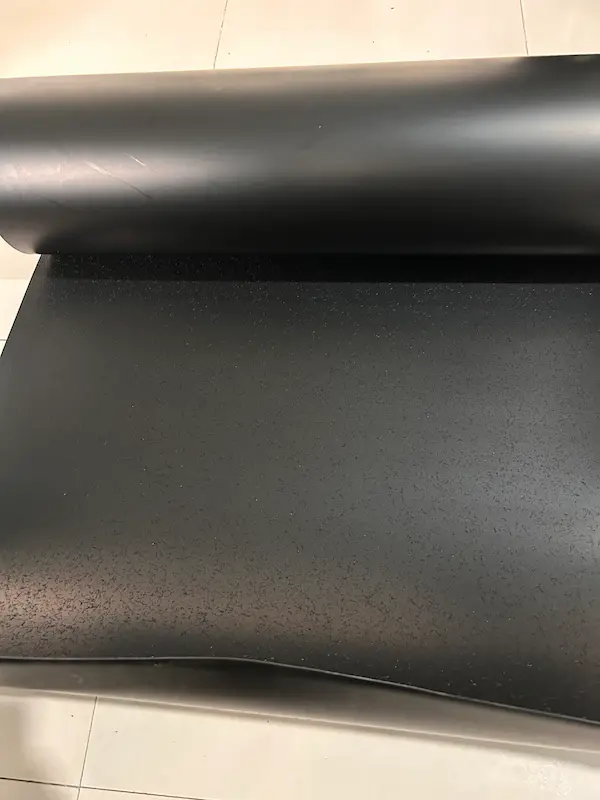

Geomembrane

A geomembrane is a synthetic membrane liner or barrier with very low permeability, used primarily to control fluid movement in a variety of civil, mining, and environmental engineering applications. Geomembranes are typically made from polymers such as polyethylene (PE), polyvinyl chloride (PVC), and polypropylene (PP), among others. These materials are selected for their chemical resistance, durability, and flexibility.

Key Characteristics of Geomembranes

Low Permeability

Geomembranes are synthetic membranes engineered with an unparalleled ability to resist the passage of water and other fluids. This exceptional low permeability is a core feature that sets them apart from other materials, enabling them to serve as an impeccable barrier against seepage and leakage in a range of applications.

The impermeability of geomembranes is achieved through the use of high-density materials, such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). These materials are specifically designed to offer an exceptional level of impermeability, effectively blocking the passage of even the smallest particles and molecules. This allows geomembranes to be used in demanding environments where even the slightest amount of leakage could have significant consequences.

In landfills, for instance, geomembranes are used to line the bottom and sides of the facility, preventing the leakage of harmful leachate into the surrounding environment. Similarly, in reservoirs and ponds, geomembranes provide a waterproof barrier that ensures the integrity of the stored water. Their low permeability also allows geomembranes to be used in chemical storage facilities, where they prevent the escape of hazardous chemicals and protect against groundwater contamination.

The effectiveness of geomembranes in preventing seepage and leakage is further enhanced by their ability to conform to the underlying terrain. They can be installed over uneven surfaces, fitting tightly against the contours of the ground. This ensures that there are no gaps or weaknesses in the barrier, minimizing the risk of leakage.

Geomembranes' low permeability makes them an ideal choice for applications where fluid containment is crucial. Their impermeability, durability, and ability to conform to the terrain allow them to provide a reliable barrier against seepage and leakage, protecting the environment and ensuring the integrity of the stored fluids.

Chemical Resistance

Geomembranes are renowned for their resilience against a diverse array of chemicals, a key attribute that ensures their consistent and reliable performance even in the most demanding and harsh environments.

These synthetic membranes are designed to withstand exposure to various chemicals, including acids, alkalis, solvents, and other aggressive substances. Their resistance to chemical degradation is due to the use of high-grade materials, such as polyvinyl chloride (PVC) and ethylene propylene diene monomer (EPDM), which are specifically engineered to offer superior chemical stability.

In industries where chemical storage and handling are critical, geomembranes play a pivotal role. They are commonly used to line chemical tanks and reservoirs, providing a robust barrier that prevents the chemicals from leaking or contaminating the surrounding environment. Even when exposed to concentrated chemicals or prolonged contact, geomembranes maintain their integrity, ensuring the safety and protection of stored materials.

