HDPE Pipe for Potable Water Supply: Ensuring Safety, Sustainability, and Efficiency

In the modern era, access to clean, potable water is a fundamental necessity for public health and economic development. As urbanization accelerates and populations grow, the demand for reliable and efficient water supply systems has never been higher. High-Density Polyethylene (HDPE) pipes have emerged as a critical solution in meeting this demand, offering a range of benefits that make them ideal for potable water supply systems. This article delves into the characteristics, advantages, and applications of HDPE pipes in potable water supply, supported by specific landing data, and concludes with a spotlight on Haoyang Environmental Co., Ltd.’s contributions to this vital industry.

Understanding HDPE Pipes

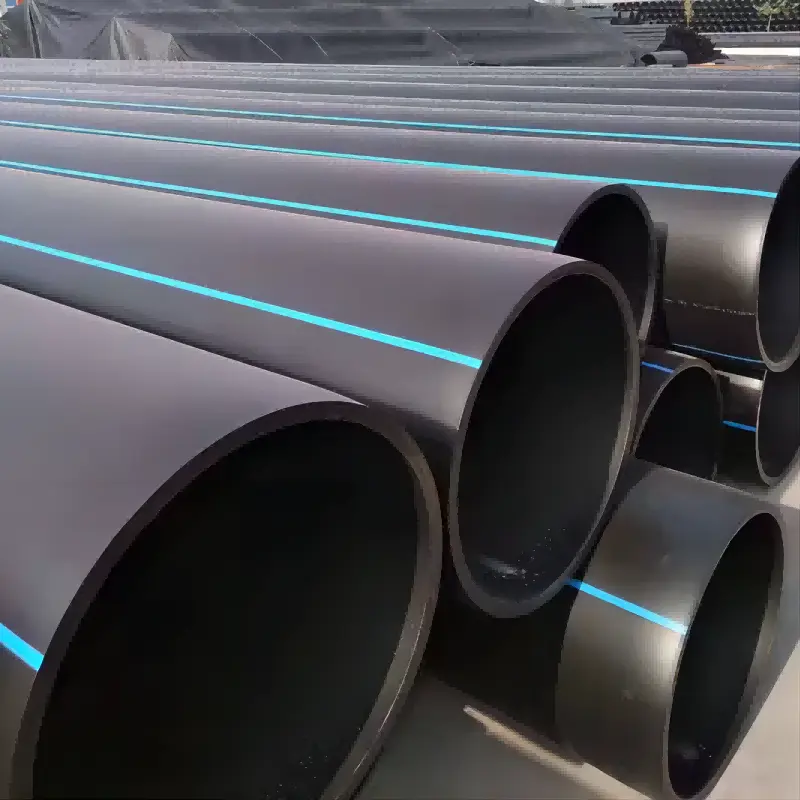

HDPE pipes are made from high-density polyethylene, a thermoplastic polymer known for its strength-to-density ratio. This material is widely used in various industries, including water supply, owing to its excellent properties such as flexibility, chemical resistance, and durability. HDPE pipes are designed to transport potable water, making them a key component in infrastructure projects worldwide.

Advantages of HDPE Pipes in Potable Water Supply

High-Density Polyethylene (HDPE) pipes have rapidly become the preferred choice for potable water supply systems across the globe. Compared to traditional materials such as steel, copper, or concrete, HDPE pipes offer several distinct advantages that contribute to their widespread adoption in both new installations and infrastructure upgrades.

1. Longevity and Durability:HDPE pipes are renowned for their exceptional longevity, often surpassing 50 years of service under normal operating conditions. This durability is a significant improvement over traditional materials like steel or iron, which are prone to corrosion and rust over time. For example, steel pipes typically have a lifespan of 20 to 30 years, depending on environmental factors and maintenance practices. In contrast, HDPE’s resistance to various environmental and chemical stressors ensures minimal degradation over time, resulting in fewer replacements and repairs, and lower life-cycle costs.

2. Corrosion Resistance:Unlike metal pipes, HDPE is immune to corrosion, both internally and externally. This feature is particularly crucial in potable water applications where the quality of water must be maintained. Traditional metal pipes, when corroded, can introduce contaminants into the water supply, posing health risks to consumers. HDPE’s non-reactive nature ensures that the water remains clean and safe throughout its journey from the source to the tap.

