HDPE Geomembrane with Anti-Leakage Function

Haoyang Environmental Co., Ltd., established in 2008, is a trusted leader in geosynthetic material manufacturing and environmental engineering solutions. Our HDPE Geomembrane with anti-leakage function is a top-tier product designed to provide an impermeable barrier for diverse applications, ensuring environmental safety and structural integrity. With cutting-edge technology and adherence to global quality standards, Haoyang delivers innovative solutions that meet the needs of industries worldwide.

HDPE Geomembrane

HDPE Geomembrane, also known as HDPE Anti-seepage Membrane, is a waterproof and isolating sheet produced through the process of film spraying, rolling, or co-extrusion by using HDPE virgin resin combined with 3%-5% high-quality dual-resistant masterbatch.

HDPE geomembrane acts as a robust barrier, effectively inhibiting the passage of liquids and gases. Its anti-leakage function makes it an ideal choice for various applications, including environmental protection projects, landfill lining, and containment systems. The use of HDPE Geomembrane with anti-leakage function ensures enhanced durability and reliability, providing an essential solution for maintaining the integrity of structures and safeguarding the surrounding environment from potential contaminants.

Types of HDPE Geomembrane

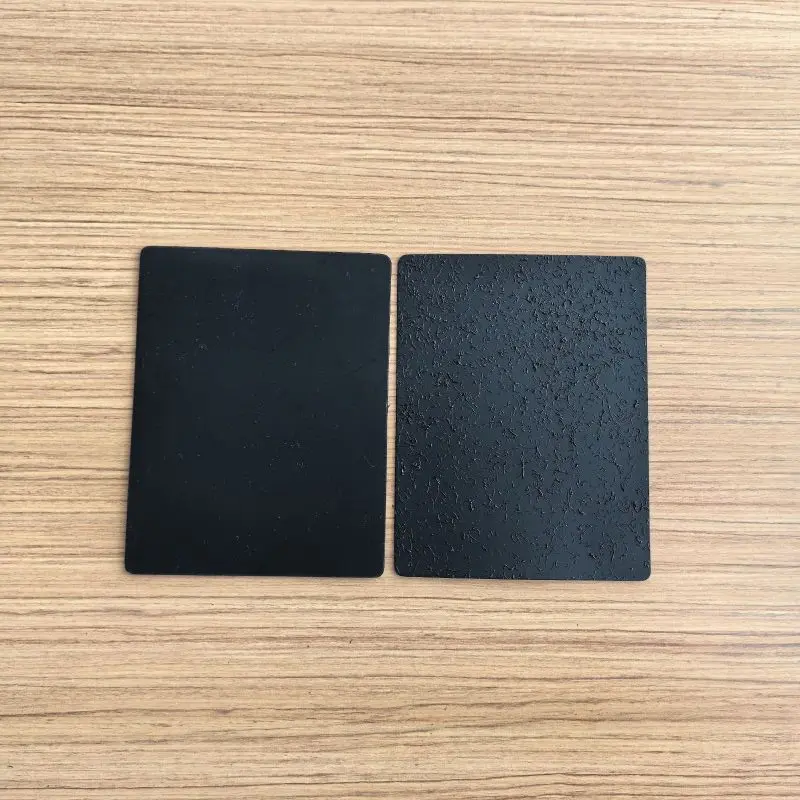

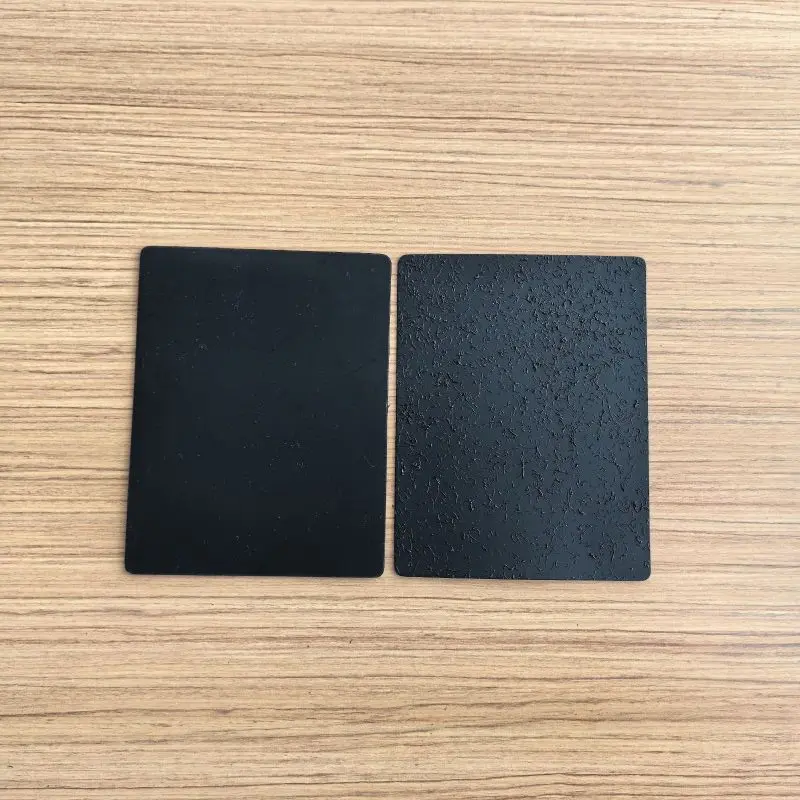

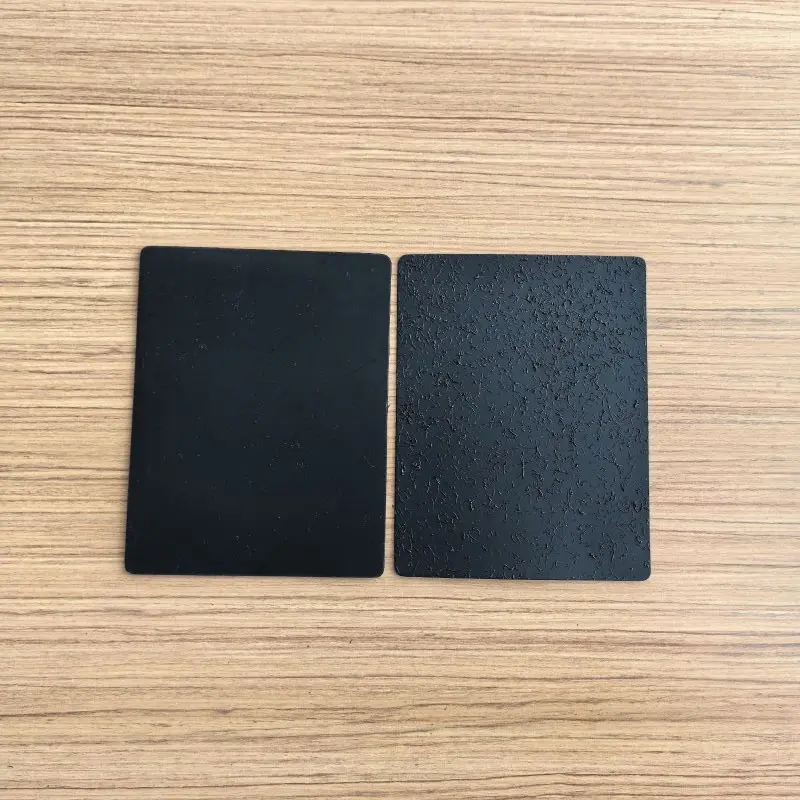

Smooth hdpe geomembrane

A smooth HDPE (High-Density Polyethylene) geomembrane is a type of geomembrane with a smooth surface texture.

Smooth HDPE geomembranes are characterized by their flat and smooth surface, which contributes to their impermeability and enhances their performance in preventing the passage of liquids.

Single-textured hdpe geomembrane

A single-rough surface geomembrane has one side with a relatively rough texture, distinguishing it from traditional smooth geomembranes. This rough surface may enhance adhesion with other materials and provide additional friction.

One of the primary functions of a single-rough surface geomembrane is to offer an anti-slip surface, improving stability when walking or placing other materials on it. This is crucial for projects that require enhanced stability. By increasing surface roughness, the geomembrane helps prevent soil erosion, protecting the surface cover from weathering and erosion effects.