Moreover, geomembranes' chemical resistance extends to their ability to withstand biological degradation. They are resistant to the growth of bacteria, fungi, and algae, further enhancing their durability and longevity. This makes them an excellent choice for applications where water or wastewater storage is involved, such as in ponds, lagoons, and wastewater treatment facilities.

Geomembranes' resistance to a wide range of chemicals is a significant advantage that sets them apart from other materials. Their ability to withstand chemical degradation, even in harsh environments, ensures long-term performance and reliability. This makes them an invaluable asset in industries where chemical storage and containment are crucial for the safety and integrity of stored materials.

Durability

One of the primary characteristics that sets geomembranes apart is their ability to withstand UV exposure. In outdoor environments, materials are constantly exposed to ultraviolet radiation from the sun. Over time, this UV exposure can degrade materials, causing them to become brittle, crack, or lose their original properties. Geomembranes, however, are formulated with UV stabilizers and other additives that protect them from the harmful effects of UV radiation. These additives absorb or reflect UV rays, minimizing the amount of energy that reaches the membrane's surface. This allows geomembranes to maintain their integrity and performance even in harsh, sun-exposed conditions.

In addition to UV resistance, geomembranes are also highly resistant to temperature fluctuations. Whether it's the extreme heat of a desert summer or the frigid temperatures of a winter night, geomembranes can maintain their structural integrity and functionality. They are formulated using materials that have a wide operating temperature range, allowing them to expand and contract with changing temperatures without suffering damage. This makes geomembranes suitable for use in a variety of climates and environments.

Moreover, geomembranes are designed to be resistant to mechanical damage. They are typically made from high-strength, flexible materials that can withstand impact, abrasion, and puncture. This durability makes them suitable for use in applications where they may be exposed to sharp objects, heavy loads, or other potential sources of damage. Geomembranes are often used as liners in landfills, wastewater treatment facilities, and other similar applications where they must protect sensitive soils and groundwater from contamination.

The durability and resilience of geomembranes make them an essential tool in environmental engineering and civil engineering projects. They provide a reliable barrier against contaminants and pollutants, helping to protect the environment and public health. Whether they are used to line landfills, contain wastewater, or serve as a protective barrier in other applications, geomembranes play a crucial role in ensuring the safety and sustainability of our built environment.

Furthermore, geomembranes are also known for their longevity. They are designed to last for decades, often exceeding the lifespan of traditional lining materials. This means that once a geomembrane is installed, it can provide reliable protection for an extended period, reducing the need for frequent maintenance or replacement. This longevity makes geomembranes a cost-effective solution for many applications, as the initial investment in the material is offset by its long-term durability and performance.

Geomembranes are a versatile and durable material that is widely used in a variety of engineering and environmental applications. Their ability to withstand UV exposure, temperature fluctuations, and mechanical damage makes them an ideal choice for protecting sensitive soils and groundwater from contamination. Whether they are used in landfills, wastewater treatment facilities, or other similar applications, geomembranes play a crucial role in ensuring the safety and sustainability of our built environment.

Flexibility

Geomembranes are not only renowned for their durability and resilience against environmental stresses, but they also possess a remarkable flexibility that allows them to conform seamlessly to the underlying terrain. This flexibility is a crucial factor in ensuring effective installation and optimal performance of geomembranes in various engineering and environmental applications.

One of the key benefits of geomembranes' flexibility is their ability to adapt to complex and uneven terrain. Unlike rigid materials, geomembranes can easily conform to slopes, curves, and irregularities in the ground surface. This adaptability ensures that there are no gaps or creases in the installation, which could potentially compromise the barrier's integrity and allow contaminants to leak through.

During installation, the flexibility of geomembranes also makes them easier to handle and manipulate. Workers can easily position and stretch the membrane to fit the contours of the terrain, using various techniques such as staking, ballasting, or the application of tensioning forces. This flexibility allows for faster and more efficient installation, reducing labor costs and minimizing the potential for damage to the membrane.