3. Flexibility and Impact Resistance:HDPE pipes are highly flexible, which allows them to absorb and dissipate stress from external forces, such as ground movements and pressure variations. This flexibility is especially beneficial in regions prone to seismic activity or ground subsidence. For instance, during the 1995 Kobe earthquake in Japan, many traditional pipelines were severely damaged, while HDPE pipelines remained largely intact due to their ability to flex and move with the ground. This characteristic not only minimizes the risk of pipe failure but also reduces the cost and complexity of installation, as HDPE pipes can be installed in continuous lengths with fewer joints.

4. Leak-Free Joints:HDPE pipes are typically joined using heat fusion, which creates a seamless, monolithic system. The strength of these fused joints matches or exceeds that of the pipe itself, virtually eliminating the risk of leaks. In contrast, traditional materials often rely on mechanical joints, which can be prone to leakage over time due to wear, corrosion, or improper installation. A study conducted by the Water Research Foundation found that the annual water loss in U.S. municipal systems due to leaks from traditional piping systems is approximately 14-18%, representing billions of gallons of wasted water. HDPE’s leak-free joints help mitigate such losses, ensuring more efficient water use and conservation.

5. Cost-Effectiveness:While the initial material cost of HDPE pipes may be slightly higher than some traditional materials, the overall cost-effectiveness of HDPE is evident in its lower installation, maintenance, and replacement costs. The lightweight nature of HDPE reduces transportation and handling costs, and its flexibility allows for trenchless installation methods such as horizontal directional drilling, which minimizes the need for extensive excavation. Additionally, the long lifespan and low maintenance requirements translate into significant savings over the lifetime of the pipe system.

Case Study:In New York City, the Department of Environmental Protection (DEP) undertook a major project to replace aging water mains with HDPE pipes in certain areas. The decision was driven by the frequent failures and maintenance challenges associated with the old cast iron pipes. After the installation of HDPE pipes, the city experienced a notable reduction in water main breaks and maintenance calls, leading to improved water service reliability and lower operational costs.

In summary, HDPE pipes offer a host of benefits over traditional materials in potable water supply applications. Their durability, corrosion resistance, flexibility, leak-free joints, and cost-effectiveness make them an ideal choice for modern water infrastructure projects.

Landing Data: The Growing Adoption of HDPE Pipes

The adoption of HDPE pipes in potable water supply systems is on the rise globally. According to recent market research, the global HDPE pipes market size was valued at approximately USD 16.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is driven by the increasing demand for durable and sustainable water infrastructure, particularly in developing regions where urbanization and industrialization are rapidly expanding.

In regions like North America and Europe, where infrastructure renewal is a priority, HDPE pipes are increasingly being used to replace aging water systems. For instance, in the United States, various states have initiated projects to replace old lead and iron pipes with HDPE pipes to ensure safe drinking water for their populations. Similarly, in Europe, the European Union’s directives on water quality and infrastructure modernization have spurred the adoption of HDPE pipes across member states.

In developing regions, particularly in Asia-Pacific and Africa, the focus on expanding access to clean water is driving the demand for HDPE pipes. Governments and international organizations are investing heavily in water infrastructure projects that prioritize the use of HDPE pipes for their cost-effectiveness, durability, and ease of installation.

