HDPE Smooth and Coated Texture Geotextile Membrane for Landfill

Haoyang Environmental Co., Ltd. is a pioneer in the production of HDPE (High-Density Polyethylene) geotextile membranes, providing exceptional solutions for landfill applications. Established in 2008, Haoyang leverages its expertise in geosynthetic material development and environmental engineering to deliver high-quality and durable geotextile membranes that meet global standards. Our products are engineered to address the most demanding challenges in landfill containment, offering unmatched protection and environmental safety.

What is Landfill Facility

A landfill is a facility used for the treatment and disposal of municipal, industrial, and household waste. The process involves burying the waste underground, slowing down its decomposition process through the use of cover layers. Landfills typically consist of the following key components:

1, Landfill Area: This is the designated zone where waste is buried, gradually accumulating and compacted.

2, Base Layer: Usually a layer of specialized soil designed to slow the infiltration of liquids from the waste into the groundwater.

3, Cover Layer: At the end of each day, a layer of cover material is applied to the landfill area to reduce odors, prevent the spread of waste, and provide additional isolation.

4, Collection Systems: These systems collect and process leachate (liquid produced during the decomposition of waste) and methane gas generated during the landfill process.

5, Environmental Monitoring System: This system monitors the surrounding environment of the landfill to ensure that no harmful substances leak into groundwater or surrounding soil.

Problems it may caused

Landfills are a common method of waste disposal, but they raise environmental and health concerns, such as groundwater and soil pollution, odor issues, and the generation of greenhouse gases. In order to solve the above problem, HDPE geomembrane have become a fundamental component in landfill engineering project, acting as liquid and gas barriers. It can effectively prevents seepage, safeguarding the surrounding environment from the infiltration of harmful substances. The smooth HDPE layer provides a robust impermeable barrier, while the coated texture layer enhances friction and stability, catering to the specific demands of landfill applications.

Functions of HDPE Smooth and Coated Textured Geomembrane in Landfill

What is HDPE geomembrane

HDPE (High-Density Polyethylene) Geomembrane is a type of synthetic polymer liner or barrier material that is made from high-density polyethylene. It is widely used in civil and environmental engineering applications for containment, environmental protection, and various geotechnical projects. HDPE geomembranes are known for their excellent chemical resistance, durability, and flexibility.

Key features and uses of HDPE geomembranes include:

1, Impermeability: HDPE geomembranes are highly impermeable to liquids and gases, making them effective for creating barriers in applications such as landfill lining, pond liners, and wastewater containment.

2, Chemical Resistance: They exhibit resistance to a wide range of chemicals, making them suitable for applications where exposure to potentially corrosive substances is a concern.

3, UV Resistance: Many HDPE geomembranes are formulated with additives to enhance their resistance to ultraviolet (UV) radiation, ensuring long-term performance in exposed outdoor applications.

4, Durability: They have a high tensile strength and puncture resistance, providing long-term stability and reliability in containment applications.

5, Environmental Protection: HDPE geomembranes are commonly used in environmental protection projects, such as landfill liners and caps, to prevent the migration of contaminants into the surrounding soil and water.

Functions of HDPE Smooth Geotextile Membrane

The smooth High-Density Polyethylene (HDPE) geomembrane plays several crucial roles in a landfill setting:

1, Permeability Resistance: The smooth surface of HDPE geomembrane exhibits outstanding impermeability, effectively preventing the infiltration of leachate generated within the waste into the ground. This helps reduce the risk of environmental pollution.

2, Liquid Barrier: During landfilling, waste generates liquid, known as leachate. The smooth HDPE geomembrane forms an effective liquid barrier, preventing leachate from penetrating into the underlying soil and groundwater.

3, Odor Control: The smooth surface of HDPE geomembrane effectively prevents the diffusion of odors from the waste into the surrounding environment. This enhances the comfort of the landfill site and mitigates negative impacts on nearby communities.

4, Cover Layer Support: In the operational phase of the landfill, the geomembrane is often used to cover a portion of the waste at the end of each day, providing an additional isolation layer to reduce odor diffusion and environmental impact.

5, Soil Protection: The smooth HDPE geomembrane serves to protect the underlying soil at the base of the landfill, preventing infiltration of leachate and harmful substances, thereby contributing to maintaining soil quality.

In summary, the smooth HDPE geomembrane is a vital engineering material in landfill applications, effectively addressing issues related to liquid permeation, environmental protection, and odor control. It ensures the sustainability and environmental friendliness of the landfill.

