Geosynthetic Reinforcement: Revolutionizing Infrastructure Strength and Durability

In today's world, infrastructure development is essential for the growth and prosperity of communities. As urbanization and population growth continue to accelerate, the need for durable, resilient, and sustainable infrastructure has become paramount. Geosynthetic reinforcement is a cutting-edge technology that is revolutionizing the way we build and maintain critical infrastructure.

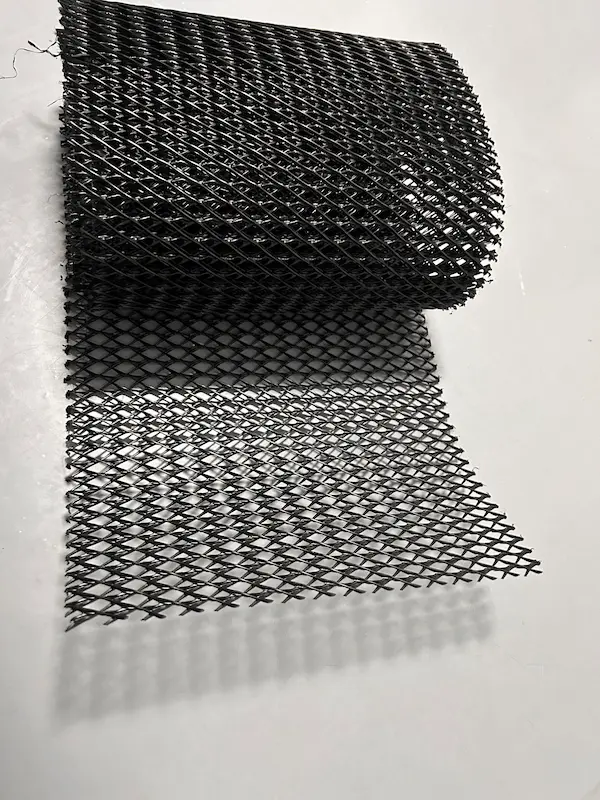

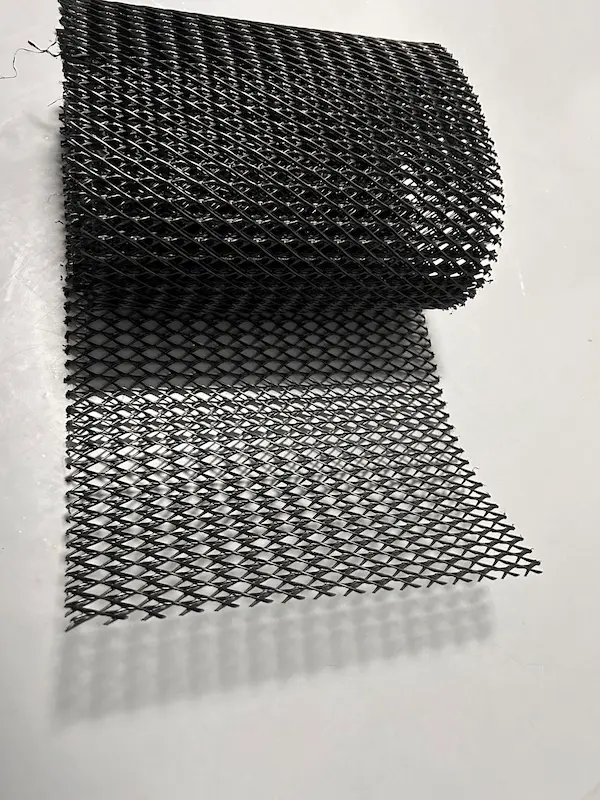

(3D black filament composite drainage net)

What is geosynthetic reinforcement?

Geosynthetic reinforcement is the use of specialized geosynthetic materials to enhance the strength, durability, and performance of infrastructure components. These materials are designed to withstand the demands of the natural environment and provide exceptional reinforcement properties. Geosynthetic reinforcement can be used in various applications, such as roads, bridges, dams, tunnels, and more.

(Black 3D drainage net,generally also used as the core of composite drainage net)

Why use geosynthetic reinforcement?

The benefits of geosynthetic reinforcement are numerous and include:

Durability: Geosynthetic materials are highly durable and can withstand harsh environmental conditions, such as temperature variations, moisture, and erosion. This durability ensures long-lasting reinforcement and extends the lifespan of infrastructure components.

Strengthening: Geosynthetic reinforcement significantly improves the load-bearing capacity and stability of infrastructure components. It provides a cost-effective alternative to traditional reinforcing methods, such as steel and concrete reinforcing bars.

Flexibility: Geosynthetic materials offer flexibility that allows them to adapt to various stress patterns and movements. This flexibility reduces the risk of cracking and failure in critical infrastructure components.

Environmental friendliness: Geosynthetic materials are often made from recycled materials or sustainable sources, making them environmentally friendly alternatives to traditional reinforcing materials. Their use helps reduce waste and lower the carbon footprint of infrastructure projects.

Cost-effectiveness: While the initial cost of geosynthetic materials may be higher than some traditional materials, their durability and performance make them a cost-effective choice in the long run. The reduced need for maintenance and repairs, along with the increased lifespan of infrastructure components, can significantly offset initial costs.

Geosynthetic reinforcement is a game-changer in infrastructure development, offering unparalleled strengthening capabilities that improve the performance and durability of critical infrastructure components. As we strive to build sustainable and resilient infrastructure for future generations, geosynthetic reinforcement will continue to play a vital role in meeting these challenges.