Applications of HDPE Pipes in Potable Water Supply

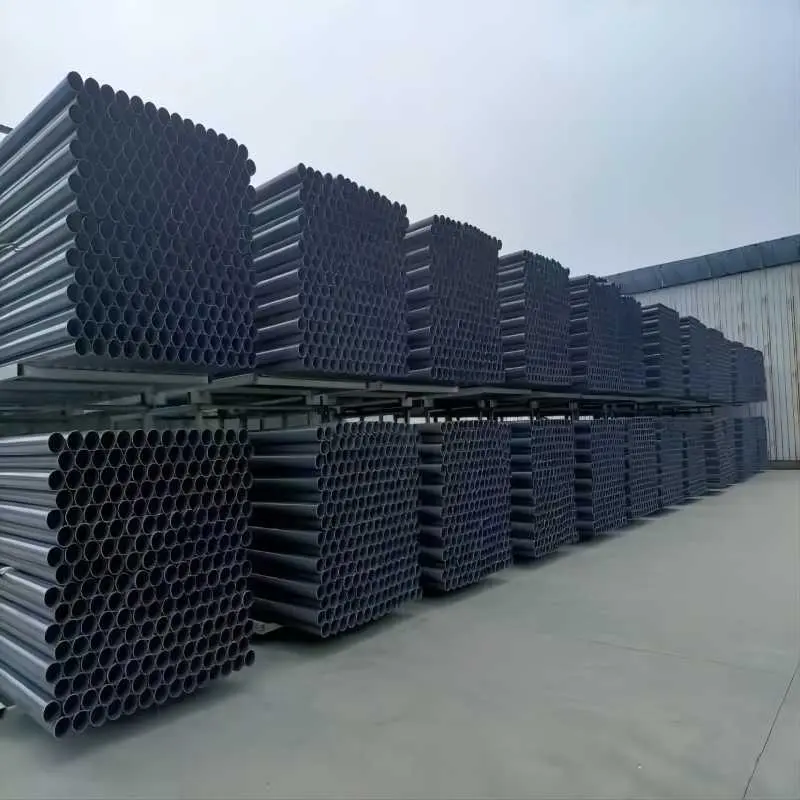

HDPE pipes are versatile and can be used in a variety of potable water supply applications, including:

Municipal Water Distribution

HDPE pipes are extensively used in municipal water distribution systems, where they transport water from treatment plants to residential, commercial, and industrial areas. Their ability to handle high pressure and resist corrosion makes them ideal for these large-scale applications.Rural and Remote Water Supply

In rural and remote areas, where access to water infrastructure is limited, HDPE pipes offer a reliable solution. Their lightweight nature and flexibility make them easy to transport and install in challenging terrains, ensuring that even the most isolated communities have access to clean water.Irrigation Systems

HDPE pipes are also used in agricultural irrigation systems, where they provide a durable and efficient means of delivering water to crops. Their resistance to UV radiation and chemicals commonly found in fertilizers ensures that they perform well in agricultural settings.Industrial Water Supply

Industries that require large volumes of water for their operations, such as food processing, beverage manufacturing, and chemical production, rely on HDPE pipes for their water supply needs. The pipes' ability to withstand aggressive substances and high temperatures makes them suitable for these demanding environments.

Case Study: HDPE Pipes in Action

A notable example of the successful application of HDPE pipes is the water supply project in the city of Windhoek, Namibia. Faced with the challenge of ensuring a reliable water supply in a semi-arid region, the city authorities opted to replace their aging water infrastructure with HDPE pipes. The project involved the installation of over 150 kilometers of HDPE pipes, which now deliver potable water to more than 300,000 residents. The use of HDPE pipes has resulted in a significant reduction in water losses due to leaks, improved water quality, and lower maintenance costs.

The Installation Process of HDPE Pipes Differ from Traditional Piping Systems

The installation of HDPE (High-Density Polyethylene) pipes differs significantly from traditional piping systems, offering several advantages that contribute to their growing popularity in potable water supply infrastructure. Understanding these differences is essential for engineers, contractors, and project managers to fully leverage the benefits of HDPE pipes in water distribution projects.

1. Lightweight and Flexibility:One of the most notable differences in the installation process of HDPE pipes is their lightweight nature and flexibility. Traditional materials like cast iron or steel are heavy and rigid, requiring extensive labor and equipment to transport, handle, and install. In contrast, HDPE pipes are much lighter, which simplifies transportation and handling on-site. This reduction in weight not only decreases shipping costs but also enables quicker and more efficient installation, especially in challenging terrains.

The flexibility of HDPE pipes further enhances their installation versatility. They can be easily bent to follow the natural contours of the land, which is particularly advantageous in areas with uneven terrain or where the pipe route must navigate around obstacles. For instance, in rural areas with rocky or hilly landscapes, the ability to bend HDPE pipes reduces the need for extensive trenching, thereby lowering installation costs and minimizing environmental disruption.

2. Trenchless Installation Methods:HDPE pipes are uniquely suited for trenchless installation techniques, such as Horizontal Directional Drilling (HDD), pipe bursting, and slip lining. These methods involve minimal excavation and are ideal for projects in urban areas where digging trenches would be disruptive to traffic, utilities, and the environment. HDD, for example, allows the installation of HDPE pipes underneath roads, rivers, and other obstacles without the need for open-cut trenches. This method not only reduces surface disruption but also shortens project timelines and lowers costs.

