What is getextile fabrice?

Geotextiles are permeable fabrics used in civil engineering applications. They're typically made from synthetic fibers like polyester or polypropylene. These fabrics are designed to improve soil stability, provide erosion control, aid in drainage, and separate different soil layers.

Applications of geotextile fabric

Geotextile fabric has a wide range of applications across various industries. Some of the common applications include:

1,Road Construction: Geotextiles are used in road construction for reinforcing weak soils, separating different soil layers to prevent mixing, and providing filtration and drainage capabilities to prolong road lifespan.

2,Erosion Control: Geotextiles are used in erosion control applications such as slope stabilization, shoreline protection, and riverbank protection. They help to prevent soil erosion by stabilizing the soil and allowing vegetation to establish.

3,Drainage Systems: Geotextiles are used in drainage systems to facilitate water flow while preventing soil loss. They are commonly used in retaining walls, French drains, and subsurface drainage systems.

4,Landfill Liners: Geotextiles are used as liners in landfills to prevent contaminants from leaching into the surrounding soil and groundwater. They provide a barrier layer while allowing for the passage of liquids.

5,Geotextile Tubes: Geotextile tubes or bags are used for dewatering sludge, sediment, or dredged material in various environmental and construction applications.

6,Geotextile Reinforced Embankments: Geotextiles are used to reinforce embankments and slopes, providing stability and preventing soil erosion.

7,Railway Applications: Geotextiles are used in railway construction for ballast reinforcement, track stabilization, and erosion control along railway embankments.

8,Landscaping: Geotextiles are used in landscaping projects for weed control, soil stabilization, and erosion control in gardens, parks, and green spaces.

9,Sports Field Construction: Geotextiles are used in the construction of sports fields to improve drainage, prevent soil compaction, and provide a stable base for turf or artificial turf systems.

10,Civil Engineering Projects: Geotextiles are used in various civil engineering projects such as retaining walls, reservoirs, dams, and canals to improve soil stability, provide erosion control, and enhance drainage.

Types of geotextile fabric

671906.webp)

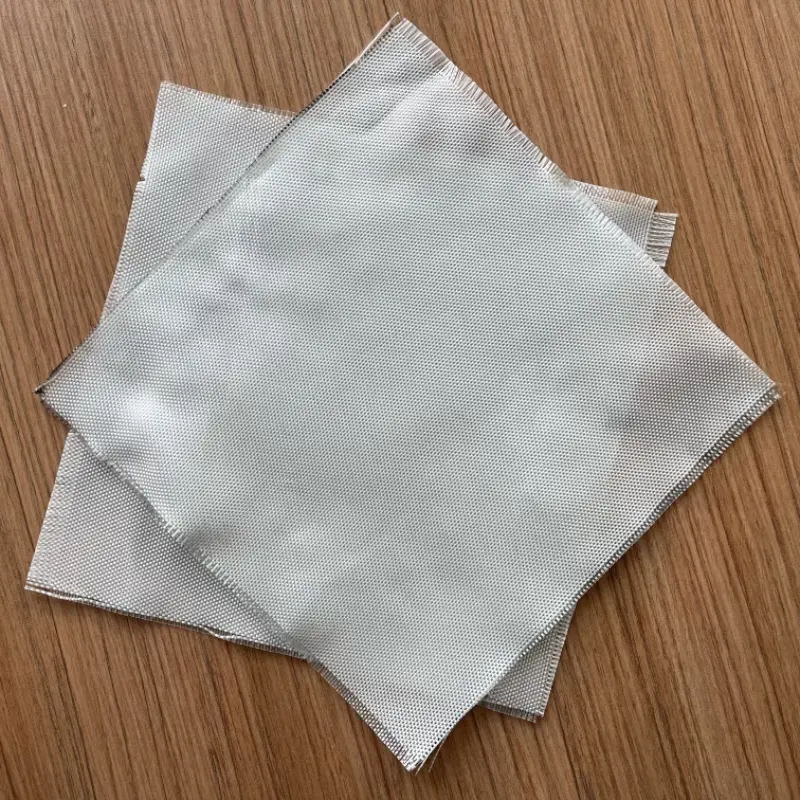

According to whether they are woven or knitted, they can be divided into two types.

1, Woven Geotextiles: These geotextiles are composed of interlaced fiber threads, similar to traditional fabrics. Woven geotextiles typically have high strength and stiffness, suitable for applications requiring high mechanical performance, such as road base reinforcement and soil separation.

2, Non-woven Geotextiles: These geotextiles are formed by stacking short fibers or fiber sheets together and then fixing them together chemically or mechanically. Non-woven geotextiles typically have good filtration performance and water permeability, suitable for applications such as soil anti-corrosion and hydrological control.