485387.webp)

(White filament geotextile black geomembrane core-composite geomembrane)

Principles of geotechnical material reinforcement

Geosynthetic reinforcement involves the use of synthetic materials to enhance the performance and stability of soil structures in civil engineering and construction projects. The principle behind geosynthetic reinforcement lies in the ability of these materials to distribute loads, improve soil strength, and provide additional support to various types of structures. Here are the key principles of geosynthetic reinforcement:

Load Distribution:

One of the primary principles of geosynthetic reinforcement is load distribution. Geosynthetic materials, such as geogrids, geotextiles, and geocells, are strategically placed within the soil to distribute applied loads more evenly. This helps prevent localized failures and reduces the potential for settlement or deformation of the structure.

Soil Reinforcement:

Geosynthetics reinforce soil by providing additional tensile strength. In applications like retaining walls, slopes, and embankments, these materials resist forces such as gravity and lateral earth pressure. This reinforcement improves the stability and overall performance of the soil structure.

Confinement of Soil Particles:

Certain geosynthetic materials, like geocells, function by confining and stabilizing soil particles. When filled with soil or aggregate, geocells create a three-dimensional structure that restricts lateral movement of particles. This confinement enhances the load-bearing capacity of the soil and reduces the potential for erosion.

Prevention of Differential Settlement:

Geosynthetic reinforcement helps prevent differential settlement, which occurs when different parts of a structure settle at different rates. By distributing loads more uniformly, these materials minimize differential settlement, ensuring that the structure settles evenly over time.

Erosion Control:

Geosynthetics, particularly geotextiles, are effective in erosion control. They stabilize soil surfaces, preventing erosion caused by wind and water. The materials act as a barrier that protects against the loss of soil particles, preserving the integrity of slopes and embankments.

Increased Bearing Capacity:

Geosynthetic reinforcement increases the bearing capacity of weak or soft soils. This is achieved by improving the tensile strength of the soil and reducing the potential for shear failure. Geogrids, in particular, are commonly used to enhance the load-bearing capacity of pavements and foundations.

Improvement of Slope Stability:

Geosynthetics play a crucial role in improving the stability of slopes. By reinforcing the soil structure, these materials counteract the forces that lead to slope failure, such as gravity and water-induced erosion. This is particularly important in road construction and infrastructure projects.

Construction of Mechanically Stabilized Earth (MSE) Walls:

Geosynthetic reinforcement is a fundamental principle in the construction of Mechanically Stabilized Earth (MSE) walls. Geogrids or geotextiles are used to reinforce the soil backfill behind the wall, providing tensile strength to resist lateral pressures and stabilize the structure.

In summary, the principle of geosynthetic reinforcement involves strategically placing synthetic materials within the soil to distribute loads, reinforce weak soils, prevent erosion, and enhance the overall stability and performance of civil engineering structures. The selection and application of specific geosynthetic materials depend on the unique requirements of each project.

(600g white filament geotextile)

Geosynthetic reinforcement specific technical parameters

The specific technical parameters of geosynthetic reinforcement materials can vary based on the type of geosynthetic and the intended application. Here are some typical technical parameters along with specific numerical values for common geosynthetic materials:

Geotextiles:

Tensile Strength: Typically ranges from 50 kN/m to 1200 kN/m.

Elongation at Break: Varies between 10% and 25%.

Grab Strength: Around 0.5 kN to 5 kN.

Permeability: Can range from 10^-2 cm/s to 10^-4 cm/s.

Geogrids:

Tensile Strength (Ultimate): Commonly between 20 kN/m and 2000 kN/m.

Tensile Modulus: Typically in the range of 1000 kN/m to 20000 kN/m.

Aperture Size: Varies but often in the range of 20 mm to 200 mm.

Rib Thickness: Typically between 1 mm and 3 mm.

Geomembranes:

Thickness: Commonly ranges from 0.5 mm to 3 mm.

Tensile Strength: Usually greater than 10 MPa.

Elongation at Break: Around 10% to 20%.

Permeability: Low permeability, often in the range of 10^-13 cm/s.

Geocells:

Cell Height: Typically ranges from 50 mm to 300 mm.

Cell Size (Expanded): Commonly 150 mm x 150 mm to 300 mm x 300 mm.

Cell Wall Thickness: Varies but often in the range of 0.5 mm to 2 mm.

Collapse Ratio: Typically less than 5%.

Geocomposites:

Components: Geocomposites can consist of various combinations, such as geotextile-geonet, geotextile-geomembrane, etc.

Thickness: Varies based on components, often in the range of 5 mm to 20 mm.

Drainage Capacity: Commonly in the range of 1 l/s/m^2 to 50 l/s/m^2.

Gabions:

Wire Diameter: Typically ranges from 2.0 mm to 4.0 mm.

Mesh Size: Varies but often in the range of 80 mm x 100 mm to 120 mm x 150 mm.

Dimensions: Commonly available in units of 1 m x 1 m x 1 m or 2 m x 1 m x 1 m.

These numerical values are indicative and may vary based on specific product specifications, manufacturers, and project requirements. It's important to consult with geotechnical engineers and geosynthetic manufacturers to determine the most suitable material and specifications for a particular application.

567.webp)

840.webp)

503.webp)

759.webp)

628.webp)