be completed and one section protected to ensure the strength and stability of the roadbed.

2. Excavation of roadbed

Excavation should reduce large-area disturbance and damage to the sand body to avoid sand damage and increase the amount of work. Therefore, the construction organization design should be done before excavation and subgrade construction, and the earthwork transportation chart should be verified and adjusted. Before excavation, the outline indicated by the roadbed stakeout mark should be followed to reduce over-excavation and prevent random excavation. Equip a complete set of various necessary construction machinery according to the organization's design, and make preparations for maintenance.

During cutting excavation, if the soil quality changes or the design requirements cannot be met and the construction plan and slope slope need to be modified, timely approval should be reported.

On-site footage of roadbed excavation

3. Use of geotextile materials

Laying geosynthetic materials on the sand base in mobile desert areas can improve the shear resistance and load-bearing capacity of the sand base, strengthen the sand base, effectively prevent the sand base from deforming under load, and facilitate construction.

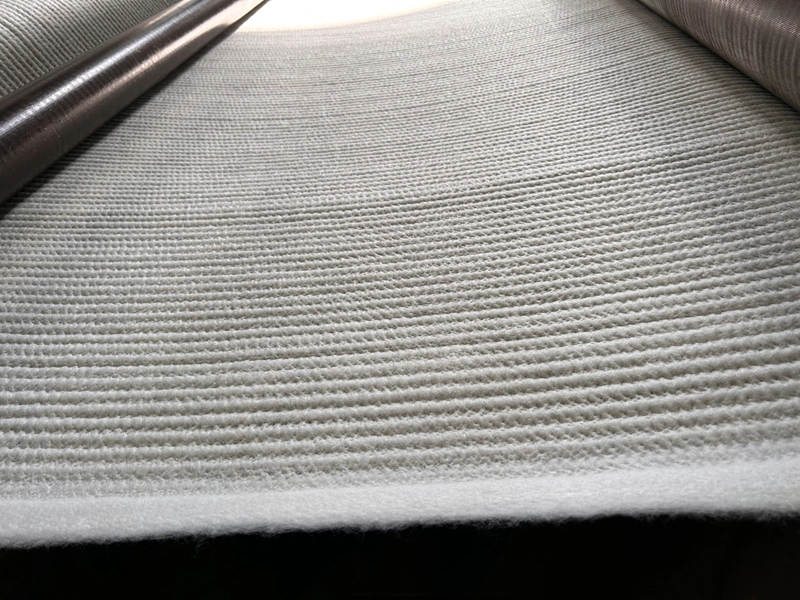

(1) The geotextile uses polypropylene woven fabric, and the width depends on the width of the road surface. Use the entire geotextile paving whenever possible.

The appearance of the woven fabric should be uniform and the weaving should be regular. Defective products that are bonded, broken, or missing long and short wefts should not be used. They should be stored in a cool room or buried in the soil. The storage period should not exceed 18 months from the date of production.

The geotextile construction is carried out by manual or mechanical traction along the longitudinal direction of the route. Each roll of geotextile is spread on the sand base, and wrinkles are minimized when spreading. Non-operational vehicles are strictly prohibited from driving on the pavilion after it has been paved. The woven fabric should be stretched and flat. To prevent it from being lifted up by the wind, a little wind-blown sand or natural gravel can be sprinkled on the edge overlap to suppress it. The joints between two adjacent pieces of geotextile can be tied in a zigzag shape with fine iron wire or nylon rope with a small elongation rate, or other effective methods can be used to connect them.

After the geotextile is laid, it is vibrated and rolled with a vibratory roller to make the geotextile and the sand base tightly combined and enhance the surface density of the sand base. When the geotextile is damaged, a square geotextile with an area larger than 200mm on each side of the damaged surface should be placed under it and paved flat. Filament geotextiles can be used to control and slow down soil erosion in desert areas and improve the stability of roadbeds. Enhance the tensile strength of soil, which is helpful to improve soil stability.

(2) Application of geomembrane or geosynthetic clay liner: Geomembrane or geosynthetic clay liner is usually used to prevent moisture from penetrating into the roadbed, especially in areas that require waterproofing. Lay a geomembrane or geosynthetic clay liner over the subgrade surface or beneath the base layer, making sure it is installed correctly to prevent moisture penetration.

(3) Drainage network: In desert areas, it is crucial to prevent moisture from accumulating under the roadbed. Drainage mesh can be used to help drain water and prevent moisture retention, thereby improving the stability of the roadbed.

(4) Geoliner: Geoliner can be used to disperse the load on the road surface and reduce the risk of subsidence of the roadbed. Geolining can also play a certain waterproofing role where moisture penetration needs to be prevented.

(5) Geogrid: Geogrid is a structural material made of plastic or polymer with rigidity and tensile strength. It can be used to reinforce soil, disperse loads, and improve the resistance to deformation of roadbeds.

