Definition of Geotextile

A geotextile is a permeable synthetic textile material used with foundation, soil, rock, earth, or any other geotechnical engineering-related material. It is typically made from polypropylene, polyester, or other synthetic fibers and is designed to be durable and resistant to environmental factors. Geotextiles are used in various civil engineering applications to perform functions such as separation, filtration, reinforcement, protection, and drainage. They help improve the stability and performance of soil and other geotechnical structures while allowing water to pass through, thereby preventing soil migration and enhancing overall structural integrity.

Understanding Geotextile Properties

Before diving into testing, it’s crucial to understand the key properties of geotextiles:

Mechanical Properties | ü Tensile Strength: Determines the fabric's ability to withstand pulling forces. ü Tear Resistance: Assesses how well the material resists tearing. |

Hydraulic Properties | ü Permeability: Indicates how well water can flow through the geotextile. ü Filtration Efficiency: Measures its ability to retain soil particles while allowing water to pass. |

Durability | ü Resistance to ultraviolet (UV) radiation, chemical exposure, and microbial activity. |

Resistance to ultraviolet (UV) | ü Heat resistance, particularly for applications in high-temperature environment. |

Key Geotextile Testing Techniques

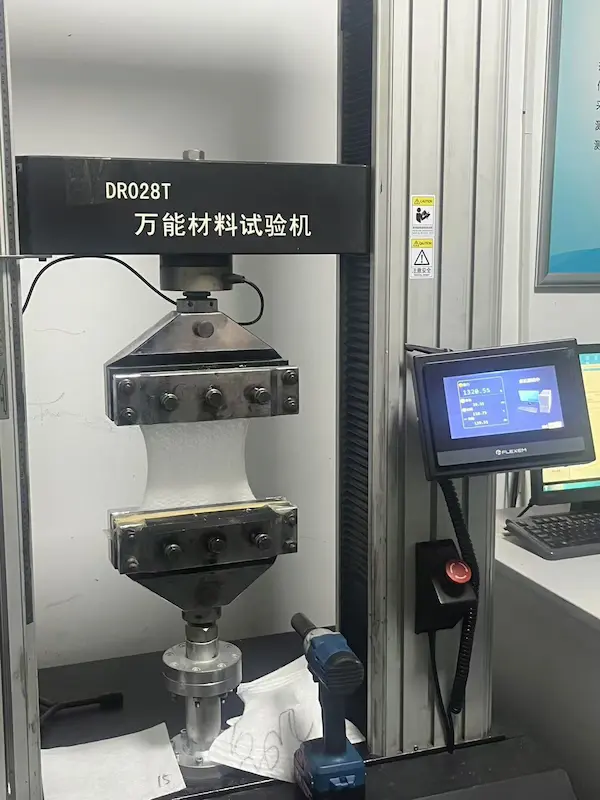

1. Tensile Strength Testing

Tensile strength testing evaluates the fabric's ability to withstand pulling forces. The test is conducted according to standards such as ASTM D4595 or ISO 10319.

· Procedure: A geotextile sample is clamped and stretched at a constant rate until it breaks.

· Output: The maximum force applied (in kN/m) and the corresponding elongation percentage.

· Applications: Ensures the geotextile can support loads in road construction and retaining walls.

2. Puncture Resistance Testing

This test determines the fabric's resistance to being punctured by sharp objects, simulating real-world conditions where stones or debris could penetrate.

Procedure: A pointed probe is pushed into the fabric at a controlled speed until it punctures.

Standards: ASTM D6241 or ISO 12236.

Applications: Critical for geotextiles used under roads or heavy equipment.

3. Permittivity Testing

Permittivity testing measures how quickly water can pass through the fabric.

Procedure: Water is poured vertically through the geotextile, and the flow rate is recorded.

Standards: ASTM D4491 or ISO 11058.

Applications: Important for drainage and filtration systems.

4. UV Resistance Testing

Geotextiles exposed to sunlight can degrade over time. UV resistance testing evaluates the fabric's durability under simulated sunlight exposure.

Procedure: Samples are subjected to artificial UV radiation for a specified duration.

Standards: ASTM D4355.

Applications: Ensures long-term performance in outdoor applications, such as erosion control.

5. Filtration Efficiency Testing

This test measures the geotextile's ability to retain soil particles while allowing water to flow through.

Procedure: Soil and water are passed through the fabric, and the retained particles are analyzed.

Standards: ASTM D4751.

Applications: Essential for geotextiles used in drainage and sediment control.

6. Chemical Resistance Testing

Geotextiles often encounter harsh chemicals in industrial or landfill environments. Chemical resistance tests simulate these conditions to ensure the fabric's stability.

Procedure: Samples are immersed in chemical solutions, and their physical and mechanical properties are assessed after exposure.

Applications: Relevant for geotextiles in hazardous waste management.

Applications of Geotextiles

1. Road Construction

Geotextiles are used as separators to prevent the mixing of soil layers, enhancing the stability of roads and highways. By reinforcing the subgrade, they extend the lifespan of roads and reduce maintenance costs.

Example: In soft soil conditions, woven geotextiles provide additional strength, reducing rutting and deformation.

2. Erosion Control

Geotextiles stabilize slopes, riverbanks, and shorelines, preventing soil erosion caused by water or wind. Non-woven geotextiles are particularly effective for such applications due to their permeability and durability.

Example: Coastal protection projects use geotextiles to reinforce dunes and prevent sand erosion.

3. Drainage Systems

In drainage systems, geotextiles facilitate water flow while preventing soil from clogging the system. Their filtration efficiency ensures long-term functionality.

Example: French drains and retaining wall backfills commonly incorporate non-woven geotextiles.

4. Landfill Liners

Geotextiles are used in conjunction with geomembranes to protect liners from punctures and enhance their performance. They also help manage leachate and gas drainage.

Example: A composite liner system with geotextiles is standard in modern landfill designs.

5. Agriculture

In agricultural settings, geotextiles improve soil drainage and protect crops from excessive waterlogging. They are also used for soil stabilization in irrigation channels.

Example: Geotextile-lined canals reduce water loss and soil erosion in arid regions.

6. Mining and Industrial Projects

Geotextiles play a crucial role in mining projects by stabilizing access roads, managing tailings, and preventing soil erosion. Their chemical resistance ensures durability in harsh industrial environments.

Example: Geotextiles are used under mining tailings ponds to prevent seepage and contamination.

Future Trends in Geotextile Testing and Application

1. Smart Geotextiles

Emerging technologies are integrating sensors into geotextiles to monitor stress, strain, and environmental conditions in real-time.

2. Sustainable Geotextiles

With a growing focus on sustainability, research is advancing biodegradable and recycled geotextiles to minimize environmental impact.

3. Enhanced Standards

The development of more rigorous international testing standards ensures consistency and reliability across applications worldwide.

Conclusion

Geotextiles are essential in modern engineering, offering unparalleled solutions for soil stabilization, erosion control, and drainage. Rigorous testing ensures their performance and reliability in diverse conditions. From road construction to environmental conservation, geotextiles are transforming the way we build and protect our infrastructure. As technology advances, we can expect smarter, more sustainable geotextiles to emerge, further expanding their applications and benefits.

897.webp)

942.webp)

237.webp)