In contrast, traditional piping systems, especially those made from rigid materials, typically require open-cut trenching, which can be labor-intensive, time-consuming, and costly. Open trenches also pose safety risks and can cause significant inconvenience to the surrounding community.

3. Fusion Welding for Leak-Free Joints:A major difference in the installation process of HDPE pipes is the use of fusion welding to create leak-free joints. Unlike traditional materials that rely on mechanical couplings, flanges, or gaskets to join pipe segments, HDPE pipes are joined using heat fusion techniques. This process involves heating the pipe ends and then pressing them together to form a single, continuous piece of pipe. The resulting joint is as strong as the pipe itself, eliminating the common issue of leaks that can occur at mechanical joints.

There are two primary methods of fusion welding used in HDPE pipe installation: butt fusion and electrofusion. Butt fusion involves heating the ends of two pipes and then fusing them together. Electrofusion, on the other hand, uses a specialized fitting that contains embedded heating elements to create the fusion bond. Both methods are highly effective and are chosen based on the specific requirements of the project.

4. Installation Speed and Efficiency:The installation of HDPE pipes is generally faster and more efficient compared to traditional materials. The combination of lightweight pipes, flexibility, and fusion welding means that large sections of pipe can be installed quickly with minimal disruption. For example, a project in Los Angeles that involved the replacement of old water mains with HDPE pipes was completed ahead of schedule due to the rapid installation process. The contractor was able to install longer continuous sections of pipe with fewer joints, resulting in a faster, more efficient process.

Traditional piping systems, by comparison, often require more time for trench excavation, pipe laying, joint assembly, and backfilling. The rigid nature of materials like cast iron or concrete means that more joints are needed, each of which requires careful assembly and testing to prevent leaks. This complexity can slow down the installation process and increase the overall project cost.

5. Environmental Considerations:HDPE pipe installation is also more environmentally friendly. The trenchless methods reduce surface disruption and preserve the natural landscape. Additionally, the material itself is recyclable, and the installation process generally produces less waste compared to traditional methods.

The Environmental Benefits of Using HDPE Pipes for Potable Water Supply

The environmental benefits of using High-Density Polyethylene (HDPE) pipes for potable water supply are significant and multifaceted, making them a preferred choice for sustainable infrastructure projects. As global awareness of environmental issues grows, the demand for materials and practices that reduce environmental impact has never been higher. HDPE pipes, with their numerous eco-friendly attributes, play a critical role in promoting sustainable water management practices.

1. Reduced Carbon Footprint:The production and transportation of HDPE pipes result in a lower carbon footprint compared to traditional materials like steel, copper, or concrete. HDPE is a lightweight material, which means that less energy is required to manufacture and transport the pipes. For instance, the energy consumption associated with producing and delivering HDPE pipes is approximately 50-70% lower than that of concrete or steel pipes. This reduction in energy use translates into lower greenhouse gas emissions, making HDPE pipes a more environmentally friendly option.

In addition, the installation process of HDPE pipes often utilizes trenchless methods, which require less excavation and therefore less heavy machinery operation. This further reduces the overall carbon footprint of the project. A study conducted by the Plastics Pipe Institute highlighted that trenchless installation methods can reduce greenhouse gas emissions by up to 77% compared to traditional open-cut methods, primarily due to the reduced need for excavation and surface restoration.

2. Water Conservation Through Leak Prevention:HDPE pipes are known for their leak-free performance, which is a crucial factor in water conservation. Traditional pipes, especially those made from materials like cast iron or copper, are prone to leaks due to corrosion, joint failures, and aging. According to the American Society of Civil Engineers (ASCE), the United States loses an estimated 6 billion gallons of treated water each day due to leaking pipes. This not only represents a significant waste of a precious resource but also leads to increased energy consumption for water treatment and pumping.

The fusion welding techniques used to join HDPE pipes create a seamless system that virtually eliminates leaks. This high level of integrity ensures that the water that enters the pipe system reaches its destination without loss, thus conserving water and reducing the energy required for pumping and treatment. For example, the city of Calgary in Canada replaced its aging water mains with HDPE pipes, leading to a substantial reduction in water loss and a more efficient water distribution network.