Functions of HDPE Coated Textured Geotextile Membrane

The role of coated textured High-Density Polyethylene (HDPE) geomembrane in a landfill setting encompasses several key aspects:

1, Enhancement of Adhesion between Geomembrane and Soil: The coated textured design increases the adhesion between the geomembrane and the underlying soil, enhancing the stability of the geomembrane with the subsurface structures. This is crucial for the robustness and sustainability of the engineering structures in the landfill.

2, Improvement of Geomembrane's Anti-Slippage Properties: The coated textured surface of the geomembrane adds surface friction, preventing slippage during the landfilling process. This helps maintain the position of the geomembrane, preventing structural instability.

3, Prevention of Surface Soil Intrusion: The coated textured geomembrane effectively prevents the infiltration of upper-layer soils into the landfill area, reducing the mixing of soil and waste. This preserves the structural stability and environmental safety of the landfill.

4, Inhibition of Odor and Leachate Diffusion: The coated textured geomembrane aids in reducing the diffusion of odors from the waste and slowing down the permeation of leachate. By increasing the surface resistance of the geomembrane, it can more effectively control the movement of liquids and gases, improving the environmental quality of the landfill.

5, Enhancement of Geomembrane's Anti-Abrasion Performance: The coated textured design contributes to reinforcing the geomembrane's resistance to abrasion, enabling it to withstand physical damage that may occur during the landfilling process and extending its service life.

Factors Need to Consider When Choose HDPE Geomembrane

1. Thickness

The required thickness depends on the application.

Thicker membranes provide greater durability and puncture resistance, suitable for heavy-duty applications like landfills and mining.

2. Chemical Resistance

Assess the type of chemicals the geomembrane will be exposed to.

HDPE membranes are highly resistant to a wide range of chemicals, making them ideal for hazardous waste containment.

3. Environmental Factors

Consider UV exposure, temperature variations, and weather conditions.

UV-resistant HDPE geomembranes are necessary for outdoor applications with prolonged sun exposure.

4. Mechanical Properties

Evaluate tensile strength, tear resistance, and puncture resistance based on the load and stress the membrane will endure.

5. Permeability

HDPE geomembranes should be impermeable to prevent leakage of liquids and gases, critical for applications like landfill liners and wastewater treatment.

6. Installation Requirements

Choose membranes that are easy to install and compatible with welding technologies for creating secure joints.

7. Application Type

Landfill liners, wastewater containment, mining, or agriculture may require specific properties like textured surfaces for slope stability or smooth surfaces for ease of cleaning.

8. Certifications and Standards

Ensure the geomembrane complies with international standards like ASTM, GRI-GM13, or ISO certifications for quality assurance.

9. Project Budget

Balance the cost of the material with its performance and longevity to ensure a cost-effective solution.

The Common Specifications and Dimensions of HDPE Geomembrane

The specifications and dimensions of High-Density Polyethylene (HDPE) geomembrane used in landfill applications can vary based on specific project requirements and design standards. However, here are some common specifications and dimensions, which may vary depending on suppliers and regions:

1, Thickness: The thickness of HDPE geomembrane typically ranges from 0.5 millimeters to 3 millimeters, usually, the bottom liner of the landfill is equipped HDPE geomembrane with a thickness of 1.5 millimeters to prevent seepage. For the interim cover of the landfill, a HDPE geomembrane with a thickness greater than 0.5 millimeters is chosen. The final cover of the landfill can be comprised of a HDPE geomembrane with a thickness exceeding 1.0 millimeters.

2, Width: The width of the geomembrane is usually between 4 meters and 7 meters, depending on the specific application and engineering design, the HDPE geomembrane our factory produced can reach a maximum width of 9 meters.

3, Length: The length of rolls of geomembrane can be customized based on project needs, typically ranging from 50 meters to 100 meters.