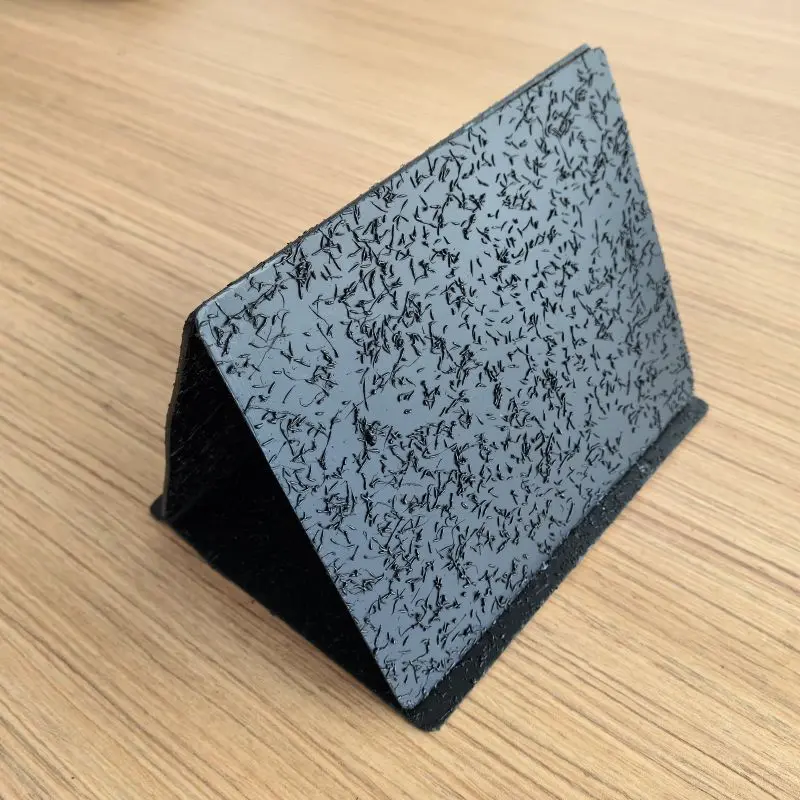

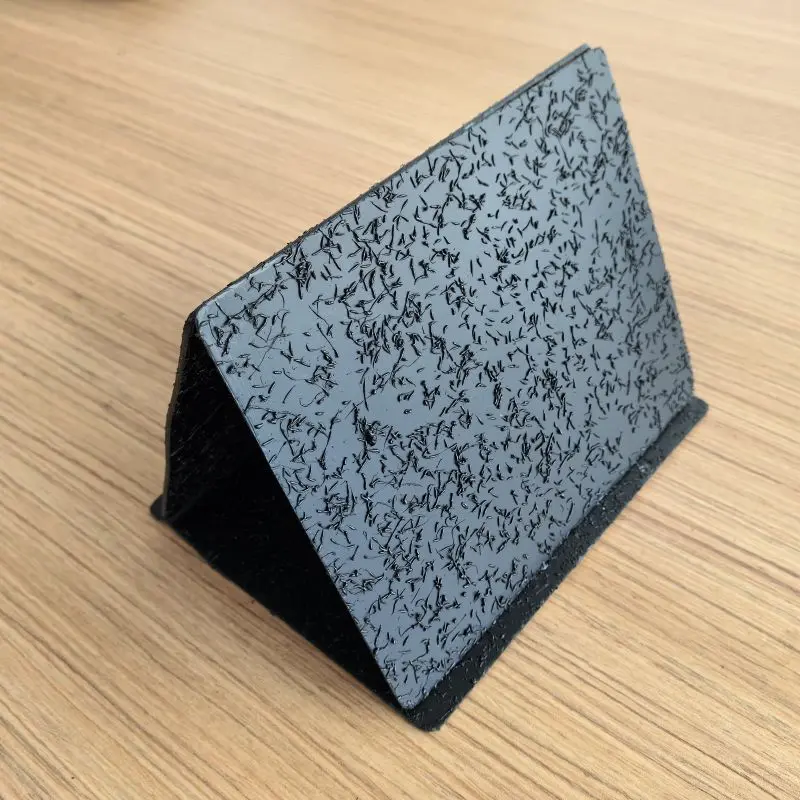

Double-textured hdpe geomembrane

Double-textured HDPE geomembrane is high-density polyethylene (HDPE) geomembrane with rough textures on both sides, providing improved adhesion and slip resistance.

The double-textured design aims to increase the adhesion between the geomembrane and other materials, thereby enhancing stability in engineering projects. It is often used in projects with slopes, which can increased stability, adhesion, and slip resistance of the project, while mitigating soil erosion issues and enhancing overall engineering durability.

Specifications

| Specification | Details |

|---|---|

| Product Name | HDPE Geomembrane with Anti-Leakage Function |

| Material | High-Density Polyethylene (HDPE) |

| Thickness Options | 0.75mm, 1.0mm, 1.25mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm |

| Width | Up to 8 meters |

| Roll Length | Varies based on thickness and project requirements |

| Tensile Strength | Varying according to thickness and ASTM standards |

| Elongation at Break | ≥700% (depending on thickness and grade) |

| Tear Resistance | Varies according to specifications and ASTM standards |

| UV Resistance | Excellent (Carbon Black content: ≥2%) |

| Chemical Resistance | High resistance to acids, alkalis, and hydrocarbons |

| Water Vapor Permeability | ≤1.0 × 10⁻¹³ g•cm/(cm²•s•Pa) |

| Operating Temperature | -40°C to +85°C |

| MOQ | 2000㎡ |

| Certifications | ISO 9001, ISO 14001, OHSAS 18001, CQC |

Advantages of HDPE Geomembrane

The first and most important funtion is its impermeability, providing an impermeable effect that ordinary impermeable materials cannot match.

