High-Density Polyethylene (HDPE) geomembranes are synthetic membranes made from high-density polyethylene resin. HDPE geomembranes are indispensable in modern engineering and environmental protection due to their superior properties, versatility, and reliability. Their role in safeguarding our environment and resources makes them a crucial component in the pursuit of sustainable development. Whether for landfills, water containment, mining operations, agriculture, or environmental protection, HDPE geomembranes offer versatile and reliable solutions for a wide range of applications.

Types of HDPE Geomembranes

High-Density Polyethylene (HDPE) geomembranes are available in different types, primarily categorized as smooth geomembrane, textured geomembrane, and geomembrane liners. Each type has unique properties, advantages, and drawbacks, making them suitable for specific applications. This article explores these three main types of HDPE geomembranes, detailing their pros and cons and common use cases.

1. Smooth HDPE Geomembrane

Description

Smooth HDPE geomembranes are characterized by their flat, smooth surface. They are the most common type of HDPE geomembrane used in various containment and lining applications.

Pros

High Chemical Resistance: Smooth HDPE geomembranes offer excellent resistance to a wide range of chemicals, making them suitable for hazardous waste containment.

Low Permeability: Their low permeability ensures an effective barrier against liquids and gases.

Ease of Installation: The smooth surface makes them easier to handle and install, reducing installation time and labor costs.

Cost-Effective: Generally, smooth geomembranes are more cost-effective compared to textured versions.

Cons

Slippery Surface: The smooth surface can be slippery, posing safety risks during installation and making it less suitable for applications requiring high friction.

Limited Stability on Slopes: Due to the lack of texture, smooth geomembranes may not provide adequate stability on steep slopes.

Applications

Landfills: Used as liners to prevent leachate migration.

Water Containment: Suitable for reservoirs, ponds, and canals.

Industrial Waste Containment: Used in industrial settings to contain hazardous chemicals and waste.

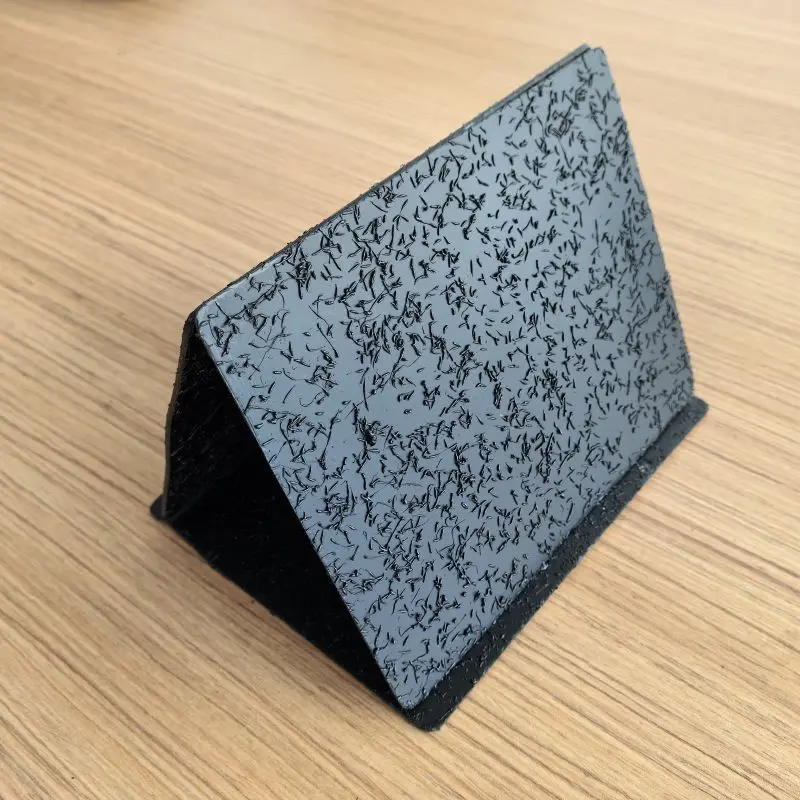

2. Textured HDPE Geomembrane

Description

Textured HDPE geomembranes have a rough, textured surface that provides additional friction and stability, making them ideal for applications where slip resistance is critical.