3. Long Lifespan and Durability:HDPE pipes have a long lifespan, often exceeding 50 years, which reduces the frequency of replacements and the associated environmental impact. Traditional materials, such as steel and iron, are prone to corrosion and degradation over time, leading to more frequent replacements and repairs. Each replacement cycle involves the extraction of raw materials, manufacturing, transportation, and installation, all of which contribute to environmental degradation.

The durability of HDPE pipes means that once installed, they require minimal maintenance and are less likely to fail, further reducing the need for additional raw materials and energy. A case in point is the extensive use of HDPE pipes in the water distribution system of Rotterdam, Netherlands, where the city has experienced minimal pipeline failures over decades, contributing to a more sustainable infrastructure.

4. Recyclability and Waste Reduction:HDPE is a recyclable material, which adds to its environmental benefits. At the end of their service life, HDPE pipes can be recycled and reprocessed into new products, reducing the demand for virgin materials and minimizing waste. This is in stark contrast to materials like PVC or metal pipes, which are more challenging to recycle and often end up in landfills.

Moreover, the manufacturing process of HDPE pipes generates less waste compared to traditional materials. The production process is highly efficient, and any off-cuts or waste material can often be recycled within the production facility. This contributes to a more sustainable manufacturing process with a lower environmental impact.

5. Minimal Environmental Disruption During Installation:The flexibility and strength of HDPE pipes allow for installation using trenchless technology, which significantly reduces environmental disruption. Traditional pipe installation methods involve extensive digging and surface disruption, which can damage ecosystems, disrupt local communities, and lead to soil erosion. Trenchless methods, such as Horizontal Directional Drilling (HDD), minimize the need for open trenches, thereby preserving the natural landscape and reducing the impact on local flora and fauna.

HDPE Pipes in Extreme Environmental Conditions

HDPE (High-Density Polyethylene) pipes are recognized for their exceptional performance in a wide range of environmental conditions, including extreme temperatures, corrosive environments, and areas with significant ground movement. Their unique properties make them an ideal choice for potable water supply systems in challenging climates and terrains.

1. Temperature Resistance:One of the key advantages of HDPE pipes is their ability to perform well across a broad temperature range. HDPE pipes remain ductile and flexible even in extreme cold, making them less prone to cracking or brittleness compared to traditional materials like PVC or metal. For example, in regions like Alaska, where temperatures can drop significantly below freezing, HDPE pipes are widely used for water supply because they can withstand the expansion and contraction caused by temperature fluctuations without compromising their integrity.

In high-temperature environments, HDPE pipes also perform reliably. They have a thermal resistance range that allows them to handle temperatures up to 60°C (140°F) for continuous operation, and even higher for short durations. This makes HDPE pipes suitable for use in areas with hot climates, where other materials might soften, warp, or degrade. A study by the Plastic Pipe Institute (PPI) demonstrated that HDPE pipes maintained their structural integrity and flow efficiency in temperatures ranging from -40°C to 60°C, making them versatile for both cold and hot climates.

2. Chemical and Corrosion Resistance:HDPE pipes exhibit excellent resistance to a wide variety of chemicals, making them ideal for use in corrosive environments. Unlike metal pipes, which can corrode when exposed to acidic or alkaline soils, HDPE pipes do not react with most chemicals, ensuring the longevity of the pipe system. This resistance is particularly beneficial in industrial areas or regions with aggressive soil conditions, where traditional metal pipes would require protective coatings or cathodic protection to prevent corrosion.

For instance, in the mining regions of Australia, where the soil and water can be highly acidic due to mining operations, HDPE pipes are commonly used for water transport. Their chemical resistance ensures that the pipes do not degrade over time, thereby maintaining water quality and system reliability.

3. Impact Resistance and Flexibility:HDPE pipes are highly resistant to impact, which is critical in areas prone to natural disasters such as earthquakes, landslides, or heavy snow loads. The flexibility of HDPE pipes allows them to absorb and dissipate energy from external forces without cracking or breaking. This characteristic is especially important in seismically active regions.

For example, after the 2011 earthquake in Christchurch, New Zealand, HDPE pipes in the water distribution network demonstrated superior resilience compared to other piping materials. While many traditional pipes suffered extensive damage, the HDPE pipes remained intact, allowing for continued water service and reducing the need for costly repairs. This case highlights the importance of using HDPE pipes in areas where ground movement is a concern.