Once installed, the flexibility of geomembranes helps to maintain a continuous and effective barrier against contaminants. Even as the ground surface shifts and moves over time due to natural processes such as soil consolidation or groundwater flow, the geomembrane can stretch and conform to these changes, maintaining its integrity and preventing leaks. This flexibility is especially important in applications where the terrain is subject to significant movements, such as landfills or waste containment facilities.

In addition to their adaptability and ease of installation, the flexibility of geomembranes also contributes to their durability. Materials that are rigid and brittle are more likely to crack or break under stress, while flexible materials can absorb and distribute forces more evenly. This helps geomembranes to resist punctures, tears, and other types of damage that could compromise their performance.

Moreover, the flexibility of geomembranes enables them to be used in a wide range of applications. Whether it's lining a pond or reservoir, containing wastewater, or protecting a landfill from leachate migration, geomembranes can be tailored to fit the specific needs and contours of the site. This versatility makes them a valuable tool for engineers and contractors who need to find a reliable solution for containing and protecting against contaminants.

The flexibility of geomembranes is a crucial factor in ensuring their effective installation and performance. Their ability to conform to the underlying terrain, adapt to changes over time, and resist damage makes them an ideal choice for a wide range of environmental and engineering applications. Whether it's protecting the environment from contamination or ensuring the integrity of a waste containment facility, geomembranes provide a reliable and cost-effective solution.

Applications of Geomembranes

Landfill Liners: Used to prevent leachate from contaminating groundwater and soil. Geomembranes are a critical component of modern landfill design, often used in conjunction with other materials like geotextiles and clay liners to create a composite barrier system.

Reservoirs and Ponds: Used to line reservoirs, artificial lakes, garden ponds, and landscape pools to prevent water loss due to seepage. They ensure efficient water storage and management.

Mining: Employed in heap leach pads and tailings ponds to contain hazardous chemicals used in mining processes, protecting the surrounding environment from contamination.

Tunnels and Underground Structures: Provide waterproofing for tunnels, basements, and other underground constructions, preventing water ingress that could damage structures or pose safety hazards.

Environmental Protection: Used in various environmental containment applications, such as lining wastewater treatment lagoons and hazardous waste storage facilities.

Types of Geomembranes

High-Density Polyethylene (HDPE): Known for its high strength and chemical resistance, HDPE geomembranes are commonly used in landfill liners, mining, and water containment applications.

Low-Density Polyethylene (LDPE): Offers more flexibility than HDPE, making LDPE geomembranes suitable for applications requiring conformability to irregular surfaces.

Polyvinyl Chloride (PVC): PVC geomembrane provides excellent flexibility and is used in applications where the geomembrane needs to fit complex shapes and contours.

Polypropylene (PP): Known for its durability and resistance to chemicals, PP geomembranes are used in demanding applications like chemical containment and mining.

Installation and Quality Control

The installation of geomembranes requires careful planning and skilled workmanship to ensure effectiveness. Key steps in the installation process include:

Site Preparation: The underlying surface must be properly graded and free of sharp objects that could puncture the geomembrane.

Seaming: Panels of geomembrane are joined together using techniques such as thermal welding or adhesive bonding to create a continuous barrier.

Anchoring: The geomembrane is anchored at the edges to prevent movement and ensure stability.

Inspection and Testing: Quality control measures, including visual inspections and leak detection tests, are conducted to verify the integrity of the installed geomembrane.

Geomembranes are essential materials in modern engineering and environmental management, providing reliable barriers against fluid movement. Their versatility, durability, and effectiveness make them indispensable in applications ranging from waste containment to water conservation and infrastructure protection. With proper installation and maintenance, geomembranes offer long-term solutions to some of the most challenging environmental and engineering problems.

Geotextile

A geotextile is a permeable fabric used in conjunction with soil, rock, earth, or any other geotechnical engineering-related material. Geotextiles are typically made from synthetic polymers like polypropylene or polyester. They are designed to perform various functions such as separation, filtration, drainage, reinforcement, and protection in a wide range of civil engineering, environmental, and construction applications.

Key Characteristics of Geotextiles

Permeability

Geotextiles are remarkable materials that possess a unique combination of properties, one of which is their ability to allow the passage of fluids while effectively retaining soil particles. This dual functionality is paramount in numerous applications where filtration and drainage are essential.