Pros

Increased Friction: The textured surface provides better friction, making it suitable for steep slopes and vertical applications.

Improved Stability: Textured geomembranes offer greater stability when used in applications requiring anchorage and reinforcement.

Versatility: Can be used in a wider range of applications due to its enhanced surface properties.

Cons

Higher Cost: Textured geomembranes are generally more expensive than smooth geomembranes.

Challenging Installation: The rough surface can make installation more challenging and labor-intensive.

Potential for Damage: The textured surface may be more susceptible to damage during handling and installation.

Applications

Slope Lining: Ideal for lining steep slopes and embankments in landfill and mining applications.

Retaining Structures: Used in retaining walls and other structures where additional stability is required.

Wastewater Treatment: Suitable for applications in wastewater treatment plants where slip resistance is beneficial.

3. Geomembrane Liners

Description

Geomembrane liners are a type of HDPE geomembrane designed specifically for lining applications, including large containment areas and environmental protection projects.

Pros

Durability: Geomembrane liners are highly durable, providing long-term performance in demanding environments.

Chemical and UV Resistance: They offer excellent resistance to chemicals and UV radiation, ensuring longevity in exposed applications.

Customizable: Available in various thicknesses and configurations to meet specific project requirements.

Cons

Installation Complexity: Installing geomembrane liners can be complex and may require specialized equipment and expertise.

Initial Cost: The initial cost of geomembrane liners can be high, although they offer long-term cost savings through reduced maintenance and extended lifespan.

Applications

Landfills: Widely used as base liners and cover systems to contain waste and prevent contamination.

Mining Operations: Used for lining tailings ponds and heap leach pads to prevent environmental contamination.

Water and Wastewater Containment: Ideal for lining reservoirs, ponds, and treatment facilities to prevent seepage and contamination.

Conclusion

Each type of HDPE geomembrane—smooth, textured, and geomembrane liners—offers distinct advantages and disadvantages, making them suitable for specific applications. Smooth geomembranes are cost-effective and easy to install, while textured geomembranes provide enhanced stability on slopes. Geomembrane liners are versatile and durable, making them ideal for large-scale containment and environmental protection projects. Understanding the properties and applications of each type helps in selecting the most appropriate HDPE geomembrane for a given project, ensuring effective containment and environmental safety.

HDPE Geomembranes Specifications

| Specification | Description |

|---|---|

| Thickness | Typically ranges from 0.5 mm to 3.0 mm |

| Density | ≥ 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa (ASTM D638) |

| Elongation at Break | ≥ 700% (ASTM D638) |

| Tear Resistance | ≥ 125 N (ASTM D1004) |

| Puncture Resistance | ≥ 240 N (ASTM D4833) |

| Carbon Black Content | 2 - 3% (ASTM D1603) |

| Hydrostatic Resistance | ≥ 80 MPa (ASTM D751) |

| Water Vapor Permeability | ≤ 1.0 x 10^-13 g·cm/(cm²·s·Pa) (ASTM E96) |

| Dimensional Stability | ± 2% (ASTM D1204) |

| UV Resistance | ≥ 90% retention after 1600 hours (ASTM D4355) |

| Chemical Resistance | Resistant to a wide range of chemicals including acids, alkalis, and salts |

| Environmental Stress Crack Resistance | ≥ 500 hours (ASTM D5397) |

| Seam Strength | ≥ 90% of parent material tensile strength (ASTM D6392) |

| Service Temperature Range | -40°C to +70°C |

These specifications ensure that HDPE geomembranes are suitable for a wide range of applications, offering excellent durability, chemical resistance, and overall performance.

Properties of HDPE Geomembranes

HDPE geomembranes are manufactured from high-density polyethylene resin, which gives them a unique set of properties. These properties include:

Durability: HDPE geomembranes are highly resistant to punctures, tears, and abrasions, making them suitable for harsh environments.

Chemical Resistance: They exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and hydrocarbons, ensuring longevity and reliability in various applications.