During the design process, the interaction of these geotechnical materials is comprehensively considered. For example, a geomembrane or geosynthetic clay liner can be combined with a geoliner to improve waterproofing, and a geodrainage mesh can be combined with a filament geotextile to enhance drainage performance.

The selection and use of these materials should be based on specific engineering requirements, geological conditions and design standards. Working with professional civil engineers and design teams, detailed engineering analysis and design were conducted to ensure that the materials and methods selected in desert highway construction were consistent with the characteristics of the local environment and able to provide long-term stability and sustainability.

The laying process of geotextile materials

Haoyang Environmental Geoliner Production Line

782787.webp)

Environmentally friendly dust-proof flat yarn woven geotextile production line

4. Drainage design

(1) Surface drainage design:

Cross and longitudinal slopes: Ensure that desert roads have sufficient cross and longitudinal slopes to allow rapid drainage of rainfall water.

Lateral Gutters: Design effective lateral gutters to direct stormwater to drainage facilities. This helps reduce the potential for moisture to become trapped on the pavement.

(2) Channel and drainage ditch design:

Depth and Width: Make sure your gutters are deep and wide enough to contain rainwater and prevent sand and dust from accumulating.

Mulch Protection: Use mulch or grid structures to protect drains from clogging by sand, dust and gravel.

(3) Permeable roadbed materials:

Choose permeable road base materials: Use permeable road base materials to help water penetrate into the ground and reduce moisture retention on the road surface.

(4) Permeable pavement materials:

Permeable pavement: Choose permeable pavement materials to reduce the accumulation of rainwater on the pavement. This helps reduce rainwater erosion and erosion of roadbeds and pavements.

(5) Dust-proof treatment:

Dust sealing agent: Use appropriate dust sealing agent to reduce the generation of sand and dust and reduce the impact on the drainage system.

Vegetation cover: Planting drought-tolerant vegetation along the route will help stabilize the soil, slow down water loss, and prevent flying sand and dust.

(6) Hydrological condition analysis:

Hydrological Studies: Conduct detailed hydrological studies to understand precipitation frequency and intensity to better predict and respond to drainage problems that stormwater may cause.

(7) Maintenance of drainage facilities:

Regular cleaning: Regularly clean drainage facilities to prevent clogging by sand, dust and gravel and ensure smooth drainage.

When designing a drainage system, it is best to have a professional civil engineer conduct detailed engineering analysis and design to ensure that the drainage system can effectively handle the special environmental challenges of desert areas.

Haoyang Environmental Drainage Net Production Line

5. Desert roadbed compaction

Sand base compaction should be determined by dry compaction or wet compaction method according to local climate and water source conditions. Generally, wet compaction method is used in areas with water sources or humid areas. Dry compaction method can be used in extremely arid mobile desert areas. During dry compaction, vibrating compaction equipment should be used.

Compaction process of roadbed

6. Sand control project

For desert highways, attention should be paid to the protection of both the main body of the roadbed and the protection of the sandy surface within a certain range on both sides of the roadbed. Protection methods include: engineering protection, plant protection, comprehensive management and other measures.

Real-life shooting of the completed desert highway

7. Some suggestions for desert highway maintenance

(1) Sandstorm protection: Desert areas are often affected by strong winds and sandstorms. In order to reduce the erosion of sand and dust on the road surface, you can consider installing wind erosion control facilities, such as vegetation belts along the road, wind erosion barriers, etc., to reduce the direct impact of wind and sand.

(2) Pavement covering: On roads in desert areas, the use of special road covering can reduce the accumulation of sand and dust and improve the wear resistance of the road. This can include special asphalt concrete or Haoyang Environmental’s plastic flat yarn woven geotextile dustproof materials.

(3) Drainage systems: Rainfall may be rare in desert areas, but when it occurs, effective drainage systems are still critical. Properly design the drainage system, including drainage ditches and drainage pipes, and use Haoyang Environmental Geocomposite Drainage Network when building roadbeds to prevent moisture from accumulating under the road surface.

(4) Ground reinforcement: Use appropriate geotechnical materials, such as Haoyang Environment’s filament geotextiles, geonets, etc., to reinforce the roadbed and enhance the load-bearing capacity and stability of the road surface. This helps slow down wind erosion and soil erosion in desert areas.

(5) Monitoring and maintenance: Regularly monitor road conditions, especially during sandstorms and extreme weather conditions.

(7) Regular cleaning: Highways in desert areas need to be cleaned regularly to remove sand, dust and other accumulated particulate matter. This helps maintain the viability and safety of roads.

(8) Use wear-resistant materials: When constructing or maintaining roads in desert areas, choosing wear-resistant materials can extend the service life of the road surface and reduce the wear and tear on the road surface.

In highway maintenance in desert areas, the durability and safety of highways can be improved by comprehensively considering climate, geology, traffic load and other factors, and adopting scientific and reasonable engineering measures.

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

503.webp)

759.webp)

992.webp)

855.webp)