The design of geotextiles is such that they feature a porous structure, allowing water and other fluids to pass through freely. At the same time, the fibers and the weave of the material are dense enough to trap and retain soil particles, preventing them from escaping or migrating into unwanted areas. This characteristic is particularly useful in applications where soil stabilization and erosion control are paramount.

In filtration applications, geotextiles serve as an effective barrier between the soil and the underlying material, such as a filter layer or drainage system. As water percolates through the soil, the geotextile allows the water to pass while retaining the soil particles, ensuring that the filtration system remains unobstructed and functioning effectively. This prevents clogging and maintains the integrity of the filtration system, ensuring that water quality is preserved.

In drainage applications, geotextiles are used to create a permeable layer that facilitates the movement of water away from an area. They are commonly placed beneath pavement, around foundations, or in other areas where water needs to be drained away to prevent flooding or waterlogging. The porous structure of the geotextile allows water to flow through freely, while the retained soil particles provide stability and prevent erosion.

The ability of geotextiles to retain soil particles is also beneficial in applications where soil stabilization is critical. For example, in road construction, geotextiles can be used as a separator between the soil and the pavement, preventing soil particles from migrating into the pavement structure and causing damage. Similarly, in landscaping projects, geotextiles can be placed beneath a layer of mulch or gravel to prevent soil from washing away during rainfall or irrigation.

Moreover, the flexibility and durability of geotextiles make them suitable for use in a wide range of environments and conditions. They can withstand the rigors of construction and traffic loads, while also resisting degradation from UV rays, chemicals, and biological agents. This ensures that the filtration and drainage functions of the geotextile are maintained over time, providing long-term benefits.

In summary, the ability of geotextiles to allow the passage of fluids while retaining soil particles is a crucial characteristic that makes them invaluable in numerous applications requiring filtration and drainage. Whether it's in road construction, landscaping, or any other field where soil stabilization and erosion control are important, geotextiles provide a reliable and effective solution.

Durability

Geotextiles are materials that exhibit exceptional resilience against both biological and chemical degradation, ensuring their consistent and reliable performance even in the most challenging environmental conditions. This unique property is a testament to the durability and versatility of geotextiles, making them a valuable tool in a wide range of applications.

First, let's consider the biological degradation factor. Many natural environments, such as wetlands, riverbanks, and coastal areas, are home to a diverse array of microorganisms and enzymes that can break down organic materials. However, geotextiles are specifically designed to resist such biological attacks. Their fibers are often treated with biocides or coated with protective layers that inhibit the growth of bacteria, fungi, and other microorganisms. This ensures that the integrity of the geotextile remains intact, preventing the degradation that can occur due to biological activity.

On the other hand, chemical degradation is another significant threat to the durability of materials in many applications. Industrial chemicals, acids, alkalis, and solvents can all pose a risk to the structural integrity of conventional materials. However, geotextiles are formulated using fibers and coatings that are highly resistant to these chemicals. They can withstand exposure to harsh chemicals without experiencing significant degradation, making them suitable for use in industrial and agricultural applications where chemicals are present.

The combination of biological and chemical resistance in geotextiles provides a significant advantage over traditional materials. They can be confidently used in environments where both types of degradation are a concern, such as wastewater treatment plants, landfills, and mining sites. In these applications, geotextiles play a crucial role in filtration, drainage, and erosion control, ensuring the safe and efficient management of liquids and solids.

Moreover, the long-term performance of geotextiles is also essential in applications where maintenance and replacement are difficult or expensive. For example, in road construction and landscaping projects, the use of geotextiles can significantly reduce the need for future repairs and replacements, saving time and money. The resistance to biological and chemical degradation ensures that the geotextiles will maintain their structural integrity and functionality for extended periods of time.

The resistance of geotextiles to both biological and chemical degradation is a crucial property that sets them apart from traditional materials. This durability ensures that they can be used reliably in a wide range of applications, including those that are exposed to harsh environmental conditions. As a result, geotextiles are a valuable tool for engineers, contractors, and landscapers who require materials that can withstand the rigors of their work and provide long-term performance.

