High-Density Polyethylene (HDPE) geomembranes are widely used in various industries, particularly in construction, environmental protection, and water containment projects. They are known for their durability, chemical resistance, and flexibility, making them an ideal choice for applications like landfill liners, pond linings, and mining operations. However, the cost of HDPE geomembranes can vary significantly based on several factors. Understanding these factors is crucial for project planners, engineers, and procurement officers to make informed decisions.

Material Costs

1, The primary determinant of HDPE geomembrane pricing is the cost of raw materials. HDPE is derived from petroleum, so fluctuations in global oil prices directly impact the cost of producing these geomembranes. When crude oil prices rise, the cost of producing HDPE resin increases, leading to higher prices for geomembranes. Conversely, when oil prices fall, the cost of HDPE geomembranes tends to decrease.

2, Additionally, the quality of the HDPE resin used can influence the price. High-quality resin, which offers better durability and chemical resistance, typically commands a higher price. Manufacturers may also incorporate additives to enhance specific properties of the geomembrane, such as UV resistance or flexibility in extreme temperatures, which can further increase the cost.

Thickness and Specifications

1, The thickness of the HDPE geomembrane is another critical factor in determining its price. Geomembranes are available in various thicknesses, typically ranging from 0.5 mm to 3.0 mm. Thicker geomembranes are generally more expensive due to the increased amount of material required and the additional manufacturing processes involved. However, thicker geomembranes offer better durability and resistance to punctures, making them a preferred choice for projects with stringent environmental protection requirements.

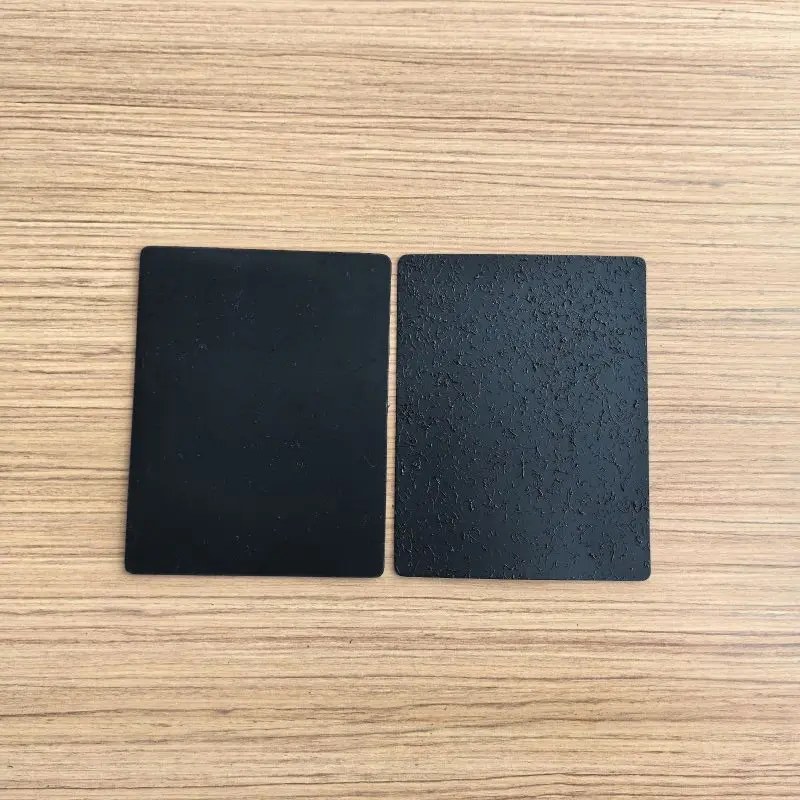

2, Other specifications, such as the geomembrane’s texture, can also affect pricing. Textured geomembranes, which provide better friction and are used in applications where slip resistance is critical, are typically more expensive than smooth geomembranes. The choice between single-sided or double-sided textured geomembranes can also influence the cost.

Manufacturing and Supply Chain Factors

1, The manufacturing process itself plays a role in the cost of HDPE geomembranes. Advanced manufacturing techniques, such as co-extrusion and blown film processes, can produce higher-quality geomembranes with better performance characteristics, but they may also result in higher costs. Additionally, manufacturers with more automated and efficient production lines can offer more competitive pricing.

2, Supply chain dynamics, including transportation and logistics, are also essential in determining the final price of HDPE geomembranes. Shipping costs can vary depending on the distance from the manufacturing plant to the project site, and fluctuations in fuel prices can also impact these costs. Furthermore, tariffs and trade regulations can affect the cost of imported geomembranes, particularly in regions where local production is limited.

Market Demand and Regional Differences

1, Market demand for HDPE geomembranes is influenced by trends in industries such as construction, mining, and environmental protection. In periods of high demand, prices may rise due to increased competition for available materials. Conversely, during economic downturns or periods of reduced construction activity, prices may stabilize or even decrease.

2, Regional differences in pricing are also notable. In areas with a high concentration of manufacturers or where raw materials are readily available, prices may be lower due to reduced transportation costs and increased competition. In contrast, in regions where HDPE geomembranes are less commonly produced or have to be imported, prices can be significantly higher.

Environmental and Regulatory Factors

1, Environmental regulations and standards can also impact the price of HDPE geomembranes. In regions with strict environmental protection laws, projects may require higher-quality geomembranes with specific certifications, which can drive up costs. Additionally, compliance with international standards, such as ISO or ASTM, can influence both the price and the selection of geomembranes for specific projects.

2, Moreover, the growing emphasis on sustainability and environmental responsibility has led to increased interest in geomembranes made from recycled materials or those with a reduced environmental footprint. While these options may be more expensive initially, they offer long-term benefits in terms of reduced environmental impact and potential cost savings in waste management and disposal.

Conclusion

The price of HDPE geomembranes is influenced by a complex interplay of factors, including raw material costs, product specifications, manufacturing processes, supply chain logistics, market demand, and regulatory requirements. For project planners and procurement officers, understanding these factors is essential to making informed purchasing decisions that balance cost with performance and compliance. As the global focus on environmental protection and sustainable development continues to grow, the demand for high-quality HDPE geomembranes is likely to increase, further shaping pricing trends in the industry.

At Haoyang, we are committed to providing our global customers with the highest cost-performance HDPE geomembranes. As a manufacturing factory in China, we focus on optimizing every stage of the production process to ensure cost savings for our clients. Our advanced production techniques and stringent quality control measures allow us to deliver reliable, durable, and environmentally friendly products that meet international standards. By eliminating unnecessary expenses and streamlining operations, we offer our customers not just a product, but a value-driven solution that enhances the efficiency and sustainability of their projects. Choose Haoyang for quality and cost-effectiveness.

![]() 1.5mm single textured geomembrane report.pdf

1.5mm single textured geomembrane report.pdf

897.webp)

942.webp)

237.webp)