HDPE Geomembrane for Water Conservancy Projects

Haoyang Environmental Co., Ltd., a leader in geosynthetic material solutions, proudly presents our High-Density Polyethylene (HDPE) Geomembrane. Specifically designed for water conservancy projects, this durable and reliable product ensures excellent waterproofing, environmental protection, and enhanced project performance. With over 15 years of experience and cutting-edge technology, Haoyang is committed to delivering world-class solutions for water management and infrastructure development.

What is HDPE Geomembrane

High-Density Polyethylene (HDPE) geomembrane is a specialized synthetic liner widely used in civil and environmental engineering applications. Manufactured from high-density polyethylene resin, geomembrane exhibits exceptional durability, flexibility, and impermeability. HDPE geomembranes serve as crucial barriers to prevent the seepage of liquids, offering reliable containment solutions in diverse settings such as landfills, reservoirs, ponds, and hydraulic engineering projects. The material's high molecular weight and molecular arrangement contribute to its robust mechanical properties, making it resistant to punctures, tears, and chemical degradation. HDPE geomembranes play a pivotal role in environmental protection, water resource management, and infrastructure stability by effectively controlling fluid movement and ensuring the integrity of containment systems.

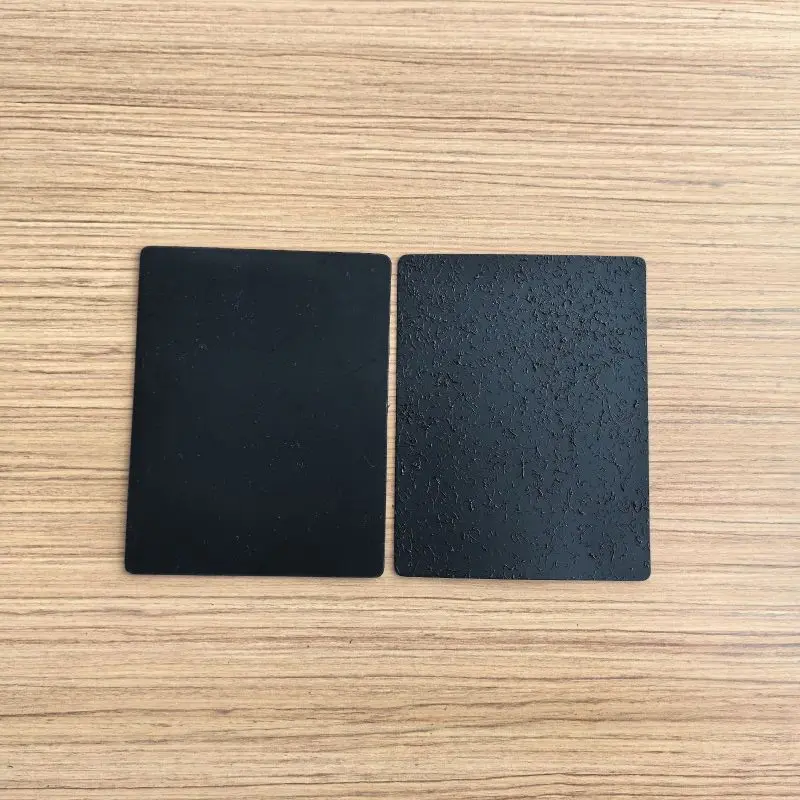

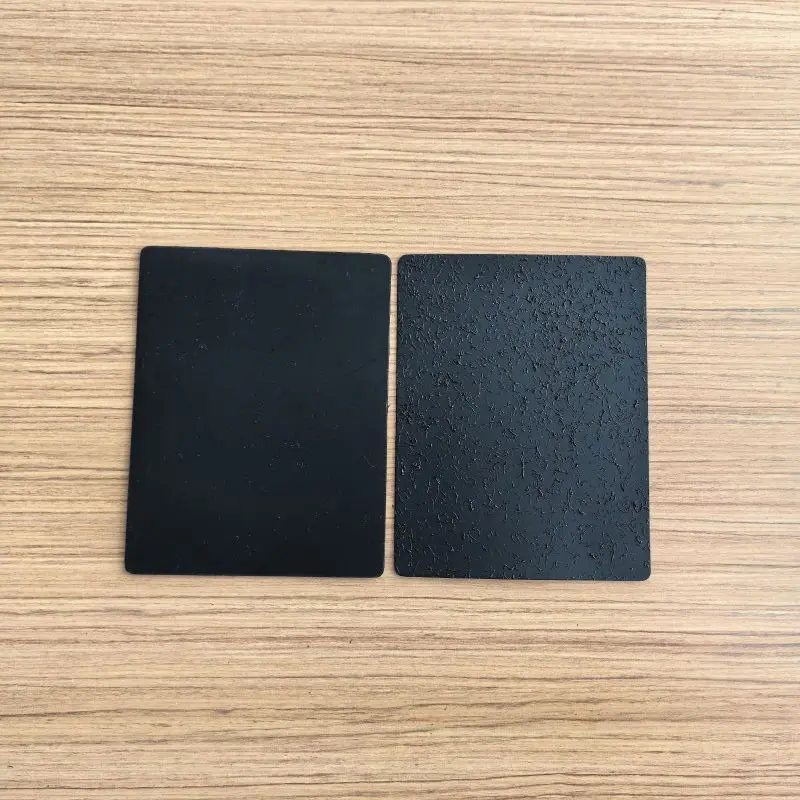

According to its surface, it can be divided into smooth geomembrane and textured geomembrane, you can choose any type according to your needs.