Mechanical Strength

Geotextiles are materials that exhibit remarkable tensile strength, enabling them to withstand significant loads and stresses with ease. This unique characteristic makes them a highly suitable choice for various reinforcement applications, where stability and durability are paramount.

In the field of civil engineering, geotextiles are commonly used for soil reinforcement. They can be installed within soil masses to improve their overall strength and stiffness. By providing reinforcement, geotextiles help reduce the potential for soil failure, such as slumping or liquefaction, under heavy loads or seismic conditions. This reinforcement capability makes geotextiles invaluable in the construction of roads, railways, dams, and other infrastructure projects.

Moreover, geotextiles' tensile strength also allows them to be used in slope stabilization applications. When installed on slopes, they can reinforce the soil and prevent it from sliding or eroding away. This is particularly important in areas prone to landslides or where steep slopes need to be stabilized for safety reasons.

In addition to their reinforcement capabilities, geotextiles are also known for their flexibility and adaptability. They can conform to irregular shapes and contours, making them suitable for use in complex reinforcement applications. Furthermore, geotextiles are relatively lightweight and easy to handle, which reduces the need for heavy equipment during installation.

In summary, geotextiles' superior tensile strength and ability to withstand significant loads and stresses make them a valuable tool for reinforcement applications. Whether it's soil reinforcement in civil engineering projects or slope stabilization in landslide-prone areas, geotextiles provide a reliable and cost-effective solution to ensure stability and durability.

Flexibility

The flexibility of geotextiles is a crucial attribute that greatly enhances their effectiveness and applicability in various reinforcement applications. This inherent flexibility allows geotextiles to conform to irregular surfaces and contours with ease, ensuring a tight and secure fit. This adaptability is especially significant in real-world scenarios where the ground conditions are often not perfectly flat or uniform.

By conforming to irregular surfaces, geotextiles can achieve maximum contact with the soil or substrate, providing optimal reinforcement. This close contact ensures that the loads and stresses are evenly distributed across the entire surface, minimizing the chances of localized failure.

Furthermore, the flexibility of geotextiles also makes them easier to install, as they can be draped or wrapped around complex structures and shapes. This reduces the need for extensive preparation or modification of the existing surfaces, saving time and cost during installation.

The flexible nature of geotextiles allows them to conform to irregular surfaces, enabling effective installation and optimal performance in reinforcement applications. This adaptability and ease of installation make geotextiles a versatile and reliable choice for various civil engineering and environmental projects.

Functions of Geotextiles

Separation: Geotextiles are used to separate different layers of soil or aggregate materials to prevent them from mixing. This is essential in road construction and railway trackbed stabilization, where maintaining the integrity of distinct layers is critical.

Filtration: They act as a filter, allowing water to pass through while retaining soil particles. This function is important in drainage applications, such as in retaining walls or underdrain systems, where preventing soil erosion while ensuring proper water flow is necessary.

Drainage: Geotextiles facilitate the movement of water or other fluids within the soil. They are used in drainage systems to channel water away from structures or areas prone to waterlogging.

Reinforcement: By providing additional strength to the soil, geotextiles improve the load-bearing capacity of the ground. This is particularly useful in embankments, retaining structures, and soft soil stabilization.

Protection: Geotextiles protect geomembranes and other materials from damage by providing a cushioning layer that absorbs impact and prevents punctures.

Types of Geotextiles

Woven Geotextiles: Made by weaving together individual yarns or fibers, woven geotextiles are known for their high tensile strength and are commonly used in applications requiring reinforcement and separation.

Non-Woven Geotextiles: Produced by bonding fibers together using mechanical, chemical, or thermal processes, non-woven geotextiles offer excellent filtration and drainage properties. They are often used in filtration, drainage, and protection applications.

Knitted Geotextiles: Created by interlocking loops of yarn, knitted geotextiles combine the properties of woven and non-woven geotextiles. They are used in specialized applications requiring specific mechanical properties.

Applications of Geotextiles

Road Construction: Geotextiles are used to stabilize and reinforce the subgrade, separate different soil layers, and provide drainage under roadways, extending the lifespan and improving the performance of roads.

Erosion Control: They help prevent soil erosion on slopes, riverbanks, and coastal areas by retaining soil particles while allowing water to flow through.