The second is its high tensile strength and elongation at break, with a tensile strength of up to 27 megapascals and an elongation at break of ≥700%.

The third is its high chemical stability and aging resistance. It can withstand corrosion from strong acids and alkalis, and it is resistant to aging, UV radiation, decomposition, and freezing, making it suitable for outdoor use.

The fourth is its low cost and fast construction speed. The standard size of an HDPE geomembrane is 6 meters wide and 50 meters long, with a single roll covering an area of 300 square meters. A skilled welder can weld 3000 square meters in a day, a capability unmatched by traditional cement impermeability and other waterproof membranes.

Application

1, Environmental Protection and Sanitation:

Landfills for household waste, sewage treatment plants, power plant regulation ponds, disposal of industrial, medical, and hazardous solid waste, etc.

2, Mining:

Leachate ponds, heap leaching ponds, ash disposal sites, dissolution ponds, settling ponds, evaporation ponds, storage yards, and seepage prevention for tailings ponds.

3, Petroleum and Petrochemical:

Chemical plants, oil refineries, gas stations, impermeable linings for oil storage tanks, internal linings for chemical reaction tanks, and settling ponds.

4, Water Conservancy Projects:

Impermeable linings for rivers, lakes, reservoir embankments, leak plugging and reinforcement, seepage prevention for water channels, slope protection, etc.

5, Agriculture:

Impermeable linings for reservoirs, drinking water ponds, water storage ponds, and irrigation systems.

6, Aquaculture:

Linings for intensive and industrialized breeding ponds, fish ponds, and shrimp ponds.

7, Municipal Engineering:

Impermeable linings for subways, underground constructions, green roofs, rooftop gardens, sewage pipe leak prevention, etc.

8, Landscaping:

Artificial lakes, waterways, reservoirs, and golf courses.

9, Transportation Facilities:

High-speed railways and other transportation infrastructure.

Company Advantages

Expertise and Innovation: Backed by over 15 years of experience and a professional R&D team recognized for patented technologies and provincial-level certifications.

Comprehensive Certifications: ISO 9001, ISO 14001, OHSAS 18001, and CQC environmental product certification ensure product quality and safety.

Recognized Excellence: Accredited as a "Shandong Enterprise Technology Center" and "Environmental Protection New Materials Engineering Laboratory."

Global Reach: Trusted by clients in various industries across the globe for reliable and sustainable solutions.

Contact Us

Let Haoyang Environmental Co., Ltd. provide you with the ideal solution for your containment and environmental protection needs. Choose Haoyang's HDPE Geomembrane for uncompromising quality, durability, and environmental responsibility. Connect with us today to discuss your project requirements!

FAQ

1. How does the anti-leakage function of HDPE geomembrane work?

The anti-leakage function of HDPE geomembrane is achieved through its high-density polyethylene (HDPE) material characteristics, providing excellent impermeability and chemical stability. With the use of specialized production processes and the addition of anti-leakage agents, it forms an effective waterproof barrier, preventing the penetration of liquids and gases.

2. In which engineering fields is HDPE geomembrane applicable?

HDPE geomembrane is widely used in environmental protection, mining, petroleum, water conservancy, agriculture, municipal, and other engineering fields. Applications include landfill sites, slag dams, chemical ponds, reservoirs, water channels, and agricultural anti-seepage projects.

3. What are the tensile strength and elongation at break of HDPE geomembrane?

The tensile strength of HDPE geomembrane can reach 27 megapascals, with an elongation at break greater than 700%, demonstrating excellent tensile performance suitable for various engineering applications.

4. What are its specific applications in environmental engineering?

HDPE geomembrane is commonly used in environmental engineering for applications such as landfill sites, sewage treatment plants, and hazardous waste disposal. It plays a role in anti-leakage and chemical corrosion resistance, contributing to the overall health of the environment.

5. What advantages does HDPE geomembrane have compared to traditional waterproofing materials?

Compared to traditional materials, HDPE geomembrane has superior anti-leakage performance, faster construction speed, chemical corrosion resistance, aging resistance, and strong adaptability. These advantages make it more competitive in engineering applications.、

Related articles recommended for you:

https://hygeosynthetics.com/How-to-Implement-an-Effective-Liner-System-in-Landfill-Echo_87.html

503.webp)

759.webp)

942.webp)

237.webp)

106.webp)