Specifications and price of nonwoven geotextile fabric

These are the regular specifications and corresponding price list of our non-woven geotextiles. The price unit is $. If your needs are not in the specification list, please contact our professionals and we will give you an answer.

Product name | color | specification | Price(FOB USD) |

Filament geofabric | white | 150g/㎡,5.29oz/㎡ | 0.19 |

Filament geofabric | white | 200g/㎡,7.05oz/㎡ | 0.25 |

Filament geofabric | green | 200g/㎡,7.05oz/㎡ | 0.28 |

Filament geofabric | black | 300g/㎡,10.582oz/㎡ | 0.39 |

Staple pet geofabric | white | 150g/㎡,5.29oz/㎡ | 0.16 |

Staple pet geofabric | white | 200g/㎡,7.05oz/㎡ | 0.22 |

Staple pp geofabric | white | 150g/㎡,5.29oz/㎡ | 0.23 |

Staple pp geofabric | white | 200g/㎡,7.05oz/㎡ | 0.3 |

Specifications and price of woven geotextile fabric

These are the price lists of woven geotextiles, the unit is $. If the specifications of the woven geotextile you purchased are not in the table below, please contact us for customized processing. The price will be quoted to you separately.

Product name | color | specification | Price(FOB USD) |

Filament pp geofabric | white | 150g/㎡, 5.29oz/㎡ | 0.3 |

Filament pp geofabric | white | 200g/㎡, 7.05oz/㎡ | 0.4 |

Filament pp geofabric | white | 250g/㎡,8.8oz/㎡ | 0.5 |

Filament pp geofabric | white | 300g/㎡, 10.6oz/㎡ | 0.6 |

Staple pet geofabric | white | 100g/㎡, 3.5oz/㎡ | 0.23 |

Staple pet geofabric | white | 150g/㎡, 5.29oz/㎡ | 0.34 |

From the above we can see that the factors influence the price of the geotextile fabric includes:

1,Material Type: Geotextile fabrics can be made from various materials such as polyester, polypropylene, or other synthetic fibers. The cost of the raw materials used in manufacturing will affect the overall price of the fabric.

2, Fabric Type: The type of geotextile fabric, whether it's woven or non-woven, affects its price. Woven geotextiles tend to be more expensive due to their higher strength and stiffness compared to non-woven fabrics.

3, Weight and Thickness: Geotextile fabrics are available in different weights and thicknesses, and heavier or thicker fabrics usually cost more due to the increased material usage.

Manufacturing Process: The manufacturing process used to produce geotextile fabric can influence its price. Some manufacturing techniques may be more cost-effective than others, affecting the final product price.

4,colors

Colors also is another factor influence the price, usually the standard color is white, but some clients need green, black or other colors, we can also do that, but the price is higher than white. You can choose the color according to your need.

Factory price advantage

At Haoyang Environmental, we take pride in being one of China's foremost manufacturers of geosynthetic products, boasting a state-of-the-art factory equipped with over 20 production lines. Our commitment to excellence extends beyond quality; it encompasses affordability as well.

Our competitive edge lies in our ability to offer highly competitive prices without compromising on quality. Here's how we do it:

We control the entire production process in-house, from raw material sourcing to manufacturing and distribution. By eliminating middlemen and streamlining operations, we reduce costs significantly.

With a large-scale production facility, we benefit from economies of scale. Bulk purchasing of raw materials and efficient production processes allow us to lower production costs per unit, translating into cost savings for our customers.

Customization at No Extra Cost. We understand that every project is unique, which is why we offer customization options at no extra cost. Whether it's adjusting grams, choosing specific colors, or tailoring roll sizes to your requirements, we ensure flexibility without additional expenses.

Strategic Pricing. Leveraging our industry expertise and market insights, we strategically price our products to remain competitive without compromising profitability. Our pricing reflects our commitment to providing exceptional value to our customers.

Transparent Pricing Policy. We believe in transparency in pricing. Our pricing structure is straightforward, with no hidden fees or surcharges. What you see is what you get, ensuring peace of mind and trust in our partnership.

By choosing Haoyang Environmental as your geosynthetic products supplier, you not only gain access to top-quality products but also benefit from cost-effective solutions tailored to your needs. Partner with us and experience the difference that our competitive pricing advantage can make for your projects.

Contact us today to learn more about how we can meet your requirements while offering unbeatable prices. Let's build a brighter future together with Haoyang Environmental.

Feel free to cotact Echo:

email: export@hygeosynthetics.com

phone/Whatsapp: 0086-18853127527

897.webp)

942.webp)

237.webp)