Flexibility: Despite their strength, HDPE geomembranes are flexible enough to conform to the contours of the underlying surface, providing a secure and efficient barrier.

UV Resistance: HDPE geomembranes are resistant to UV radiation, which prevents degradation when exposed to sunlight, thereby extending their lifespan.

Low Permeability: The low permeability of HDPE geomembranes ensures that liquids and gases do not pass through, making them ideal for containment applications.

Applications of HDPE Geomembranes

The versatility of HDPE geomembranes allows them to be used in a wide range of applications, including:

1. Landfills

HDPE geomembranes are commonly used as liners for landfills to prevent leachate, a liquid formed by the decomposition of waste, from contaminating the surrounding soil and groundwater. By providing a robust barrier, these membranes help in maintaining environmental integrity.

2. Water Containment

In water containment projects such as reservoirs, ponds, and canals, HDPE geomembranes serve as liners to prevent water loss through seepage. Their flexibility and impermeability ensure efficient water management and conservation.

3. Mining Operations

Mining operations generate significant amounts of waste, including toxic chemicals. HDPE geomembranes are used to line tailings ponds and heap leach pads, providing a secure barrier that prevents the contamination of soil and water resources.

4. Agriculture

In agriculture, HDPE geomembranes are used to line irrigation ponds, channels, and tanks, ensuring efficient water usage and preventing loss. They are also used in biogas plants for lining digesters and storage facilities.

5. Environmental Protection

HDPE geomembranes play a crucial role in environmental protection projects such as wastewater treatment plants and industrial containment facilities. They prevent harmful substances from leaking into the environment, safeguarding ecosystems and human health.

Benefits of HDPE Geomembranes

1. Longevity

Due to their resistance to chemicals, UV radiation, and physical damage, HDPE geomembranes have a long service life. This durability translates into lower maintenance costs and long-term reliability.

2. Cost-Effectiveness

While the initial cost of HDPE geomembranes may be higher compared to some alternatives, their longevity and low maintenance requirements make them a cost-effective solution over time.

3. Ease of Installation

HDPE geomembranes are relatively easy to install. Their flexibility allows them to be laid over complex surfaces, and they can be welded together to form a continuous barrier. This ease of installation reduces project timelines and labor costs.

4. Environmental Safety

By providing effective containment, HDPE geomembranes help in preventing pollution and protecting natural resources. Their use in waste management and environmental protection projects underscores their importance in sustainable development.

How to Choose HDPE Geomembranes: Examples for Different Applications

Introduction

Selecting the right HDPE geomembrane for a specific application is crucial for ensuring the success and longevity of a project. Factors such as chemical resistance, durability, flexibility, and surface texture should be considered to match the geomembrane with the project requirements. This guide provides an overview of how to choose HDPE geomembranes and offers examples for different use cases.

Factors to Consider

1. Chemical Resistance

For projects involving hazardous materials, chemical resistance is a key factor. HDPE geomembranes are known for their high resistance to chemicals, making them suitable for containment applications.

2. Durability

Durability is essential for long-term applications. HDPE geomembranes are highly durable and resistant to punctures and abrasions, making them ideal for harsh environments.

3. Flexibility

The flexibility of a geomembrane allows it to conform to the underlying surface. This is important for applications with irregular or uneven surfaces.

4. Surface Texture

The surface texture affects the geomembrane's stability and slip resistance. Smooth geomembranes are easy to install, while textured geomembranes provide better stability on slopes.

5. Permeability

Low permeability is crucial for applications requiring effective containment of liquids and gases.

Application Examples

1. Landfills

Recommended Geomembrane: Smooth HDPE Geomembrane

Reason: Smooth HDPE geomembranes are cost-effective and provide excellent chemical resistance and low permeability, making them suitable for landfill liners to prevent leachate migration.

Example: In a municipal landfill project, a smooth HDPE geomembrane can be used as a base liner to contain leachate and protect groundwater from contamination.

2. Water Containment

Recommended Geomembrane: Smooth HDPE Geomembrane

Reason: For water containment applications such as reservoirs and ponds, smooth HDPE geomembranes offer ease of installation, flexibility, and low permeability.