Product Performance

(1).Anti-Seepage Performance: HDPE geomembrane exhibits excellent anti-seepage characteristics, effectively preventing the penetration of water, liquids, or contaminants. Its high-density polyethylene composition forms a robust barrier, ensuring that groundwater and hazardous substances cannot permeate into the surrounding environment in applications such as hydraulic engineering and landfill sites.

(2).Isolation Capability: As a geotechnical membrane, HDPE demonstrates superior isolation capabilities, effectively separating substances between different mediums and preventing their mutual penetration. In soil applications, HDPE geomembrane can isolate groundwater from surface soil, preventing cross-contamination of water and dissolved substances and preserving soil quality.

(3).Chemical Resistance: Due to its high-density polyethylene construction, HDPE geomembrane exhibits excellent chemical resistance, withstanding the corrosive effects of chemicals. This makes it suitable for environments containing chemical substances, such as chemical waste landfill sites, maintaining stability without being compromised.

Specification

| Specification | Details |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Thickness | 0.5mm – 3.0mm |

| Width | Up to 8 meters |

| Length per Roll | Customized based on project requirements |

| Density | ≥ 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa |

| Elongation at Break | ≥ 700% |

| Puncture Resistance | High durability against punctures |

| Water Vapor Permeability | < 1.0×10⁻¹³ g·cm/(cm²·s·Pa) |

| Chemical Resistance | Resistant to acids, alkalis, and hydrocarbons |

| UV Resistance | Excellent resistance to UV degradation |

| Operating Temperature | -40°C to +85°C |

| Color Options | Black, White, or Customized |

| Standards Compliance | ISO 9001, ISO 14001, OHSAS 18001, CQC |

| Certifications | ISO, CQC, and Environmental Product Certified |

Applications

Suitable for anti-seepage in landfill sites, sewage or waste residue treatment, as well as for isolation purposes. It is used in riverbanks, dam construction, tailings dams, sewage dams and reservoir areas, channels, storage ponds (pits, mines), subway and tunnel projects, tunnel anti-seepage lining bricks, roadbeds, and other foundation saline soil anti-seepage measures. It is also employed in horizontal anti-seepage coverings for dikes and dams, vertical anti-seepage layers in foundations, construction cofferdams, waste disposal sites, foundations for highways and railways, waterproof layers for expansive soil and collapsible loess, and waterproofing for seawater and freshwater aquaculture facilities, as well as roof anti-seepage.

137987.webp)

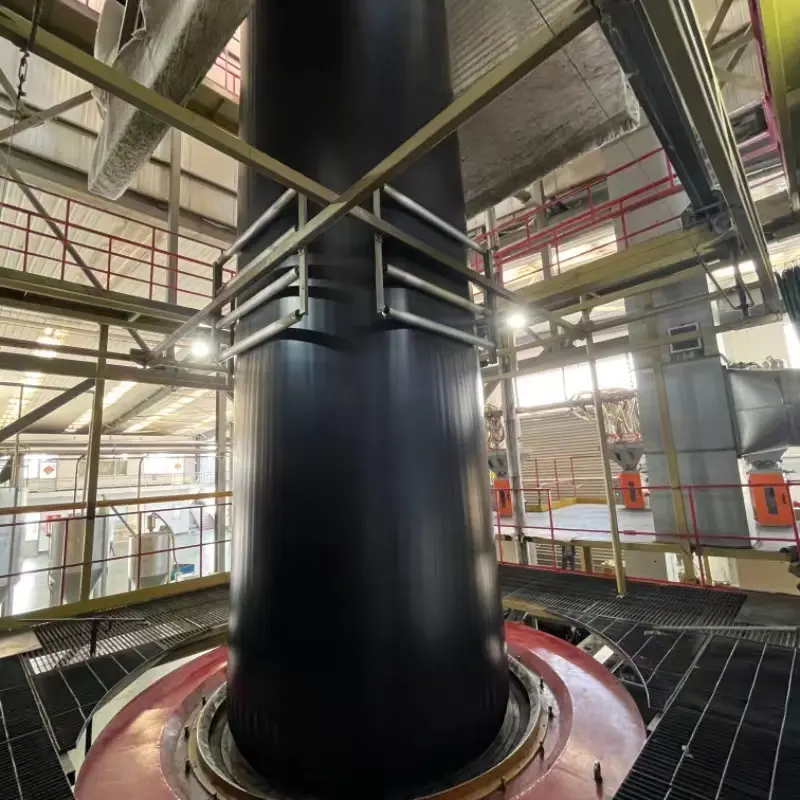

HDPE Geomembrane in Water Conservancy Projects

Application area

HDPE geotextile membrane is a polymer material known for its outstanding impermeability and durability. In water conservancy projects, geotextile membrane finds widespread applications in various scenarios.