4. UV and Weather Resistance:HDPE pipes also offer excellent resistance to ultraviolet (UV) radiation, which is essential for installations where pipes are exposed to direct sunlight. Unlike PVC or other plastic pipes, which can become brittle and degrade when exposed to UV light, HDPE pipes contain stabilizers that protect them from UV-induced damage. This makes them suitable for above-ground installations or areas with high sun exposure.

In arid regions like the southwestern United States, where UV radiation is intense, HDPE pipes are often used in water distribution networks because of their ability to withstand prolonged exposure to sunlight without degrading. This UV resistance, combined with their flexibility and impact resistance, ensures that HDPE pipes provide reliable service in a variety of environmental conditions.

Case Study:A case study from Saudi Arabia's water infrastructure illustrates the performance of HDPE pipes in extreme environmental conditions. In the harsh desert climate, where temperatures regularly exceed 50°C (122°F), HDPE pipes were chosen for a major water distribution project. The pipes demonstrated excellent performance, with no significant issues related to temperature, chemical exposure, or UV radiation over a decade of use. The success of this project has led to the increased adoption of HDPE pipes in other desert regions around the world.

HDPE Pipes Contribute to Water Quality and Public Health

HDPE (High-Density Polyethylene) pipes play a crucial role in maintaining water quality and protecting public health in potable water supply systems. Their unique properties help to ensure that water remains clean, safe, and free from contaminants as it travels from treatment facilities to consumers’ taps.

1. Non-Toxic Material Composition:HDPE pipes are made from a non-toxic, inert material that does not leach harmful chemicals into the water supply. Unlike some older piping materials, such as lead or copper, which can introduce toxic substances into the water, HDPE pipes do not pose such risks. The use of HDPE in potable water systems ensures that the water remains free from chemical contamination, safeguarding public health.

For instance, in Flint, Michigan, the lead contamination crisis highlighted the dangers of using outdated piping materials. In contrast, HDPE pipes, which are increasingly being used in new installations and infrastructure upgrades, offer a safer alternative that eliminates the risk of such contamination. Studies by the Environmental Protection Agency (EPA) have confirmed that HDPE pipes meet stringent safety standards for drinking water, making them a trusted choice for water supply networks.

2. Smooth Interior Surface Prevents Biofilm Formation:HDPE pipes have a smooth interior surface that resists the buildup of biofilms, which are colonies of bacteria that can form on the inside of pipes. Biofilms can degrade water quality by harboring harmful pathogens and contributing to the growth of microorganisms that produce taste and odor issues.

The smoothness of HDPE pipes minimizes the areas where biofilms can attach and grow, helping to maintain high water quality. A study published in the Journal of Water Supply: Research and Technology found that HDPE pipes had significantly lower biofilm formation compared to other materials like PVC or metal. This reduced biofilm growth not only preserves water quality but also reduces the need for chemical disinfectants, which can introduce byproducts into the water.

3. Leak-Free Joints Ensure Water Integrity:HDPE pipes are joined using heat fusion techniques, which create strong, leak-free joints. This is a critical factor in maintaining water quality, as leaks in the distribution system can allow contaminants to enter the water supply. Traditional pipes, which often rely on mechanical joints, are more prone to leakage, especially as they age or experience pressure fluctuations.

A case study from the city of Calgary, Canada, demonstrates the impact of HDPE pipes on water quality. After replacing aging cast iron pipes with HDPE pipes, the city experienced a significant reduction in leaks and water contamination incidents. The fusion-welded joints of the HDPE pipes provided a more secure and reliable network, ensuring that treated water reached consumers without being compromised by external contaminants.

4. Resistance to Corrosion and Chemical Leaching:HDPE pipes are highly resistant to corrosion and do not react with the chemicals commonly found in water or soil. This resistance is particularly important in areas where the soil or water is acidic, alkaline, or contains other aggressive substances that could corrode traditional metal pipes. Corroded pipes can release harmful metals into the water, affecting its quality and safety.

For example, in coastal regions where soil salinity can be high, HDPE pipes are often used because they do not corrode or degrade when exposed to saline environments. The long-term use of HDPE pipes in such conditions has demonstrated their ability to maintain water quality over decades, as documented in studies by the American Water Works Association (AWWA).