Landfills: Geotextiles are used in landfill liners and caps to separate waste from the surrounding environment, filter leachate, and provide drainage.

Retaining Walls: They improve the stability and performance of retaining walls by providing reinforcement and facilitating drainage behind the wall.

Agriculture: In agricultural applications, geotextiles are used for soil stabilization, drainage, and erosion control, enhancing soil management and crop productivity.

Environmental Protection: Geotextiles are used in various environmental applications, such as protecting geomembranes in containment systems, lining ponds, and managing contaminated sites.

Geotextiles are essential materials in modern geotechnical and civil engineering projects, providing solutions for separation, filtration, drainage, reinforcement, and protection. Their versatility, durability, and effectiveness make them invaluable in a wide range of applications, from infrastructure development to environmental protection. By integrating geotextiles into engineering designs, professionals can achieve enhanced performance, longevity, and sustainability in their projects.

The difference between Geomembrane and Geotextile

Different materials

Geomembrane: Geomembranes are highly specialized materials that are typically constructed from either polymer or asphalt. These membranes are designed to provide a continuous barrier that is impermeable to liquids and gases. Polymeric geomembranes, in particular, are made from synthetic materials such as polyvinyl chloride (PVC) or ethylene propylene diene monomer (EPDM), which offer excellent chemical resistance and durability. Asphalt geomembranes, on the other hand, utilize asphaltic compounds that are reinforced with a synthetic or natural fabric for added strength and stability.

Geotextile: On the contrary, geotextiles are primarily composed of polymeric materials that are processed in various ways to create a textile structure. These can be woven, knitted, or non-woven, depending on the specific application. Woven geotextiles have a defined pattern of interlacing yarns that provide strength and durability. Knitted geotextiles have a looser, more open structure that allows for greater flexibility and permeability. Non-woven geotextiles, meanwhile, are made from fibers that are bonded together using heat, chemicals, or mechanical processes, resulting in a strong yet flexible material.

Different properties

Geomembrane: Geomembranes are specialized materials that are renowned for their impermeability, making them ideal for partitioning and anti-seepage applications. These robust membranes create a continuous barrier that is highly resistant to liquids and gases, ensuring the integrity of the underlying structure or system. Geomembranes are often utilized in the construction of landfills, water retention structures, and other critical infrastructure where the prevention of liquid infiltration or leakage is paramount.

Geotextile: In contrast, geotextiles are permeable fabrics that possess a wide range of geotechnical functions. Made primarily from polymeric materials, geotextiles are designed to allow water and other fluids to pass through while simultaneously providing reinforcement, filtration, and separation. Their permeability allows for the drainage of excess water, which is crucial in preventing hydrostatic pressure build-up and maintaining the stability of soil and structures. Additionally, geotextiles are often used to separate different soil layers, preventing the mixing of incompatible materials and enhancing the overall performance of the geotechnical system.

Different service life

Geomembrane: Due to its impermeability and chemical resistance, it usually has a long service life.

Geotextile: It is resistant to wear and corrosion and is suitable for environments where it is buried in the soil for a long time.

Application areas

Geomembrane:

Geomembranes primary application in areas where partitioning and anti-seepage are paramount. Its impermeability and chemical resistance make it an ideal choice for a wide range of applications where containment and prevention of liquid migration are crucial.

In the field of waste disposal, geomembrane plays a vital role. Landfills, for instance, rely on geomembrane liners to effectively separate waste from the surrounding environment. These liners prevent leachate from contaminating soil and groundwater, thus minimizing the environmental impact of waste disposal. Geomembrane's durability and long service life ensure that these liners can provide a reliable barrier for decades.

Pond lining is another area where geomembrane excels. Whether it's a man-made reservoir or a natural lake being restored, geomembrane offers a robust, impermeable lining that prevents water loss through evaporation or seepage. This not only conserves water resources but also ensures the structural integrity of the pond.

In recent years, geomembrane has also gained popularity in agricultural applications, particularly in the construction of water retention ponds and irrigation canals. By lining these structures with geomembrane, farmers can reduce water loss and improve irrigation efficiency, ultimately leading to increased crop yields.