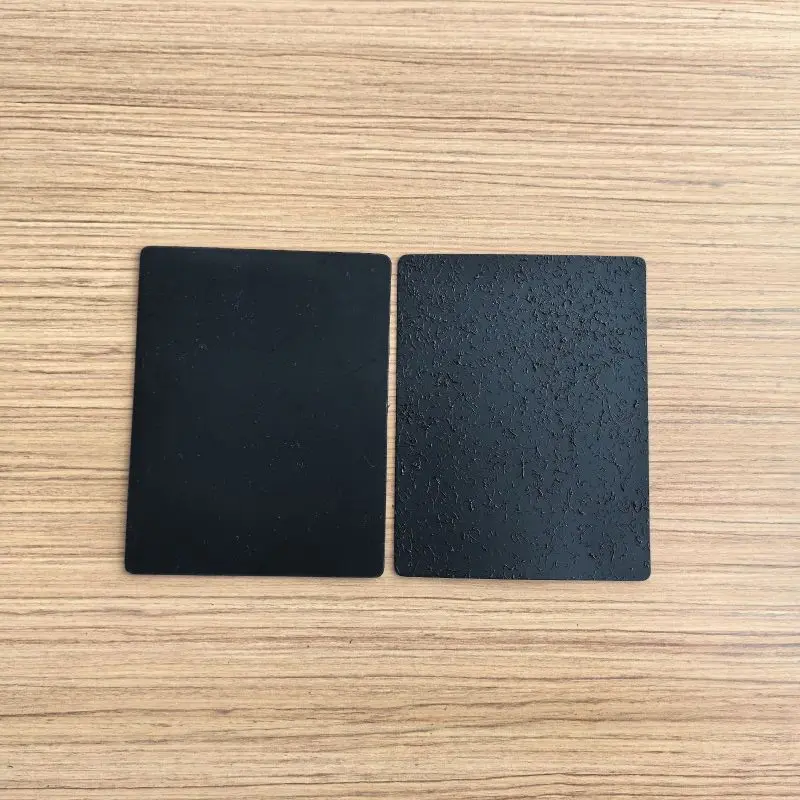

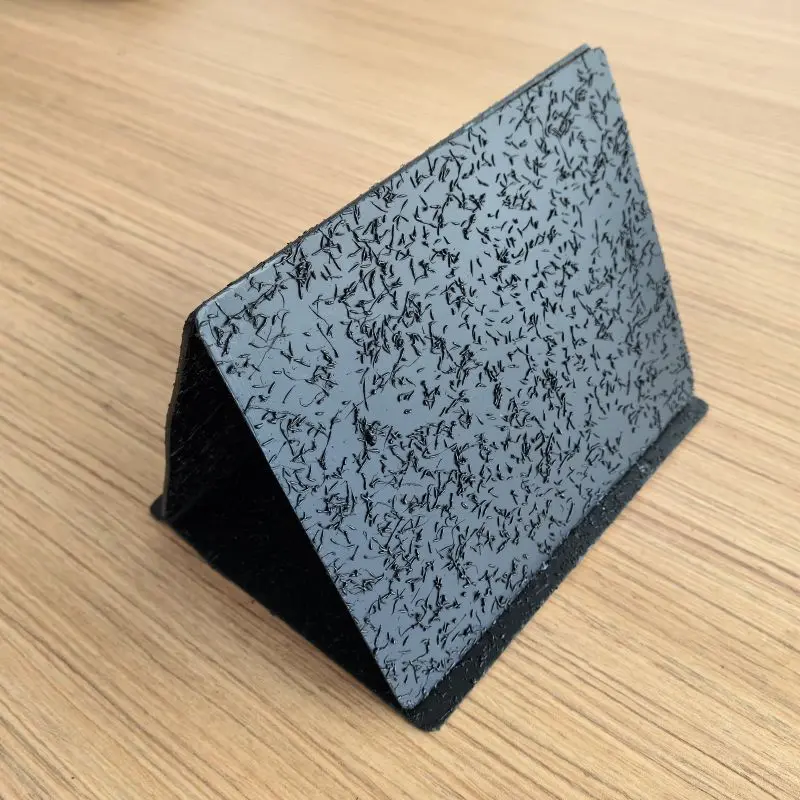

4, Surface Texture: Geomembranes can be smooth or coated textured, depending on the specific requirements of the project. Textured surfaces are often used to enhance adhesion and anti-slip properties.

5, Color: HDPE geomembranes are commonly black, as the black color helps absorb sunlight and enhances the membrane's resistance to ultraviolet radiation, but we can also provide green getextile membrane, which usually used for landfill coverage.

Specification

| Property | Details |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Finish | Smooth and Coated Texture |

| Thickness | 0.75mm, 1.0mm, 1.25mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm |

| Tensile Strength | Varies according to specifications |

| Tear Resistance | Varies according to specifications |

| Chemical Resistance | Excellent resistance to acids, alkalis, and contaminants |

| UV Stability | High resistance to UV exposure |

| Waterproofing | Fully waterproof and impermeable |

| Applications | Landfill liners and caps, wastewater treatment, mining operations, agricultural uses |

| Temperature Range | Suitable for extreme temperatures (consult specific project requirements) |

| MOQ | 2,000㎡ |

Advantages of Our Factory

◆ The world's only extrusion line for geomembranes with a width of up to 9 meters

Our factory possesses the world's only extrusion line for geomembranes with a width of up to 10 meters, featuring a five-layer co-extrusion, dual-sided rough spraying in a single online step, and nitrogen-enhanced roughening. Annual production capacity is10,000 tons.

◆ Obtained ISO 9001 Quality Management System and ISO 14001 Environmental Management System certifications

The ISO 9001 Quality Management System and ISO 14001 Environmental Management System certifications ensure the reliability of product quality, enhance service levels, promote the production of environmentally friendly products, comply with international standards and regulations, and reduce potential risks.