5. Prevention of Contaminant Ingress:HDPE pipes are impermeable to contaminants, meaning that external substances such as chemicals, pollutants, or bacteria cannot penetrate the pipe walls and enter the water supply. This is particularly important in areas with contaminated soils or where the pipes are installed near sources of pollution.

A case in point is the use of HDPE pipes in New Orleans’ water distribution system following Hurricane Katrina. The flooding from the hurricane introduced various contaminants into the environment, posing a risk to water infrastructure. However, the HDPE pipes installed in the city’s water system remained unaffected by the contaminated soil and water, ensuring that the potable water supply remained safe for residents.

The Cost Implications of Using HDPE Pipes in Water Supply Projects

When considering the cost implications of using HDPE (High-Density Polyethylene) pipes in water supply projects, it's important to take into account not only the initial material costs but also the long-term economic benefits, including reduced installation, maintenance, and operational expenses. HDPE pipes often prove to be a cost-effective solution for potable water infrastructure, particularly when viewed from a life-cycle cost perspective.

1. Initial Material and Installation Costs:The upfront cost of HDPE pipes may be higher than some traditional materials like PVC or galvanized steel. However, the cost difference is often offset by the lower transportation and handling costs associated with HDPE pipes. HDPE pipes are lightweight, which reduces the expenses related to transportation and installation. Additionally, their flexibility allows for the use of trenchless installation methods such as Horizontal Directional Drilling (HDD), which can significantly reduce labor costs and minimize disruption to existing infrastructure and the environment.

For example, in a water supply project in Los Angeles, the use of HDPE pipes enabled the city to employ trenchless technology, resulting in a 30% reduction in overall installation costs compared to conventional open trench methods. The ability to navigate around existing utilities and reduce the need for extensive excavation translated into significant savings for the project.

2. Longevity and Durability:One of the most significant cost advantages of HDPE pipes is their long lifespan, often exceeding 50 years. This longevity reduces the frequency of repairs and replacements, which are major cost drivers in the maintenance of water supply systems. Traditional materials, such as iron or steel, are more susceptible to corrosion and degradation, leading to more frequent maintenance needs and higher long-term costs.

A study by the Water Research Foundation found that the overall life-cycle cost of HDPE pipes was approximately 25% lower than that of ductile iron pipes due to the reduced need for repairs and maintenance over time. The study highlighted that even though the initial material costs for HDPE were slightly higher, the long-term savings in maintenance and replacement made HDPE the more economical choice for large-scale water supply projects.

3. Maintenance and Repair Costs:HDPE pipes require minimal maintenance due to their corrosion resistance, chemical stability, and leak-proof joints. The fusion welding technique used to join HDPE pipes ensures that the joints are as strong as the pipe itself, virtually eliminating the risk of leaks. This reduces the need for costly repairs and the associated labor and downtime.

In New York City, a water distribution network that incorporated HDPE pipes reported a 50% reduction in repair incidents compared to networks using older materials. The reduction in leaks and failures not only saved on repair costs but also minimized water loss, further contributing to cost savings. These savings are particularly significant in urban areas where the cost of labor and the impact of water outages are high.

4. Operational Cost Savings:HDPE pipes also contribute to operational cost savings through their energy efficiency. The smooth interior surface of HDPE pipes reduces friction, allowing water to flow more freely and requiring less energy for pumping. This reduced energy demand translates into lower operational costs, especially in systems with long pipeline networks or where water must be pumped over significant distances or elevations.

A case study from the state of Texas demonstrated that a water utility company achieved a 15% reduction in energy costs after replacing an aging cast iron pipeline with HDPE pipes. The reduction in energy consumption was attributed to the lower friction losses in the HDPE system, leading to a more efficient and cost-effective operation.

5. Environmental and Regulatory Cost Benefits:Using HDPE pipes can also help water utilities avoid costs related to environmental compliance and regulatory fines. The durability and leak-free performance of HDPE pipes reduce the risk of environmental contamination from leaks or pipe failures. In areas with strict environmental regulations, this can result in significant cost savings by avoiding fines and penalties associated with environmental breaches.

For example, a water utility in Michigan facing stringent state regulations on leak prevention and water quality chose to upgrade its network with HDPE pipes. The move not only ensured compliance with state laws but also avoided potential fines and legal costs associated with environmental damage caused by leaks in the old system.