One noteworthy example of geomembrane's use is in the construction of a large-scale landfill in North America. Here, geomembrane liners were installed to a depth of 6 feet, covering an area of over 100 acres. After more than 10 years of operation, the liners have shown no signs of degradation or leakage, demonstrating the durability and reliability of geomembrane in waste disposal applications.

Geotextile:

Geotextile, on the other hand, is a versatile material that finds its way into a wide range of civil engineering applications. Its resilience to wear and corrosion, as well as its ability to withstand burial in soil for extended periods, make it an indispensable tool in numerous construction projects.

Roads and highways are a prime example of where geotextile is extensively used. As a separator between the soil subgrade and the pavement layers, geotextile prevents soil particles from migrating into the pavement, thus maintaining its structural integrity. This not only improves the ride quality of the road but also extends its service life.

Embankments and retaining walls also benefit significantly from the use of geotextile. In these applications, geotextile is used as a reinforcement material to increase the stability of the structure. By reinforcing the soil with geotextile, engineers can create steeper slopes and reduce the overall size of the embankment or retaining wall, thus saving on construction costs.

Bank protection is another area where geotextile plays a crucial role. Along riverbanks and coastlines, geotextile is used to stabilize slopes and prevent erosion. Its ability to withstand the abrasive forces of flowing water and sediment makes it an effective solution for bank protection.

Data from a recent study on the use of geotextile in road construction shows that incorporating geotextile separators into the pavement structure can reduce maintenance costs by up to 30% over the lifetime of the road. This is attributed to the improved stability and durability of the pavement, resulting in fewer repairs and less frequent replacements.

Geomembrane and geotextile, though different in material properties and technical functions, complement each other perfectly in various civil engineering applications. Their combined use allows for the creation of robust, durable, and environmentally friendly structures that can stand the test of time.

Used in conjunction

In many applications, Geomembrane is used in conjunction with Geotextile, which provides reinforcement and protection, and Geomembrane, which provides an impermeable barrier.

The following is an example that combines some common data and concepts to illustrate the effect of this combination:

In the construction of landfills, the combined use of Geomembrane and Geotextile is particularly important.

Application of Geomembrane:

As an anti-permeability layer: Geomembrane is laid on the bottom and sides of the landfill to form a continuous, impermeable barrier, effectively preventing the pollution of surrounding soil and groundwater by leachate from garbage.

Data reference: The leachate leakage rate of landfills using Geomembrane can be reduced to less than 0.01%, which is much lower than that of landfills that do not use Geomembrane.

Application of Geotextile:

Filter layer: Laying one or more layers of Geotextile on top of Geomembrane can filter out particulate matter in the soil and garbage, preventing them from clogging the tiny pores of Geomembrane, thereby maintaining its anti-permeability performance.

Separation layer: Geotextile can also be used as a separation layer between different material layers to prevent soil particles from direct contact with Geomembrane and reduce wear and corrosion.

Drainage layer: Some Geotextile types also have good drainage performance, which can help quickly drain the accumulated water inside the landfill, reduce internal pressure and improve overall stability.

Data reference: The service life of landfills that use Geomembrane and Geotextile can be extended to more than 30 years, while significantly reducing the cost of subsequent maintenance and repair.

Summary:

In projects such as landfills that require strict anti-seepage, the combined use of Geomembrane and Geotextile provides strong technical support. Geomembrane, as an anti-seepage layer, ensures that the leachate of garbage does not pollute the surrounding environment; while Geotextile further enhances the stability and durability of the entire system through functions such as filtration, separation and drainage. This combined use not only improves the quality of the project, but also reduces the risks and costs of long-term operation.

Conclusion

Geomembrane and Geotextile exhibit distinct differences in their material properties, application fields, and technical functions. By leveraging their unique strengths and pairing them appropriately, we can harness the benefits of both materials to deliver effective solutions tailored for various civil engineering projects. This combination ensures optimal performance and durability in a range of construction applications. If your project requires high-quality Geomembrane and Geotextile, consider our company. We produce and sell a wide range of Geomembrane and Geotextile products at competitive prices. Compare our products with those from other manufacturers to see the difference. For more information and to discuss your needs, please contact us.

897.webp)

942.webp)

237.webp)