(1), Reservoir Construction: In reservoir construction, geotextile membrane effectively serves as an impermeable barrier, preventing seepage between the reservoir bottom and surrounding rocks. This enhances the safety and stability of the reservoir.

(2), Dam Construction: During dam construction, geotextile membrane reinforces impermeability, offering resilience against flooding disasters and ensuring the safety of downstream areas.

(3), River and Channel Management: Geotextile membrane plays a crucial role in river and channel management. It regulates water flow, protects agricultural fields, urban infrastructure, and contributes to the improvement of the overall ecological environment.

(4), Protection of Hydraulic Structures: Geotextile membrane is utilized to protect the surfaces and joints of hydraulic structures, effectively waterproofing or resisting water seepage and enhancing the durability of the structures.

(5), Rehabilitation of Channels and Rivers: Geotextile membrane is employed in the rehabilitation of channels and rivers, ensuring the integrity of cavities and underground waterways, and preventing water level rise.

(6), Marine Engineering Construction: In marine engineering construction, geotextile membrane prevents seawater infiltration, safeguarding structures from potential damage.

(7), Construction of Harbor Docks and Riverbank Slope Protection: Geotextile membrane is also used in the construction of harbor docks and riverbank slope protection, preventing erosion by sediment and enhancing structural stability.

467909.webp)

Importance of hdpe geomembrane in water conservancy projects

The application of hdpe geotextile membrane in hydraulic engineering is indispensable. Its role in enhancing impermeability, supporting efficient irrigation systems, promoting environmental friendliness, and prolonging the lifespan of hydraulic structures makes it a crucial component in water resource management.

(1). Impermeability Enhancement in Reservoirs and Dams

Geotextile membrane plays a crucial role in improving impermeability in reservoirs and dams. Its superior impermeability characteristics help prevent leakage, thereby enhancing the overall performance and flood protection capabilities of these structures.

(2).Efficient Irrigation System Support

In agricultural irrigation, a stable water supply is essential for optimal crop production. Geotextile membrane can be widely employed in irrigation channels and ponds, significantly reducing water leakage losses. Its use ensures precise water distribution to farmlands, thereby improving the efficiency of the irrigation system.

(3). Environmental Friendliness and Sustainable Development

The utilization of geotextile membrane aligns with the principles of environmental friendliness and sustainable development. In comparison to traditional impermeability measures, geotextile membrane is non-toxic, odorless, and non-polluting, minimizing its impact on the surrounding environment and contributing to the sustainable utilization of water resources.

(4). Prolonging the Lifespan of Hydraulic Structures

Hydraulic structures demand durable and reliable impermeability measures. Geotextile membrane, with its weather resistance and chemical stability, withstands the natural environment's erosive forces, thereby extending the lifespan of hydraulic structures and reducing maintenance and repair costs.

567858.webp)

Company Advantages

Innovative Expertise: Haoyang has three invention patents and 32 utility model patents, demonstrating our dedication to technological advancement.

Proven Quality: Certified by international standards and backed by provincial-level scientific achievements.

Comprehensive Solutions: From design to installation, we offer end-to-end services tailored to water conservancy projects.

R&D Excellence: A professional technical team ensures cutting-edge research, development, and application of environmental engineering materials.

Global Recognition: Trusted by clients worldwide for exceptional product quality and reliable service.

Choose Haoyang HDPE Geomembrane to secure your water conservancy projects with unmatched quality and efficiency. Contact us today to discuss your project requirements!

FAQ

1.What role does HDPE geomembrane play in water conservancy projects?

HDPE geomembrane serves as a crucial impermeable barrier, preventing water seepage in structures such as reservoirs, dams, and channels, thereby enhancing the efficiency and safety of water conservancy projects.

2. In what way does HDPE geomembrane contribute to environmental protection in water conservancy projects?

HDPE geomembrane prevents the leaching of contaminants, ensuring that hazardous substances or pollutants do not infiltrate the soil or groundwater, thus safeguarding the environment.

3. Is HDPE geomembrane capable of withstanding diverse environmental conditions in water conservancy projects?

Yes, HDPE geomembrane is known for its durability and resistance to environmental factors, including UV exposure, extreme temperatures, and chemical exposure, making it suitable for varied conditions.

4. What role does HDPE geomembrane play in water resource management within water conservancy projects?

HDPE geomembrane minimizes water seepage losses, ensuring efficient water storage and distribution, thereby optimizing water resource management in irrigation systems and reservoirs.

5. What are the critical considerations for the installation of HDPE geomembrane in water conservancy projects?

Key considerations include proper surface preparation, quality of welding during installation, and adherence to engineering specifications to ensure the effective performance and longevity of the geomembrane system.

503.webp)

759.webp)

897.webp)

942.webp)

237.webp)