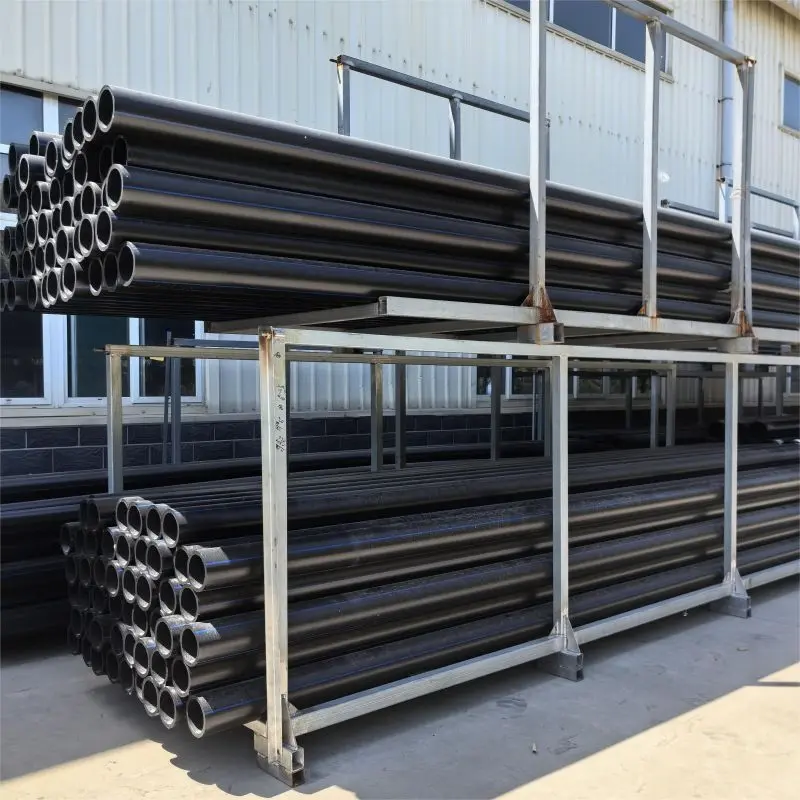

Why Choose Haoyang Environmental Co., Ltd. for Your HDPE Pipe Needs

As the demand for HDPE pipes continues to grow, selecting the right supplier is crucial to ensuring the success of your potable water supply projects. Haoyang Environmental Co., Ltd. stands out as a leader in this field, offering a comprehensive range of HDPE pipes designed to meet the specific needs of your project.

Established in June 2008, Haoyang is a high-tech comprehensive service provider specializing in the research and development, manufacturing, and supply of geosynthetic materials, including HDPE pipes. Our commitment to quality is reflected in our ISO 9001, ISO 14001, and OHSAS 18001 certifications, as well as our CQC environmental product certification. These certifications underscore our dedication to delivering products that meet the highest standards of quality and environmental responsibility.

Haoyang’s HDPE pipes are manufactured using advanced technology and materials, ensuring superior performance and durability. Our pipes are designed to withstand the rigors of potable water supply systems, from municipal distribution networks to remote rural installations. Whether you need pipes for a new installation or to replace aging infrastructure, Haoyang has the expertise and products to meet your needs.

In addition to our high-quality products, Haoyang offers unparalleled support throughout your project. Our professional technical R&D team is available to provide consulting, design, and engineering services, ensuring that your HDPE pipe system is tailored to your specific requirements. With three invention patents and 32 utility model patents, Haoyang is at the forefront of innovation in the HDPE pipe industry.

Conclusion

HDPE pipes have revolutionized the potable water supply industry, offering a combination of durability, flexibility, and environmental sustainability that is unmatched by traditional piping materials. As the world continues to prioritize access to clean, safe drinking water, the role of HDPE pipes will only become more significant.

Haoyang Environmental Co., Ltd. is proud to be a part of this important industry, providing high-quality HDPE pipes that ensure reliable and efficient water supply for communities and industries around the world. With our expertise, innovation, and commitment to excellence, Haoyang is your trusted partner in delivering safe and sustainable potable water solutions. Contact us today to learn more about how our HDPE pipes can benefit your next project.

897.webp)

942.webp)

237.webp)