168783.webp)

◆ Having a first-class laboratory and testing facilities

This specialized geomembrane tensile testing machine can assess the tensile strength and elongation at break of geomembranes.

454379.webp)

The geomembrane environmental stress cracking test machine is primarily used to assess the performance of geomembranes under environmental stress. This equipment can test the crack resistance of geomembranes under different environmental conditions, including resistance to chemical corrosion and UV radiation. By applying environmental stress, the testing machine simulates various pressures and influences that geomembranes may encounter in actual usage scenarios, thereby aiding in the evaluation of their stability and durability under complex conditions.

166340.webp)

The UV AGING TEST BOX for geomembranes is primarily used to simulate ultraviolet (UV) exposure conditions and assess the aging resistance of geomembranes under sunlight exposure. By simulating UV radiation from sunlight, this equipment can test the geomembrane's weather resistance, color stability, and physical performance changes after prolonged exposure to UV light. This helps determine the durability and reliability of geomembranes in outdoor environments, providing essential insights into their performance in practical applications.

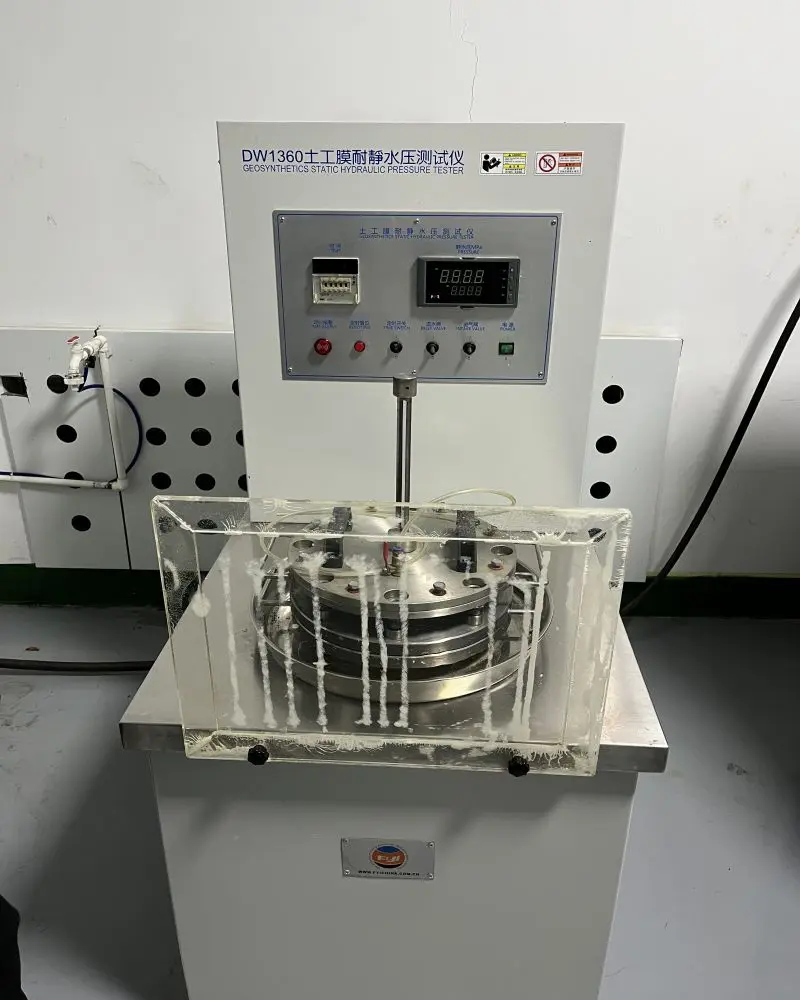

The geomembrane static water pressure tester is primarily used to assess the waterproof performance of geomembranes under certain water pressure. This equipment simulates the potential water pressure conditions in practical engineering by applying static water pressure to test the geomembrane's sealing capability. The test results help determine the reliability of geomembranes in waterproof applications, ensuring their effective resistance to static water pressure to prevent water infiltration and protect infrastructure and land from water damage.

Partner with Us

Haoyang Inviromental continue as one of the main geosynthetic innovators in the industry with our highly active Research and Development department. Our continued success in new products is as a result of an experienced team and our ongoing relationships with an expanding list of professional clients who partner with us to produce bespoke geosynthetic solutions.

Our priority is to manufacture a high quality end product that provides the exact needs of our customers, inline with function, durability, value and in accordance with all current legislation and design standards. If you need any kind of geosynthetic products, please feel free to contact us.

595.webp)