Technical Advantages of HDPE Geomembranes

| Property | HDPE Geomembrane | Traditional Materials |

|---|---|---|

| Chemical Resistance | Resistant to pH 2-12 | Limited resistance to acids |

| Tensile Strength (kN/m) | 120-160 | 40-80 |

| UV Stability | 25+ years (with additives) | 3-5 years |

| Installation Flexibility | Cold-welded seams (-40°C to 80°C) | Temperature-sensitive adhesives |

| Permeability (m³/day) | <1×10⁻¹² | 1×10⁻⁸ to 1×10⁻⁶ |

Key Features:

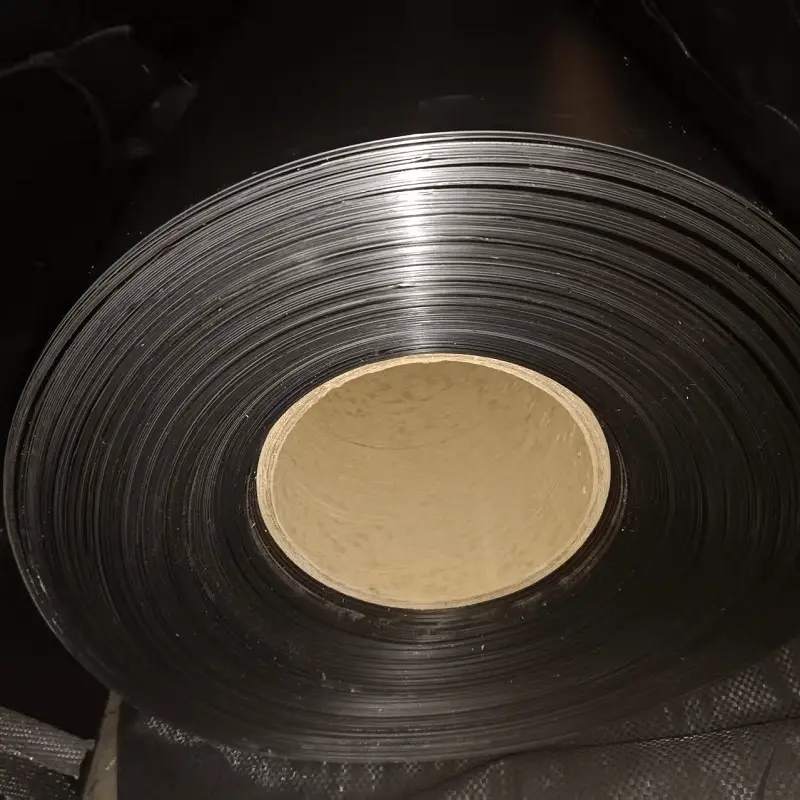

Multi-Layer Structure: Co-extruded membranes with carbon black layer provide UV protection and anti-aging properties.

Seam Strength: Double-welded seams using automated equipment achieve 85% material strength vs. 60% for hand-welded alternatives.

Customizable Thickness: 0.5mm-3mm options cater to specific applications:

0.5-1.0mm: Temporary leachate ponds

1.5-2.0mm: Tailings storage facilities (TSFs)

2.5-3.0mm: Acidic wastewater containment

Applications in Kenyan Mining Operations

1. Tailings Management

Case Study: Kwale Mineral Sands Project (2023)

98% reduction in leachate migration

Compliance with EMCA 2015 standards

20% lower operational costs vs. clay liners

Challenge: Arsenic-rich tailings threatened groundwater

Solution: 1.5mm HDPE liner with geotextile underlayment

2. Heap Leaching Pads

Gold Extraction: HDPE membranes prevent seepage of cyanide solutions

Performance Metrics:

Evaporation Reduction: 35% through controlled permeability

Solution Recovery: >90% vs. 75% in unlined pads

Service Life: 15-20 years with proper maintenance

3. Acid Mine Drainage Control

Coal Mines: 2mm HDPE liners installed in drainage channels

Chemical Resistance: Withstands Fe³⁺ concentrations up to 20,000 mg/L

Environmental Impact: Reduced water treatment costs by 40% (2019-2024)

Economic Analysis

| Cost Component | HDPE System | Clay Liner | Concrete |

|---|---|---|---|

| Initial Investment ($/m²) | 8-12 | 6-8 | 25-35 |

| Maintenance ($/year) | 0.5-1.5 | 2-4 | 3-5 |

| Lifespan (years) | 20-30 | 10-15 | 15-25 |

| Total Cost (20 years) | 160-300 | 120-240 | 500-875 |

ROI Calculation:

For a 10,000m² TSF:

HDPE saves 575,000 over 20 years

Payback period: 3-5 years (considering environmental penalties avoidance)

Environmental Benefits

Carbon Footprint Reduction:

30% lower energy consumption in production vs. PVC alternatives

Recyclable at end-of-life (90% recovery rate)

Water Conservation:

Lined ponds reduce evaporation losses by 25-40%

Enables closed-loop water systems in processing plants

Biodiversity Protection:

Prevents heavy metal leaching into waterways

Reduces soil salinity impacts on surrounding ecosystems

Regulatory Compliance

Kenya's EMCA requires:

Leak detection systems every 1,000m²

Annual permeability testing (<1×10⁻⁹ cm/s)

Emergency spill response plans

HDPE systems integrate:

Geoelectric leak detection layers

Pressure-sensitive monitoring wells

Automated valve shutoff systems

Future Trends

Nanotechnology Integration:

Self-healing membranes using graphene additives

Smart geomembranes with embedded sensors

Circular Economy Models:

Post-consumer HDPE recycling programs

Lease-return schemes for mining operators

Climate Resilience:

Development of membranes for extreme temperatures (up to 100°C)

Enhanced resistance to seismic activity in Rift Valley regions

Conclusion

HDPE geomembranes represent a transformative technology for Kenya's mining sector, balancing economic growth with environmental stewardship. By adopting these solutions, operators can achieve:

95% compliance with international environmental standards

30-40% reduction in long-term liability costs

Enhanced corporate sustainability ratings

As Kenya transitions to a green economy, investments in HDPE containment systems will be pivotal in realizing the mining industry's potential while preserving natural resources for future generations. The technology's adaptability, coupled with ongoing innovations, positions it as the cornerstone of responsible mineral extraction in East Africa.

![]() 1.5 Double-sided smooth HDPE geomembrane.pdf

1.5 Double-sided smooth HDPE geomembrane.pdf

897.webp)

942.webp)

237.webp)