Example: In a reservoir lining project, a smooth HDPE geomembrane can be used to prevent water loss through seepage, ensuring efficient water management.

3. Mining Operations

Recommended Geomembrane: Textured HDPE Geomembrane

Reason: Textured HDPE geomembranes provide increased friction and stability, making them ideal for lining tailings ponds and heap leach pads in mining operations.

Example: In a heap leach mining operation, a textured HDPE geomembrane can be used to line the leach pad, providing stability and preventing toxic chemicals from contaminating the environment.

4. Agriculture

Recommended Geomembrane: Smooth or Textured HDPE Geomembrane

Reason: Depending on the specific agricultural application, both smooth and textured HDPE geomembranes can be used. Smooth geomembranes are suitable for lining irrigation ponds and channels, while textured geomembranes provide additional stability for applications requiring anchorage.

Example: For an irrigation pond, a smooth HDPE geomembrane can be used to prevent water seepage. For a biogas plant digester, a textured HDPE geomembrane may be preferred for its enhanced stability.

5. Environmental Protection

Recommended Geomembrane: Geomembrane Liners

Reason: Geomembrane liners are highly durable and customizable, making them suitable for large-scale environmental protection projects such as wastewater treatment plants and industrial containment facilities.

Example: In a wastewater treatment plant, geomembrane liners can be used to line treatment lagoons, providing a secure barrier to prevent contamination of surrounding soil and water.

Choosing the right HDPE geomembrane involves considering factors such as chemical resistance, durability, flexibility, surface texture, and permeability. By matching these properties with the specific requirements of a project, the most suitable geomembrane can be selected to ensure effective containment and long-term performance. Whether for landfills, water containment, mining operations, agriculture, or environmental protection, HDPE geomembranes offer versatile and reliable solutions for a wide range of applications.

What are the manufacturing standards for HDPE Geomembranes?

HDPE geomembranes are manufactured and tested according to various international standards to ensure their quality and performance. Here are some of the key standards used in the industry:

Manufacturing Standards for HDPE Geomembranes

American Society for Testing and Materials (ASTM) Standards

ASTM D1505: Standard Test Method for Density of Plastics by the Density-Gradient Technique.

Determines the density of the HDPE resin used in geomembranes.

ASTM D5199: Standard Test Method for Measuring the Nominal Thickness of Geomembranes.

Specifies the method for measuring the thickness of geomembranes.

ASTM D638: Standard Test Method for Tensile Properties of Plastics.

Measures tensile strength and elongation of geomembranes.

ASTM D1004: Standard Test Method for Initial Tear Resistance of Plastic Film and Sheeting.

Evaluates the tear resistance of geomembranes.

ASTM D4833: Standard Test Method for Index Puncture Resistance of Geomembranes and Related Products.

Assesses the puncture resistance of geomembranes.

ASTM D1603: Standard Test Method for Carbon Black in Olefin Plastics.

Determines the carbon black content in HDPE geomembranes.

ASTM D1204: Standard Test Method for Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated Temperature.

Measures the dimensional stability of geomembranes.

ASTM D4355: Standard Test Method for Deterioration of Geotextiles by Exposure to Light, Moisture, and Heat in a Xenon-Arc Type Apparatus.

Tests the UV resistance of geomembranes.

ASTM D5397: Standard Test Method for Evaluation of Stress Crack Resistance of Polyolefin Geomembranes Using Notched Constant Tensile Load Test.

Evaluates the environmental stress crack resistance of geomembranes.

ASTM D6392: Standard Test Method for Determining the Integrity of Nonreinforced Geomembrane Seams Produced Using Thermo-Fusion Methods.

Assesses the seam strength of geomembranes.

International Organization for Standardization (ISO) Standards

ISO 1183: Plastics — Methods for determining the density of non-cellular plastics.

Similar to ASTM D1505 for density measurement.

ISO 527: Plastics — Determination of tensile properties.

Similar to ASTM D638 for tensile properties.

ISO 1133: Plastics — Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastics.

Determines the melt flow index of HDPE resin.

ISO 13938: Textiles — Hydrostatic pressure test for measuring the resistance of textiles to water penetration.

Used for testing hydrostatic resistance.

Geosynthetic Research Institute (GRI) Standards

GRI-GM13: Test Properties, Testing Frequency, and Recommended Warranties for High Density Polyethylene (HDPE) Smooth and Textured Geomembranes.

Provides comprehensive specifications for HDPE geomembranes, including properties, testing frequencies, and warranties.

GRI-GM17: Test Properties, Testing Frequency, and Recommended Warranties for Linear Low Density Polyethylene (LLDPE) Smooth and Textured Geomembranes.

Similar to GRI-GM13 but for LLDPE geomembranes.

Other Relevant Standards

DIN Standards (Germany): Such as DIN 16726, which specifies test methods for plastic films and sheets, including geomembranes.

BSI Standards (British Standards Institution): Such as BS EN 13361, which specifies requirements for geosynthetic barriers in liquid waste containment applications.

These standards ensure that HDPE geomembranes meet stringent quality and performance criteria, making them suitable for a wide range of applications in environmental protection, water containment, and waste management.

HDPE geomembranes are indispensable in modern engineering and environmental protection due to their superior properties, versatility, and reliability. As the demand for effective containment and environmental safety measures continues to grow, the use of HDPE geomembranes is expected to increase. Their role in safeguarding our environment and resources makes them a crucial component in the pursuit of sustainable development.

About Haoyang Environmental: Leading Manufacturer of HDPE Geomembranes

Haoyang Environmental is a premier manufacturer specializing in high-density polyethylene (HDPE) geomembranes. With a commitment to quality and innovation, Haoyang Environmental provides robust solutions for various environmental and civil engineering applications.

Our HDPE geomembranes are renowned for their superior chemical resistance, durability, and low permeability, making them ideal for a wide range of uses, including landfill liners, water containment systems, mining operations, and agricultural applications. By adhering to stringent international standards such as ASTM and ISO, we ensure that our products meet the highest quality benchmarks.

At Haoyang Environmental, we understand the critical role of geomembranes in protecting natural resources and infrastructure. Our state-of-the-art manufacturing facilities are equipped with advanced technology, enabling us to produce geomembranes that offer exceptional performance and reliability. We also provide customizable options to meet specific project requirements, ensuring optimal functionality and efficiency.

Our team of experts is dedicated to delivering unparalleled customer service and technical support, guiding clients through product selection, installation, and maintenance processes. With a focus on sustainability and environmental stewardship, Haoyang Environmental is committed to creating products that contribute to safer, more sustainable development.

Choose Haoyang Environmental for your HDPE geomembrane needs and experience the difference in quality and service from a trusted industry leader.

Download Center

![]() ASTM_D1603_HDPE_Geomembranes.pdf

ASTM_D1603_HDPE_Geomembranes.pdf

![]() ASTM_D4833_HDPE_Geomembranes.pdf

ASTM_D4833_HDPE_Geomembranes.pdf

![]() ASTM_D1004_HDPE_Geomembranes.pdf

ASTM_D1004_HDPE_Geomembranes.pdf

![]() ASTM_D638_HDPE_Geomembranes.pdf

ASTM_D638_HDPE_Geomembranes.pdf

![]() ASTM_D5199_HDPE_Geomembranes.pdf

ASTM_D5199_HDPE_Geomembranes.pdf

![]() ASTM_D1505_HDPE_Geomembranes.pdf

ASTM_D1505_HDPE_Geomembranes.pdf

![]() ASTM_D1204_HDPE_Geomembranes.pdf

ASTM_D1204_HDPE_Geomembranes.pdf

![]() DIN_16726_HDPE_Geomembranes.pdf

DIN_16726_HDPE_Geomembranes.pdf

![]() GRI-GM13_HDPE_Geomembranes.pdf

GRI-GM13_HDPE_Geomembranes.pdf

![]() ISO_1183_HDPE_Geomembranes.pdf

ISO_1183_HDPE_Geomembranes.pdf

867.webp)

897.webp)

942.webp)

237.webp)